Fluidized-bed low-rank coal upgrading utilization system and method

A fluidized bed, low-rank coal technology, used in special forms of dry distillation, petroleum industry, coke ovens, etc. The effect of extensive utilization, improving energy utilization rate and reducing the cost per ton of iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

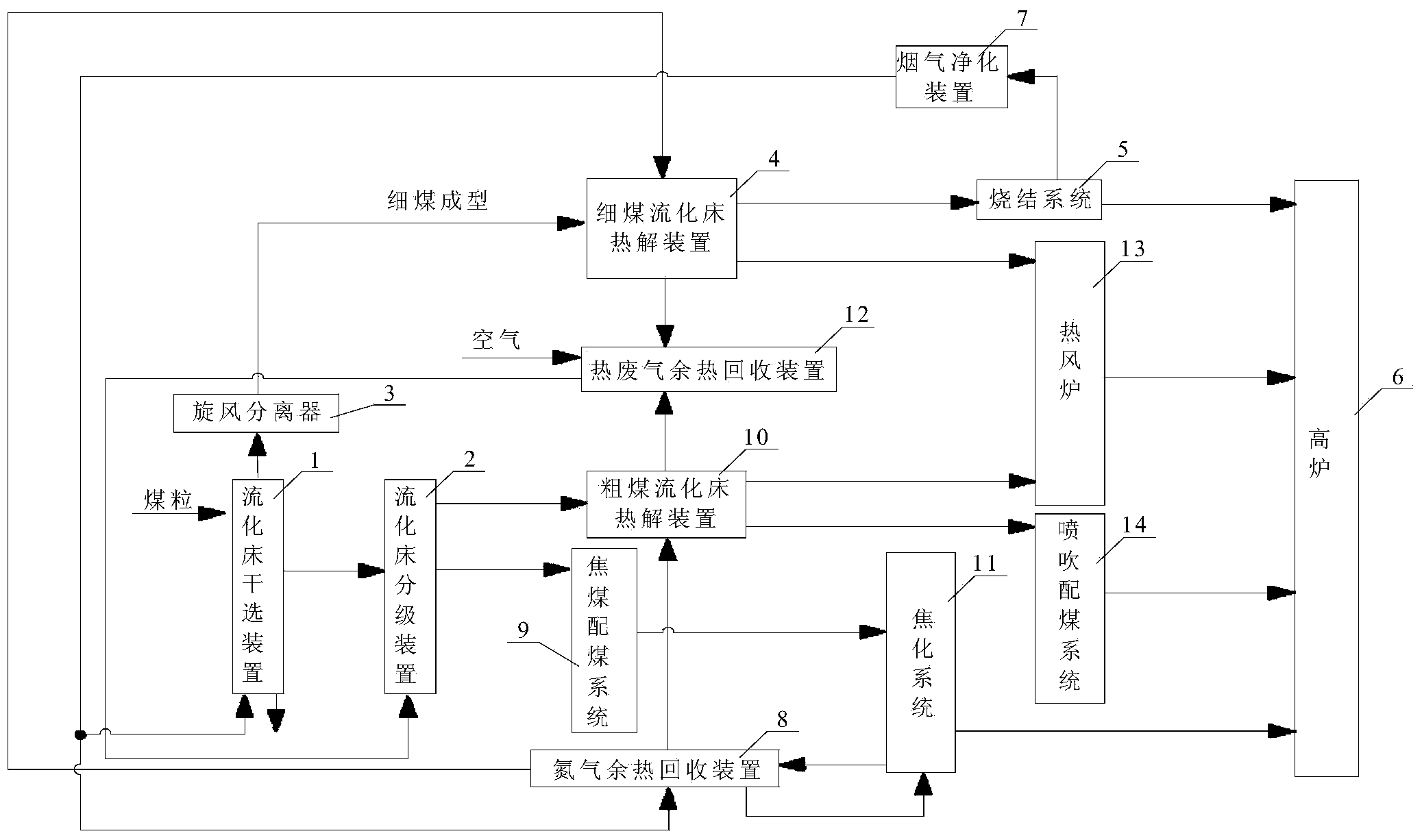

[0036] The structure and technical process of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] figure 1 A low-rank coal fluidized bed upgrading utilization system and process flow chart provided by the present invention, the system includes:

[0038] (a), fluidized bed dry separation device 1, coal particles are carried out dry separation;

[0039] (b), fluidized bed classifying device 2, carry out classifying treatment from the primary coal selection after the dry separation of fluidized bed dry separation device, obtain the coal powder of two kinds of coarse and fine particle size ranges, wherein coarse coal particle enters coarse coal fluidization The bed pyrolysis device 10 performs pyrolysis, and the fine coal particles enter the coking coal blending system 9 to participate in coal blending;

[0040] (c) Cyclone separator 3, which separates the gas discharged from above the fluidized bed dry separation device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com