Combined heat source welding method and device in vacuum/ in protective atmosphere

A welding method and protective atmosphere technology, applied in the field of welding, can solve the problems of welding cold cracks, casting superalloy welding hot cracks, etc., and achieve the effects of reducing welding stress, avoiding cracks, and facilitating thermal cycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

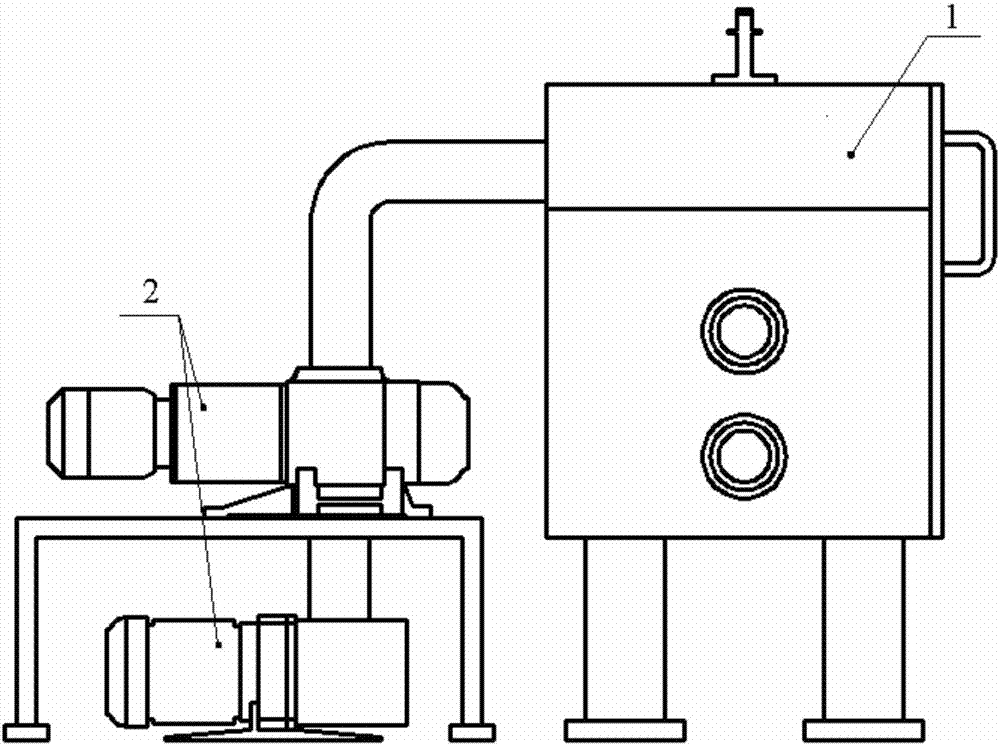

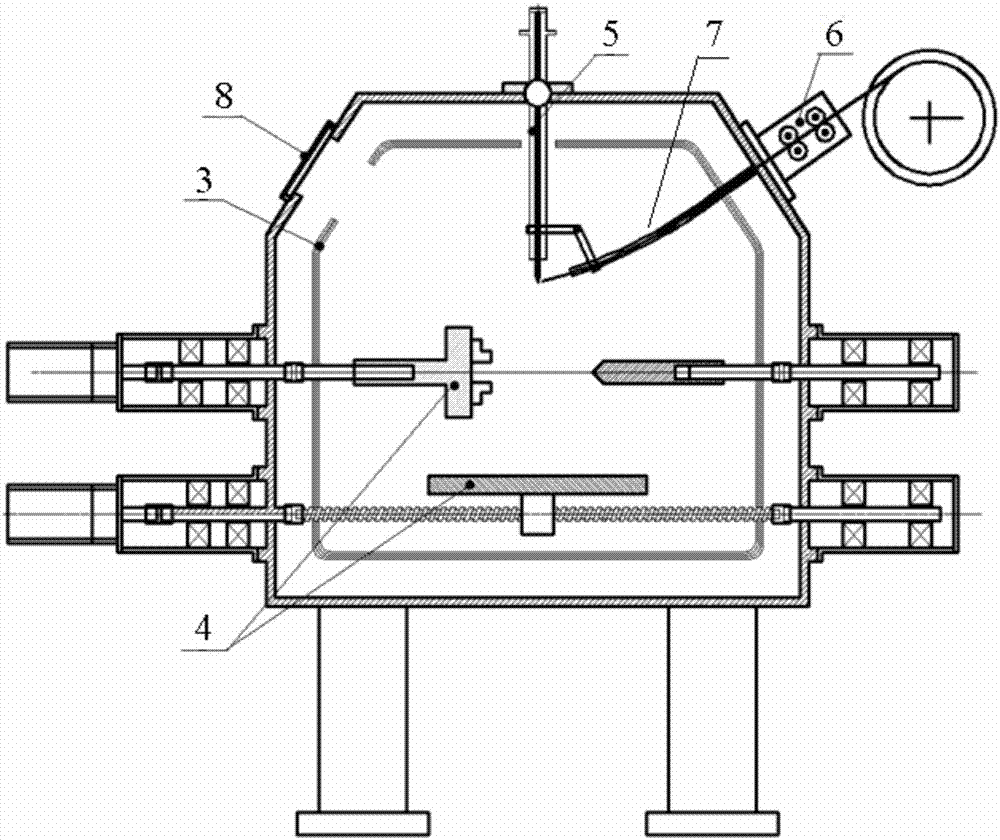

[0031] See attached figure 1 , 2 As shown, the welding device includes a furnace body 1 and a vacuum pump group 2 that provides vacuum / inert gas protection for the furnace body 1. A heating chamber 3 as a basic heat source is arranged in the furnace body 1, and a high temperature resistant CNC mobile workbench 4, heating chamber 3 surrounds the weldment to heat the weldment in an all-round way, and a welding torch 5 as a local heating welding heat source is arranged above the heating chamber 3, and the lower end of the welding torch 5 extends vertically into the heating chamber 3 The wire feeding mechanism 6 is installed between the shell of the furnace body 1 on one side of the welding torch 5 and the heating chamber 3, and the wire guide tube 7 of the wire feeding mechanism 6 is introduced into the heating chamber 3. The lower end of the welding torch 5 It is fixed together with the end of the wire guide tube 7 to ensure that the wire can be accurately fed into the molten p...

Embodiment 2

[0048] Welding device is identical with embodiment 1, adopts the method step of this welding device to carry out welding as follows:

[0049] step one

[0050] 2mm thick K465 cast superalloy plate, flat butt joint. The electric arc is used as the generation method of the welding heat source. Before welding, clamp the flat mouth of the K465 alloy plate in the tooling and place it on the mobile work platform. The surface of the test plate is 2.0mm away from the tungsten needle. Record the relative position of the tungsten needle and the welding seam in the numerical control system. vacuum. When the vacuum degree reaches below 2*10‐1Pa, stop vacuuming. Set the basic heating temperature to 700°C, turn on the heating power of the heating chamber, and fill the furnace body with argon or other inert gas at the same time to ensure that the internal pressure of the furnace body is less than 0.1MPa during the heating process; when the internal temperature of the furnace body reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com