Prefabricated distribution network civil engineering cable well assembly combination

A prefabricated, cable well technology, applied in cable installation, ground cable installation, cable installation in the cable room, etc., can solve the problem that the cable well cannot be prefabricated in a factory, the cable well cannot be effectively simplified, and the surrounding environment has a large impact, etc. problems, to achieve the effect of guaranteed process quality, reduced construction advance time, and reduced operational safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

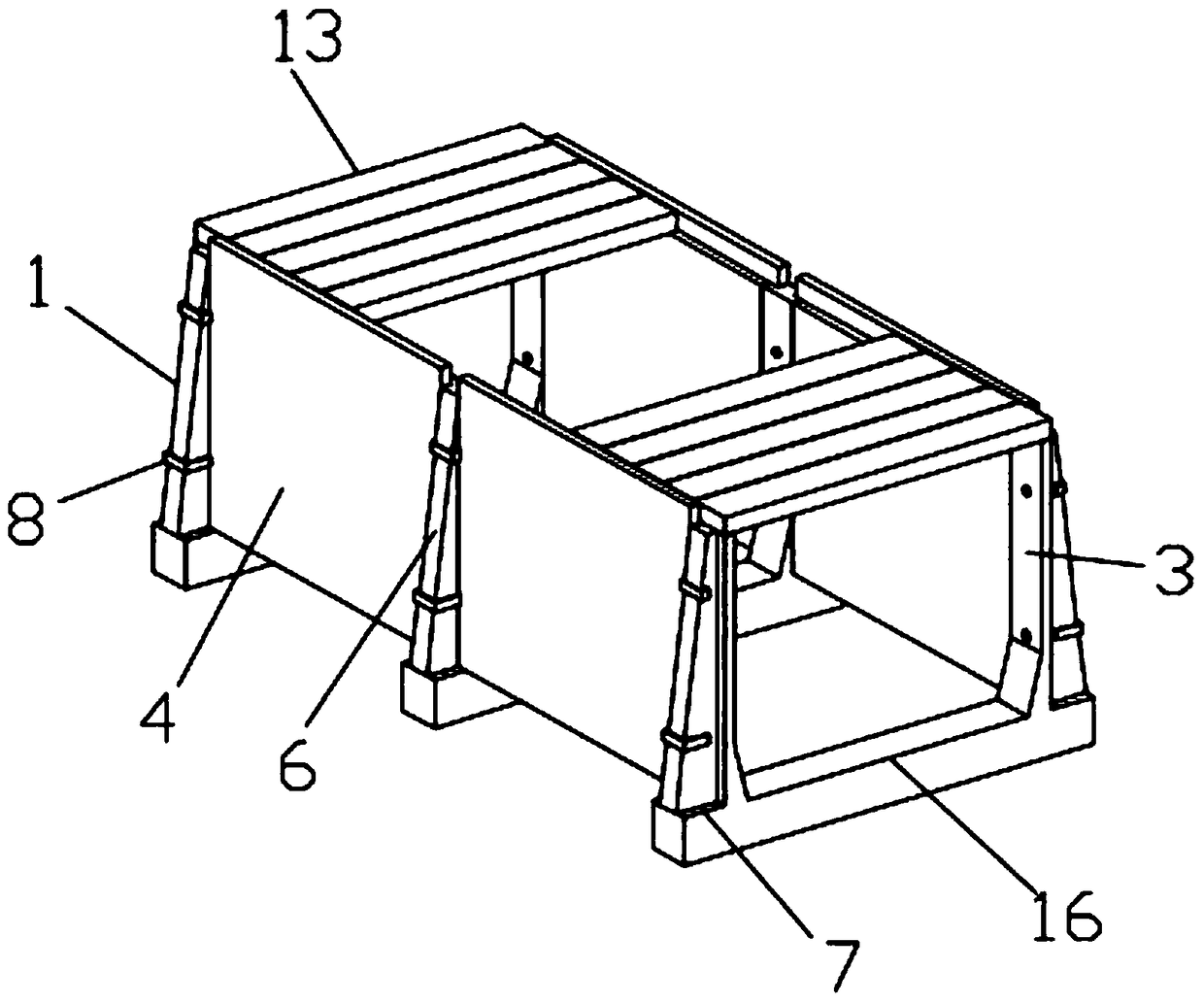

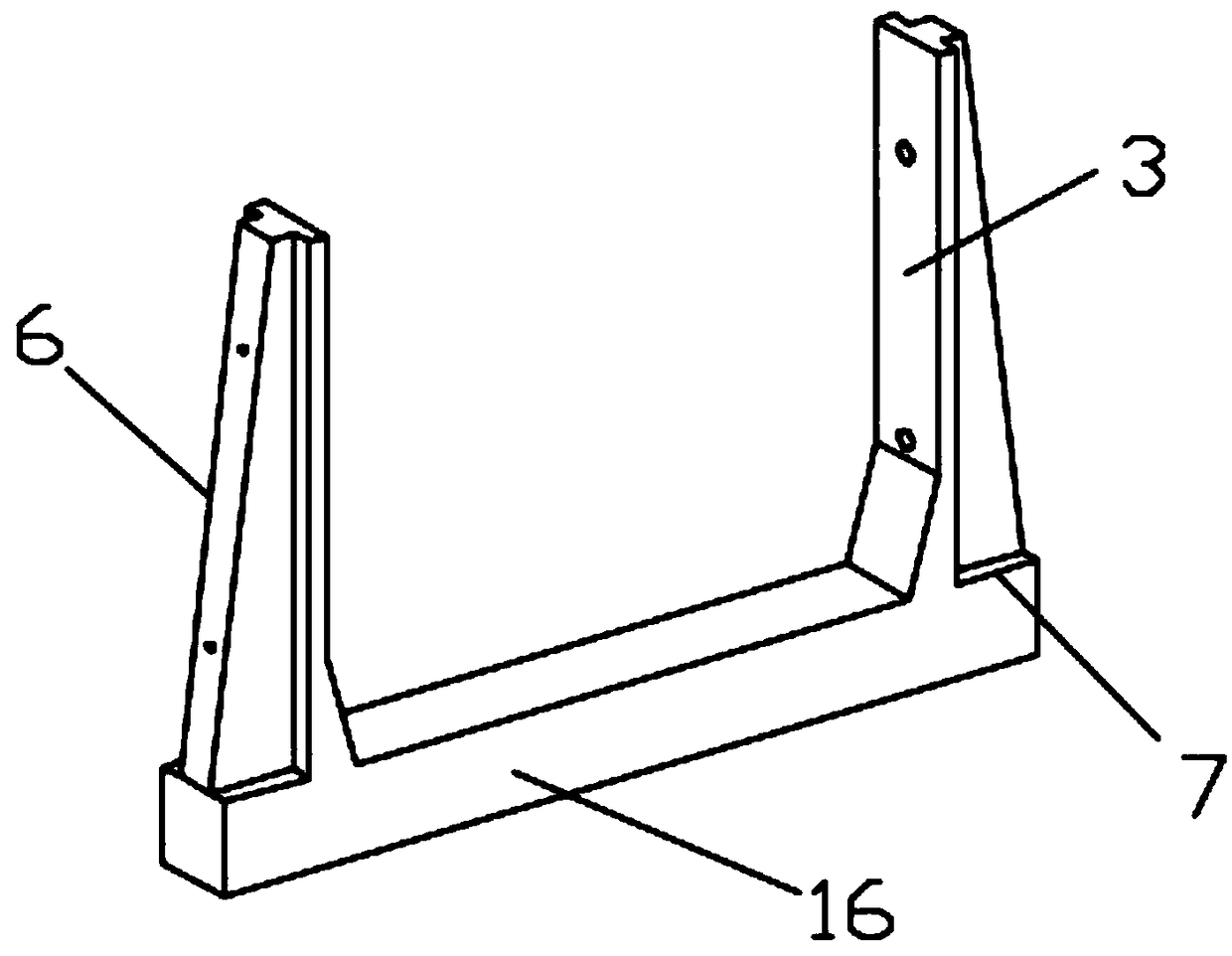

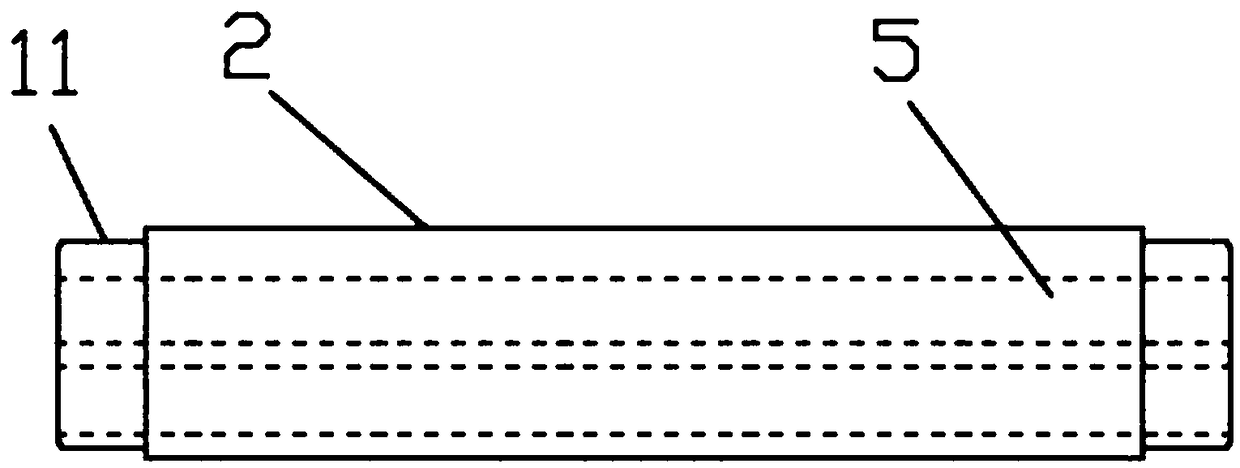

[0022] like figure 1 , 2 , 3, 4, and 5 show the prefabricated distribution network civil engineering cable well assembly combination, in which:

[0023]Prefabricated distribution network civil construction cable well assembly combination, including joint clamping pillow 1 and prefabricated pipe 2, joint clamping pillow includes pillow block 16 at the bottom and pillow arms 3 perpendicular to the pillow block on both sides, both ends of the prefabricated pipe row are horizontal In the joint clamping pillow, the adjacent joint clamping pillows are connected and fixed by the prefabricated side panels 4 on both sides, and there are several cable conduits 5 inside the prefabricated piping. Made into standard parts with uniform specifications. The joint clamping pillow and prefabricated row pipe of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com