Method for welding inner hole of heat exchanger

A welding method and heat exchanger technology, applied in welding equipment, arc welding equipment, heat exchange equipment, etc., can solve the problems of inconvenient observation of welding quality, inability to release stress, affecting welding quality, etc., and achieve good welding. performance, reducing welding stress and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

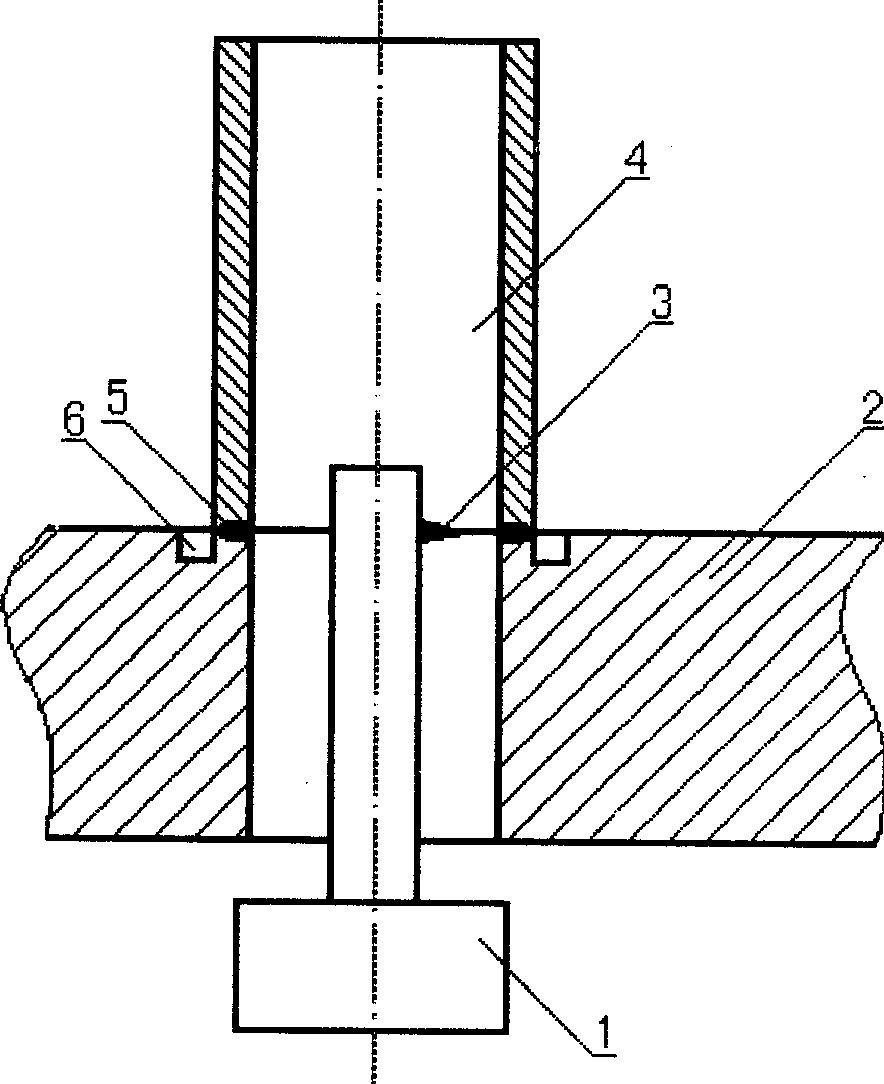

Image

Examples

Embodiment Construction

[0018] The low-pressure reaction water condenser is an important equipment for the production of nitric acid. The equipment is a shell-and-tube heat exchanger with a total length of 14.6m and a tube plate diameter of φ2124mm. There are 2020 heat exchange tubes evenly distributed on the tube plate, and the heat exchange area of the equipment is 1798m2 2 , net weight 48055Kg.

[0019] When manufacturing a low-pressure reaction water condenser, the internal parts of the condenser, including tube sheets, heat exchange tubes, baffles, and tie rods, are processed first, and then the blanking and rolling of the tube sections and the assembly between the tube sections are carried out. And welding and other processes, the simplified body of the heat exchanger is made, and then the tube bundle is assembled and the heat exchange tube is threaded, and then the tube bundle is inserted into the heat exchanger cylinder, and the inner hole welding is prepared for butt joint with the tube pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com