Method for improving weld structure and performance of magnesium alloy

A magnesium alloy and microstructure technology, which is applied in the field of magnesium alloy hot rolling strengthening processing technology after welding, can solve the problems of poor weld strength of magnesium alloy and the influence of weld seam on the appearance, etc., and achieve the improvement of weld strength, obvious weld strength, and anti-corrosion The effect of similar tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below with reference to accompanying drawing and in conjunction with specific examples, further set forth the present invention, should be understood that, these examples are for illustrating the present invention, rather than limitation of the present invention, under the concept premise of the present invention to the simple improvement of the preparation method of the present invention, All belong to the scope of protection required by the present invention.

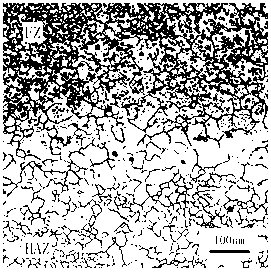

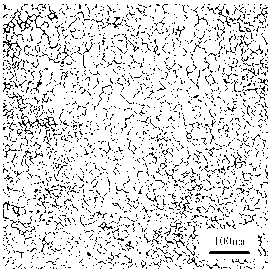

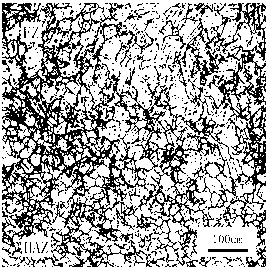

[0032] Sample 1 is a rolled AZ31 magnesium alloy plate with a thickness of 3 mm from the original plate, and the welding direction is perpendicular to the rolling direction of the original plate.

[0033] Sample 2 is an extruded AZ31 magnesium alloy plate with a thickness of 3 mm from the original plate, and the welding direction is parallel to the extrusion direction of the original plate.

[0034] A method for improving the welding microstructure and properties of magnesium alloys (improving the microstructur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com