Thermal-force coupling fatigue test device and method

A technology of fatigue experiment and thermal fatigue, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the complex service performance evaluation, brake disc and wheel material performance evaluation and life prediction uncertainty, brake disc and wheel material Issues such as performance improvement direction and target deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Effect of cold-heat fatigue on material fatigue limit

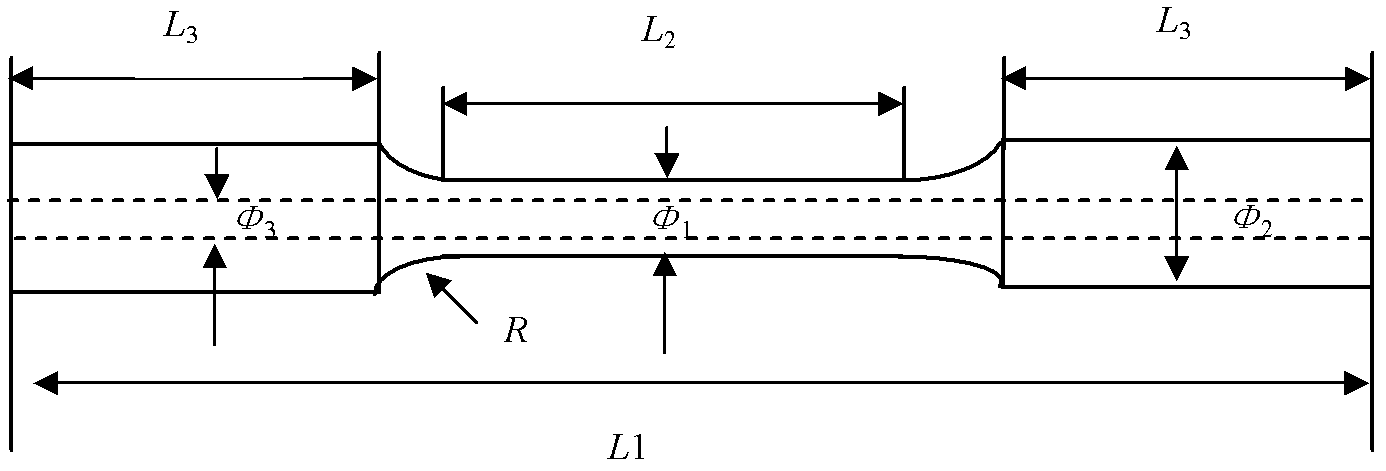

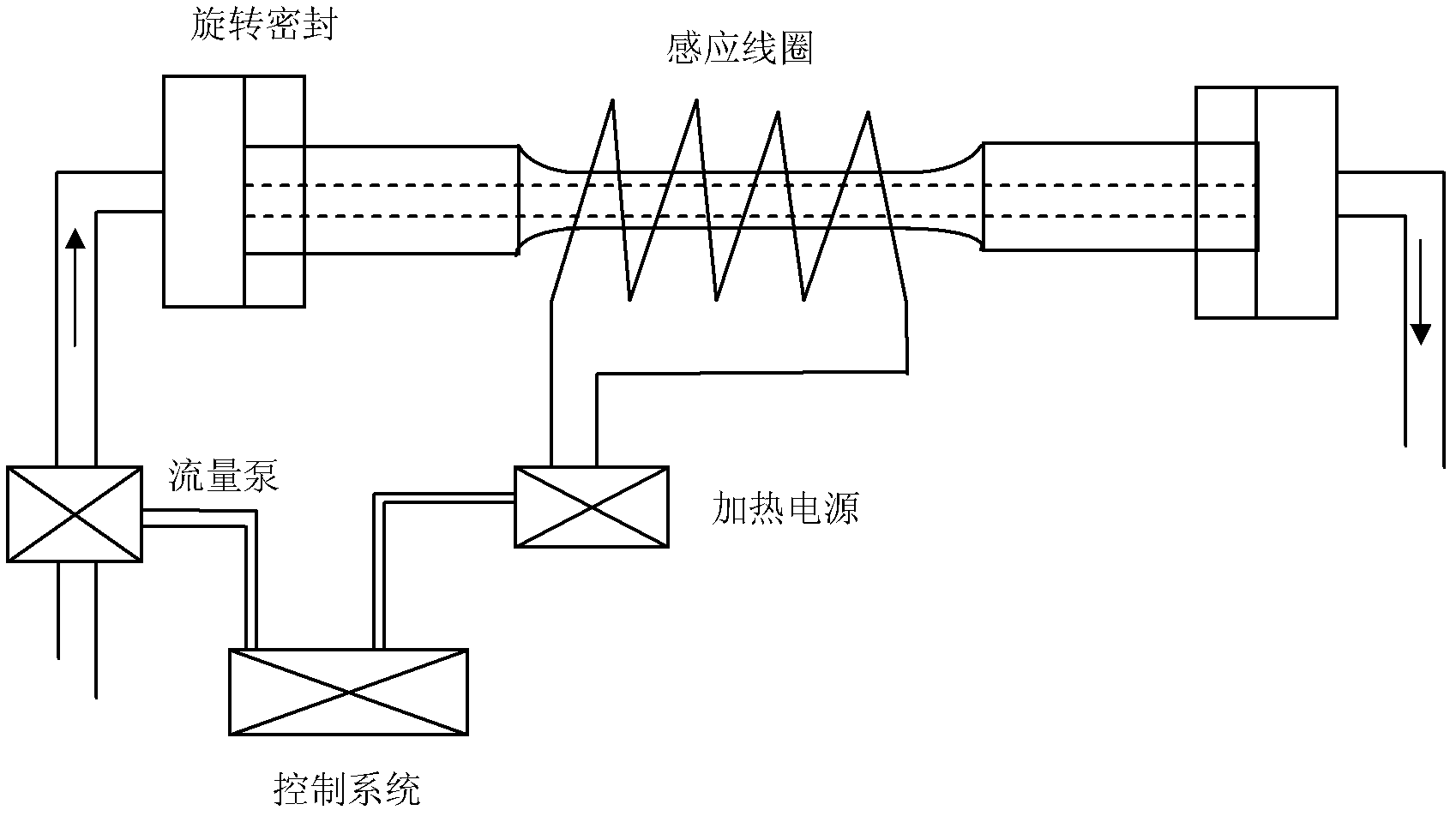

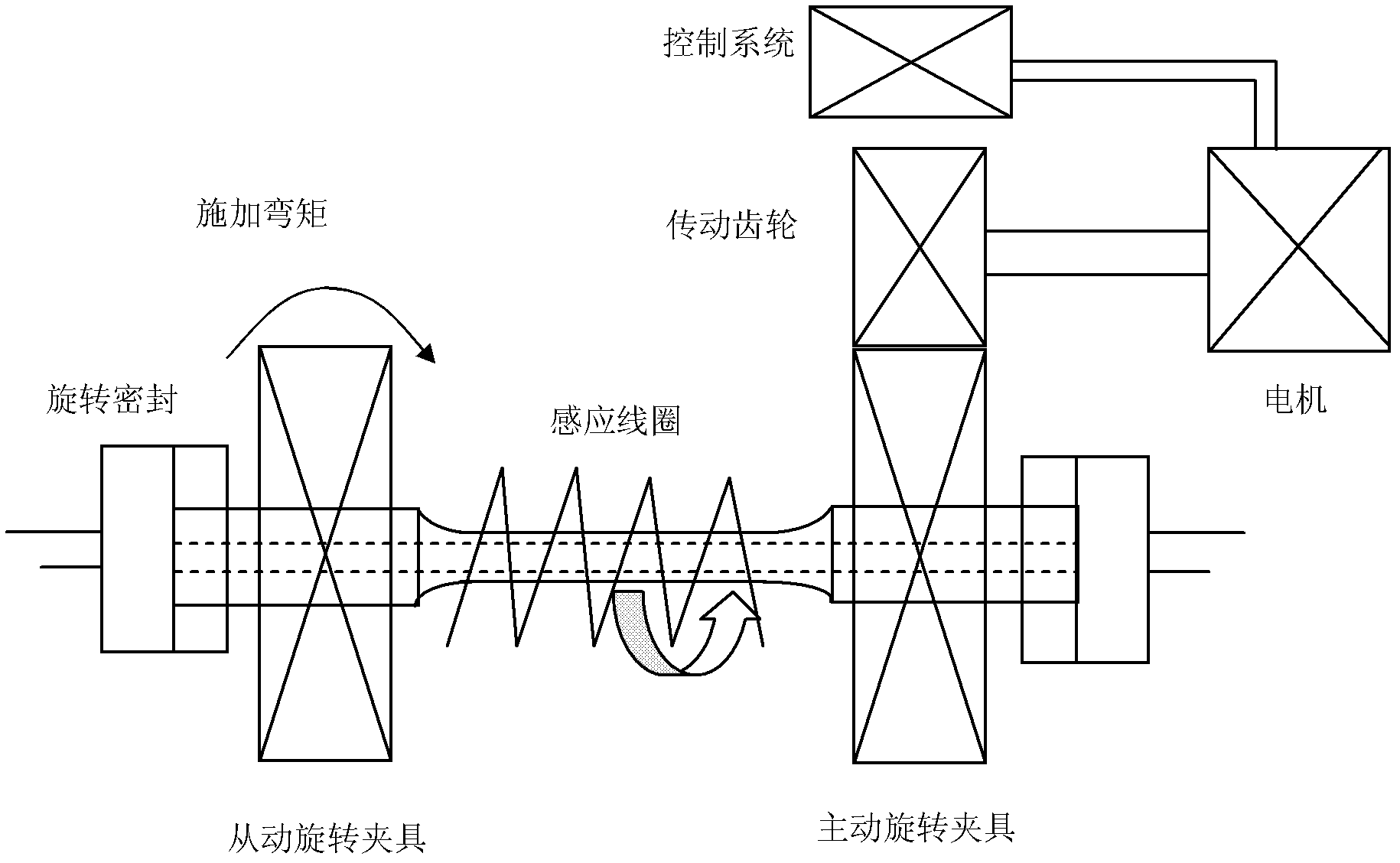

[0025] Machining the brake disc material into such figure 1 As shown in the sample, the sample is pressed figure 2 and image 3 The method shown is fixed on the experimental device, and the heating rate, holding time, cooling rate and cycle period of the material are set, such as Figure 4 shown. Stress fatigue under different stresses is carried out at the same time as cold-thermal fatigue, and the change curve of stress fatigue life with cyclic stress is obtained, namely S - N curves, such as Figure 5 shown. Adjust parameters for thermal fatigue, such as heating temperature T , the effect of thermal fatigue temperature on the fatigue performance of the material can be obtained, that is, the effect of thermal fatigue temperature on the fatigue limit can be obtained.

Embodiment 2

[0026] Example 2: Effect of Stress Fatigue on Material Thermal Fatigue Cracking Limit Temperature

[0027] Machining the brake disc material into such figure 1 As shown in the sample, the sample is pressed figure 2 and image 3 The method shown is fixed on the experimental device, and parameters such as the bending moment of the sample, that is, the maximum stress on the surface of the sample, and the fatigue frequency are set. While carrying out stress fatigue, carry out cold-heat fatigue experiments at different temperatures, and obtain the change curve of cold-heat fatigue life with cycle temperature, that is T - N curve. Varying stress fatigue parameters such as maximum stress S , the effect of fatigue stress on the thermal fatigue performance of the material can be obtained, such as Figure 6 shown.

[0028] To sum up, the present invention can well realize the testing of material properties and the research of failure mechanism under thermal-mechanical coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com