GMAW-Ar welding method for Q420B steel plate

A Q420B, welding method technology, applied in welding media, welding equipment, welding equipment, etc., can solve the problems of unstable welding performance, prone to laminar tearing, and impact on weld performance, so as to reduce welding stress and avoid cold. Cracks and lamellar tearing tendencies, avoiding the effect of hardened martensite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

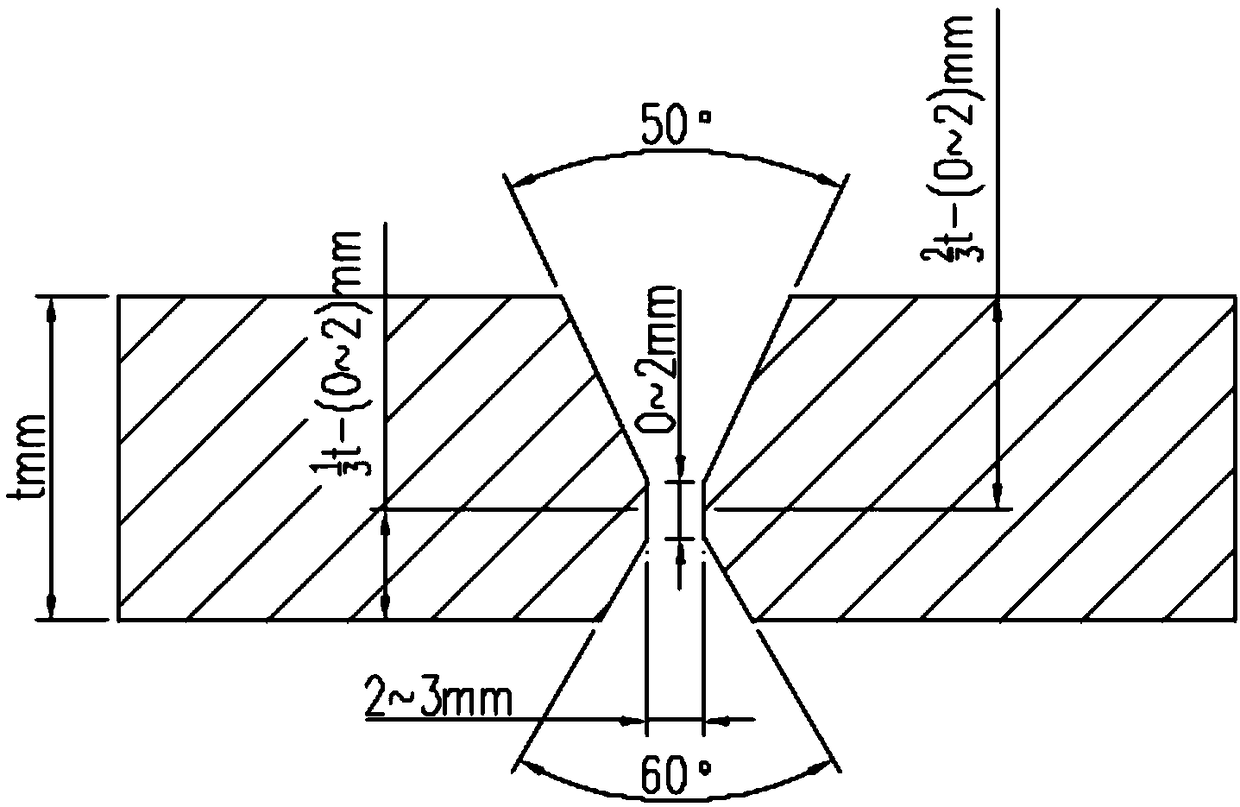

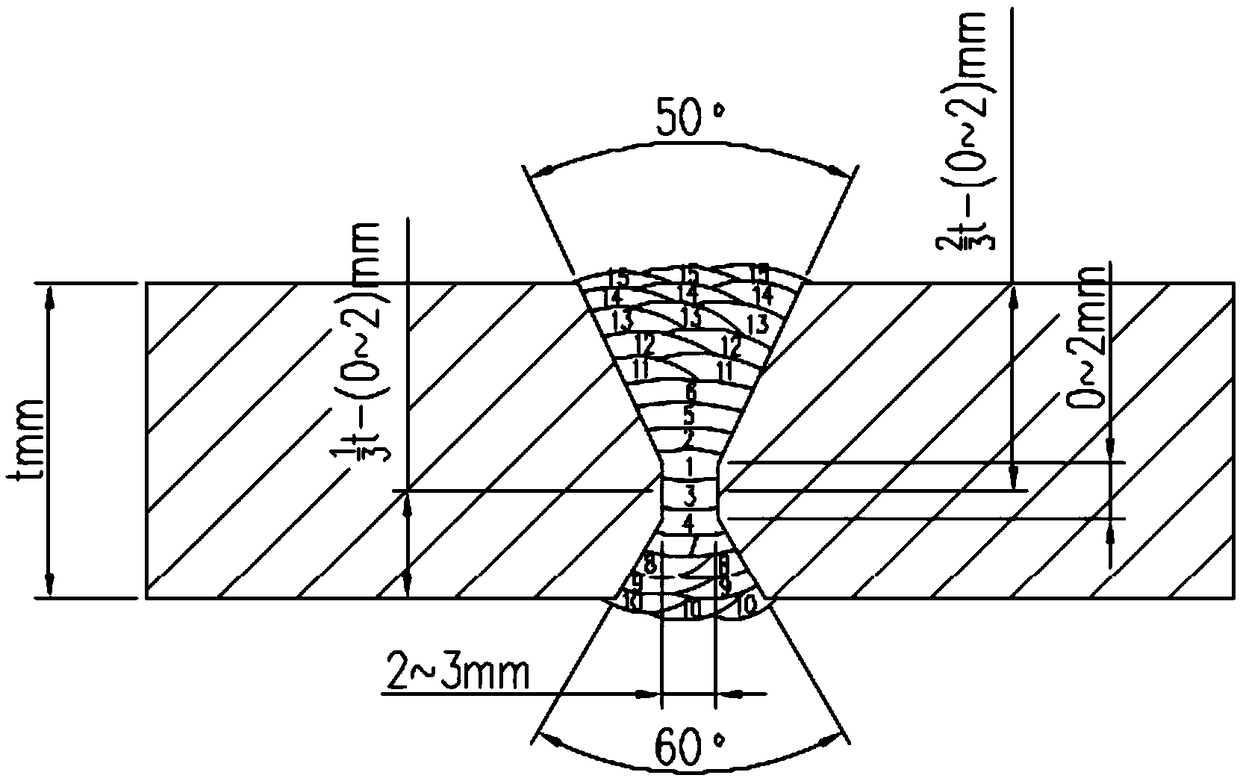

[0031] like figure 1 and figure 2 Shown, the GMAW-Ar welding method of the Q420B steel plate of the present invention comprises the following steps:

[0032] S1: Groove preparation: make an asymmetrical X-shaped groove on the test piece, and reserve a blunt edge of 0-2 mm; the angle of the deep groove is 50°, and the angle of the shallow groove is 60°; the height of the deep groove is 2 / 3tmm, the shallow groove height is 1 / 3tmm; among them, t / mm is the thickness of the test piece.

[0033] S2: Grinding the joint: use a grinder to grind the groove surface and the groove periphery within 20 mm to remove rust, oil, scale, and water, so that the test piece revea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com