Horizontal luffing grab portal crane

A bucket door seat and crane technology, which is applied to cranes and other directions, can solve problems that affect the stability and safety of the driver's operation of the grab, reduce the working efficiency of the whole machine, and unstable operating conditions, etc., to achieve good control, stable operation, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

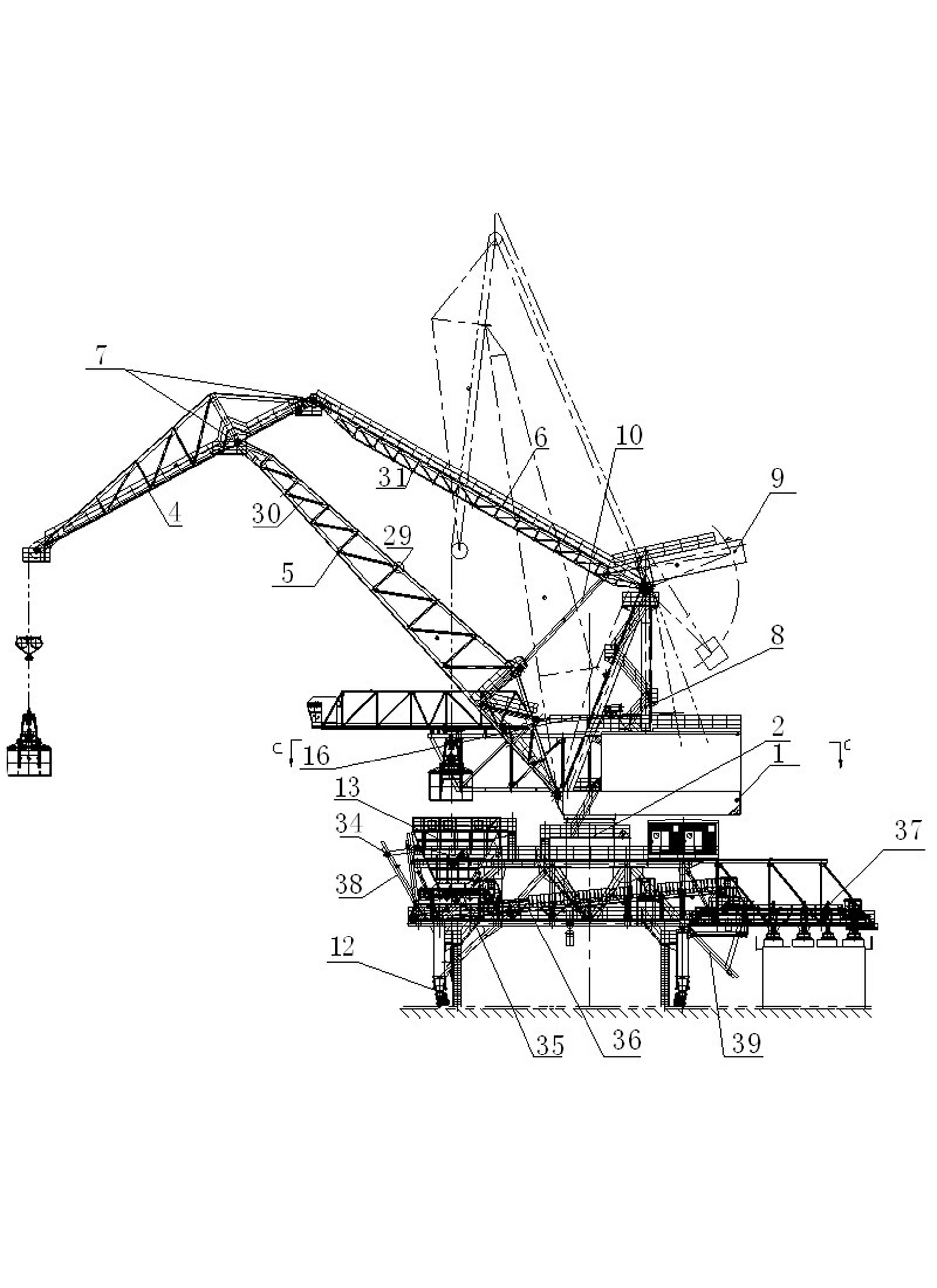

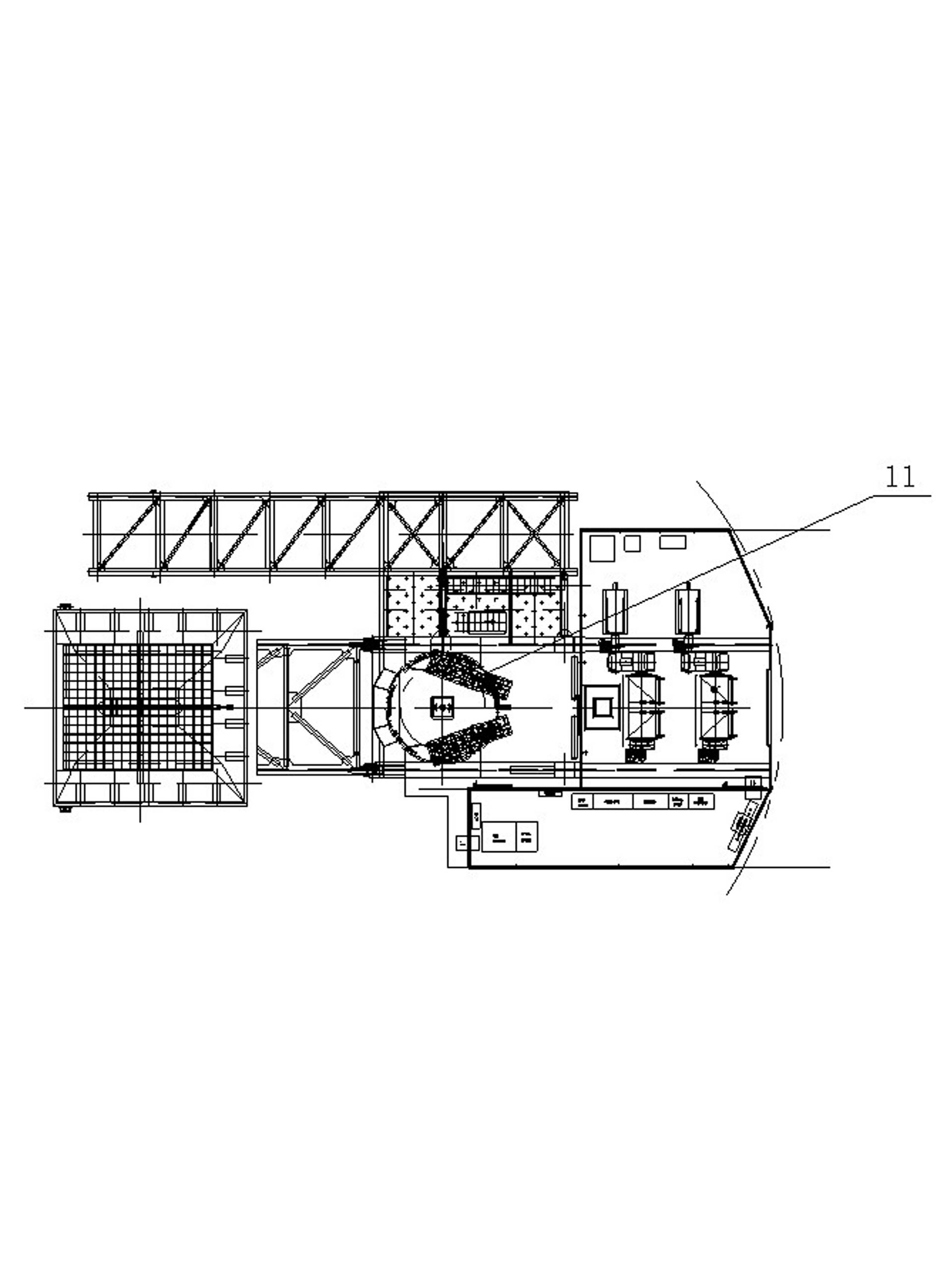

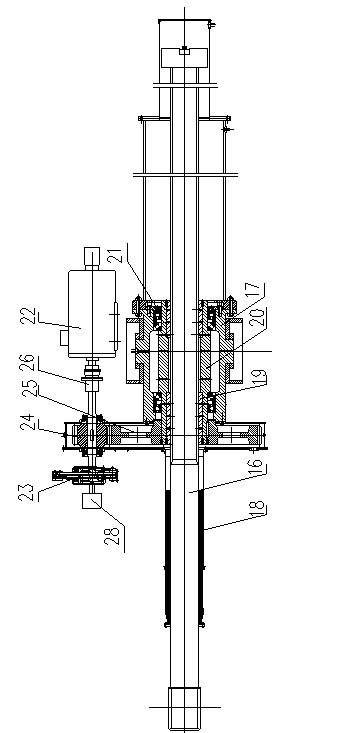

[0018] Such as figure 1 As shown in —5, the horizontal luffing crane with bucket door seat includes a four-link horizontal luffing jib system, an operating mechanism and a mast structure. The tie rod 6 and the herringbone frame 8, the four-link horizontal luffing jib system is fixed on the mast beam 3 through the rotary large bearing ring gear 2 under the swivel frame 1, the elephant trunk bridge 4 of the four-link horizontal luffing jib system 1. The boom 5 and the big pull rod 6 are connected by the hinge shaft 7, the hinge point of the boom 5 root is hinged with the swivel frame 1, the other end of the big pull rod 6 is hinged with the top support of the herringbone frame 8, and the bottom of the herringbone frame 8 is welded on On the swivel frame 1, a counterweight balance beam 9 is also hinged on the head support of the herringbone frame 8, and the counterweight balance beam 9 is hinged with the arm frame 5 through the counterweight pull rod 10. The operating mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com