Movable type trolley for bored tunnel construction and construction method of movable type trolley

A technology for tunnel construction and construction methods, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of difficult civilized construction management, many safety risk sources, and high formwork loss, and achieve cost savings for side wall formwork reinforcement measures, The effect of orderly construction environment and high trolley utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

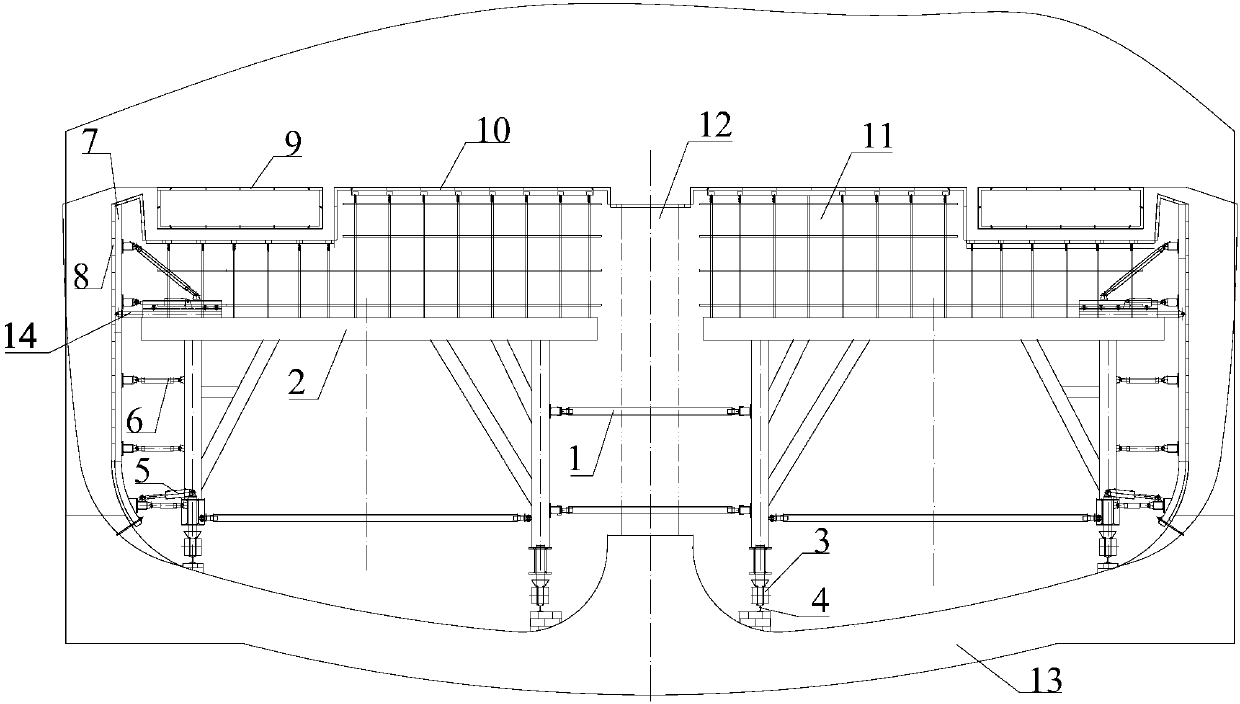

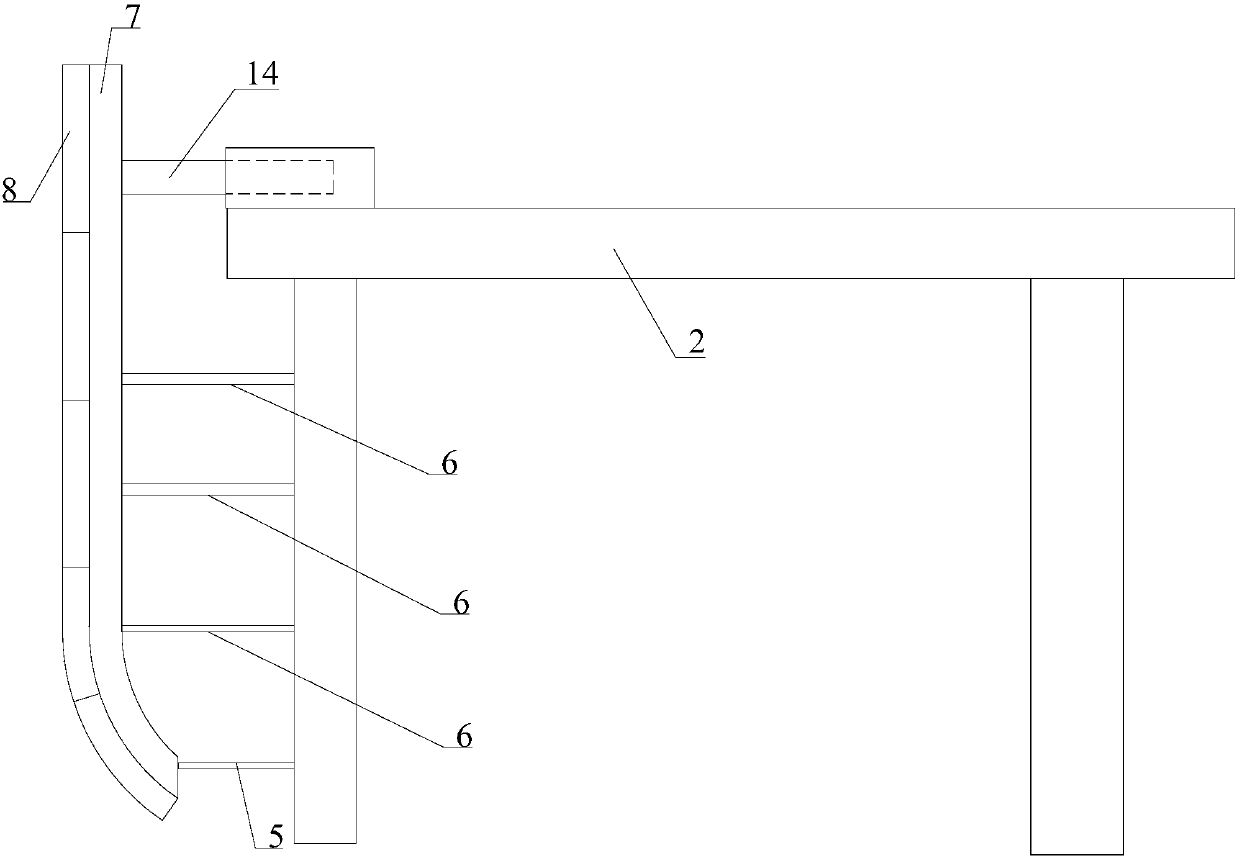

[0044] Such as Figure 1-2 As shown, a mobile trolley for underground tunnel construction includes two trolley door frames 2 installed on both sides of the completed central column 12, and the two trolley door frames 2 pass through the support rods of the trolley workshop. 1 detachable connection, the running wheel 3 installed under the trolley door frame 2, and the matching track 4 installed on the track foundation 13 and adapted to the running wheel 3, on the trolley door frame 2 Suspension arms 14 protrude from the left and right sides respectively, and the suspension arms 14 are connected with a formwork frame 7, and hydraulic struts 5 and several common struts 6 are also arranged between the trolley door frame 2 and the formwork frame 7, A side wall formwork 8 is bolted to the formwork frame 7 .

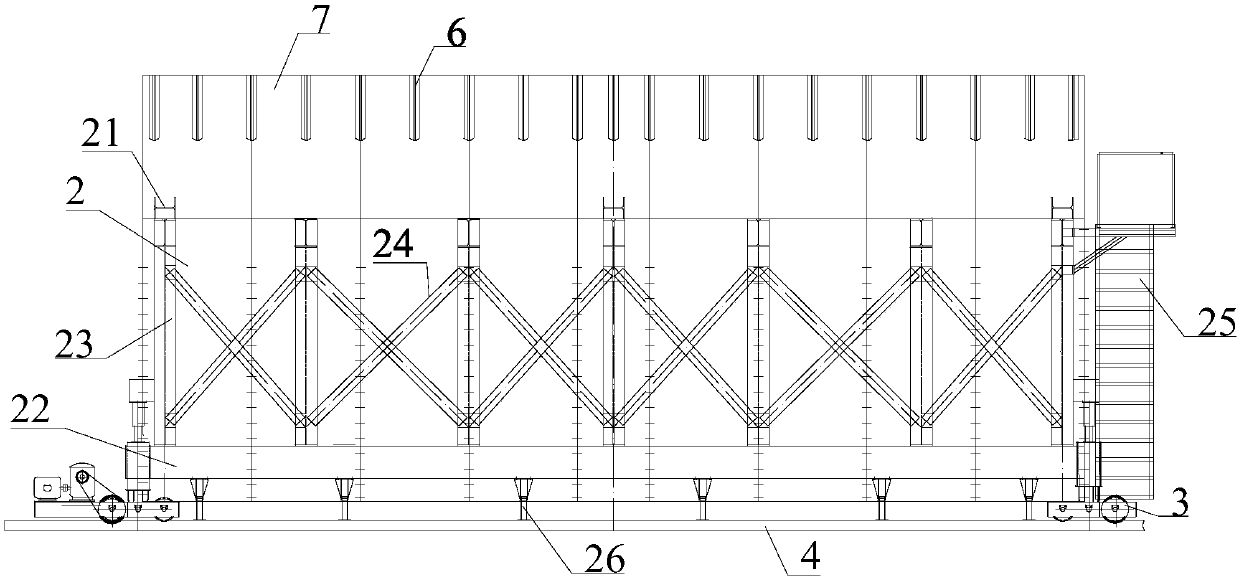

[0045] Such as Figure 1-4 As shown, each of the trolley door frames 2 includes several trolley beams 21 parallel to each other, and each of the two ends of the trolley beams ...

Embodiment 2

[0049] Such as Figure 5 As shown, a construction method of a mobile trolley for underground excavation tunnel construction includes using any one of the mobile trolleys for underground excavation tunnel construction, including the following construction steps:

[0050] Step 1: Lay the track foundation 13, set the isolation layer, and pour the foundation concrete;

[0051] Step 2: install the supporting track 4 for trolley walking;

[0052] Step 3: Assemble the door frame 2 of the trolley and install the suspension arm 14, the hydraulic strut 5 and the running wheel 3;

[0053] Step 4: install the formwork frame 7 on the suspension arm 14, and connect the side wall formwork 8 outside the formwork frame 7;

[0054] Step 5: The side wall reinforcement binding is completed;

[0055] Step 6: The trolley travels and positions, and adjusts the position of the side wall formwork 8 at the same time, and the position of the side wall formwork 8;

[0056] Step 7: Set up the roof pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com