Integrated pouring device for installation of rail column type inspection pit fastening system

A technology for system installation and pit inspection, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of low recycling value, small column size, time-consuming and material-consuming, reduce labor and cooperation between processes, overcome The formwork efficiency is slow and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

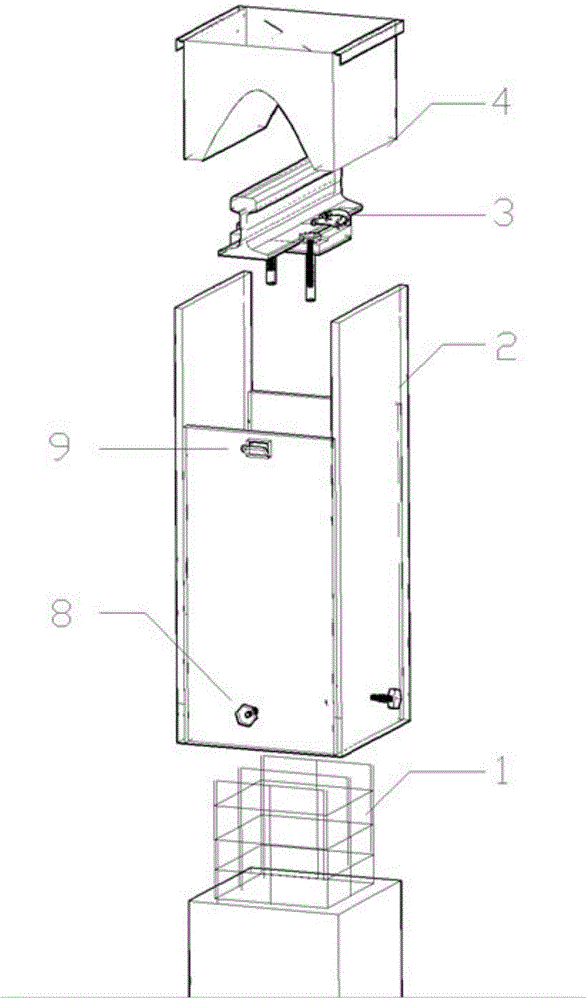

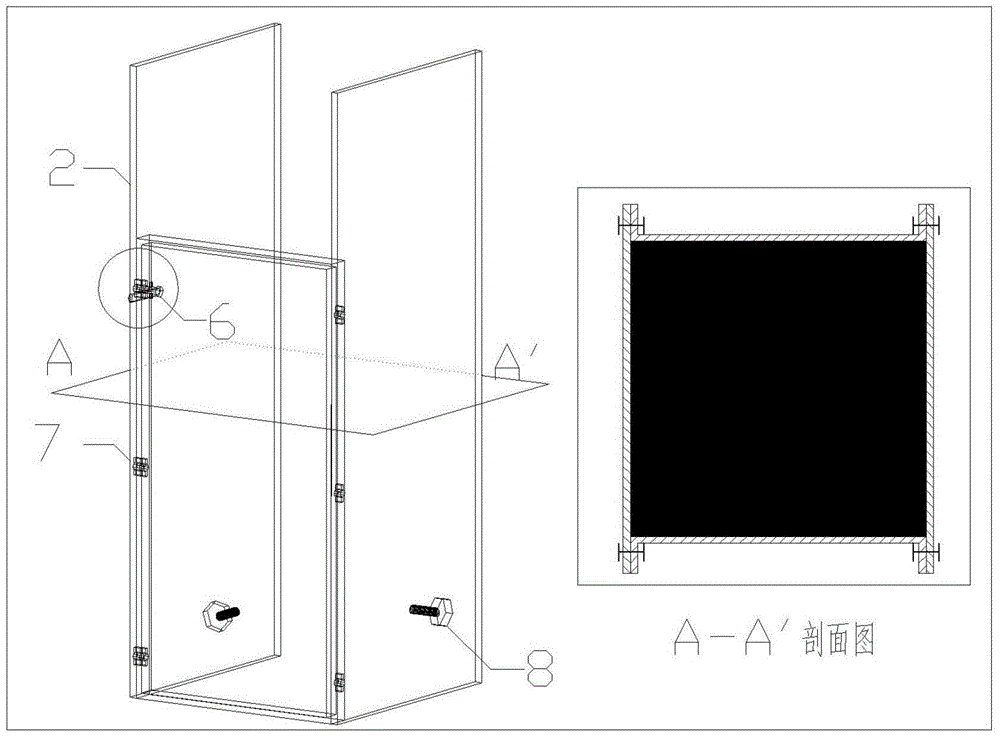

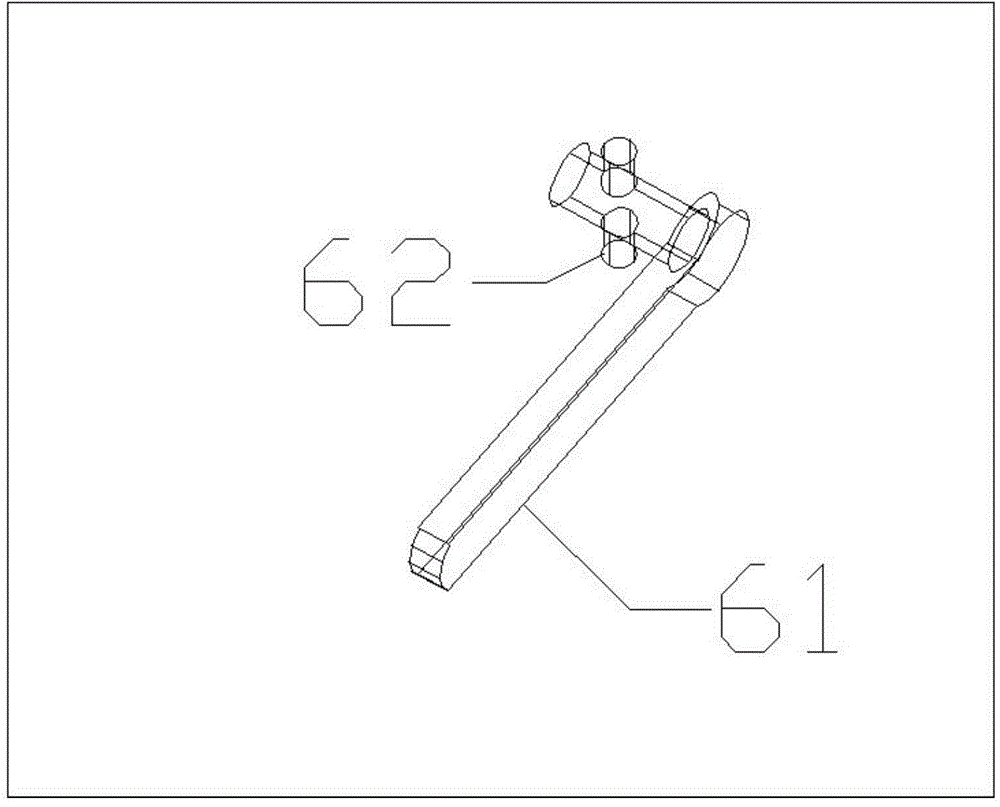

[0035] Such as Figure 1~4 As shown, an integrated pouring device for the installation of rail column-type inspection pit fastener system, the reserved steel bar 1 of the column is covered by a shaped aluminum formwork 2, and two pieces of steel rail 3 parallel to the reserved steel bar 1 The height of the shaped aluminum formwork 2 is higher than the other two shaped aluminum formworks 2 perpendicular to the rail 3, and is used to fix the matching pouring funnel 4. The bottom of the pouring funnel 4 is a parabolic bottom surface with two lower openings, and the bottom The height is flush with the bottom end of the rubber pad 5, and the two lower openings are located on both sides of the steel rail 3; the two adjacent shaped aluminum templates 2 are fixed by the connecting pin 6, and the connecting pin 6 is cross-shaped and includes a rotating head 61 and A group of protrusions 62 perpendicular to the rotor, after the connecting pin 6 passes through the reserved rectangular ba...

Embodiment 2

[0037] A method for laying an integrated pouring device for the installation of rail post-type inspection pit fastener systems, comprising the following steps: firstly erecting steel rails and assembling rail rows, placing iron backing plates, rubber pads under rails or planks and fasteners , anchor bolts, and pre-embedded casings are assembled on the rail; secondly, adjust the line status and fine-tune to the design elevation; then cover the column with the reserved steel bars from all sides with the shaped aluminum formwork, and the height of the shaped aluminum formwork on both sides of the rail It is greater than the height of the rail, and after fixing two adjacent shaped aluminum formworks with connecting pins, the combined aluminum formwork is clamped to the concrete column through the fasteners at the lower part of the formwork, and the pouring funnel is hung on the raised shaped aluminum formwork on both sides to pour. Pour concrete into the bottom surface of the rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com