Phase-change heat exchanger

A technology of heat exchangers and phase change heat, applied in indirect heat exchangers, heat exchanger types, lasers, etc., can solve problems such as low thermal conductivity and reduce the applicability of short-term burst cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following detailed description of the invention is merely exemplary in nature and not restrictive of the invention or of the practice and use of the invention. Furthermore, there is no intention to be bound by any expressed or implied belief presented in the preceding background of the invention or the following detailed description of the invention.

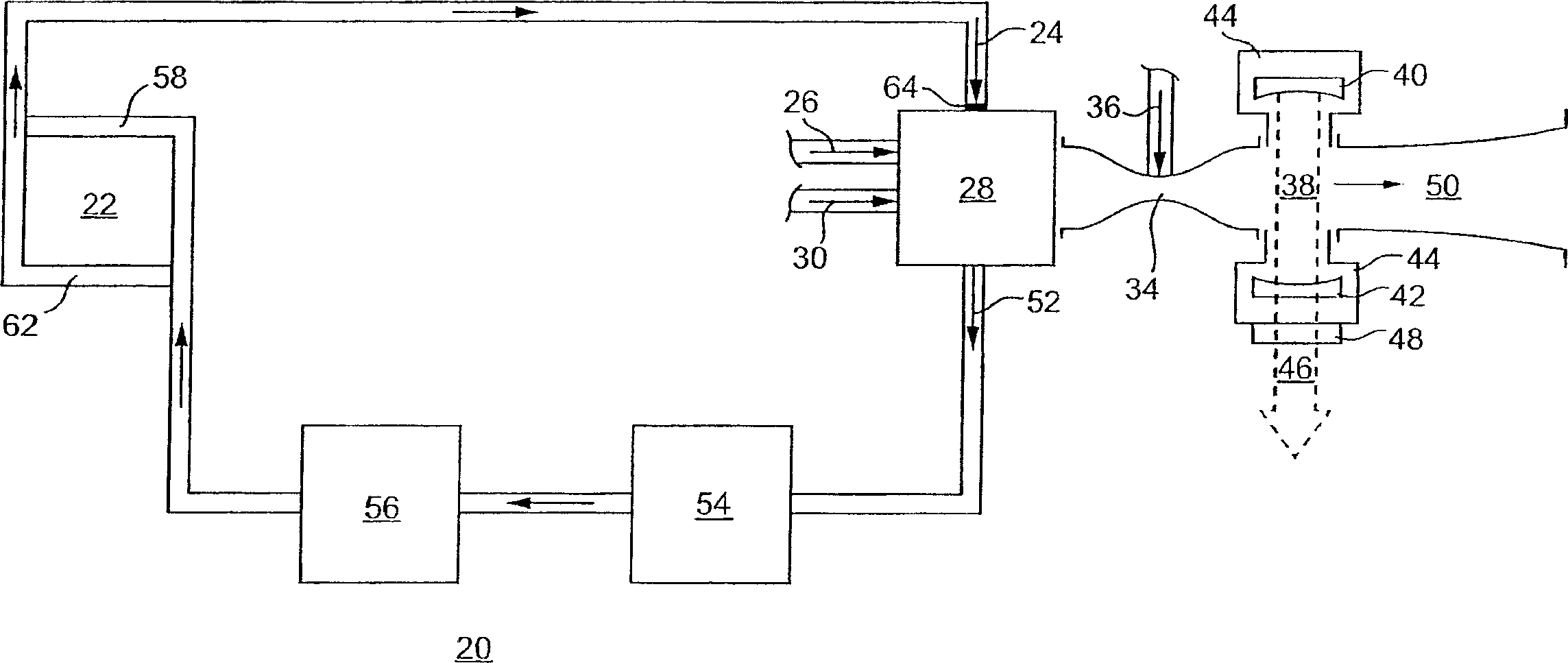

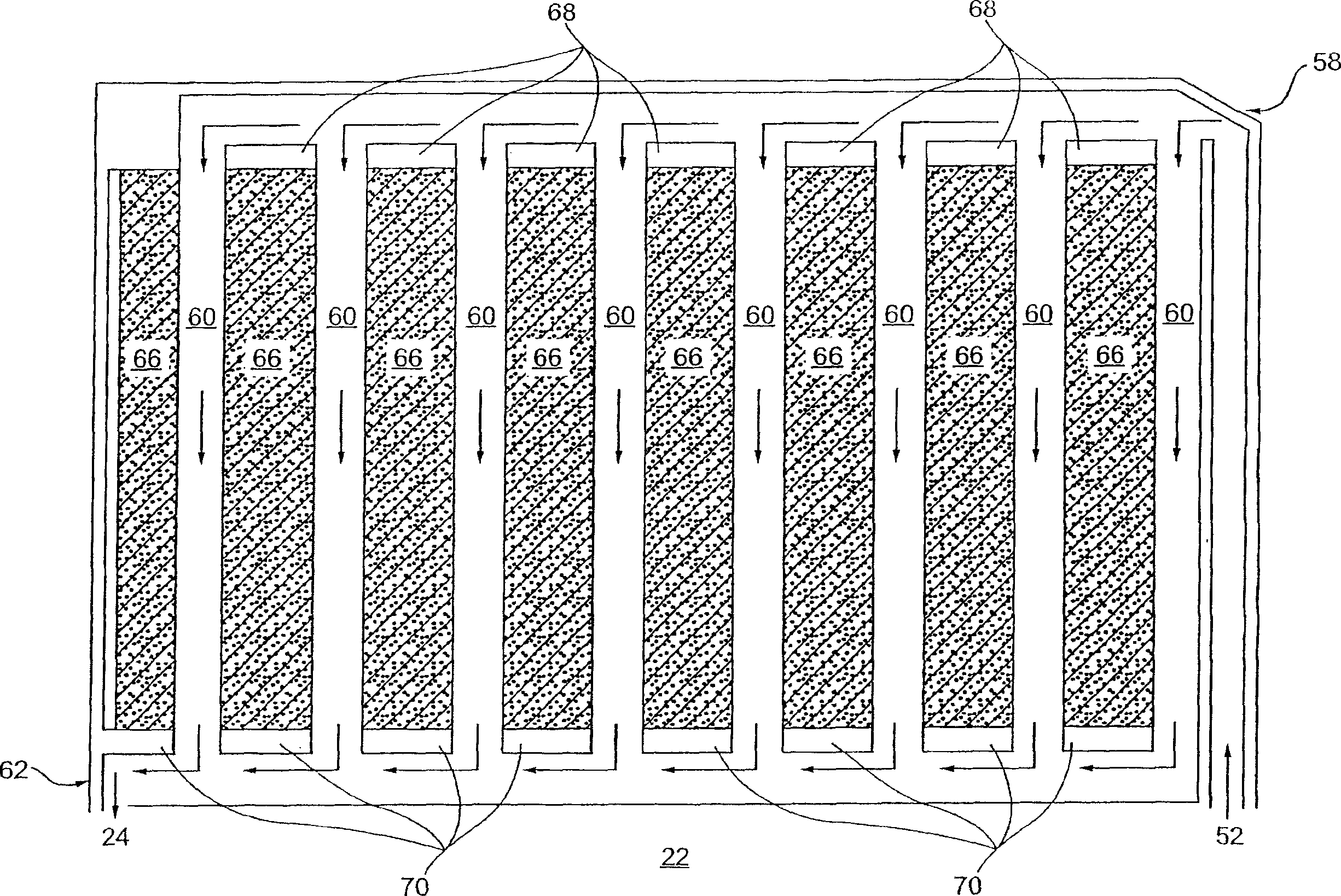

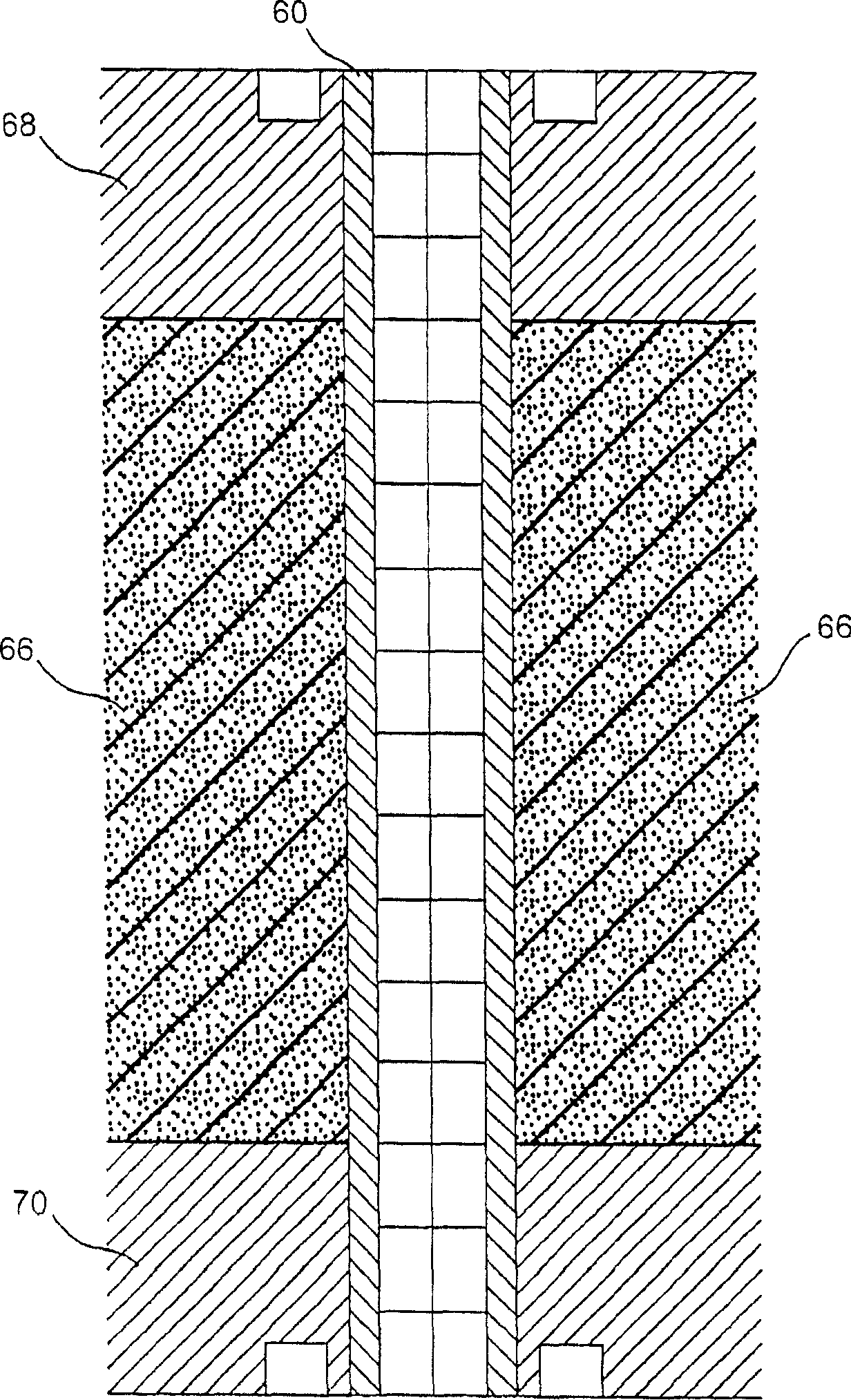

[0018] see figure 1 , the COIL 20 is shown having a phase change heat exchanger 22 of the present invention for thermally regulating the fluid of the COIL 20, which may be one or more gases, liquids, or one or more gases and liquids mixture. Although the following detailed description of the invention describes the thermal conditioning of COIL 20 fluids, the phase change heat exchanger 22 may also be used to thermally condition one or more fluids for other lasers, or may be used in non-laser applications Thermodynamic regulation of fluids in .

[0019] COIL 20 uses chlorine gas (Cl 2 )26 with basic hydrogen peroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com