On-site automatic welding device and welding method for large pipelines

An automatic welding, on-site technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of reducing the safety factor, reducing work efficiency, injury to workers, etc., to improve the safety factor, improve the effect of welding, use Safe and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

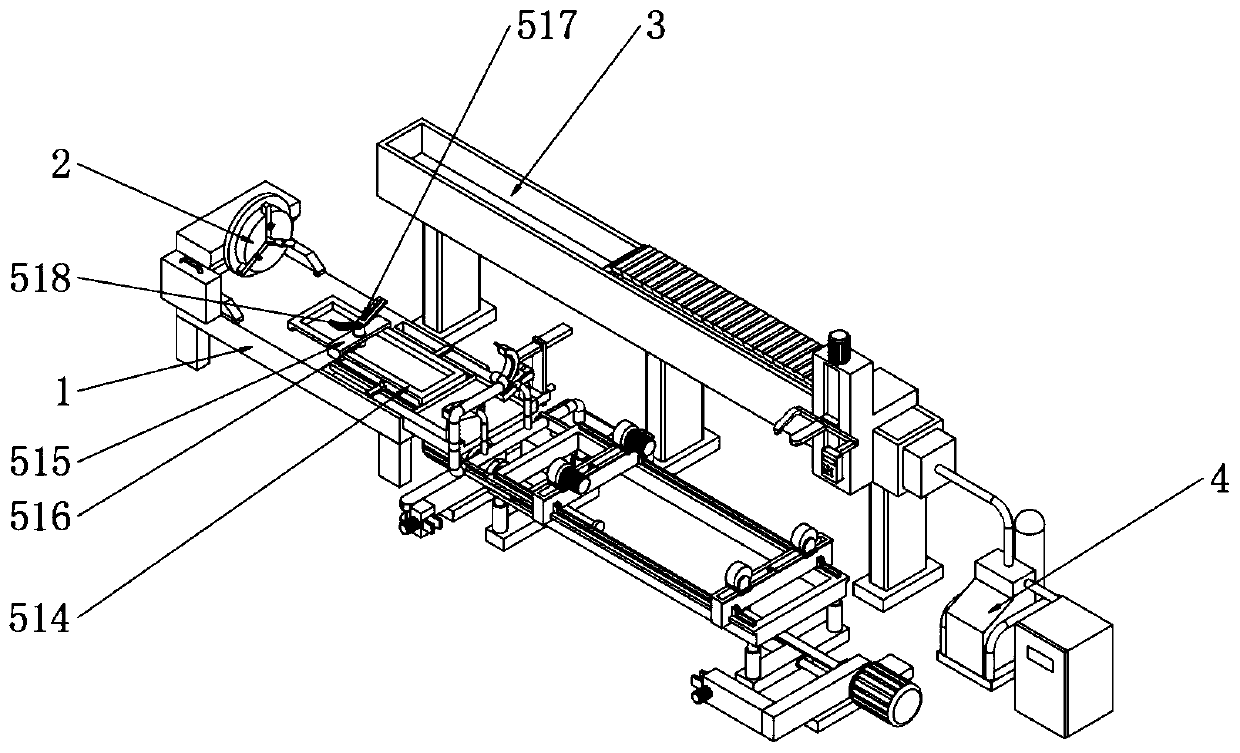

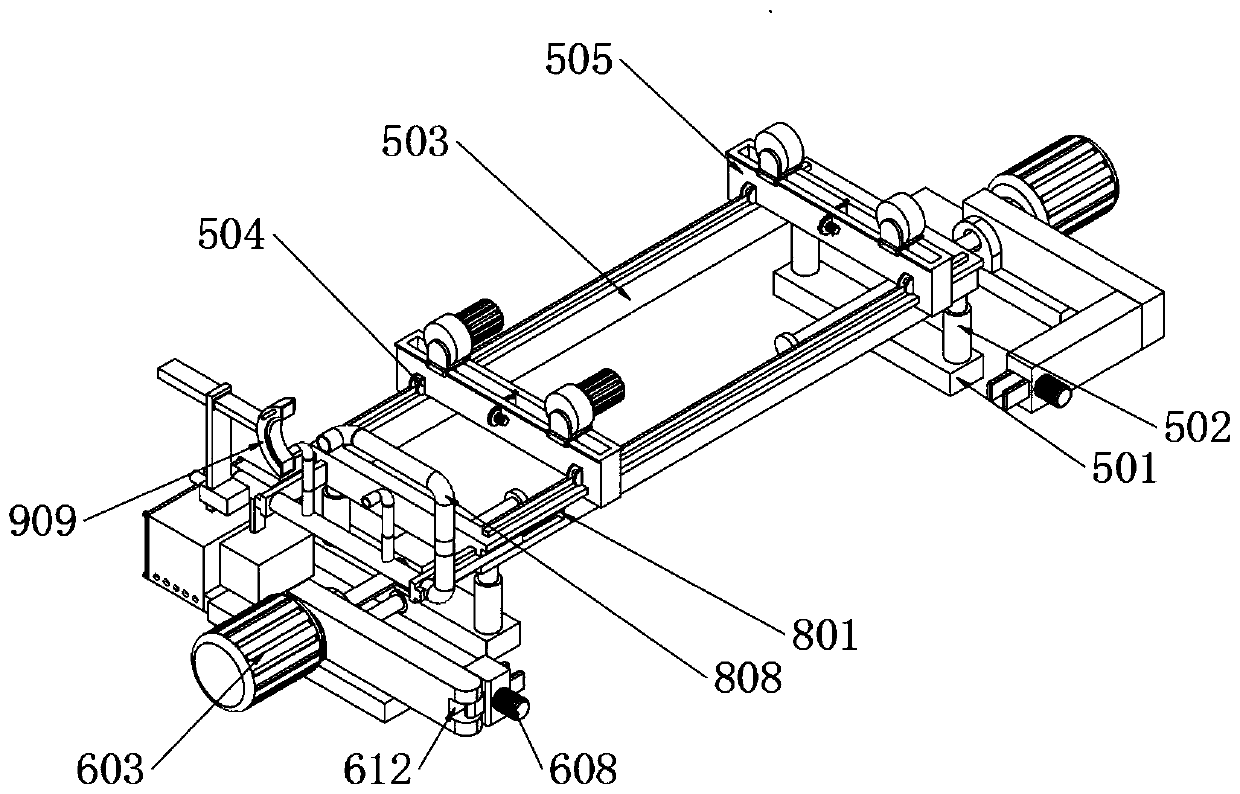

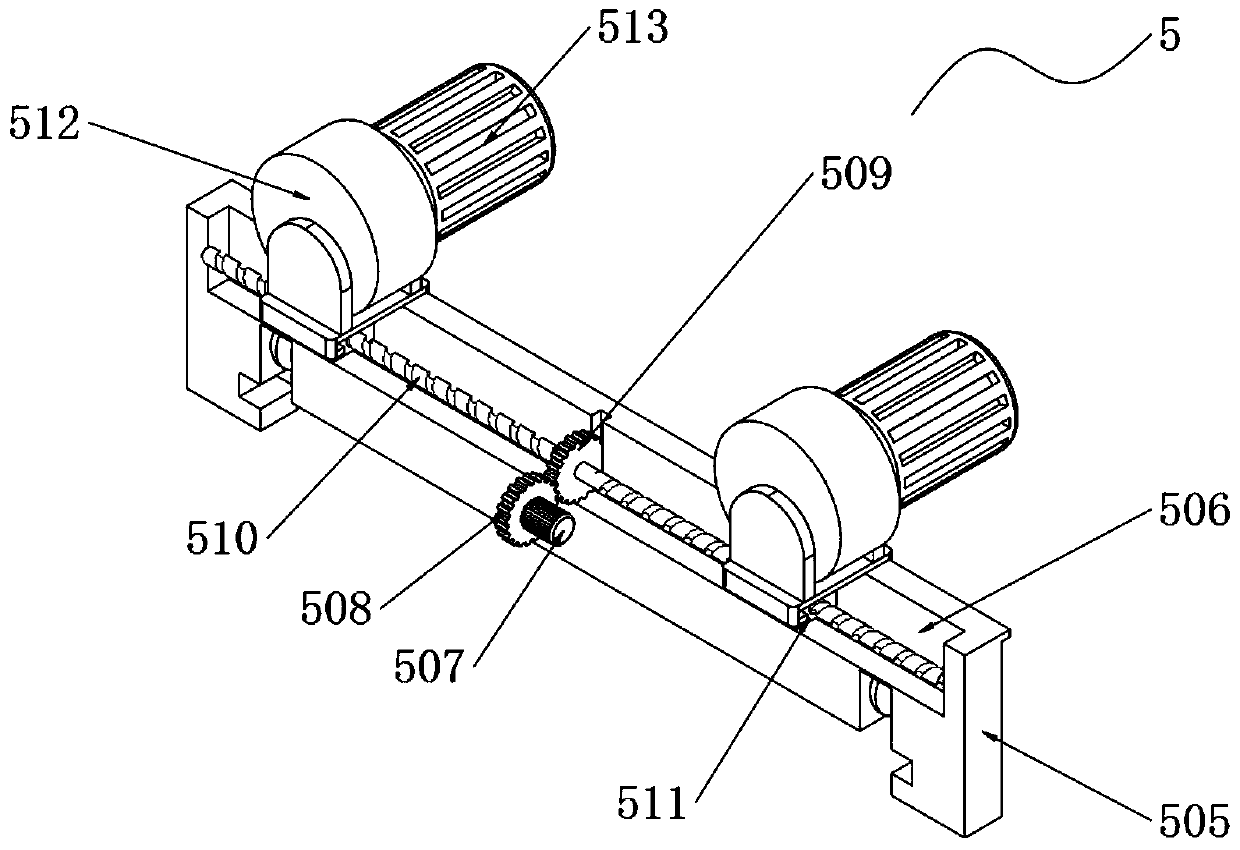

[0047] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a large pipeline on-site automatic welding device, including a welding support frame 1, a welding positioner 2 is installed on one end of the top surface of the welding support frame 1 through screws, and a welding positioner 2 is placed on one side of the welding support frame 1. The mobile support frame 3 is equipped with an automatic welding machine main body 4 at one end of the mobile support frame 3, a support adjustment assembly 5 is placed at one end of the welding support frame 1, and the bottom surfaces of the welding support frame 1, the mobile support frame 3 and the support adjustment assembly 5 are all on the same level. The length and width of one end of the support adjustment assembly 5 are respectively equal to the length and width of one end of the welding support frame 1, which facilitates the alignment of different pipes, facilitates the welding of the pipes, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com