Installation and methods for storing and restoring electrical energy using a piston-type gas compression and expansion unit

A return device and gas compression technology, which is applied in the field of storage and return electric energy devices, can solve problems such as excess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

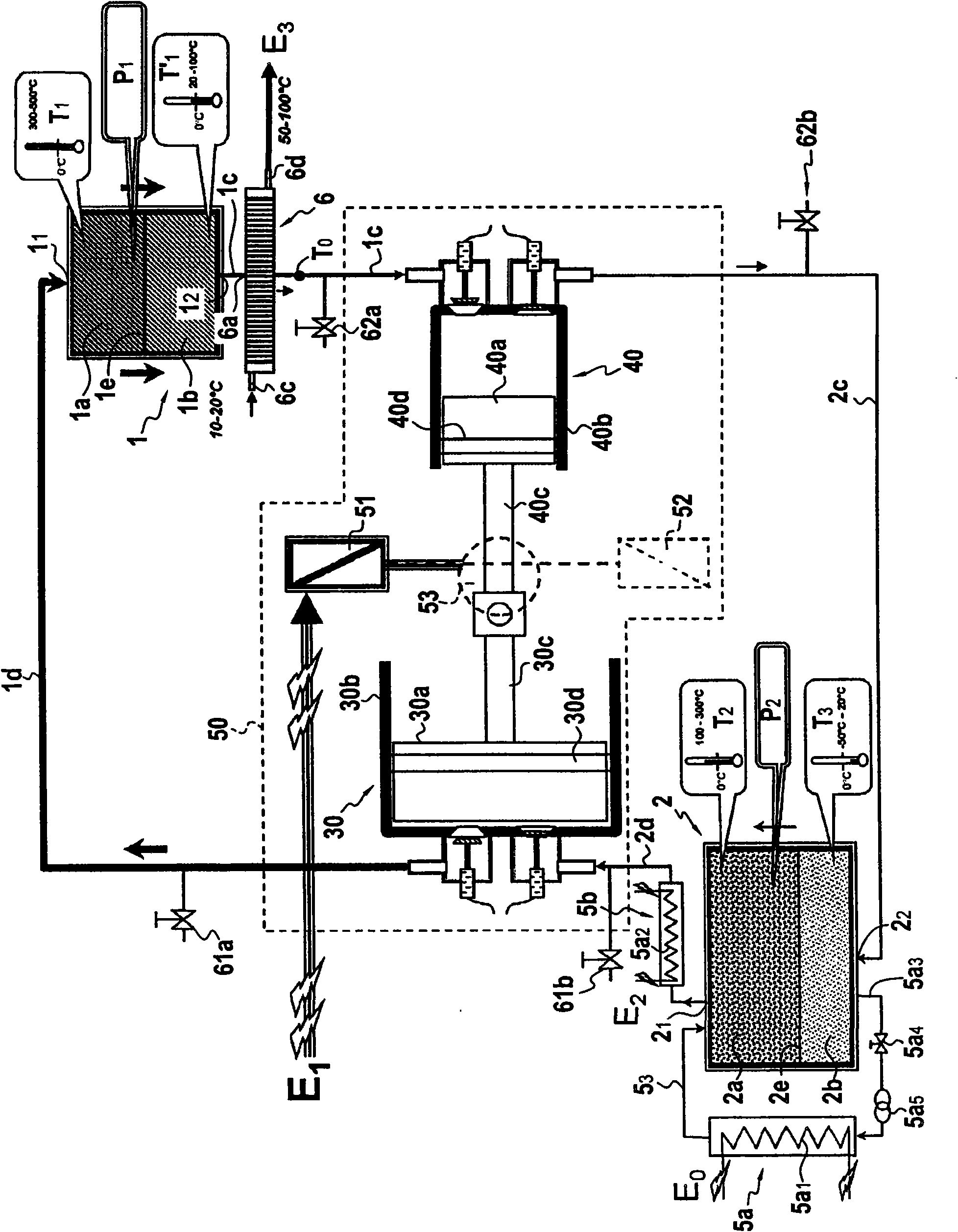

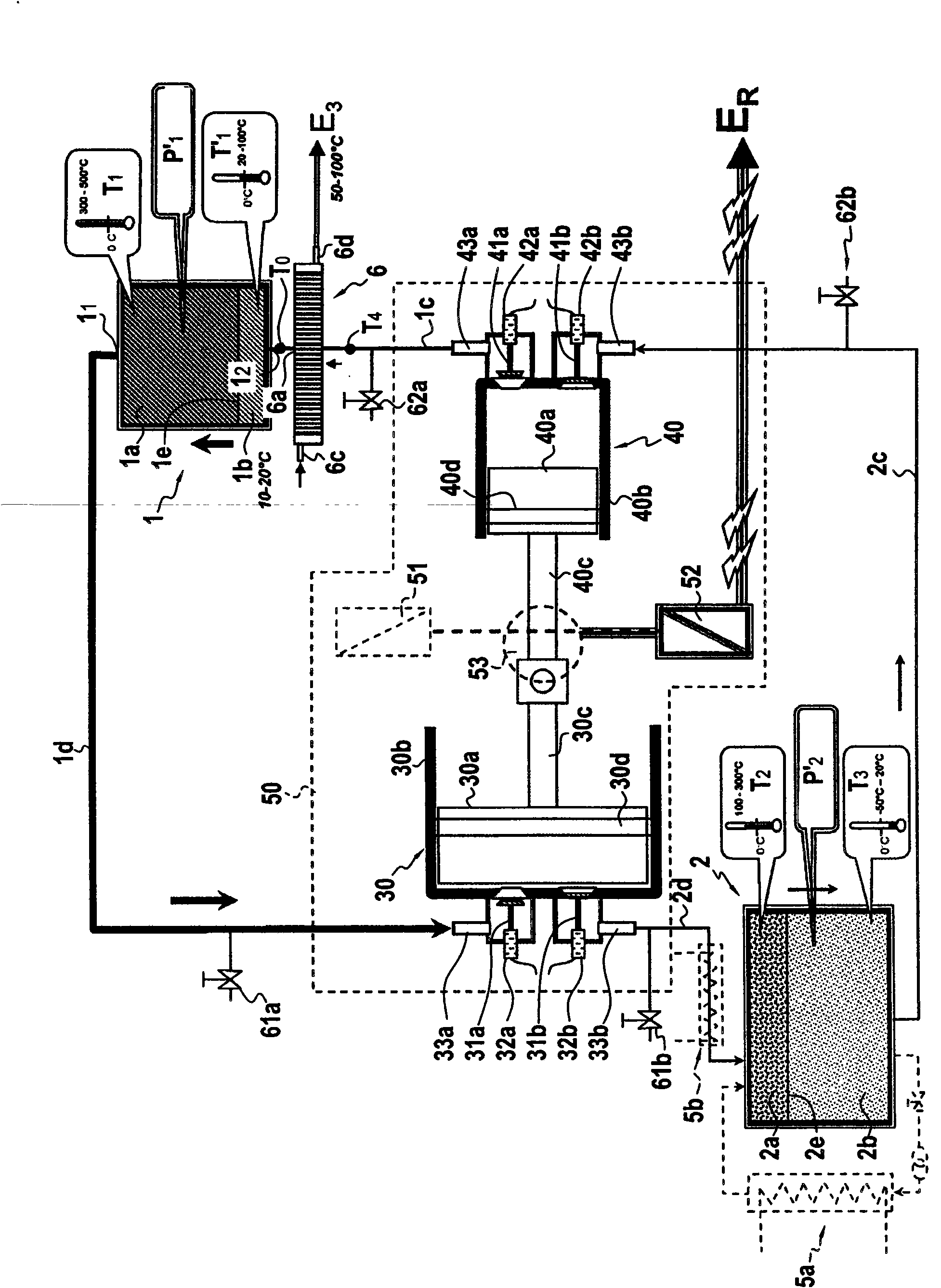

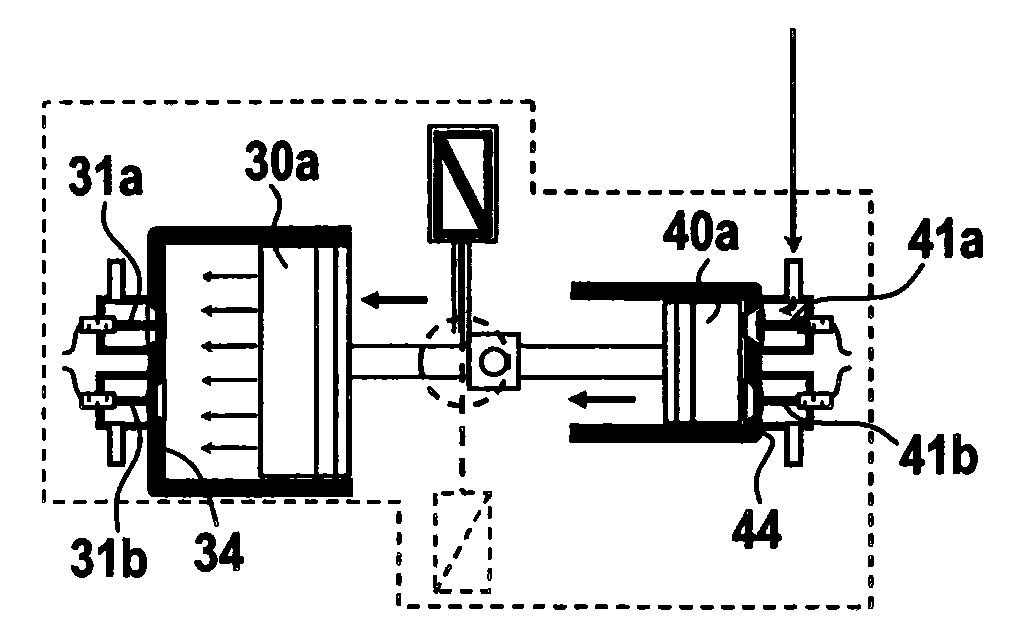

[0101] The inventive device for storing electrical energy and for returning electrical energy comprises:

[0102] a first thermally insulated enclosure 1 comprising steel walls 10 mm to 100 mm thick and filled with a first porous refractory material capable of resisting the high temperature and pressure of the inert gas contained therein, wherein the temperature T1 is in the range of 300°C to 1000°C and more particularly at 400° C. and a pressure P1 in the range of 50 bar absolute pressure (bara) to 300 bara (ie in the range of 5 MPa to 30 MPa); and

[0103] ● A second thermally insulated enclosure 2, with the same volume, eg located at 1000m 3 to 5000m 3 In the range of 10mm to 100mm, the steel wall has a thickness in the range of 10mm to 100mm and is filled with a second porous refractory material capable of resisting the temperature T2 and pressure P2 of the inert gas contained therein, that is, T2 is between 100°C and 500°C °C and more particularly about 250 °C.

[0104...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com