Production technology for automatic low alloy steel welding wire for ship

A low-alloy steel and production process technology, used in metal processing equipment, welding media, manufacturing tools, etc., can solve the problems of increasing the softening tendency of welding heat, increase production costs, and deteriorate the working environment, and achieve good welding results. The effect of avoiding cold cracks and speeding up production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

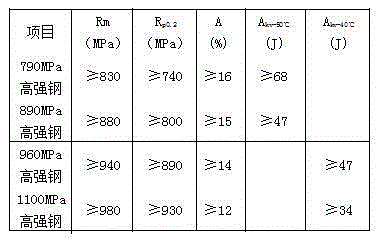

Image

Examples

Embodiment 1

[0021] The low-alloy steel automatic welding wire for ships without preheating and copper plating in this embodiment includes: C 0.02%, Mn 2%, Ni 4%, Mo 0.5%, Si 0.5%, Cu 0.2%, Cr 0.5 %, V 0.1%, Ti 0.01%; the wire diameter is drawn from Ф4.0mm to Ф1.0mm.

Embodiment 2

[0023] The low-alloy steel automatic welding wire for ships without preheating and copper plating in this embodiment includes: C 0.05%, Mn 3%, Ni 3%, Mo 0.7%, Si 0.6%, Cu 0.3%, Cr 0.6 %, V 0.06%, Ti 0.03%; the wire diameter is drawn from Ф4.0mm to Ф1.0mm

Embodiment 3

[0025] The low-alloy steel automatic welding wire for ships without preheating and copper plating in this embodiment includes: C 0.1%, Mn 4%, Ni 2%, Mo 1%, Si 0.8%, Cu 0.5%, Cr 1.2 %, V 0.12%, Ti 0.05%; the wire diameter is drawn from Ф4.0mm to Ф1.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com