Heat treatment production line for bearing parts

A bearing component and production line technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of being unsuitable for bearing production enterprises, low equipment utilization, and large floor space, so as to save cleaning work and occupy an area The effect of small area and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

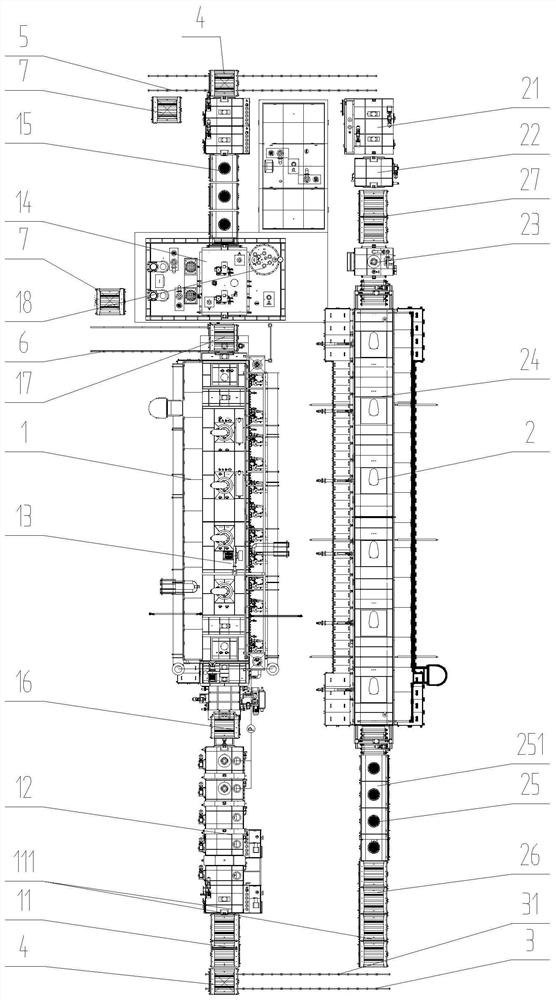

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The descriptions of "left" and "right" in the present invention are all based on figure 1 For the reference direction:

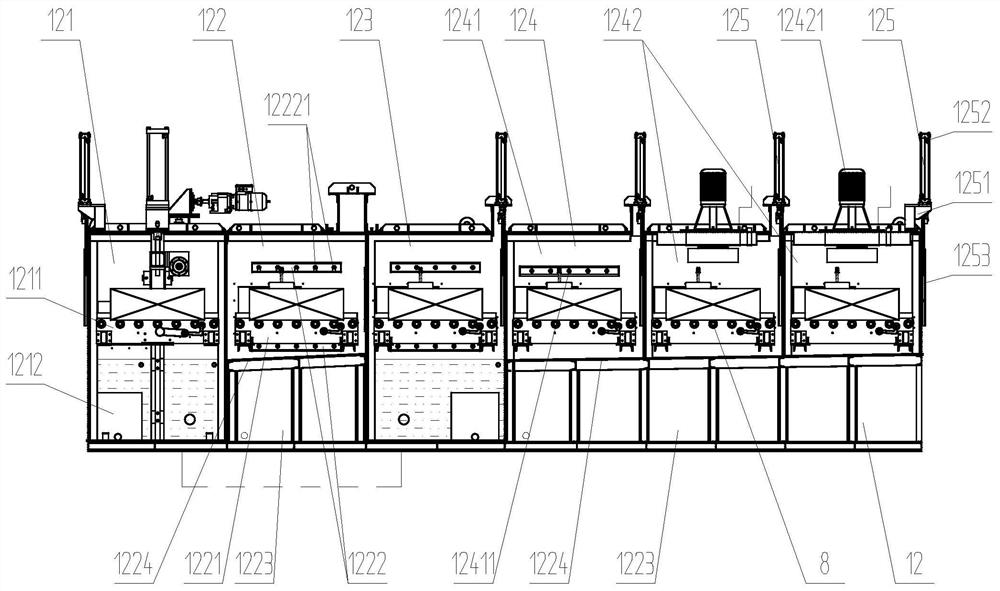

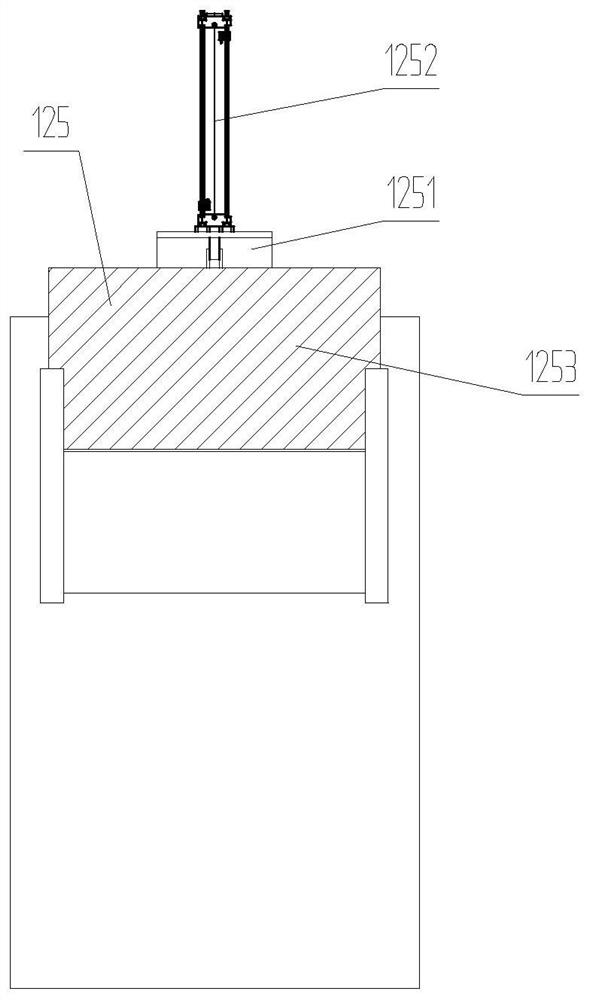

[0039] Such as Figure 1 to Figure 21 As shown, a production line for heat treatment of bearing components includes a quenching line 1 and a tempering line 2, the quenching line 1 and the tempering line 2 are arranged in parallel, and the quenching line 1 is arranged in a straight line from left to right with a feed transition table group 11 , pre-cleaning device 12, quenching heating furnace 13, salt bath quenching device 14, post-quenching air-cooled cleaning system 15, feeding transition material platform group 11 is used to adjust the length of the entire quenching line 1, so that it is consistent with the tempering line 2 Keep consistent, the bearing parts will remain sundries and dust after metal processing, so they need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com