Method for conducting laser modification welding on titanium alloy weld joint through wave absorbing coating

A wave-absorbing coating and titanium alloy technology, applied in the field of laser modification welding, can solve the problems of large welding residual stress, deformation of the workpiece, and the inability to fundamentally eliminate the undercut of the weld, and achieve the effect of low welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

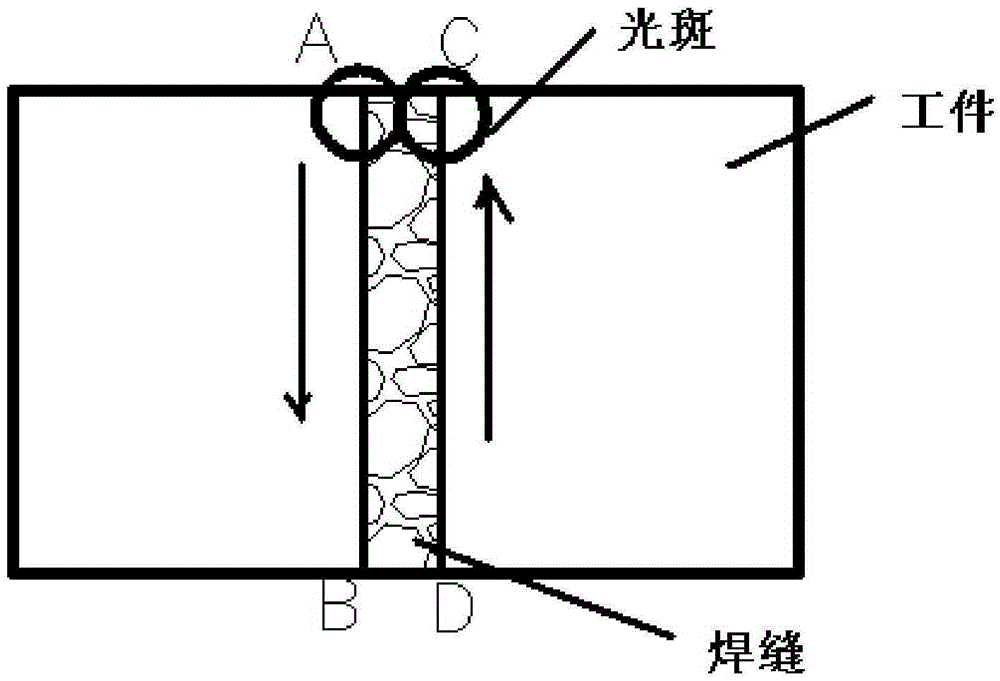

[0039] This embodiment provides a method for laser trim welding of titanium alloy weld seams by using a wave-absorbing coating, which includes the following steps:

[0040] 1) Pretreatment of the weld in the weld

[0041] Use alcohol or acetone to wipe the surface of the weld with undercut defects to remove the oil on the surface of the weld; then use a continuous laser (wavelength 1.6μm, power 2000W) to weld with a defocused laser spot The seam is scanned to remove the residual organic matter on the surface of the weld. During the scanning process, the diameter of the defocused laser spot is controlled to be 8mm, and the scanning speed is 1.2m / min;

[0042] 2) Apply a wave-absorbing coating to the weld position

[0043] NaF 2 , Y 2 o 3 、Cr 2 o 3 , La 2 o3 The powder is mixed uniformly according to the mass ratio of 40%:20%:20%:20% to obtain a wave-absorbing coating; then the mixed powder and acetone are mixed into a suspension according to the mass ratio of 1:10, Use ...

Embodiment 2

[0047] This embodiment provides a method for laser trim welding of titanium alloy weld seams by using a wave-absorbing coating, which includes the following steps:

[0048] 1) Pretreatment of the weld in the weld

[0049] Use alcohol or acetone to wipe the surface of the weld with undercut defects to remove the oil on the surface of the weld; then use a continuous laser (wavelength 1.6 μm, power 2200W) to weld with a defocused laser spot The seam is scanned to remove the residual organic matter on the surface of the weld. During the scanning process, the diameter of the defocused laser spot is controlled to be 6mm, and the scanning speed is 1.5m / min;

[0050] 2) Apply a wave-absorbing coating to the weld position

[0051] NaF 2 , Y 2 o 3 、Cr 2 o 3 , La 2 o 3 The powder is mixed uniformly according to the mass ratio of 70%:10%:10%:10% to obtain a wave-absorbing coating; then the mixed powder and acetone are mixed according to the mass ratio of 1:10 to form a suspension,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com