Surface coating process for binder clip

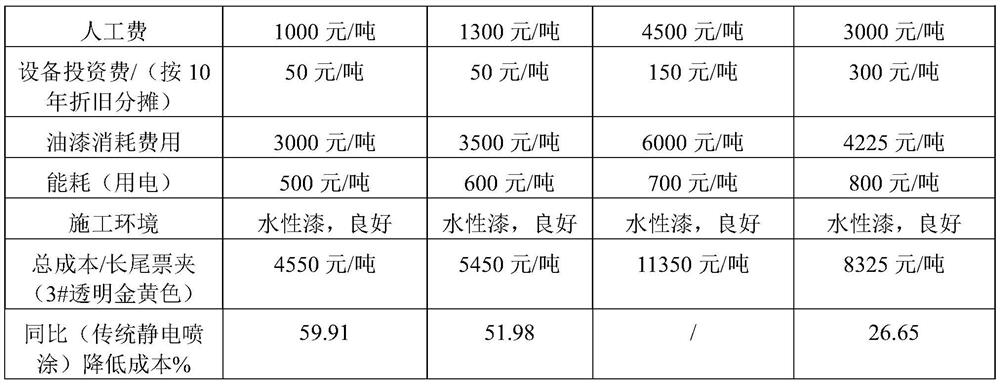

A surface coating and ticket holder technology, which is applied to the surface coating liquid device, metal material coating process, surface pretreatment, etc., can solve the problems of difficult maintenance, high equipment investment, and large floor area. Achieve the effect of optimal comprehensive cost, simple coating process and safe construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a surface coating process for long-tailed ticket holders, which is carried out by an automatic roller spraying machine, including the following steps:

[0037] S1. Surface pretreatment of long tail ticket holder:

[0038]First, heat treatment the 3# long tail ticket holder (transported by pipeline mesh belt): the quenching temperature of the main furnace is 700-900°C, and the time is 20 minutes to improve the hardness of the ticket holder. Furnace tempering temperature 300~500℃, wait for 10 minutes to improve the toughness of the long-tailed ticket holder, enter the clear water pool to cool; then dip-coat the primer, and enter S2 after drying;

[0039] S2, charging stage:

[0040] Open the cover of the rotating drum, and after confirming that the inside of the rotating drum is clean, put the 25Kg 3# long-tail ticket holder into the drum of the automatic roller spraying machine, and close the cover of the rotating drum;

[0041] S3. Preheating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com