Hardware cleaning device

A cleaning device and hardware technology, which are applied in the directions of dry gas arrangement, cleaning method and utensils, cleaning method using liquid, etc., can solve the problems of large production volume of hardware and inconvenience of complete cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

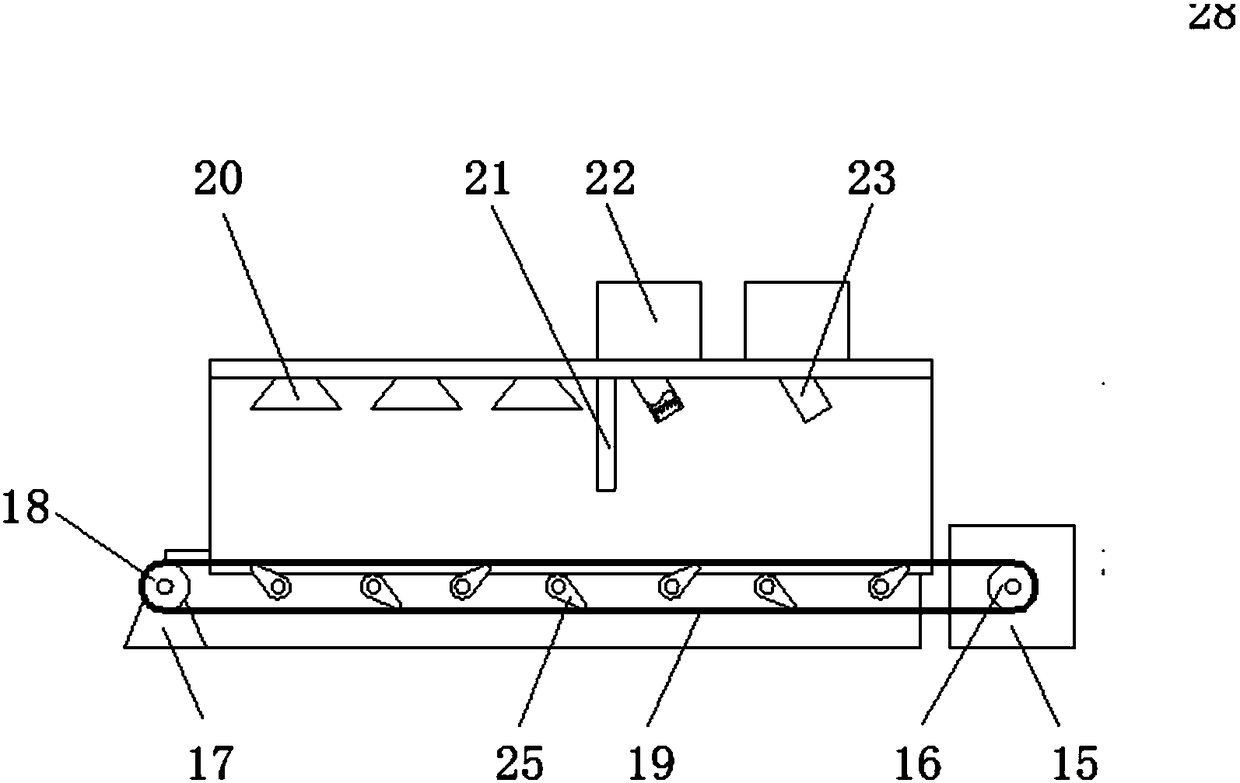

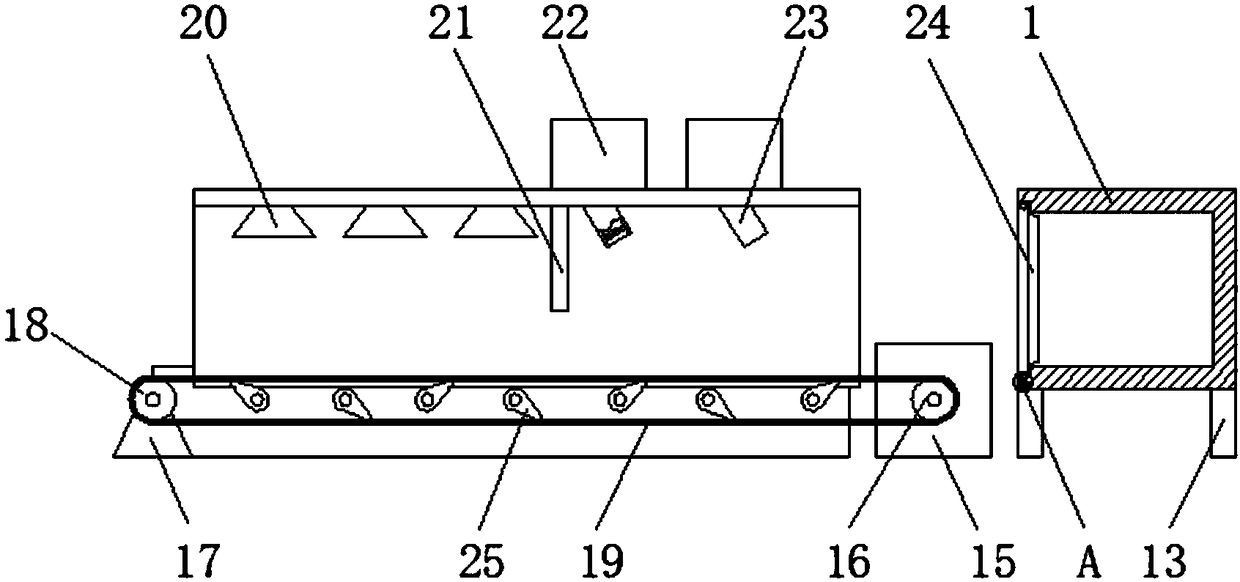

[0019] Embodiment 1: refer to Figure 1-2 , a hardware cleaning device, including a cleaning and drying machine 14, a transmission motor 15 is installed on one side of the bottom of the cleaning and drying machine 14, and a drive roller 16 is installed on the driving end of the transmission motor 15, and the cleaning and drying machine 14 is far away from the transmission One end of motor 15 is provided with mounting frame 17, and rotating shaft is installed on mounting frame 17, and driven roller 18 is sleeved on the rotating shaft, and conveyer belt 19 is wound on drive roller 16 and driven roller 18 jointly, and the upper section of conveyer belt 19 Located inside the cleaning and drying machine 14, the top wall of the cleaning and drying machine 14 is provided with a plurality of water spray ports 20, and one side of the water spray port 20 is equipped with two blowing pipes 23, the blowing pipes 23 and the water spraying ports 20 Partition plate 21 is installed between th...

Embodiment 2

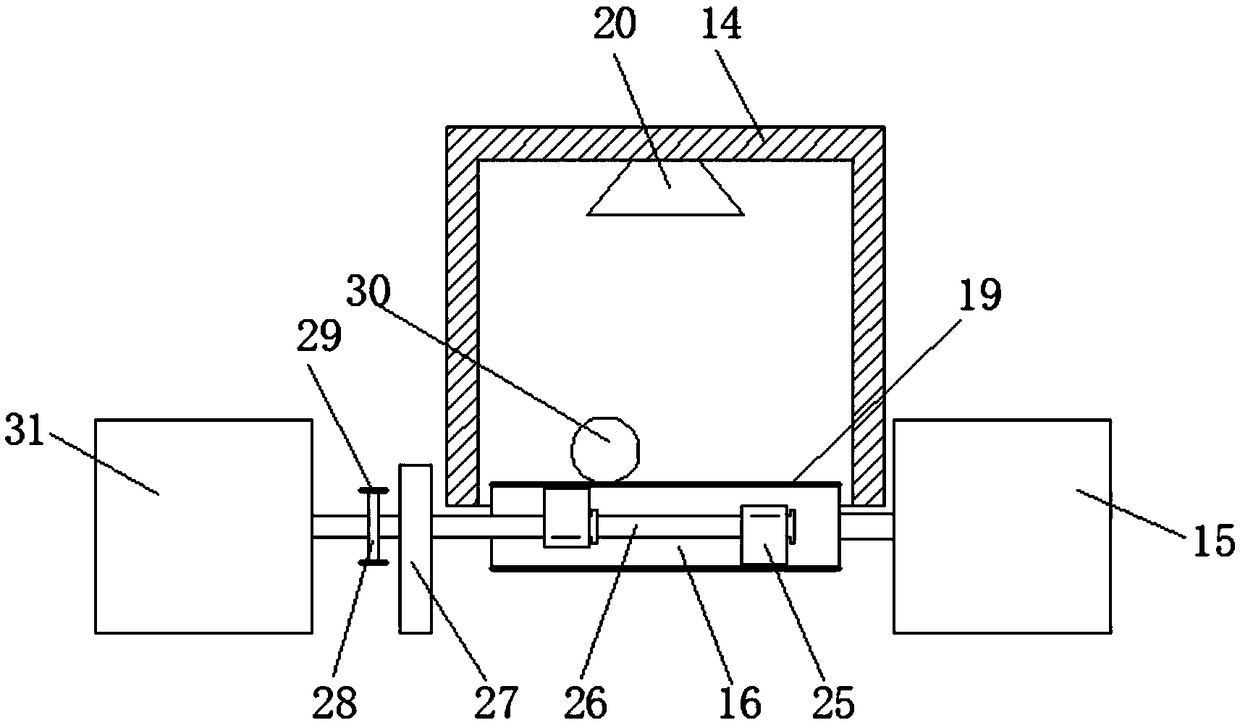

[0020] Embodiment 2: refer to Figure 2-5 , applying the present invention to a heat treatment temperature control device for hardware, comprising a heating furnace 1, a ceramic liner 2 is arranged inside the heating furnace 1, a heater 3 is installed on the lower side of the ceramic liner 2, and the ceramic liner 2 An installation box 4 with openings at both ends is fixedly connected between the outer sidewall and the inner sidewall of the heating furnace 1, and a nitrogen box 5 is installed on the outer sidewall of the ceramic liner 2, and the nitrogen box 5 is located inside the installation box 4, and the nitrogen box 5 The side wall away from the ceramic liner 2 is communicated with a piston cylinder 6, and the inside of the piston cylinder 6 is provided with a piston 7. A pressure sensor 8 is installed on the inner wall of the heating furnace 1, and the probe of the pressure sensor 8 is fixed to the piston 7. connection, the outer wall of the nitrogen box 5 is covered wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com