Reducer with bevel gear and hypocycloid in large transmission ratio for ore grinding machine

A ratio reducer and hypocycloid technology, which is applied in the field of bevel gear-hypocycloid large transmission ratio reducer for mining mills, can solve the problems of novelty and creativity of the invention concept, and achieve the improvement of bearing capacity and radius of curvature. Small, life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

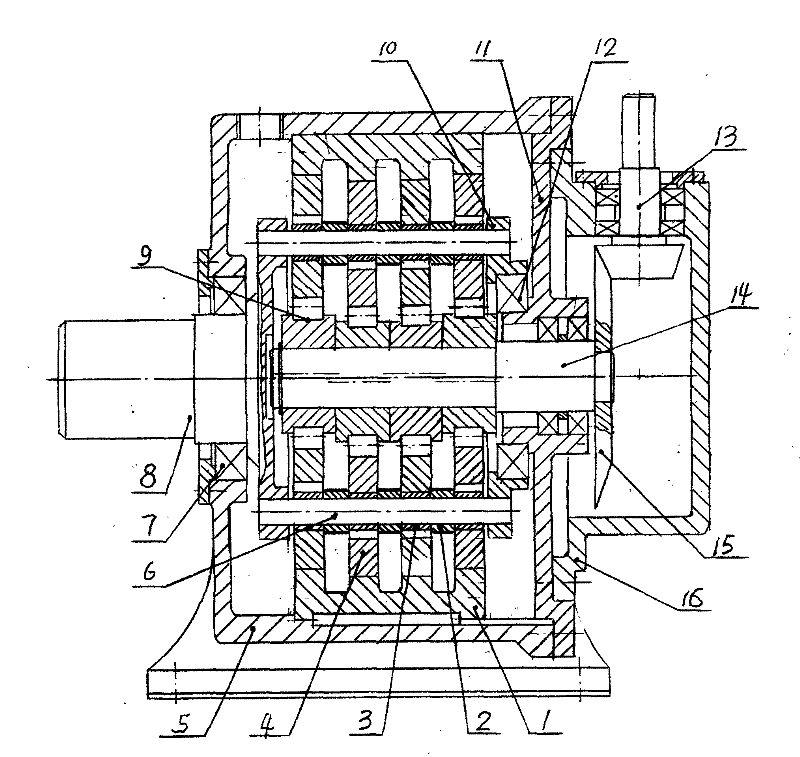

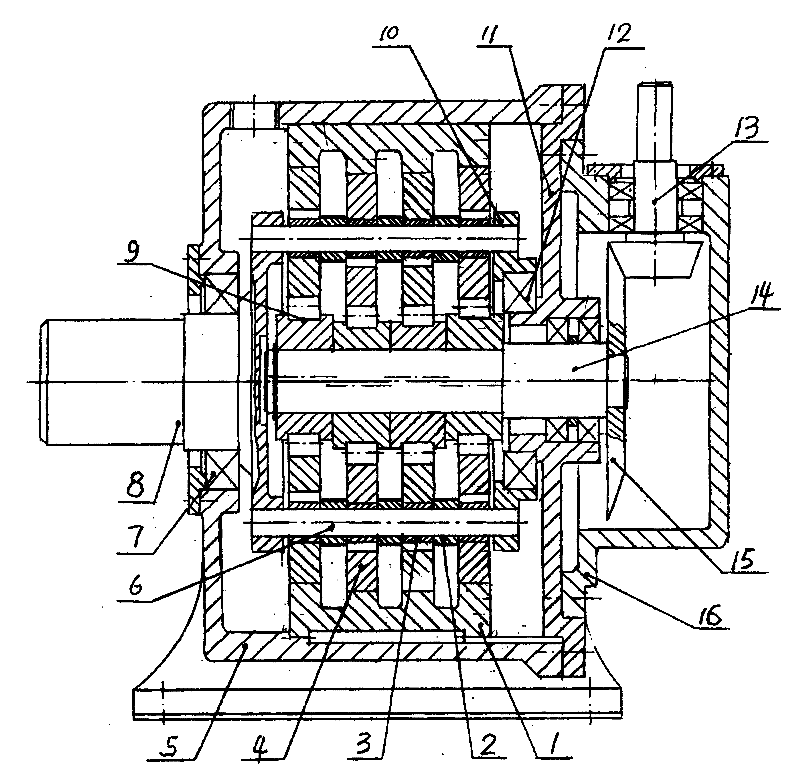

[0028] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention will be described in detail below in conjunction with the accompanying drawings:

[0029] refer to figure 1 . A mine mill bevel gear-hypocycloid pin wheel large transmission ratio reducer, characterized in that it consists of a bevel gear pair and a hypocycloid transmission part, and the bevel gear pair includes a bevel gear box (16 ) the inner drive wheel (13) and the shaft extension driven wheel (15) mounted on the input shaft (14), the bevel gear box (16) is connected to the end face of the input end of the end cover (11), and the cycloid transmission part Including body (5), hypocycloid ring gear (1), four identical single eccentric bearings (9), four identical cycloid wheels (4), column pin (6) and column sleeve (3), input shaft ( 14), W output mechanism and support bearings (7, 12), the four single eccentric bearings (9) are installed on the shaft extension end of the input shaft (14), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com