Aluminum alloy modular house quick installation structure

An installation structure and modular technology, applied in the direction of roof, building components, building structure, etc., can solve the problems of overall transportation of large aluminum alloy houses, and achieve the effect of flexible and convenient splicing method, safe construction environment, and improved waterproof ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

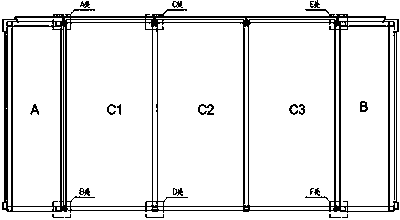

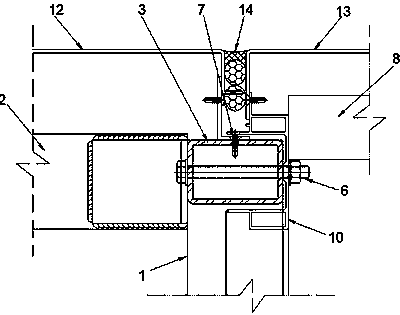

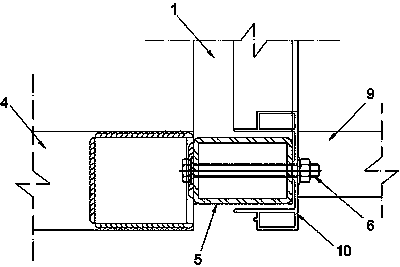

[0037] see Figure 1 to Figure 7 , the present invention provides a quick installation structure of an aluminum alloy modular house, which is mainly composed of module A, module B and middle module C, middle module C can be divided into middle module one C1, middle module two C2, middle module three C3, Each module is connected by splicing material 10.

[0038] see Figure 8 , the splicing material 10 is a bow-shaped body, and the upper and lower sides of the bow-shaped body are respectively provided with upper locking ribs 101 and lower locking ribs 102 . An upper connecting rib 103 is arranged on the upper locking rib 101 , and a resisting block 106 is arranged on the upper locking rib 103 close to the upper locking rib 101 . Reinforcing ribs 104 are provided at the upper and lower rear portions of the arcuate body. Bolt holes 105 are provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com