Zero emission steam generation process

a technology of steam generation and zero emission, applied in the direction of indirect carbon dioxide mitigation, solid fuel combustion, lighting and heating apparatus, etc., can solve the problems of increasing capital, maintenance, operating costs, environmental impact, reducing the efficiency of heaters and coolers, and reducing the capital and operating costs of thermal oil recovery processes. , to achieve the effect of reducing the capital and operating costs of the thermal oil recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

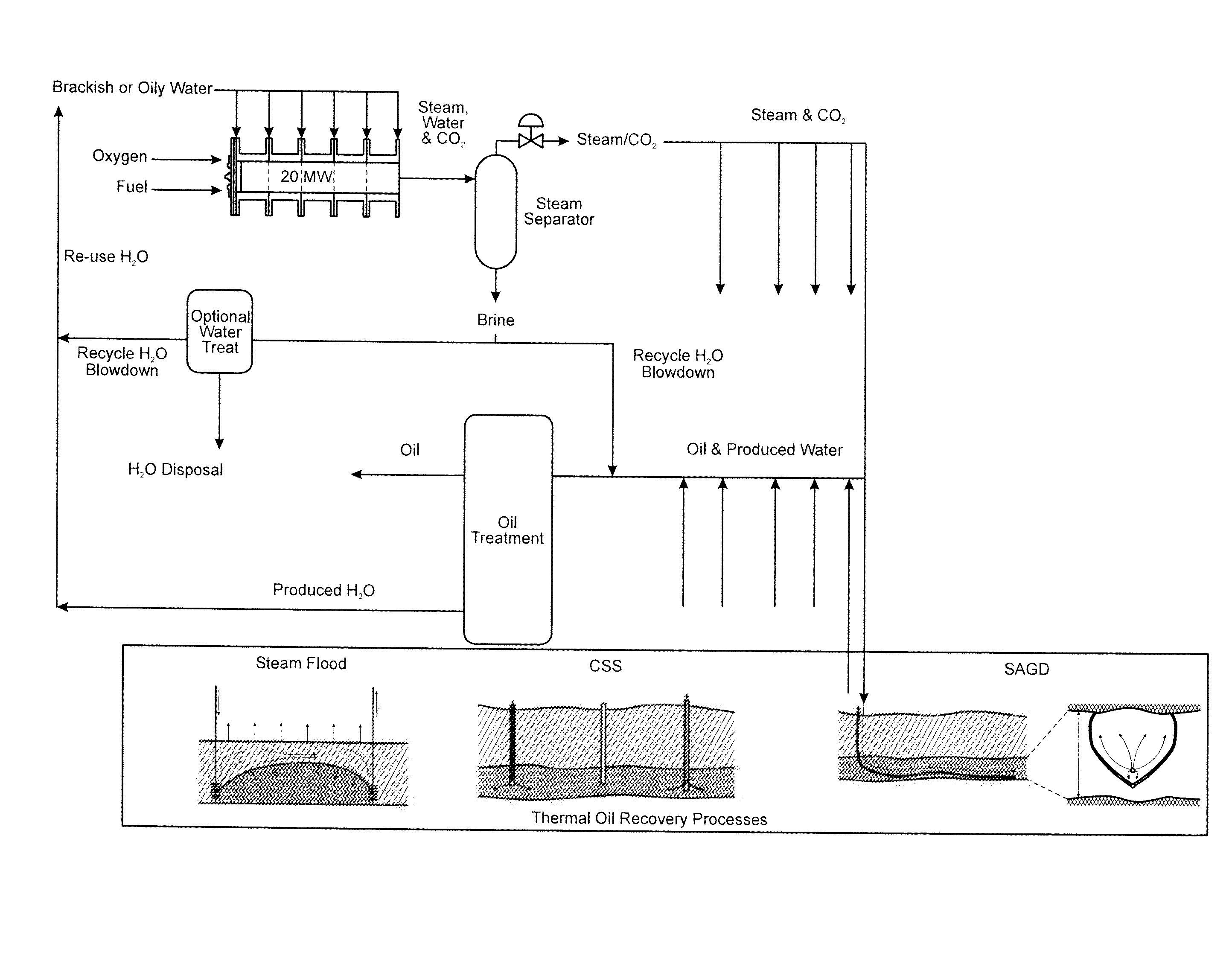

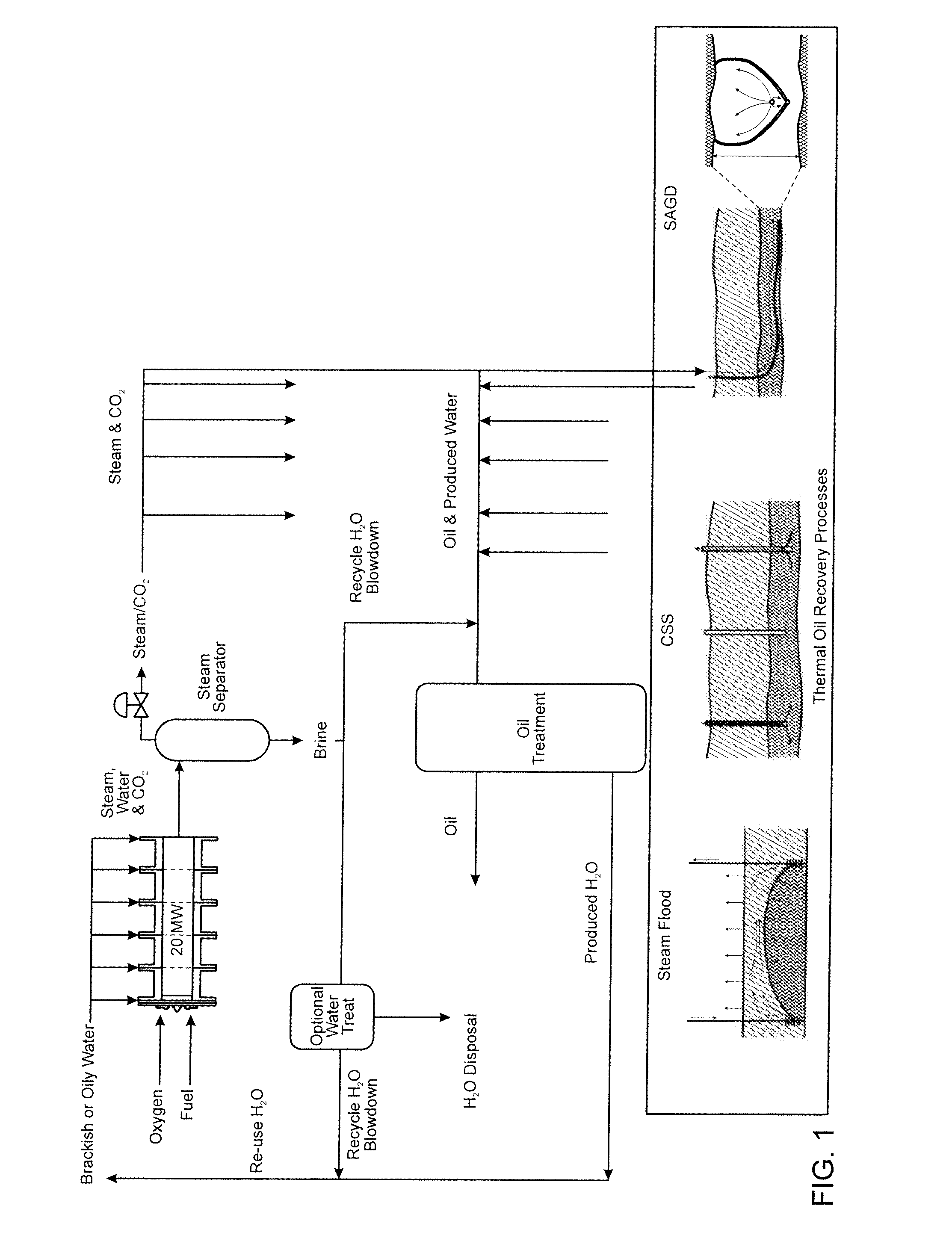

[0071]In this new process, shown in FIG. 1, the oxy-fuel steam generator directly mixes fuel such as natural gas, oxygen and feed water to generate a steam, liquid water and carbon dioxide mixture. The fuel and the Oxygen are mixed and burned in the reaction chamber which also known as a combustion chamber of the flaming unit. The feed water is added directly to this reaction chamber into the mixture of the combustion gases while part of the impurities in the water takes part in the burning process while generating steam mixture.

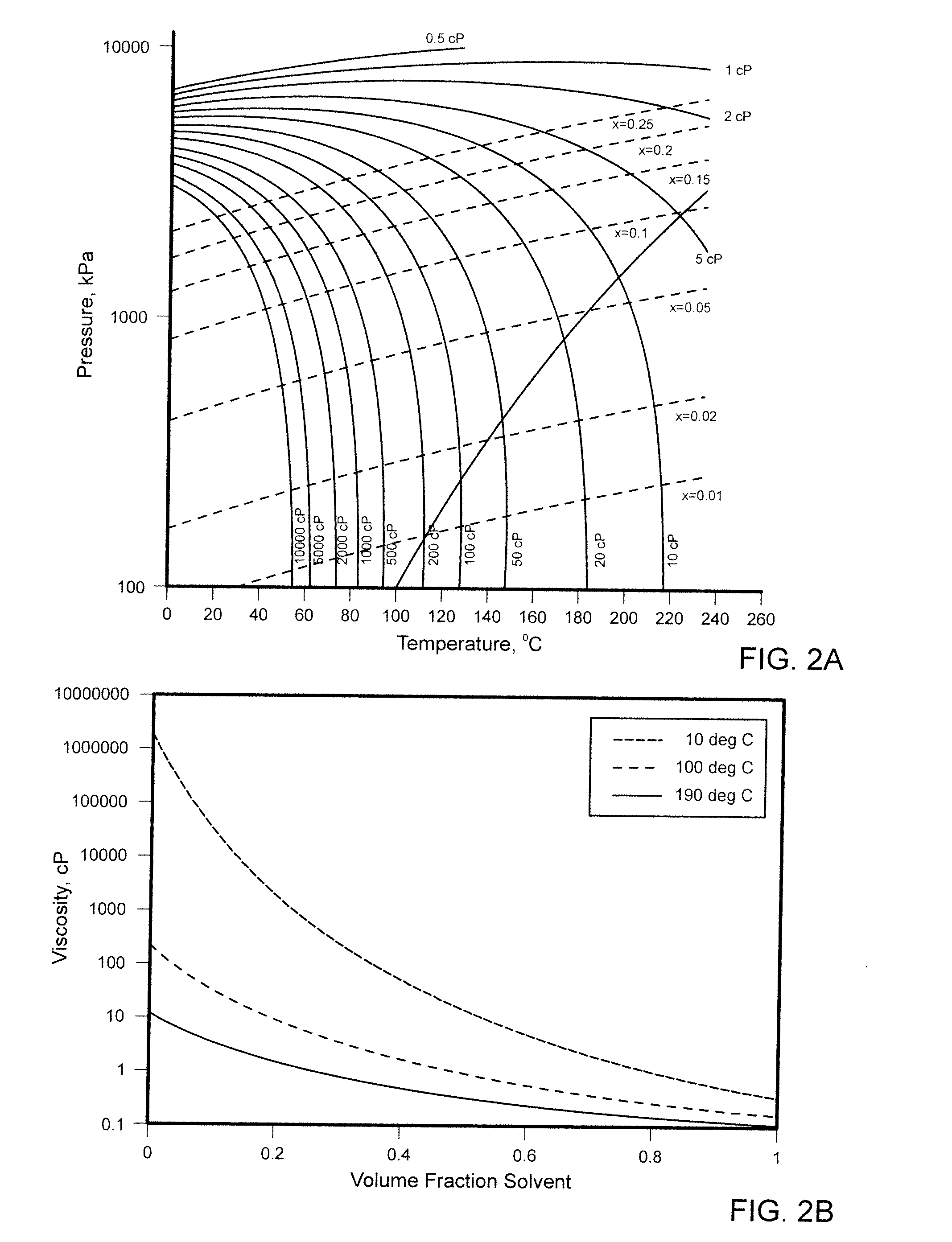

[0072]The water in the inlet of the generator containing anywhere from 500 to 20,000 ppm dissolved solids. This is a substantial improvement, since the current industrial boilers have an upper limit to dissolved solids of up to 5,000 ppm. The steam generator output quality will be altered from 100% to under 60%, depending on the suspended solids present in the input water. Steam generator metallurgy will be altered to ensure corrosion will not occur in the b...

second embodiment

[0081]In a second embodiment, the process uses the steam generator and separator combinations directly at the remote well site (at satellite locations in the oil field) instead of conventional practice where they are located at a central plant. Fuel (e.g. natural gas), oxygen, and produced water are piped to the remote satellites where the steam generators can be sited. In this embodiment, the location is no longer tied to an extensive and expensive water treatment apparatus. The suggested capacity for the remote oxy-fuel steam generator is about 20 MW. However, the sizes and capacities of those generators may vary according to the requirements of the industry.

third embodiment

[0082]In the invention, the oxy-fuel steam generator can use partially enriched air, with up to 10% remaining nitrogen content, instead of pure oxygen. The use of lower purity oxygen as the oxidizer may increase nitrogen oxides (NOx) in combustion gases, but since all combustion products are injected underground, there are no ill environmental effects.

[0083]FIG. 4 shows a conventional thermal oil process, with the water treatment block and water disposal and make-up streams highlighted. These water treatment process blocks have been required for all previous technologies because all previous thermal oil processes use either current industrial boilers, which have an upper limit to dissolved solids of up to 5,000 ppm with much lower thresholds for water hardness and silica, or have referenced operating conditions for direct fired boilers which require “dirty water” to still be below thresholds which require softening. Those process blocks are all eliminated in the proposed embodiment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com