Rapid clutch device for straightening shearing machine for wire

A technology of clutch device and shearing machine, which is applied in the direction of non-mechanical drive clutches, clutches, magnetic drive clutches, etc., can solve the problems of high production cost, jamming, and many times of shearing, and achieve fast moving separation speed and positioning lock The effect of staying steady and separating quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

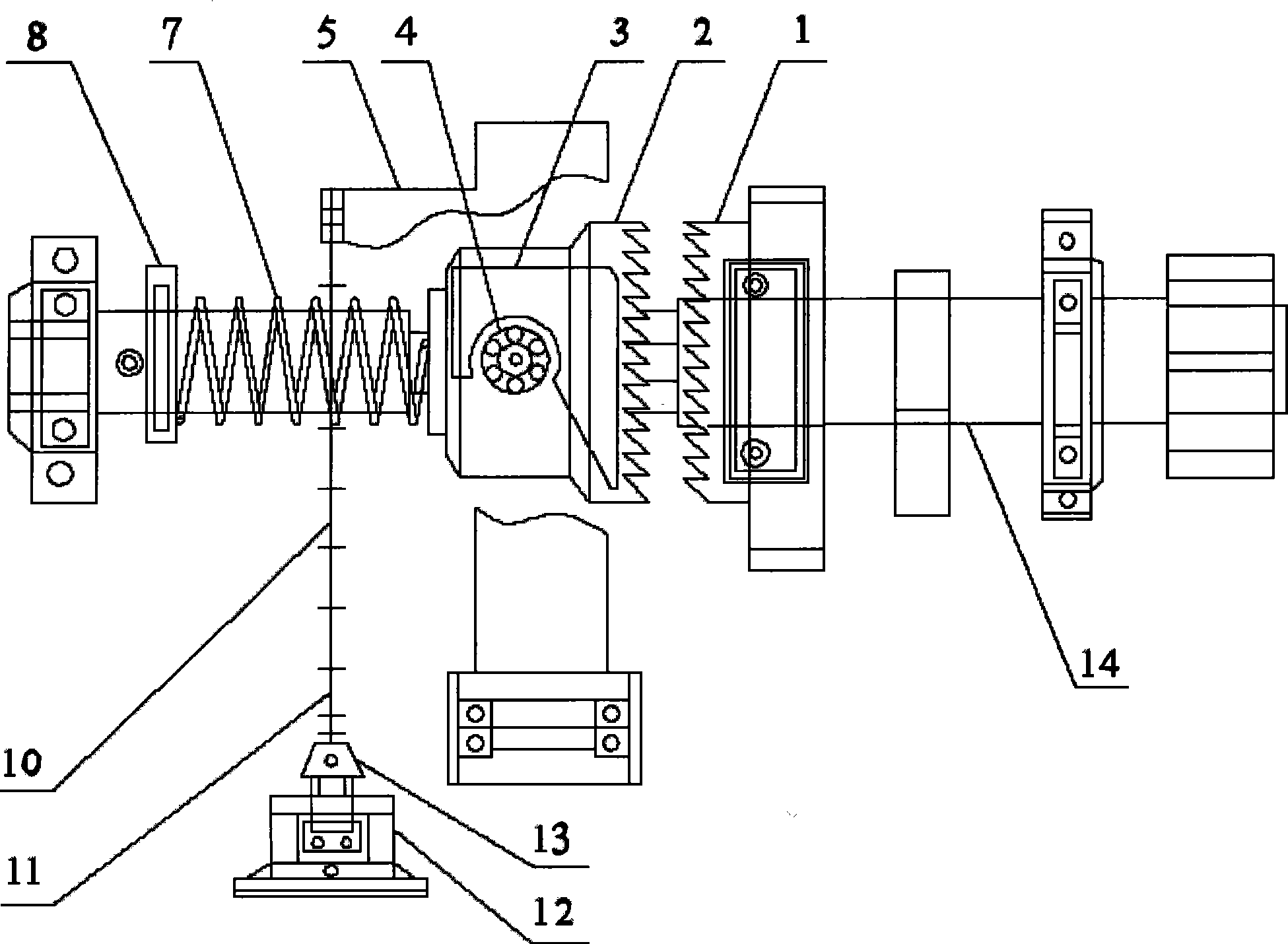

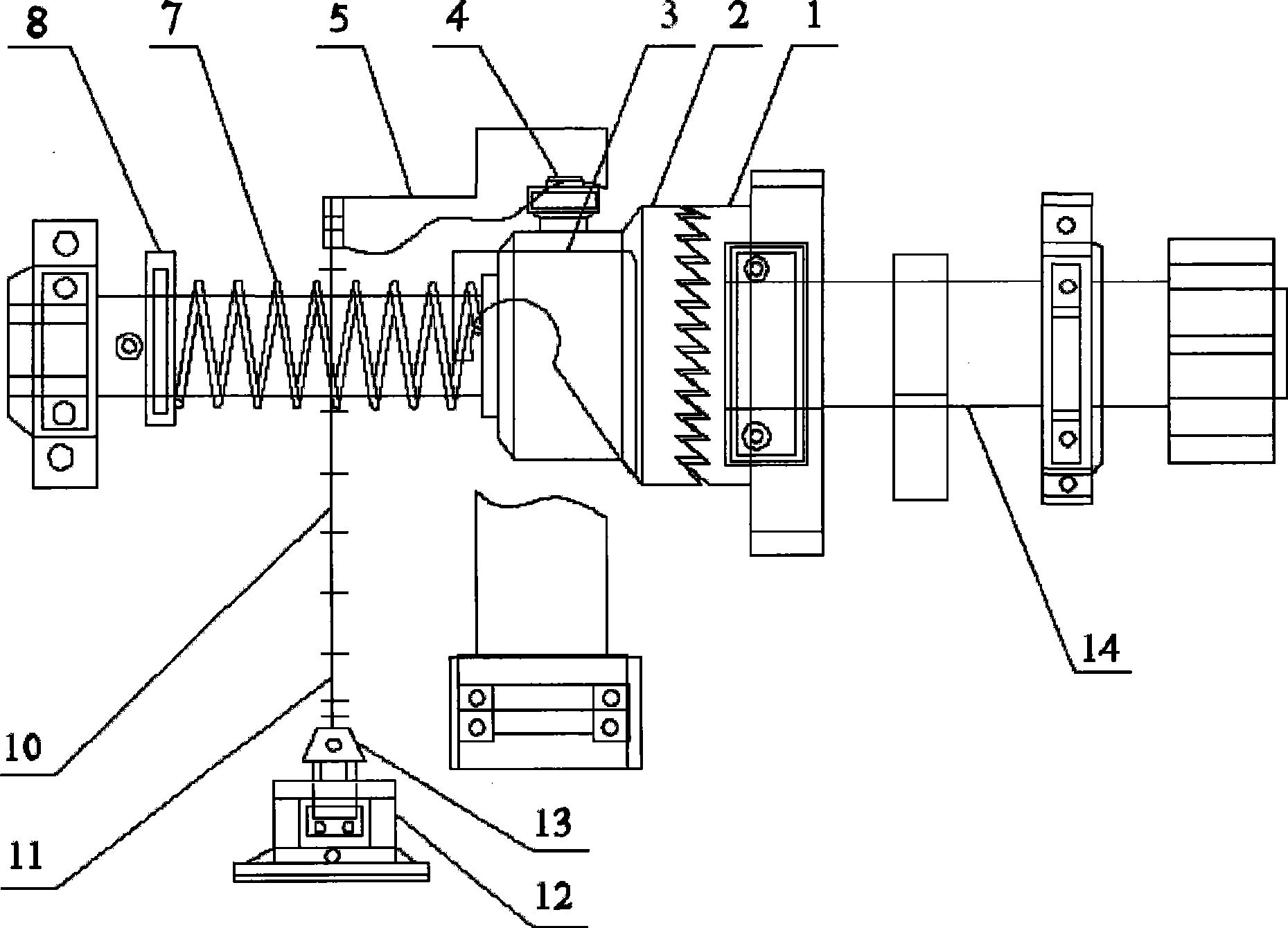

[0035] Embodiment 1. A quick clutch device for wire straightening and shearing machines, including a fixed saw gear 1, a moving saw gear 2, a tiger mouth hook 3, a return device 4, an angle iron cover plate 5, a spring 7, and a baffle 8. Actuating connectors, electromagnet frame 12, and fixed shaft 14, wherein: the fixed saw gear 1 is connected with the front end bearing of the fixed shaft 14; the moving saw gear 2 is slidingly socketed with the middle end of the fixed shaft 14; the baffle plate 8 is fixedly installed On the rear end of the fixed shaft 14; the two ends of the spring 7 are respectively fixed on the baffle plate 8 and the mobile saw gear 2; the outer circle of the mobile saw gear 2 is fixed with a return device 4; On the return device 4; the tiger mouth hook 3 is installed on the angle iron cover plate 5, and one end of the angle iron cover plate 5 is fixed on the frame; the electromagnet installed on the electromagnet frame 12 passes through the connecting piece...

Embodiment 2

[0036] Embodiment 2, a quick clutch device for a straightening and shearing machine for wire rods, wherein: the pulling connector is a chain 10, a sprocket 11, and a core hammer 13; Iron connection, center hammer 13 other ends pull angle iron cover plate 5 by sprocket wheel 11, chain 10. All the other are with embodiment 1.

Embodiment 3

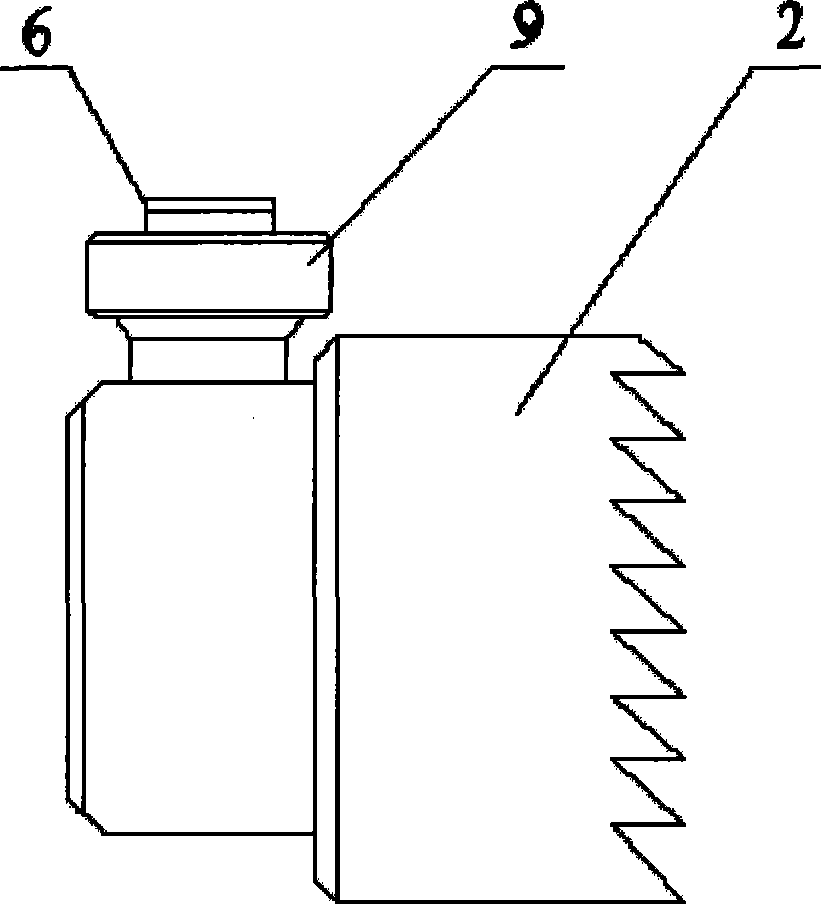

[0037] Embodiment 3, a quick clutch device for a wire straightening and shearing machine, wherein: the tiger mouth hook 3 is provided with a semicircular opening, and a slope with a certain angle is provided at the lower end of the semicircular opening, and the slope and the semicircular opening smoothly transition. All the other are with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com