A hard rock roadway excavation method integrating drilling, water exploration and milling

A milling and roadway technology, applied in the field of hard rock roadway excavation and roadway rock mass excavation, can solve the problems of low rock breaking efficiency, poor mechanical rock breaking ability, falling off, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

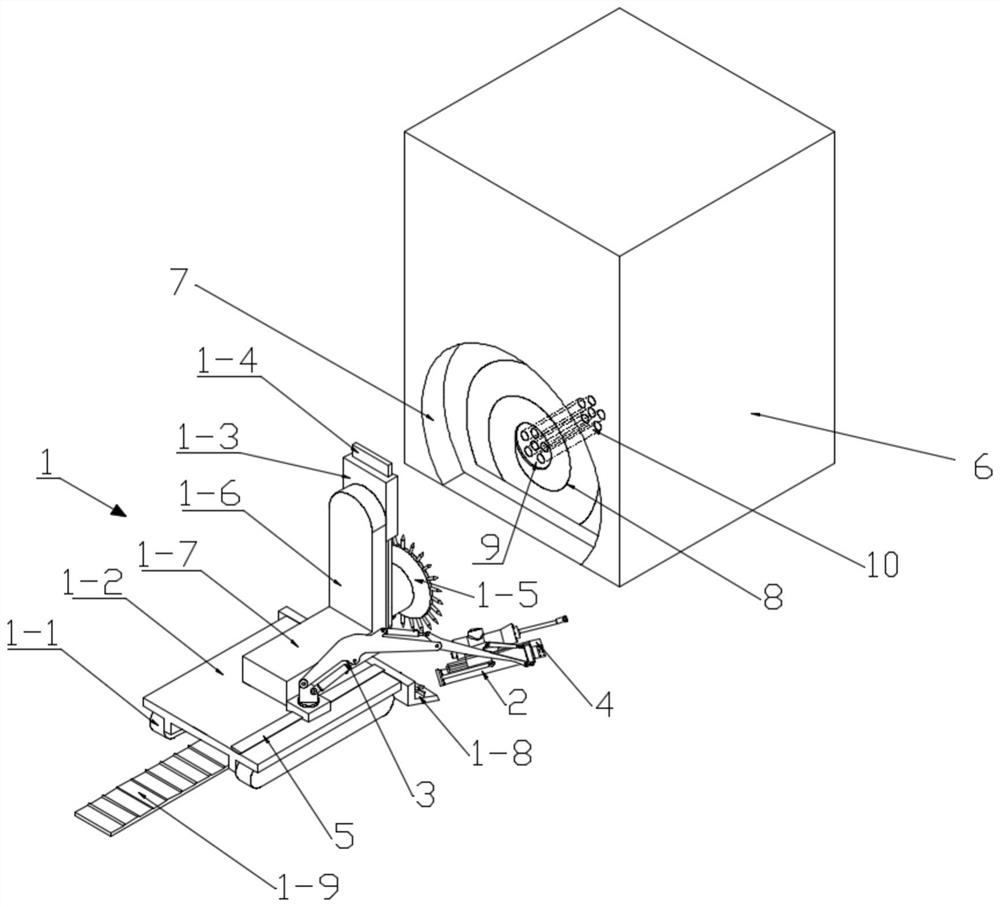

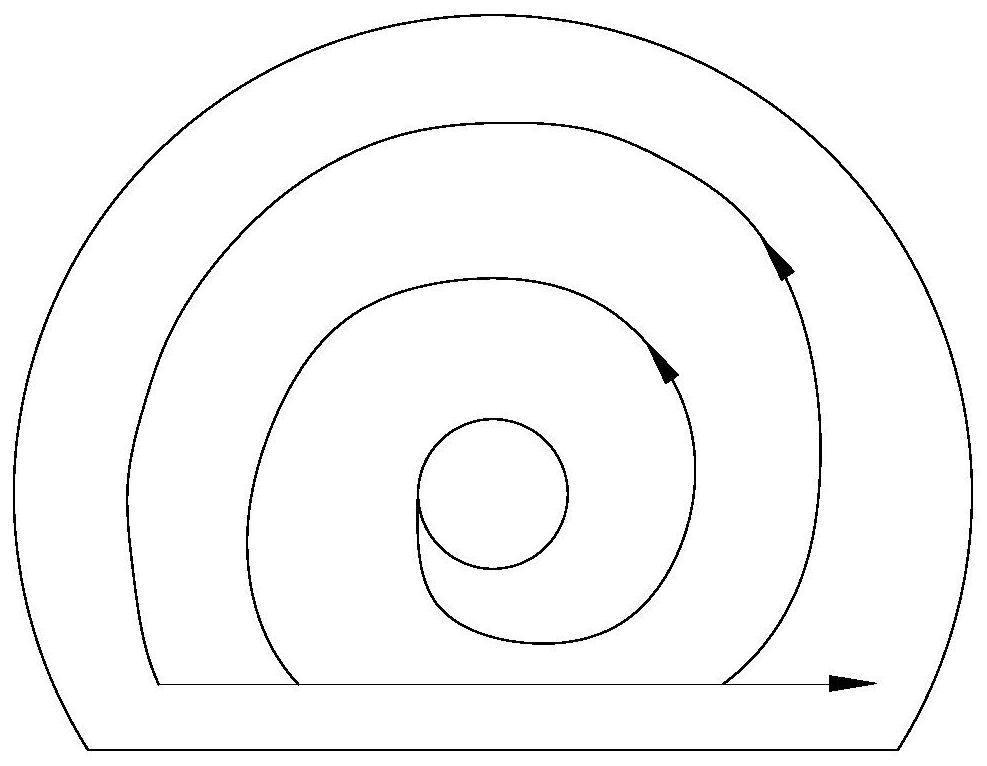

[0025] Such as figure 1 As shown, a kind of hard rock roadway excavation method integrating drilling, water exploration and milling of the present invention, the equipment involved mainly includes a milling roadheader 1, an integrated drilling machine 2 and a movable mechanical arm 3;

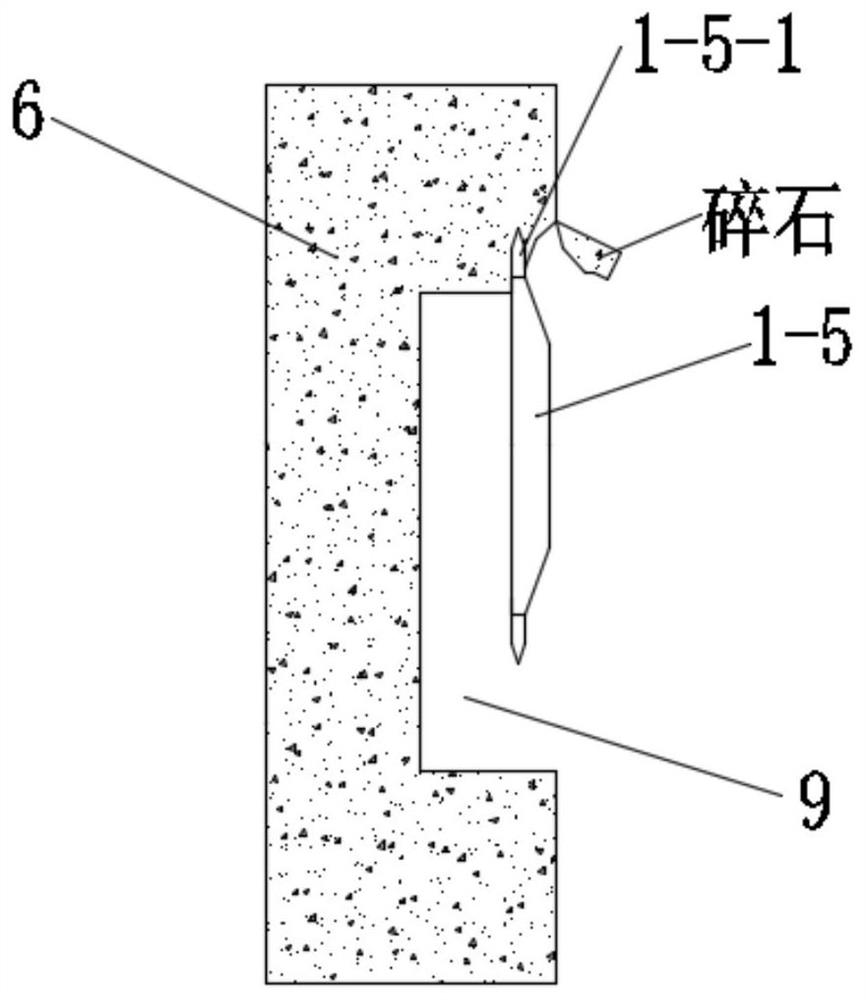

[0026] The milling and boring machine 1 includes a crawler walking mechanism 1-1, a frame 1-2, a rotating mechanism 1-3, a hob arm 1-4, a disc hob 1-5, a transmission box 1-6, a base 1- 7. Loading device 1-8 and conveying device 1-9, the frame 1-2 is installed above the crawler belt traveling mechanism 1-1, and the frame 1-2 is provided with Guide rail II5, the base 1-7 is installed on the front of the frame 1-2, the transmission box 1-6 is installed on the front end of the base 1-7, and the rotating mechanism 1-3 is installed on the front of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com