Automatic running device for on-line testing cable

A technology of online testing and cable entry, which is applied in the direction of cable laying equipment, etc., can solve the problems of limiting the application range of online testing technology, unfavorable on-site construction application, cable scrapping and running in construction, etc., so as to improve the running speed and quality of running and The effect of lowering the depth precision, being conducive to wide application, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

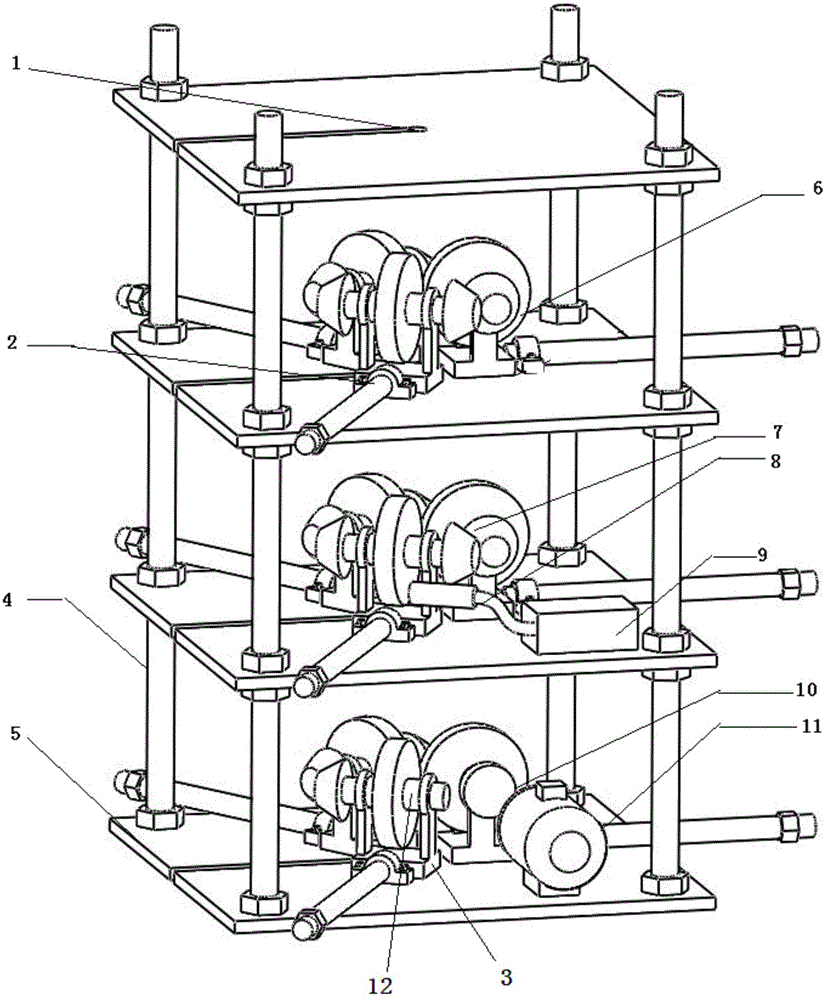

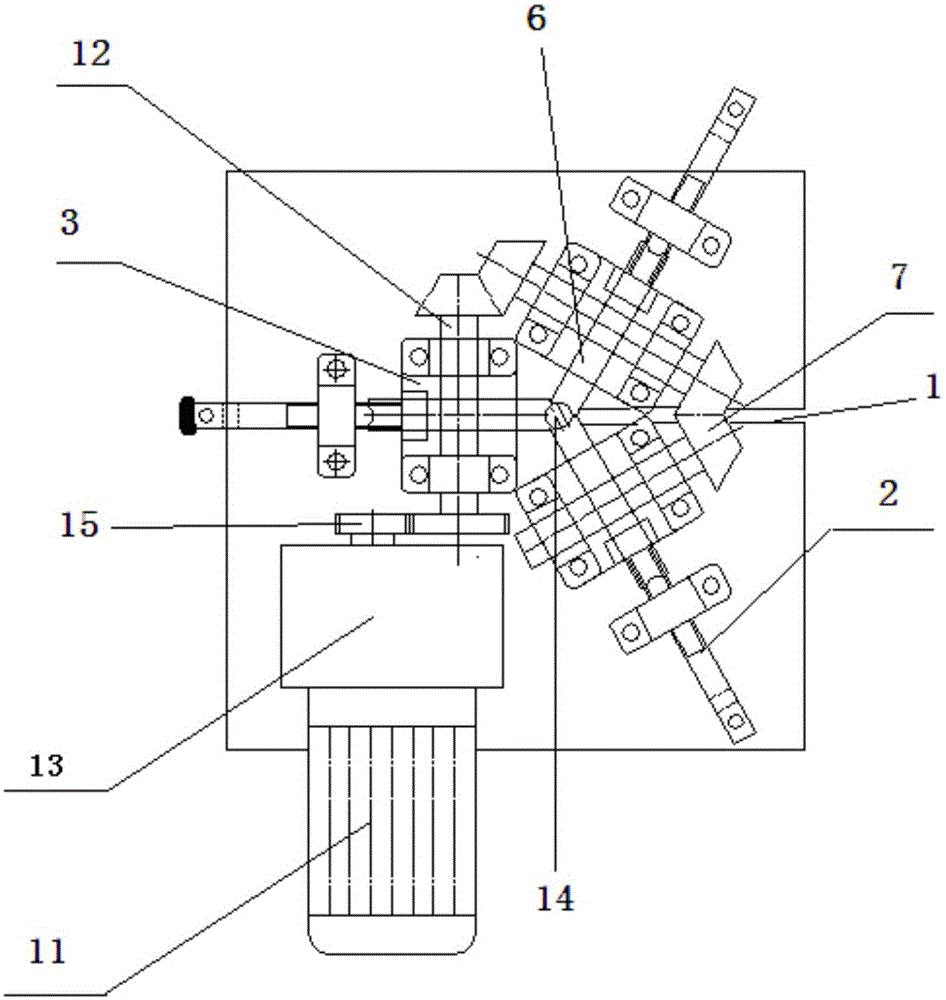

Embodiment 1

[0021] The fixed bracket 3 includes a base and a brace, the brace is fixed on both sides of the base, the transmission shaft 12 is installed on the top of the brace, the screw 2 is welded on the outside of the base and the adjusting wire sleeve is fixed on the bottom plate 5, and the screw 2 is installed on Adjust the wire sleeve. The screw rod 2 can rotate in the adjusting wire sleeve, so that the fixed support 3 equipped with the cable fixed wheel 6 can move back and forth, and the clamping degree of the cable fixed wheel 6 to the cable 14 can be adjusted, which is convenient to adjust.

Embodiment 2

[0023] Fixed support 3 comprises base and support plate, and support plate is fixed on the both sides of base, and transmission shaft 12 is installed on the top of support plate, and base is provided with screw hole, and fixing bolt is housed in it, and this fixing bolt can slide on base plate 5. Move in the slot. Adjusting the fixed distance of each fixing bracket 3 back and forth can adjust the clamping degree of the cable 14 by the cable fixing wheel 6 .

[0024] The cable fixing wheel 6 is a plane wheel or an arc wheel, and the inner diameter of the three cable fixing wheels 6 combined is smaller than the outer diameter of the cable 14 . Since the contact area of the camber wheel is large, the use of the camber wheel is more conducive to clamping the cable 14 . The straightening and lowering mechanism positioned at the top is also covered by the base plate 5, and the cable inlets 1 on each base plate 5 are all set at one position. Arranging in this way can make the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com