Online deicing device for 10KV loop closing circuit of distribution network

A line and loop closure technology, applied in overhead line/cable equipment, overhead installation, cable installation, etc., can solve the problems of high-voltage transmission line damage, time-consuming and labor-intensive, affecting power supply stability, etc., to achieve convenient operation and good guidance effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

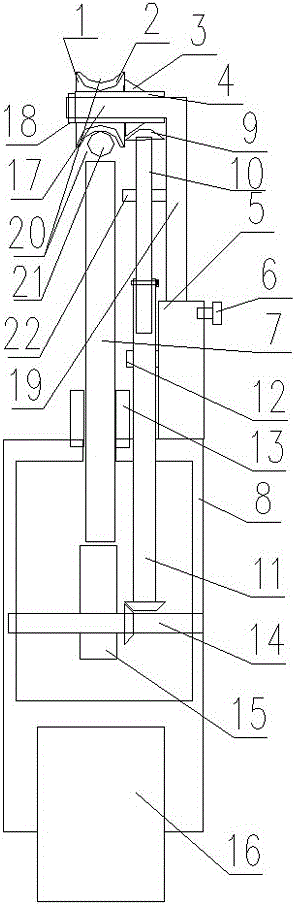

[0033] Such as figure 1 As shown, an on-line deicing device for a 10KV closed-loop line of a distribution network includes an insulating rod 16 and a housing 8 arranged on the insulating rod 16. The housing 8 is provided with a drive shaft, and the housing is provided with The deicing shovel 7 protruding from the housing moves up and down. The drive shaft 14 is provided with an eccentric wheel 15 that drives the deicing shovel to move up and down. The housing 8 is provided with a deicing guiding line protection device. The deicing The guide line protection mechanism includes a connecting rod 19 arranged on the housing 8 and a rotating shaft 17 arranged at the free end of the connecting rod 19. The rotating shaft is fitted with a rotary drum 1, and the sleeve is fitted with a roller. The side is provided with the groove 20 that matches with the lead wire 21 after freezing, and the described drum 4 is connected with the driving shaft through a driving mechanism.

[0034]The dri...

Embodiment 2

[0055] Embodiment 2 and embodiment 1 difference technical features are:

[0056] The wear-resistant and heat-resistant rubber layer is composed of the following raw materials in parts by weight: 100 parts of nitrile rubber, 20 parts of styrene-butadiene rubber, 5 parts of aluminum oxide, 50 parts of zeolite powder, 10 parts of carbon black N660, ethoxy-modified 11 parts of polytrisiloxane, 6 parts of stearic acid, 7 parts of nylon fiber.

[0057] After the deicing shovel moves upwards, the distance between the blade of the deicing shovel and the groove of the roller is L, and the diameter of the wire after freezing is l, and L-l=3mm.

Embodiment 3 Embodiment 1

[0058] Embodiment 3 Embodiment 1 distinguishing technical feature is:

[0059] The wear-resistant and heat-resistant rubber layer is composed of the following raw materials in parts by weight: 95 parts of nitrile rubber, 15 parts of styrene-butadiene rubber, 4 parts of alumina, 40 parts of zeolite powder, 8 parts of carbon black N660, ethoxy-modified 9 parts of polytrisiloxane, 5 parts of stearic acid, 6 parts of nylon fiber.

[0060] After the deicing shovel moves upwards, the distance between the blade of the deicing shovel and the groove of the roller is L, and the diameter of the wire after freezing is l, and L-l=2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com