Novel composite bio-based building template material and system

A building template, bio-based technology, applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of poor thermal insulation performance, high cost, waste of resources, etc., and achieve good physical and mechanical properties and high impact strength , The effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A new type of composite bio-based building model. The chemical composition of the building model is PVC43.63%-47.41%, light calcium 33.06%-36.67%, wood powder 10.57%-11.54%, stearic acid 0.52%- 0.71%, PE wax 0.52%-0.61%, stabilizer 2.18%-2.55%, CPE2.61%-2.75%, ACR0.86%-1.09%, DOP1.3%-1.43%. Wherein each embodiment concrete chemical component is as described in table 1:

[0041] Table 1 is the composition of the smelting end point (wt%)

[0042] .

[0043] The chemical composition of the stabilizer is calculated by weight percentage: 10% stearic acid, 15% polyethylene wax, 10% paraffin wax, 10% OPE wax, 10% lead stearate, 10% calcium stearate, tribasic sulfuric acid Lead 20%, dibasic lead phosphite 15%, tribasic lead sulfate can increase molding thermal stability, dibasic lead phosphite can increase light stability and weather resistance.

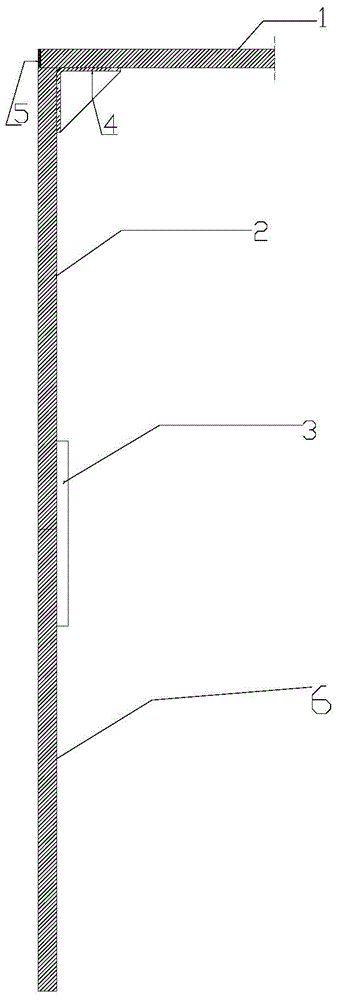

[0044] The connection structure of a novel composite bio-based building formwork erecting system disclosed in this embodiment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| release amount | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com