After-heating laser welding method for jointed gear ring and gear

A technology of laser welding and combining teeth, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as cracks and gear assembly welding deformation, eliminate cracks at the bottom of the weld, reduce welding stress, reduce Effect of Welding Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

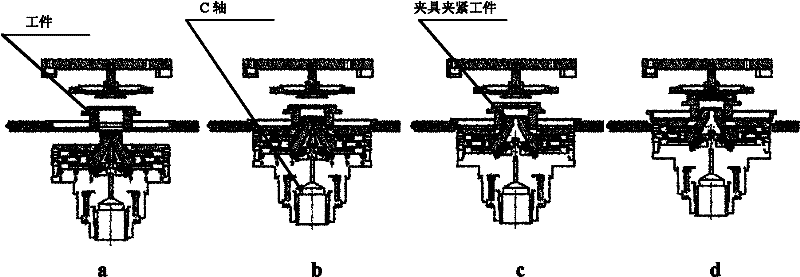

[0034] This embodiment includes the following steps:

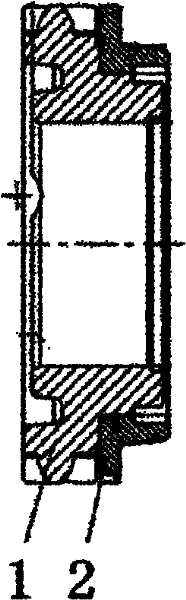

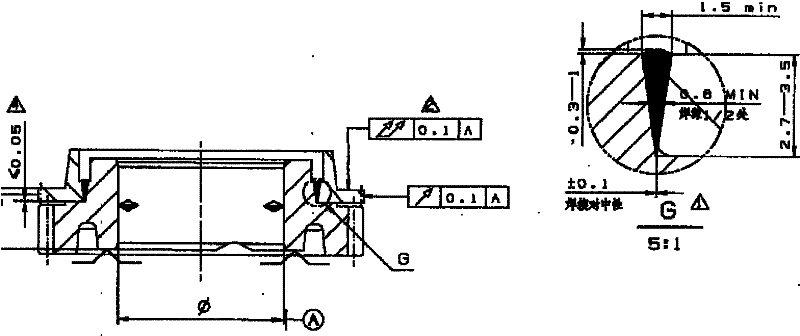

[0035] The first step will be as figure 1 The shown combined bevel and gear are pretreated separately, and the specific steps are as follows:

[0036] 1.1) Machining: The bevel and gear will be combined with thermal pre-machining, including finish turning, gear and reverse bevel machining, etc.

[0037] 1.2) Heat treatment: adopt carburizing, quenching and tempering heat treatment methods;

[0038] The quenching refers to quenching by press quenching to ensure the flatness of the press-fit large surface and the roundness of the press-fit aperture;

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com