Paper product production quality intelligent inspection method and system

A technology for production quality and paper products, applied in the field of intelligent inspection methods and systems for paper production quality, can solve the problems of increased production line procedures, complex working conditions, increased processing procedures, etc., to maximize production capacity and yield, and equipment control. The effect of capacity optimization, balance and benefit maximization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

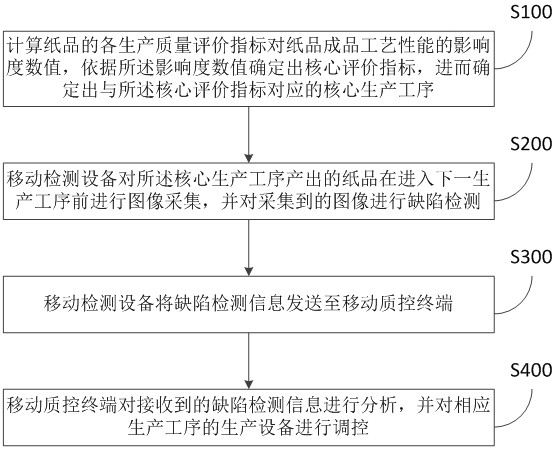

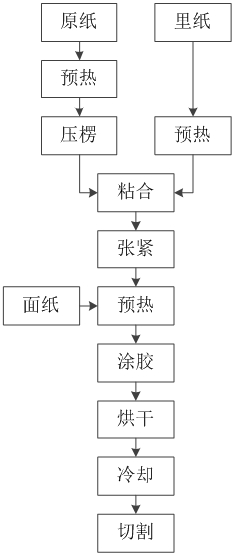

[0024] Refer below Figure 1-Figure 4 The embodiment of the intelligent inspection method for paper product production quality disclosed in this application is described in detail. Such as figure 1 As shown, the method disclosed in this embodiment includes the following steps 100 to 400 .

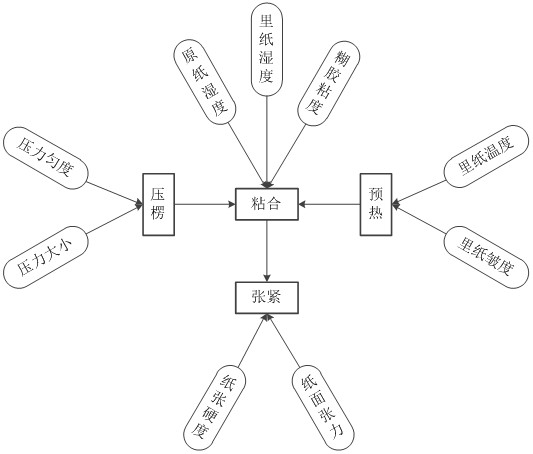

[0025] Step 100, the core process determination module of the paper production quality intelligent inspection system calculates the value of the influence degree of each production quality evaluation index of the paper product on the process performance of the finished paper product, and determines the core process from each production quality evaluation index according to each influence degree value. evaluation index, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com