Laser welding method for connecting molybdenum-group glass/kovar alloy by adding Mo-Mn-Ni metal interlayer

An intermediate layer, laser welding technology, applied in the field of laser welding, can solve the problems of large difference in thermal expansion coefficient, poor toughness of non-metallic materials, and difficult interface bonding, and achieve the effect of reducing welding stress, avoiding cracking, and avoiding cracking and fusing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Grind Kovar alloy from 400 mesh to 1200 mesh, and then perform ultrasonic cleaning in acetone solution for 20 minutes;

[0029] (2) Kovar alloy of 40×20×1.1mm is vacuumed at 10 -1 Treat in MPa environment for 20 minutes, then oxidize in a furnace at 800°C for 10 minutes;

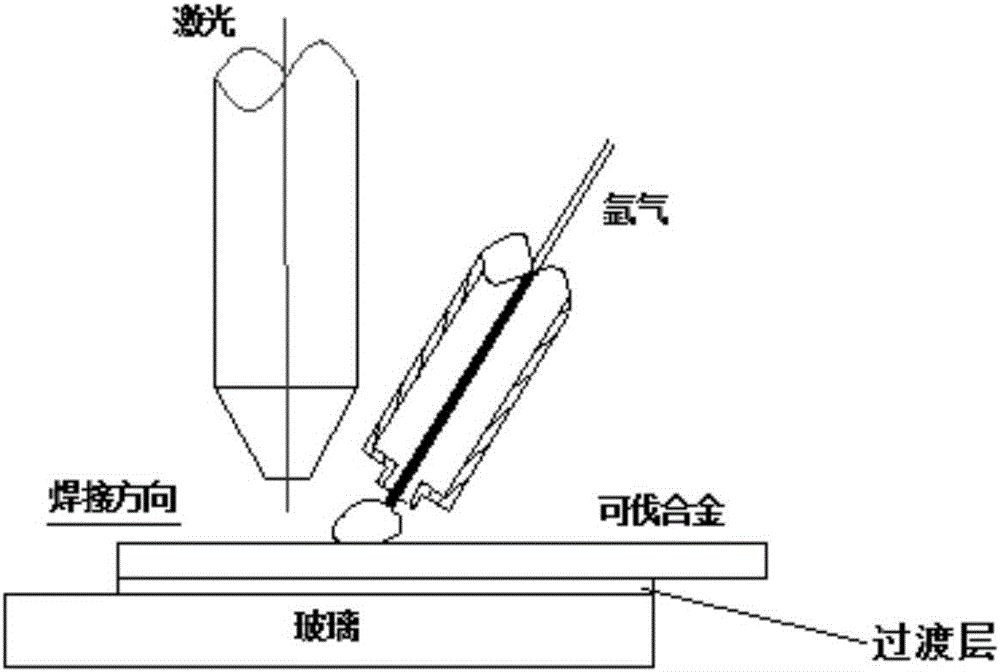

[0030] (3) Place the oxidized Kovar alloy sample on the molybdenum group glass sample (20×15×3mm), add an intermediate layer in the middle, and then place it on the fixture;

[0031] (4) The preheating temperature is 300°C, and the preheating time is 20 minutes;

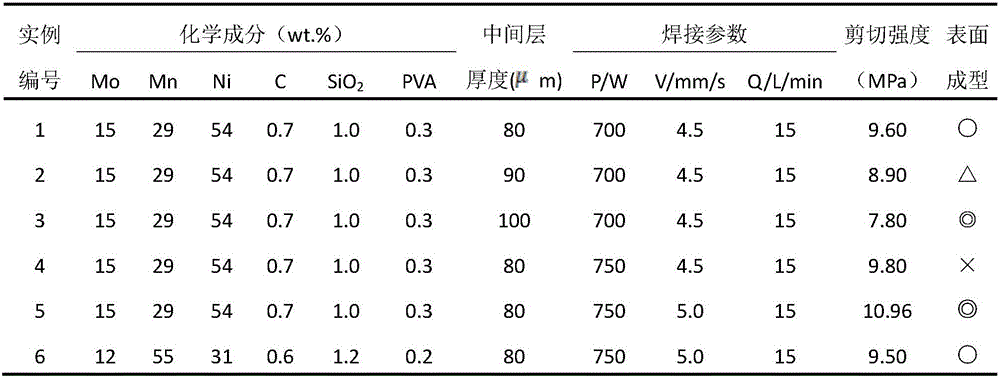

[0032] (5) The mass percentage of the middle layer is selected as: Mo: 15%, Ni: 54%, Mn: 29%, C: 0.7%, SiO 2 : 1.0%, the PVA additive accounts for 0.3%, and the thickness of the middle layer is 80 μm;

[0033] (6) Laser model: YLS-3000-SM, laser parameters: laser power 700W, welding speed 4.5mm / s, gas flow 15L / min;

[0034] (7) The post-weld heat treatment temperature is 350°C, and it is cooled with the furnace;

[0035] According t...

Embodiment 2

[0037] (1) Grind Kovar alloy from 400 mesh to 1200 mesh, and then perform ultrasonic cleaning in acetone solution for 20 minutes;

[0038] (2) Kovar alloy of 40×20×1.1mm is vacuumed at 10 -1 Treat in MPa environment for 20 minutes, then oxidize in a furnace at 800°C for 10 minutes;

[0039] (3) Place the oxidized Kovar alloy sample on the molybdenum group glass sample (20×15×3mm), add an intermediate layer in the middle, and then place it on the fixture;

[0040] (4) The preheating temperature is 300°C, and the preheating time is 20 minutes;

[0041] (5) The mass percentage of the middle layer is selected as: Mo: 15%, Ni: 54%, Mn: 29%, C: 0.7%, SiO2: 1.0%, PVA additive accounts for 0.3%, and the thickness of the middle layer is 90 μm;

[0042] (6) Laser model: YLS-3000-SM, laser parameters: laser power 700W, welding speed 4.5mm / s, gas flow 15L / min;

[0043] (7) The post-weld heat treatment temperature is 350°C, and it is cooled with the furnace;

[0044] According to the s...

Embodiment 3

[0046] (1) Grind Kovar alloy from 400 mesh to 1200 mesh, and then perform ultrasonic cleaning in acetone solution for 20 minutes;

[0047] (2) Kovar alloy of 40×20×1.1mm is vacuumed at 10-1 Treat in MPa environment for 20 minutes, then oxidize in a furnace at a temperature of 800°C for 10 minutes;

[0048] (3) Place the oxidized Kovar alloy sample on the molybdenum group glass sample (20×15×3mm), add an intermediate layer in the middle, and then place it on the fixture;

[0049] (4) The preheating temperature is 300°C, and the preheating time is 20 minutes;

[0050] (5) The mass percentage of the middle layer is selected as: Mo: 15%, Ni: 54%, Mn: 29%, C: 0.7%, SiO2: 1.0%, PVA additive accounts for 0.3%, and the thickness of the middle layer is 100 μm;

[0051] (6) Laser model: YLS-3000-SM, laser parameters: laser power 700W, welding speed 4.5mm / s, gas flow 15L / min;

[0052] (7) The post-weld heat treatment temperature is 350°C, and it is cooled with the furnace;

[0053] Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com