De-icing of a wind turbine blade

一种风力涡轮、发电机叶片的技术,应用在风力发动机、风力发电机组件、发动机等方向,能够解决转子平面质量不均衡等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

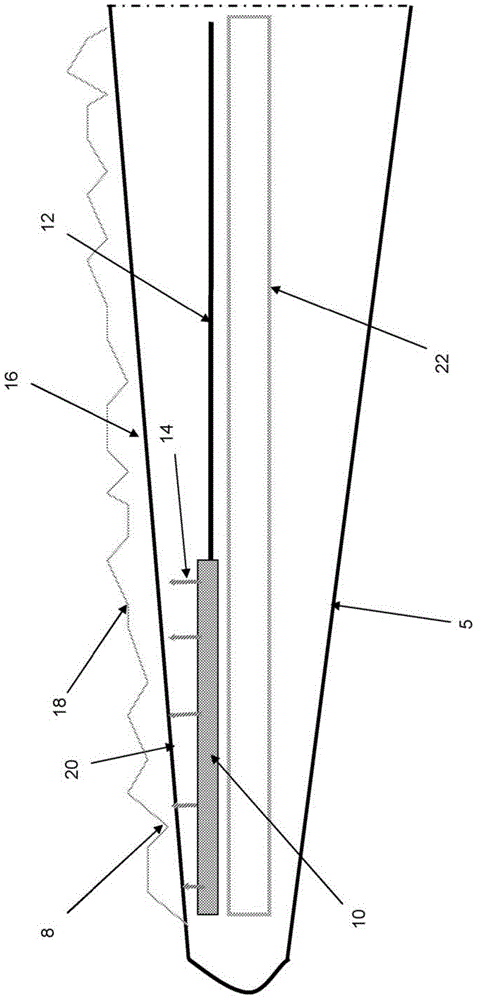

[0021] figure 1 The wind turbine generator blade 5 is shown in cross-sectional view. The blade 5 includes a spar 22 to provide structural support to the blade, mounted on which is a heat reservoir 10 for receiving a flow of hot air through an insulated duct 12 . Said duct 12 is connected to a hot air generator, such as a fan or a pump that flows air through the heating element. Alternatively, wasted energy from wind turbine generators (such as within the nacelle) may also provide a heat source.

[0022] Protruding from the heat reservoir 10 are a plurality of ducts 14 that send hot air to the leading edge 20 of the blade. Doing so allows the hot air to heat the leading edge 20 sufficiently to allow removal of ice 18 that has formed on the leading edge so that the ice partially melts and falls from the blade to provide better performance.

[0023] In the event of freezing, ice 18 may accumulate at an accelerated rate on the leading edge of the blade, changing the shape of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com