Impact and thermal force composite testing device of explosive

A technology of thermal compounding and testing equipment, which is applied in the direction of measuring equipment, mechanical equipment, and material explosiveness, can solve the problems of high testing cost, inability to know the impact safety of explosives, long cycle, etc., and achieve the effect of avoiding dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated and described below in conjunction with the accompanying drawings and embodiments of the present invention.

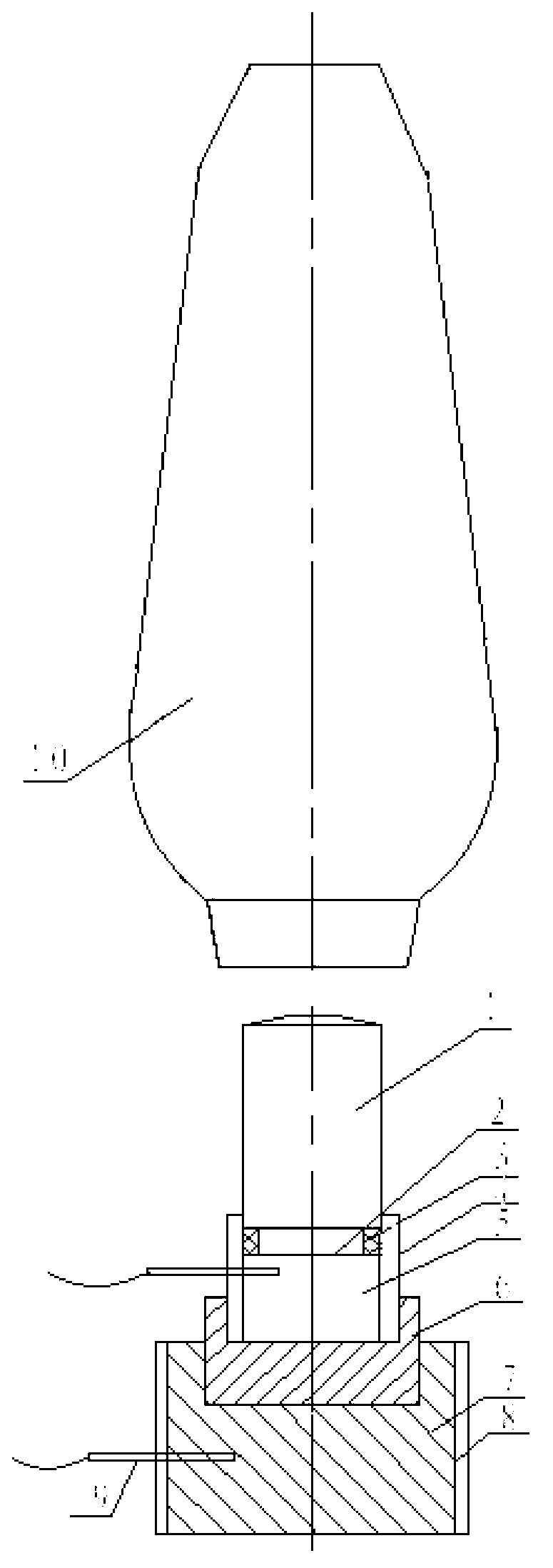

[0022] figure 1 Shows a schematic structural view of an embodiment of the present invention, as can be seen from the figure, a composite test device for explosive impact and thermal power, including a base 6; the base of the anvil 5 is embedded in the base 6; placed on the anvil 5 Explosive tablet 2, in order to prevent explosive tablet 2 from being scattered during impact, explosive tablet 2 is installed in inert ring 3, and the thickness of inert ring 3 is the same as that of explosive tablet 2; The top of explosive tablet 2 is provided with rod 1; 1 is provided with a drop hammer 10, the distance between the drop hammer 10 and the rod 1 can be adjusted, and then the impact sensitivity of explosives at different heights can be measured. In order to measure the impact sensitivity of explosives at different tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com