Drilling-pressing-digging integrated hard rock tunneling equipment

A kind of equipment and hard rock technology, applied in the field of hard rock roadway (tunnel) excavation equipment, can solve the problems of affecting work efficiency, poor mobility, ventilation and emission of harmful gases, etc., to improve the excavation efficiency, avoid potential safety hazards, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

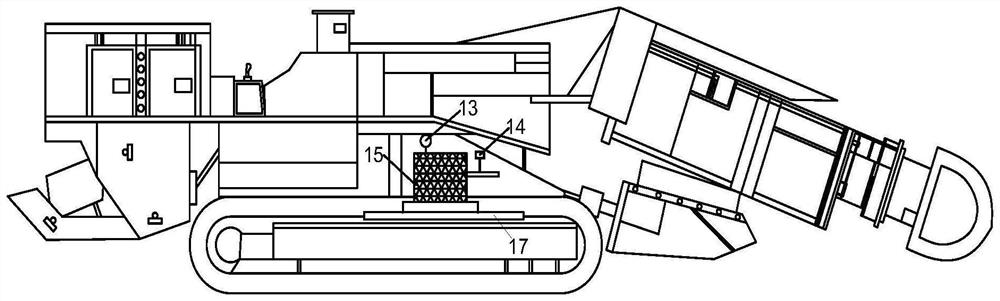

[0030] After the hydraulic fracturing is completed, the water injection pipe is disconnected, and the operator re-enters the drilling control console to carry out the excavation of the roadheader. The excavation route of the roadheader is that the cutting part of the roadheader enters the knife from one end of the bottom of the roadway (tunnel) to perform horizontal cutting, and after the pick cuts to the other end of the roadway (tunnel) in the horizontal direction, it moves upward along the direction perpendicular to the floor After cutting a certain distance, continue to cut horizontally. At this cutting depth, continue to complete the above operations in a cycle until the entire cutting depth is excavated. After the excavation is completed, continue the next section of cutting until the excavation reaches hydraulic fracturing. The bounds of the range.

[0031] Due to the integration of three machines, after the roadheader advances to the end of fracturing, the above operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com