Heat treatment quenching apparatus used for steel ball with minor diameter

A quenching device and small-diameter technology, which is applied in the field of steel ball quenching, can solve the problems affecting product quality and uneven hardness of steel balls, and achieve the effect of light weight, uniform hardness and no noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

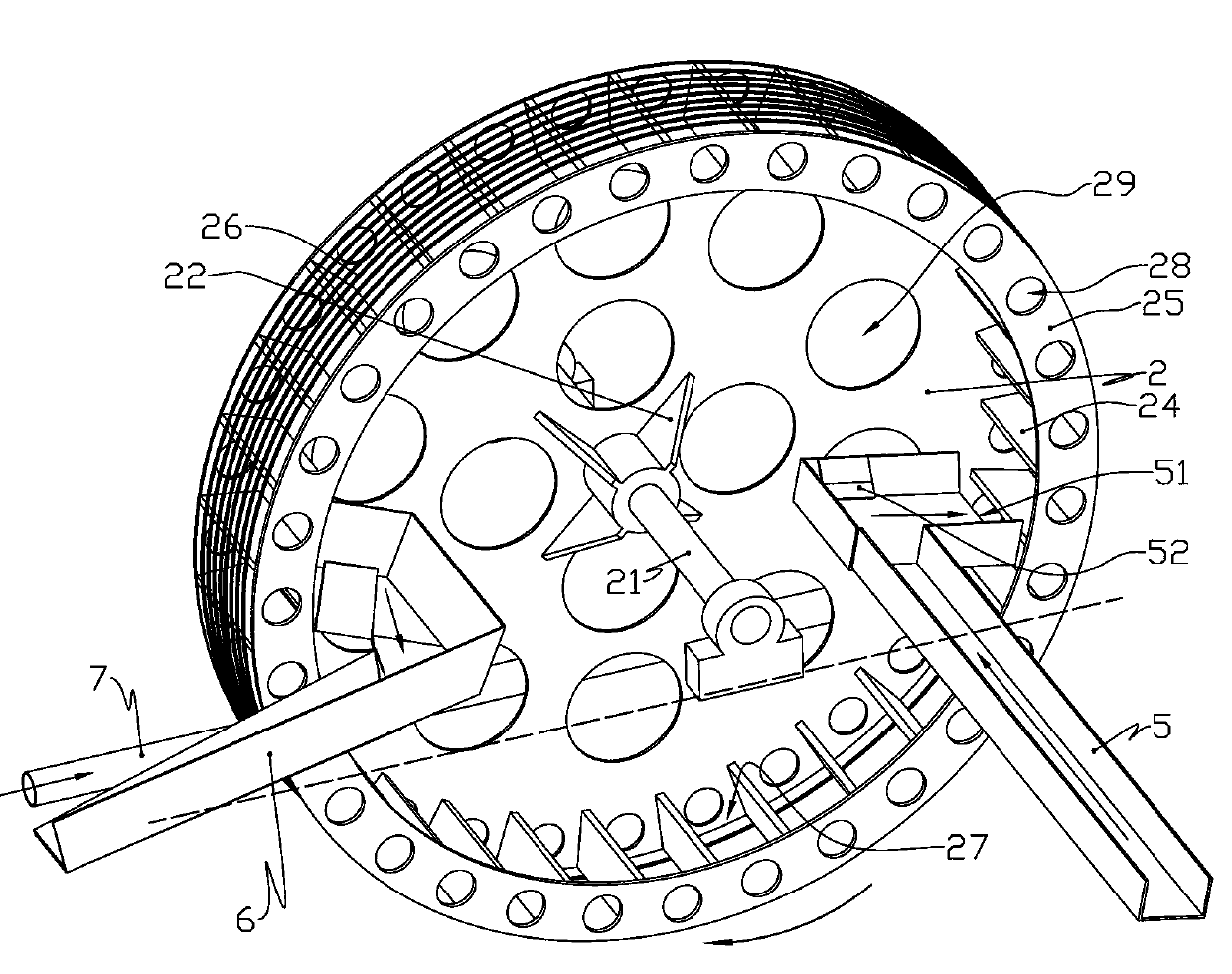

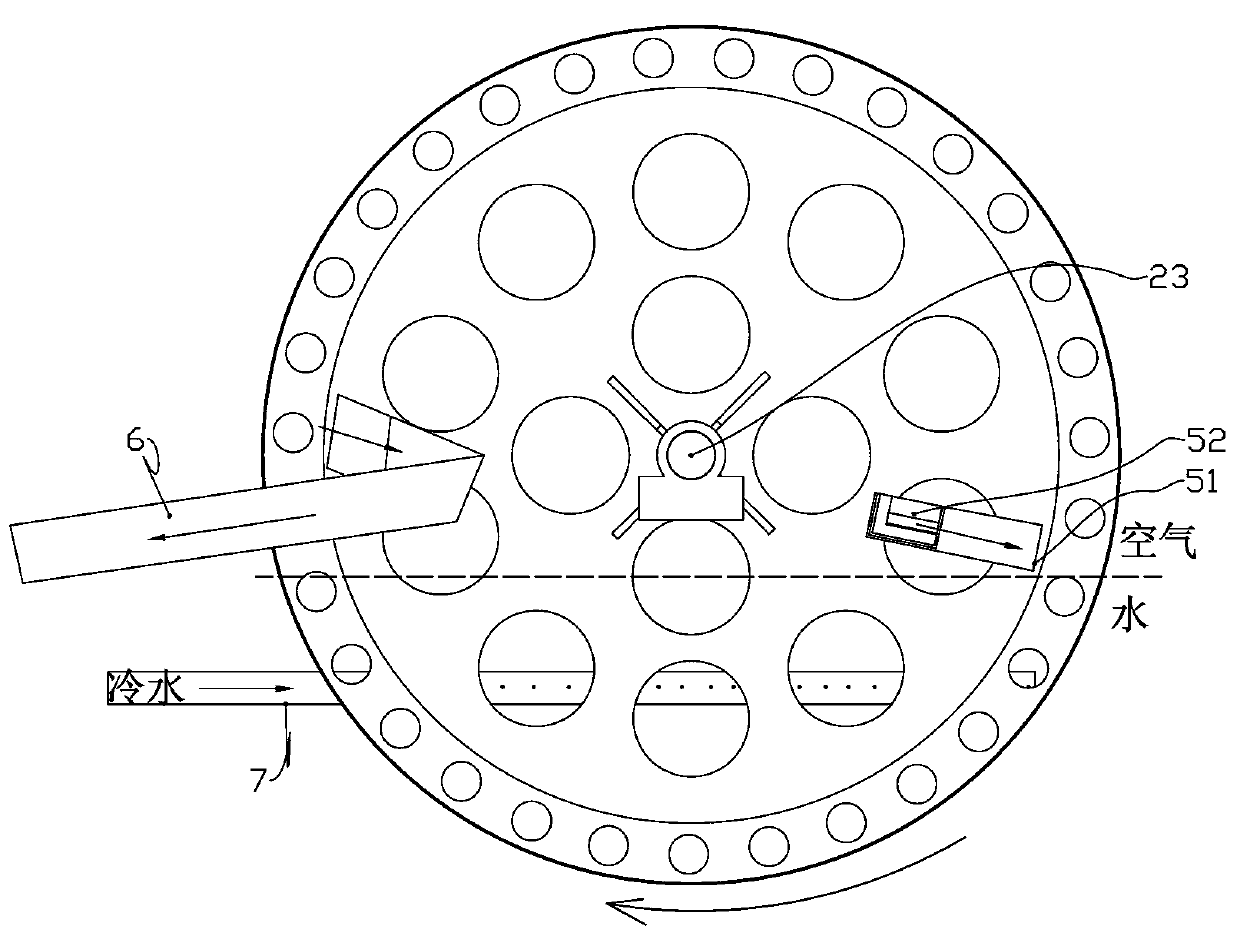

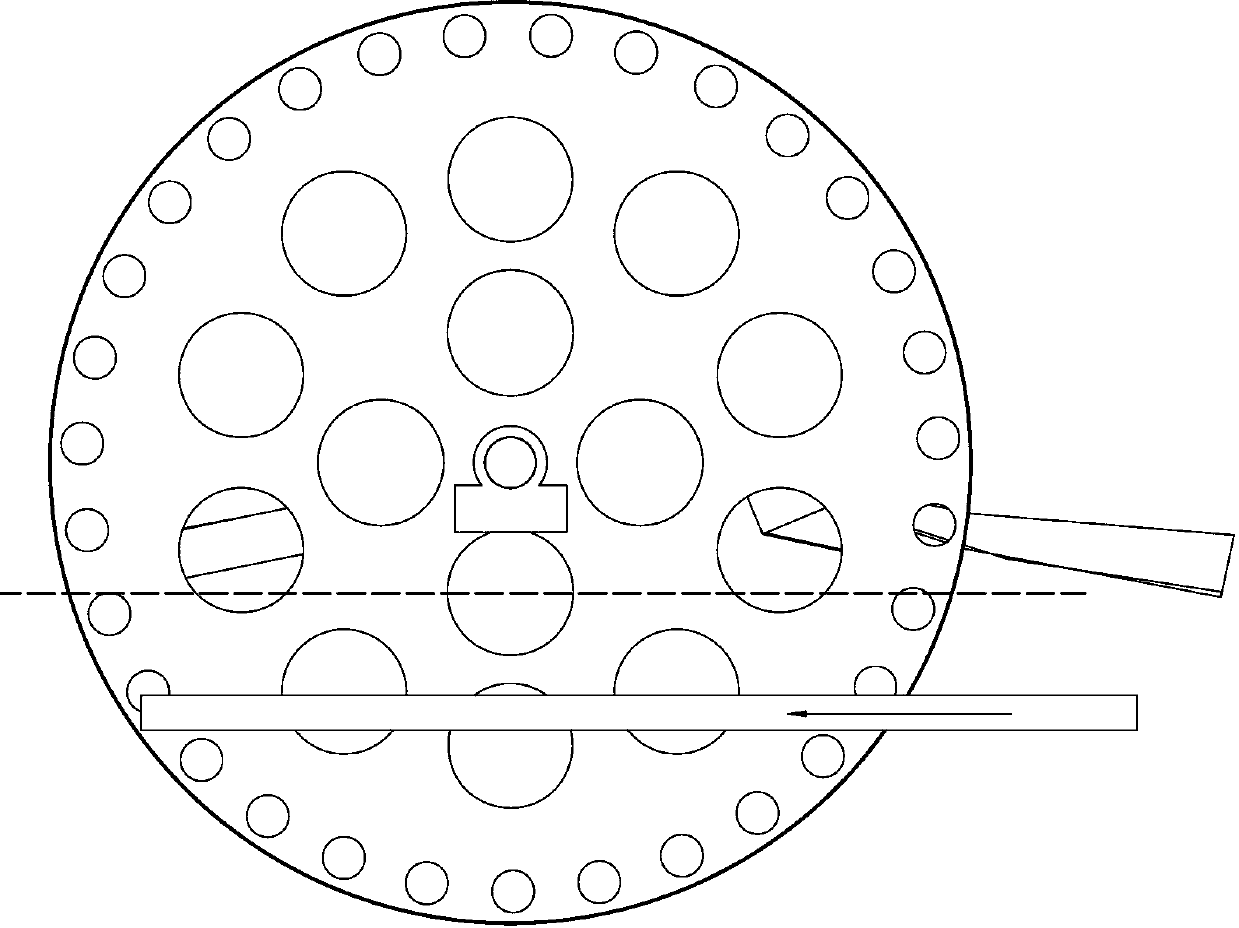

[0026] Such as Figure 1 to Figure 6 as shown,

[0027] A heat treatment and quenching device for small-diameter steel balls, including a pool 1, a turntable 2, a cold water supply pipe 7, a speed-regulating motor 4, a steel ball supply long groove 5, and a steel ball recovery long groove 6, the structure of which is described below Detailed description.

[0028] First build a large pool 1, such as Figure 4 As shown in , and an overflow port is set in the pool, so that the liquid level in the pool is at a fixed position, and then the speed regulating motor 4 and the bearing seat 11 are installed on one side of the pool.

[0029] Manufacture a disc-shaped turntable 2, fix a rotating shaft 21 in the center of the rotating disc, and set reinforcing ribs 22, the two ends of the rotating shaft 21 are installed on the foundation of the pool 1 through bearings 23, and are connected by a speed-regulating motor through a coupling 41 4 drive rotation. The rotating shaft 21 spans ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com