Crane main beam welding machine

A technology of cranes and welding machines, which is applied to welding equipment, welding rod characteristics, arc welding equipment, etc., can solve problems such as high labor intensity, increased turning hours, welding deformation, etc., to achieve the effect of reducing labor intensity and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

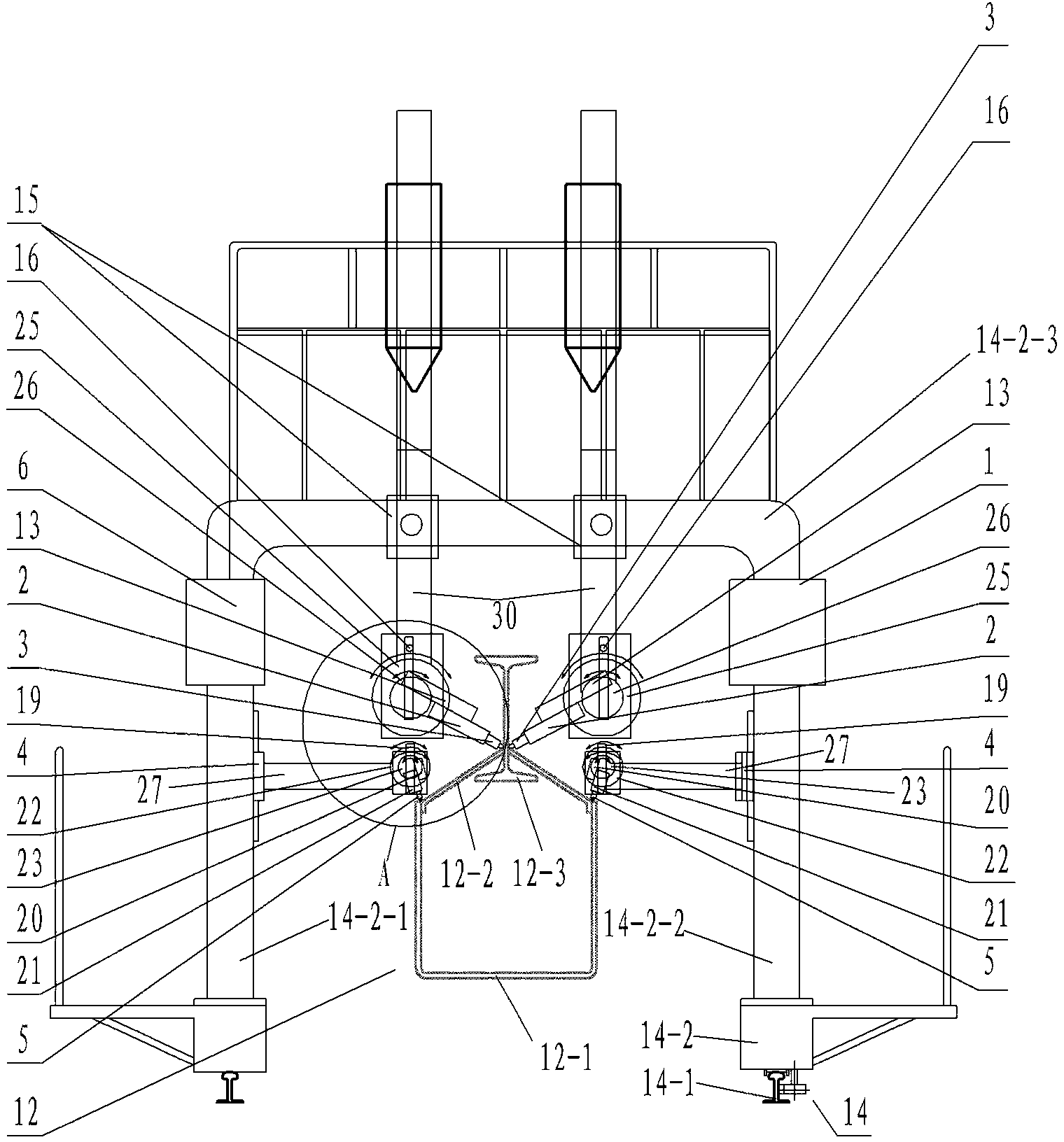

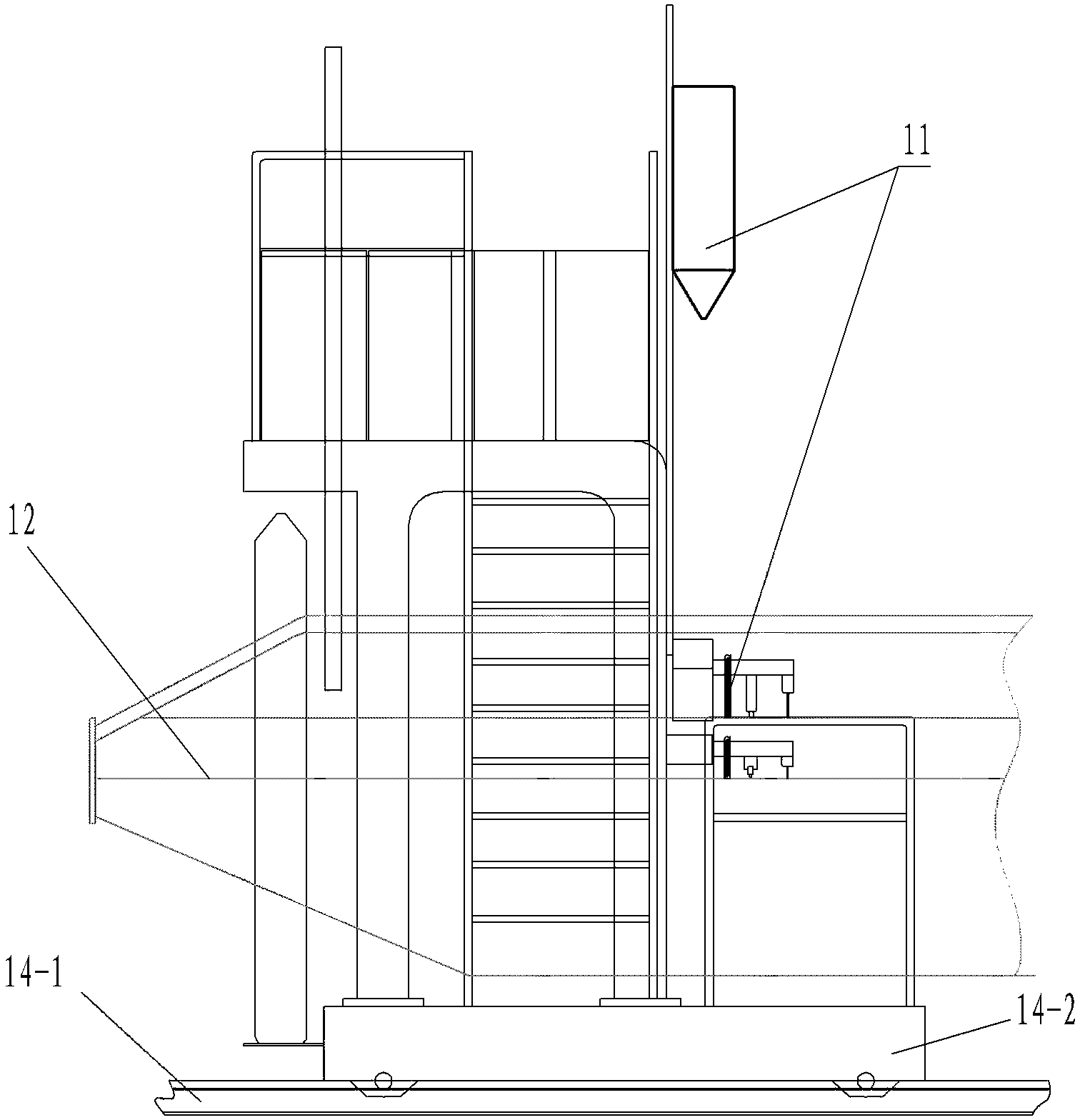

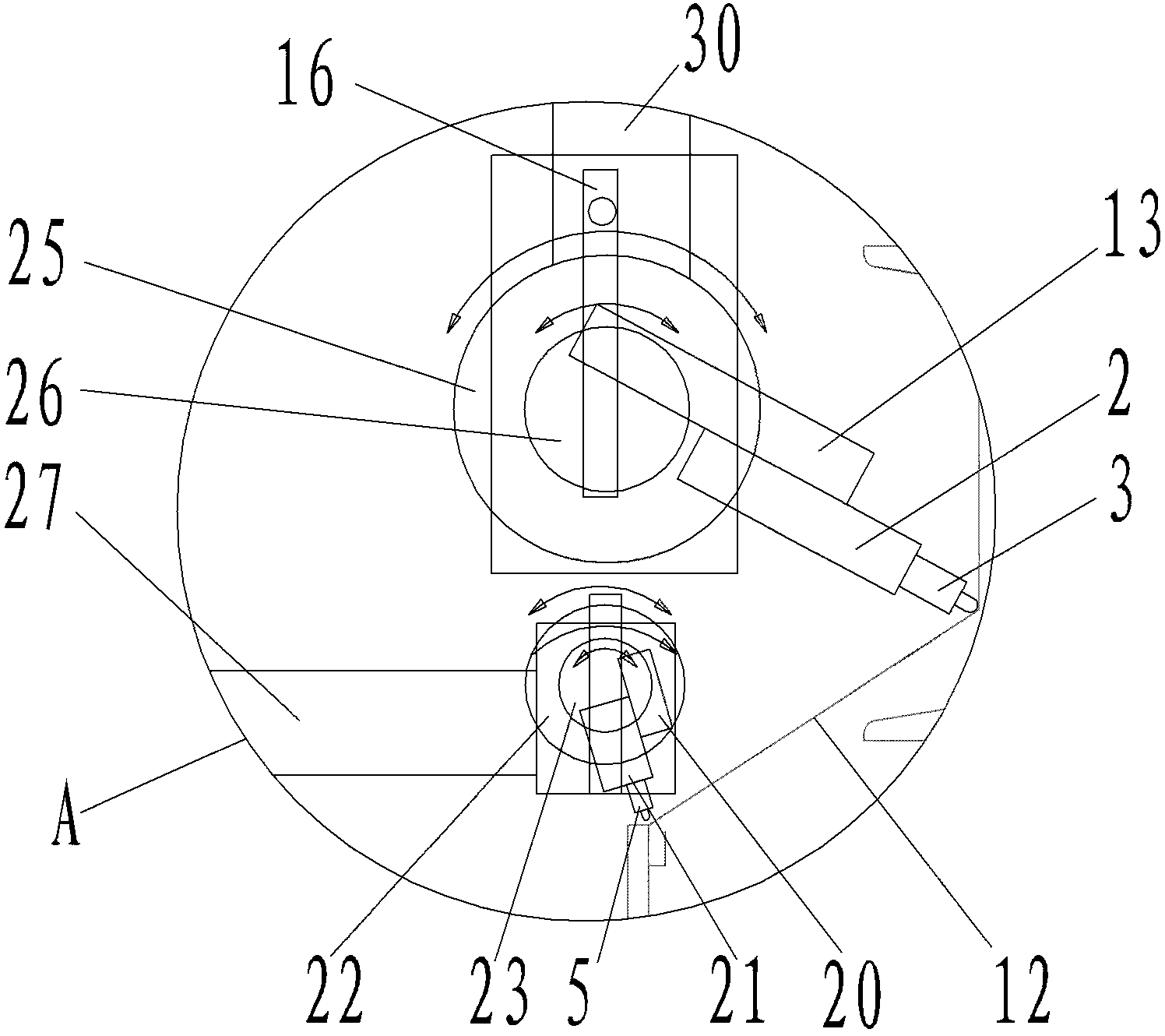

[0021] An example of a crane girder welding machine Figure 1~4 Shown: comprise frame 14, frame comprises fixed frame 14-1 and its upper sliding frame 14-2 that guides sliding assembly along the front and back direction, and movable frame 14-2 comprises the left side of lower end and fixed frame 14-1 guiding sliding assembly. Vertical frame 14-2-1, right vertical frame 14-2-2 and horizontal frame 14-2-3 erected on left and right vertical frame upper ends, left and right vertical frame and horizontal frame 14-2-3 constitute " door "Glyph structure, between the movable frame 14-2 and the fixed frame 14-1, be provided with the movable frame motor and the movable frame rack and pinion mechanism that drive the movable frame 14-2 to move along the front and rear direction, wherein in the movable frame rack and pinion mechanism The gear of the movable frame is connected with the output end of the movable frame motor, and the rack in the rack and pinion mechanism of the movable frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com