Patents

Literature

45results about "Submerged flame steam boilers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

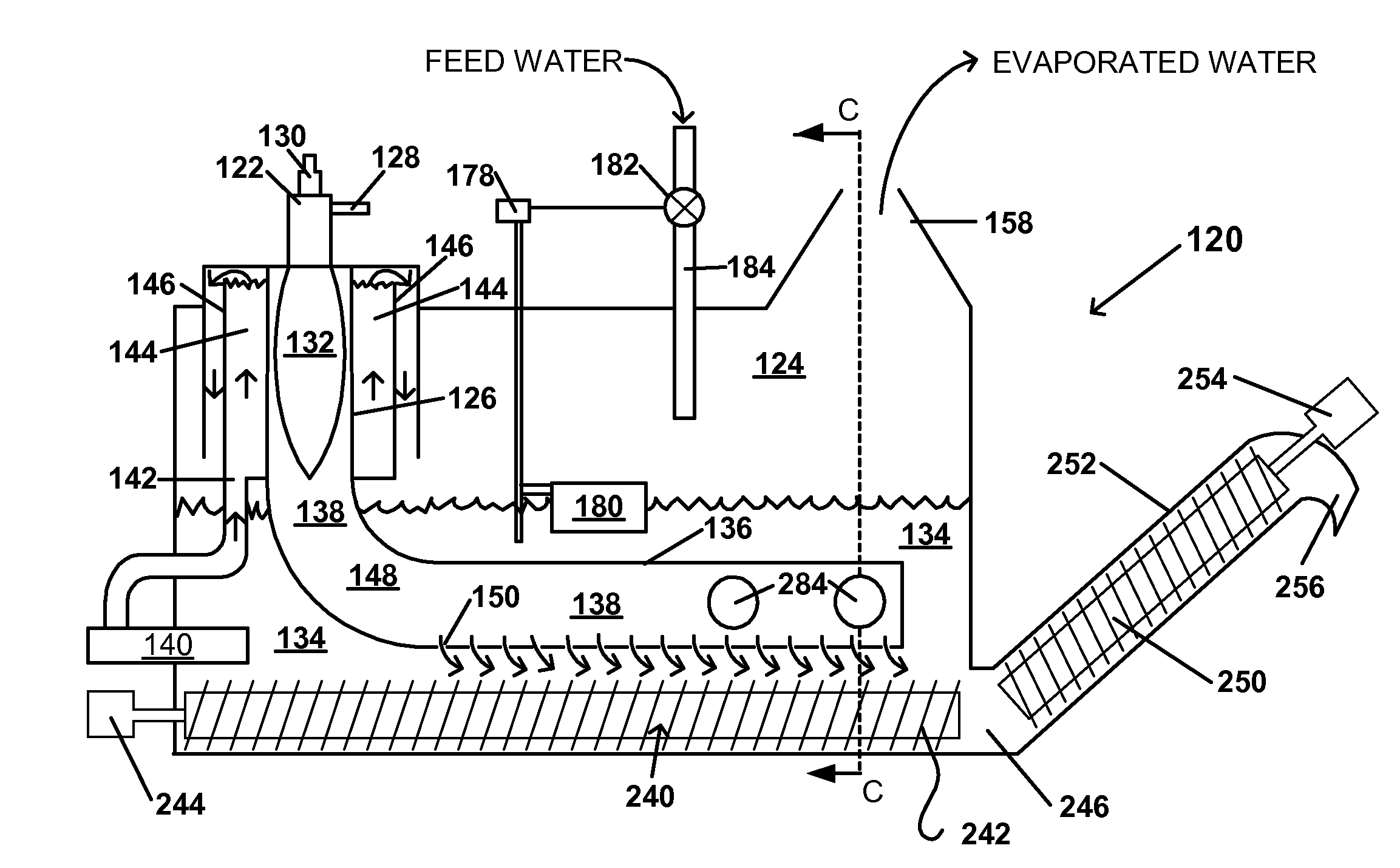

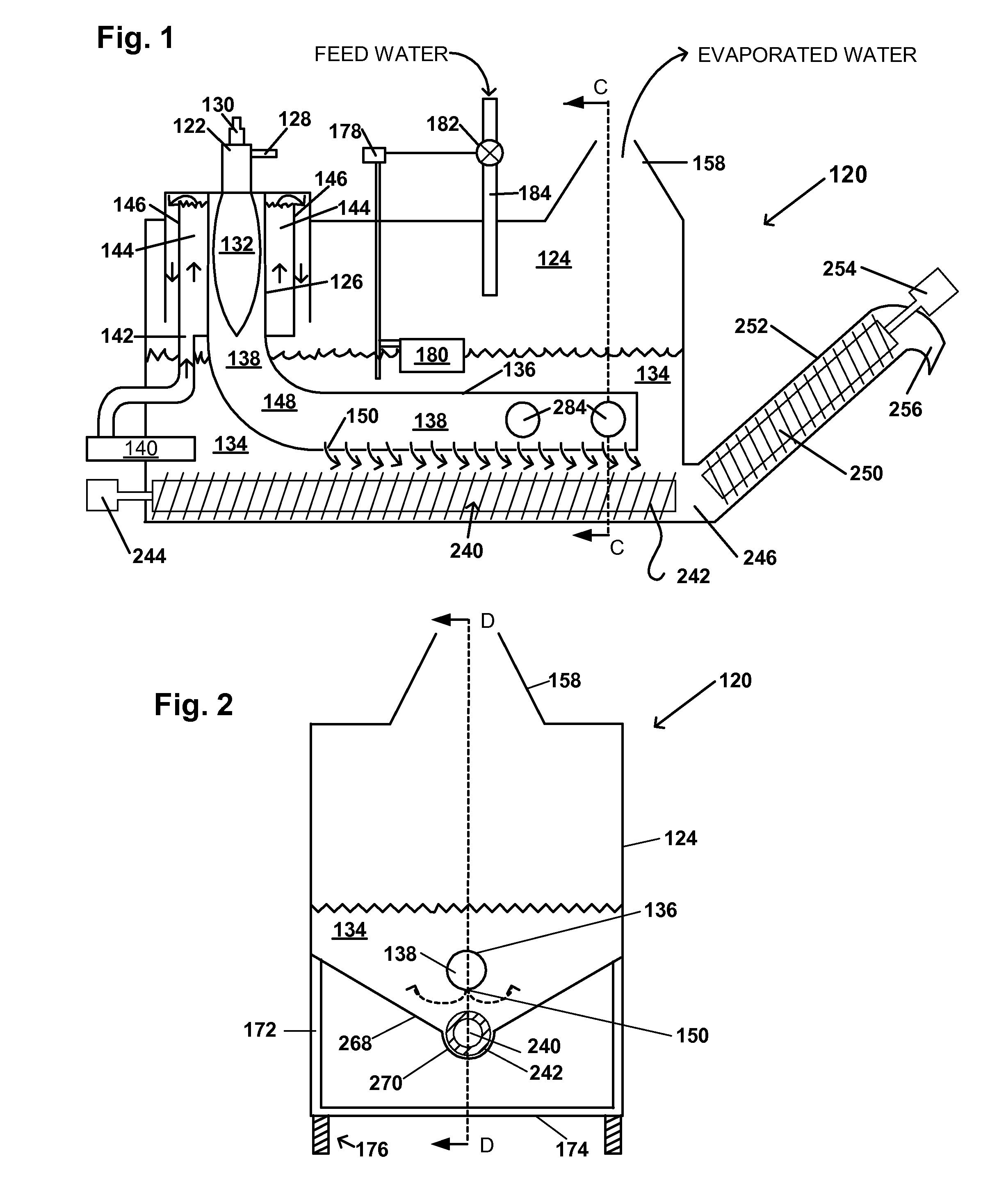

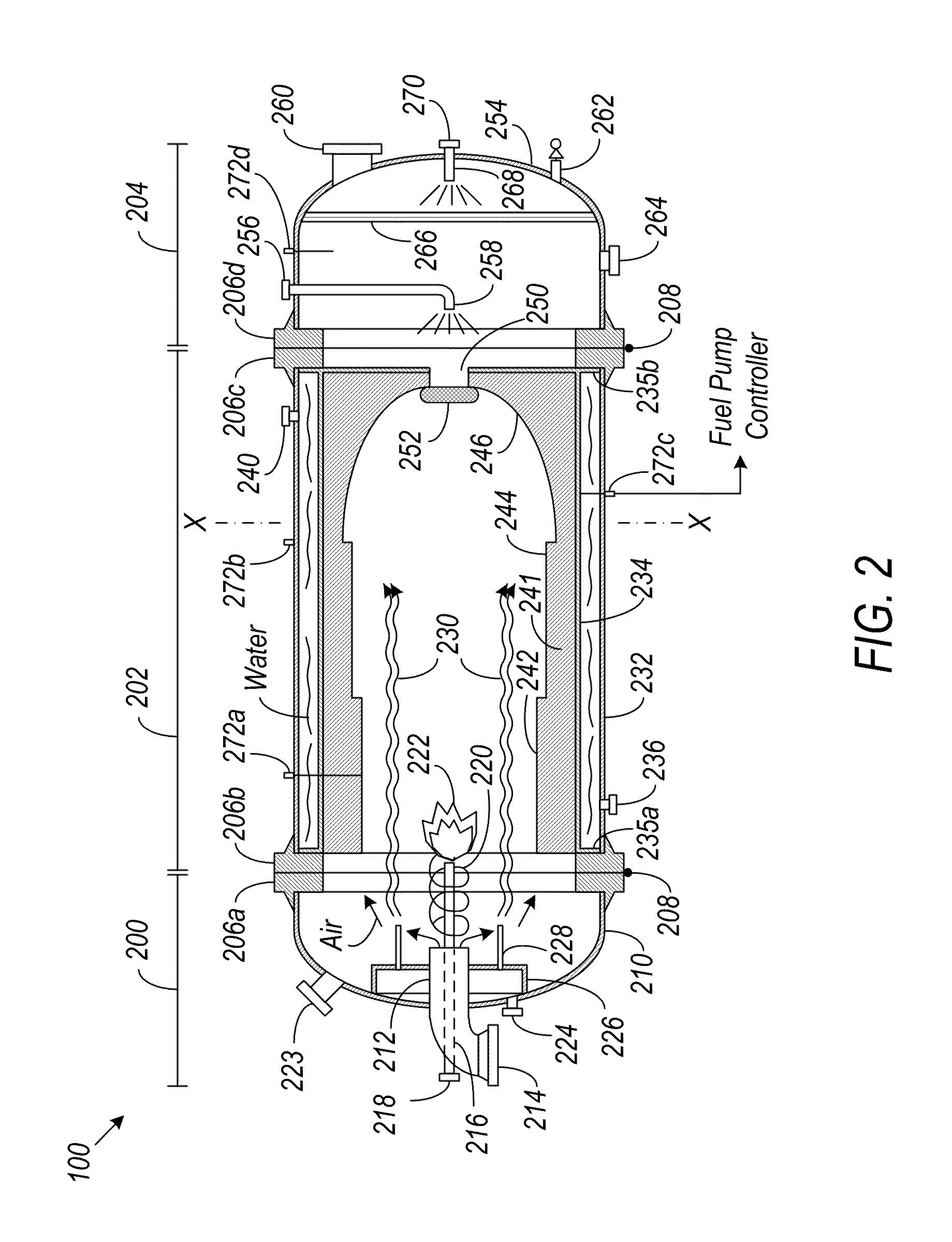

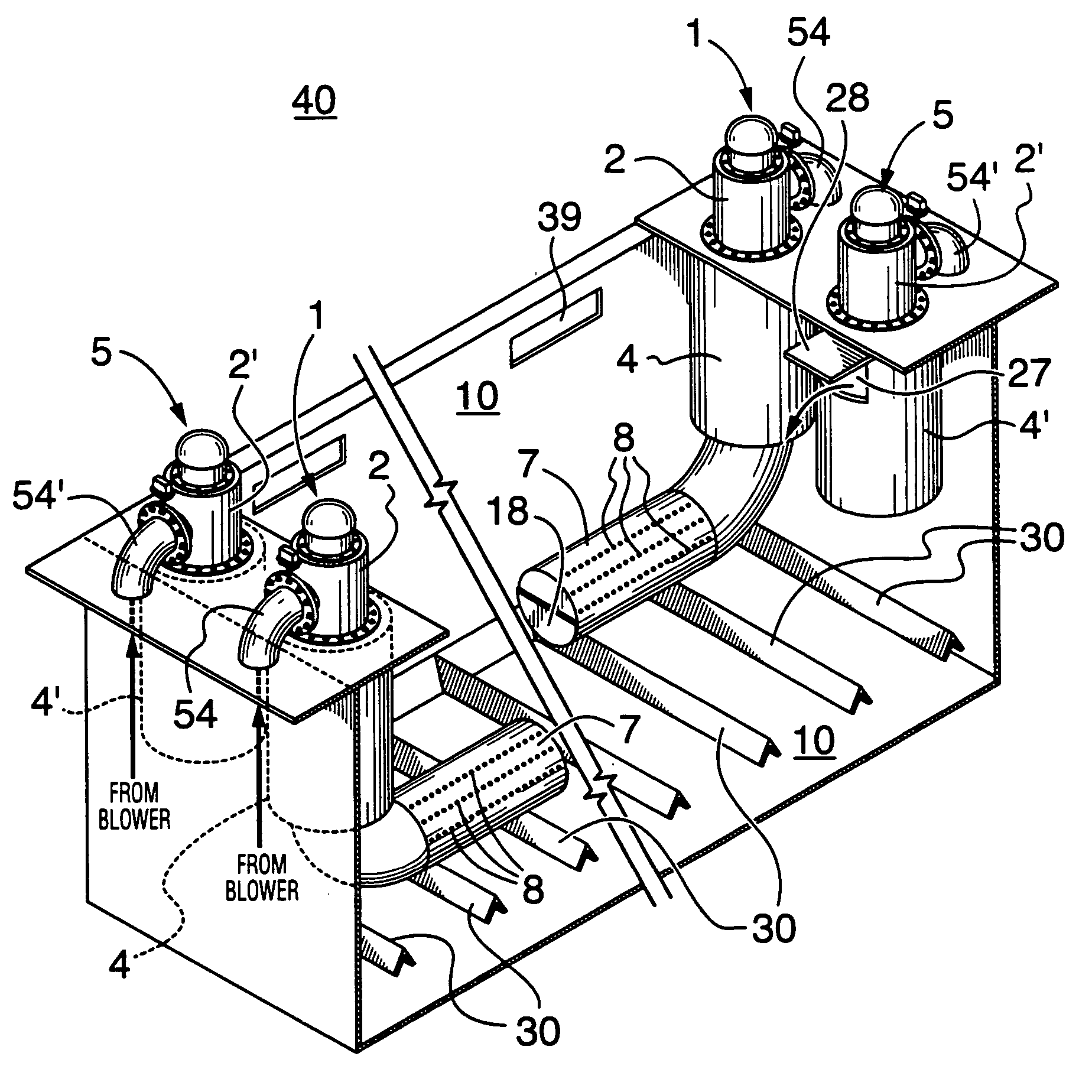

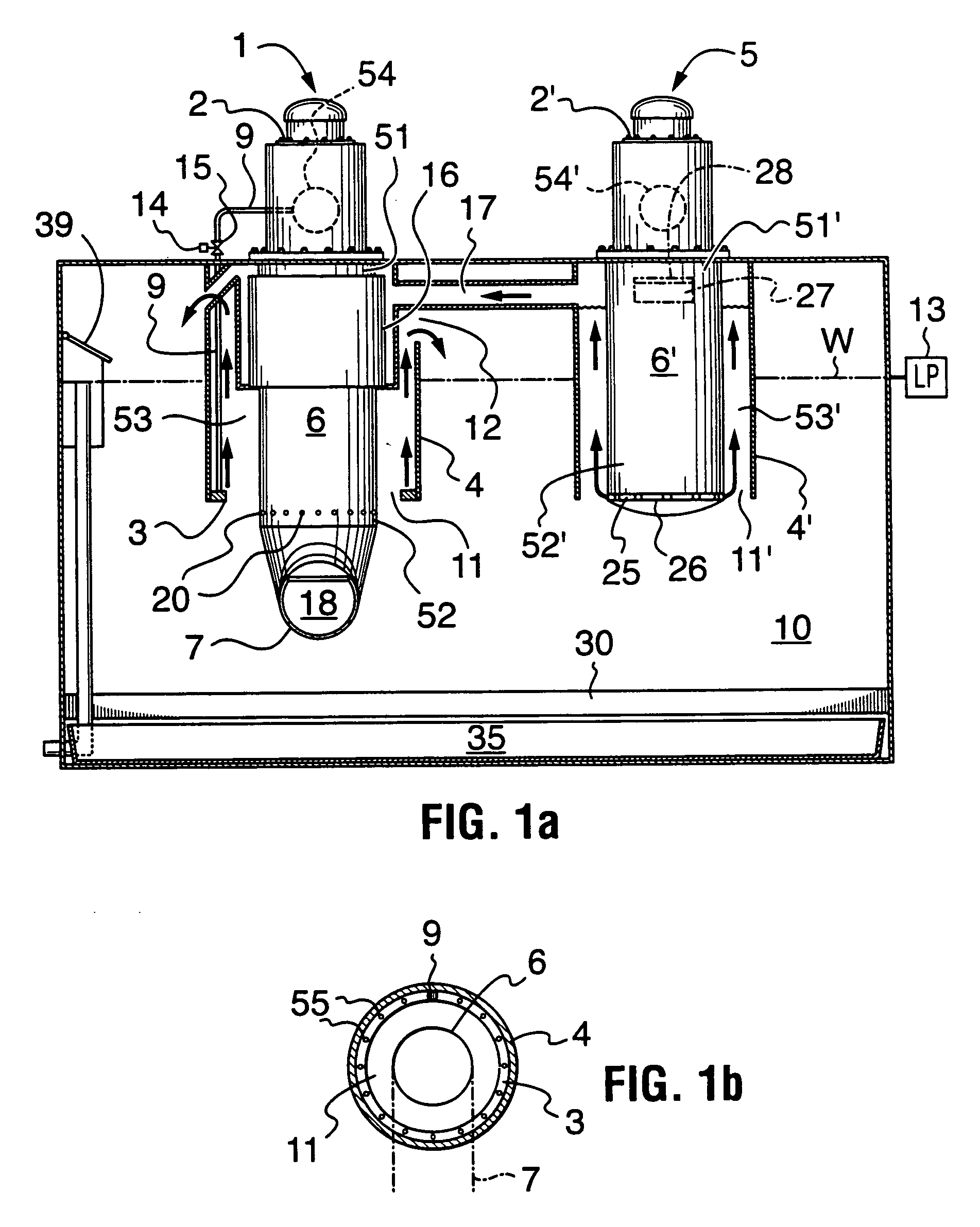

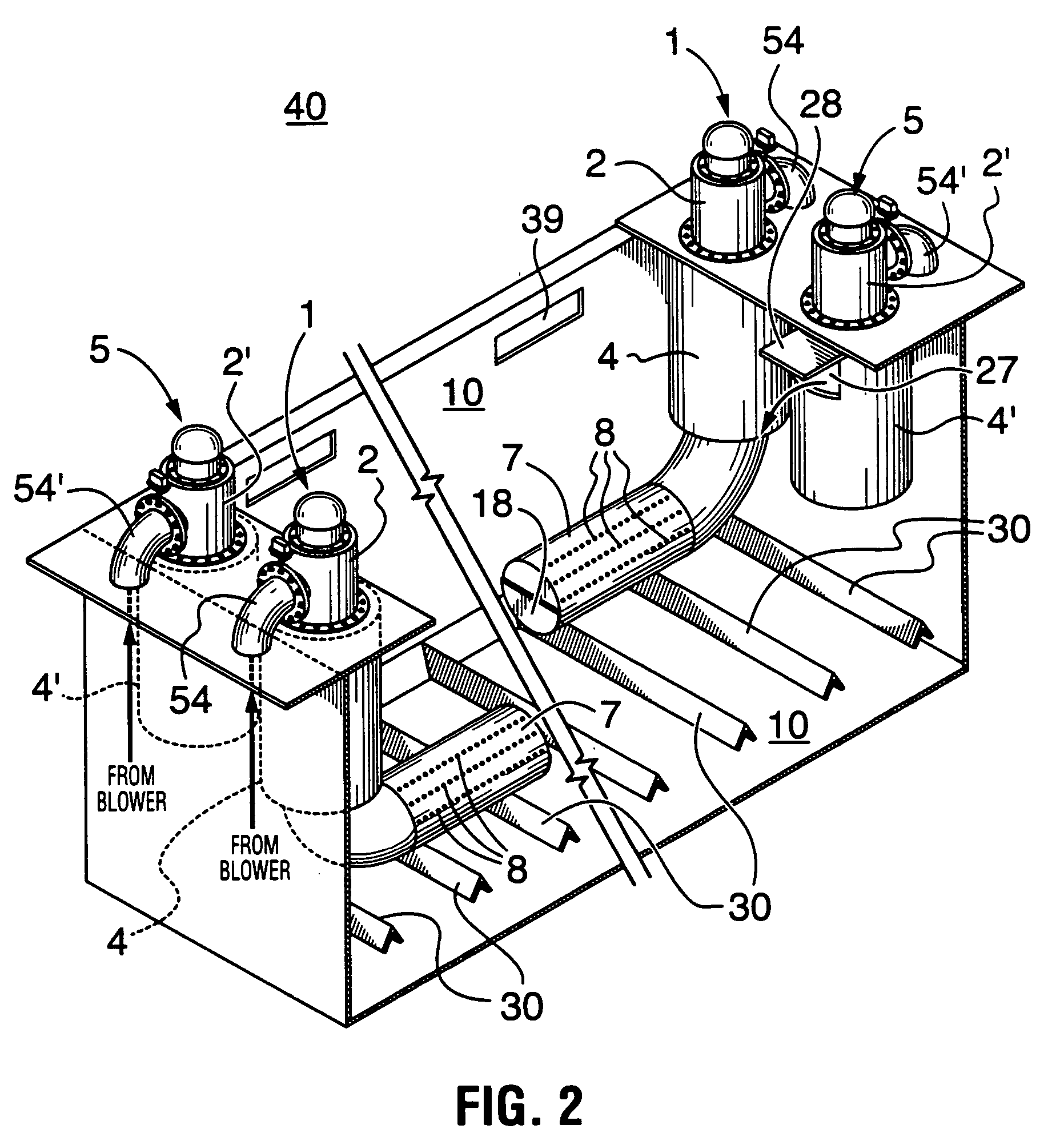

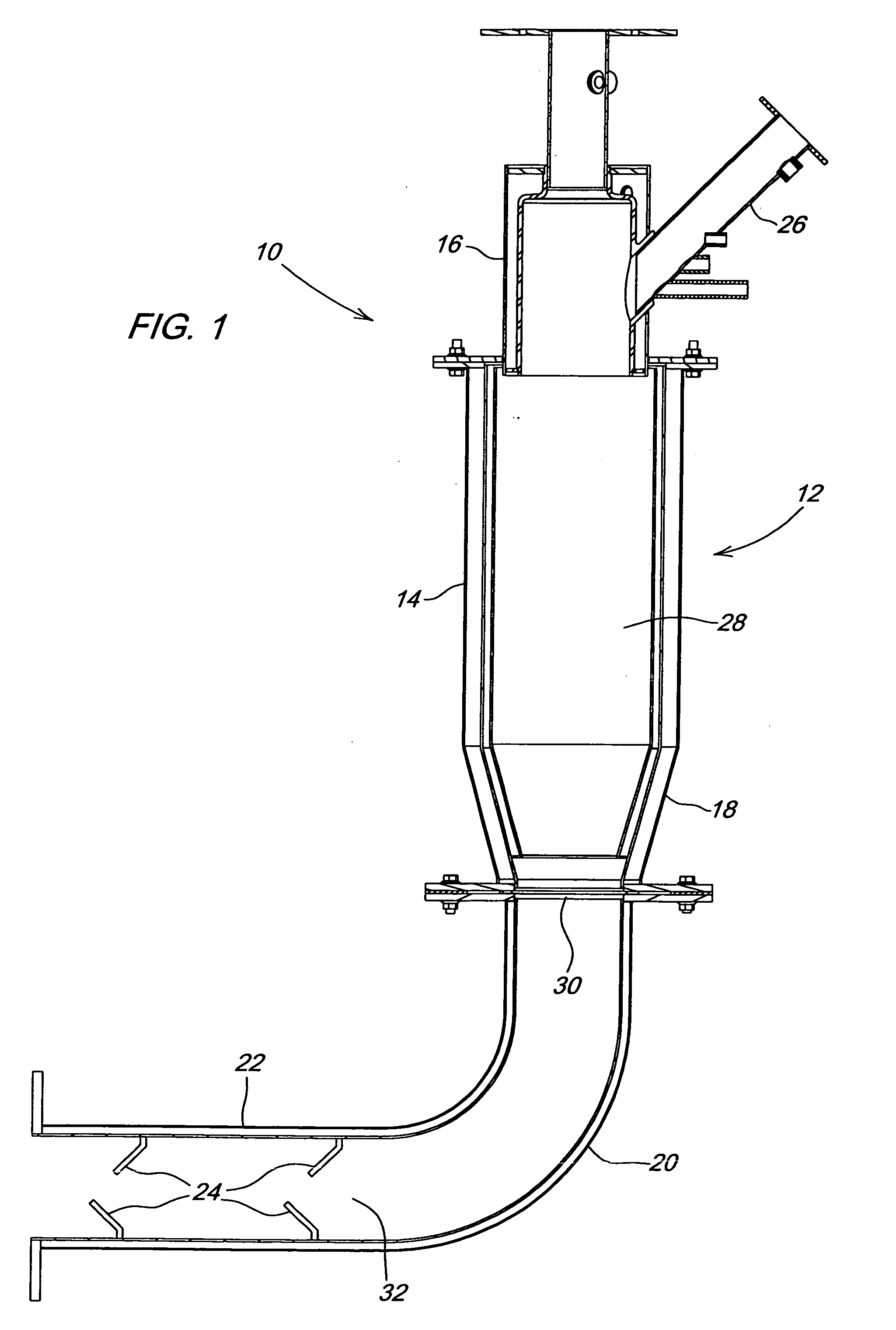

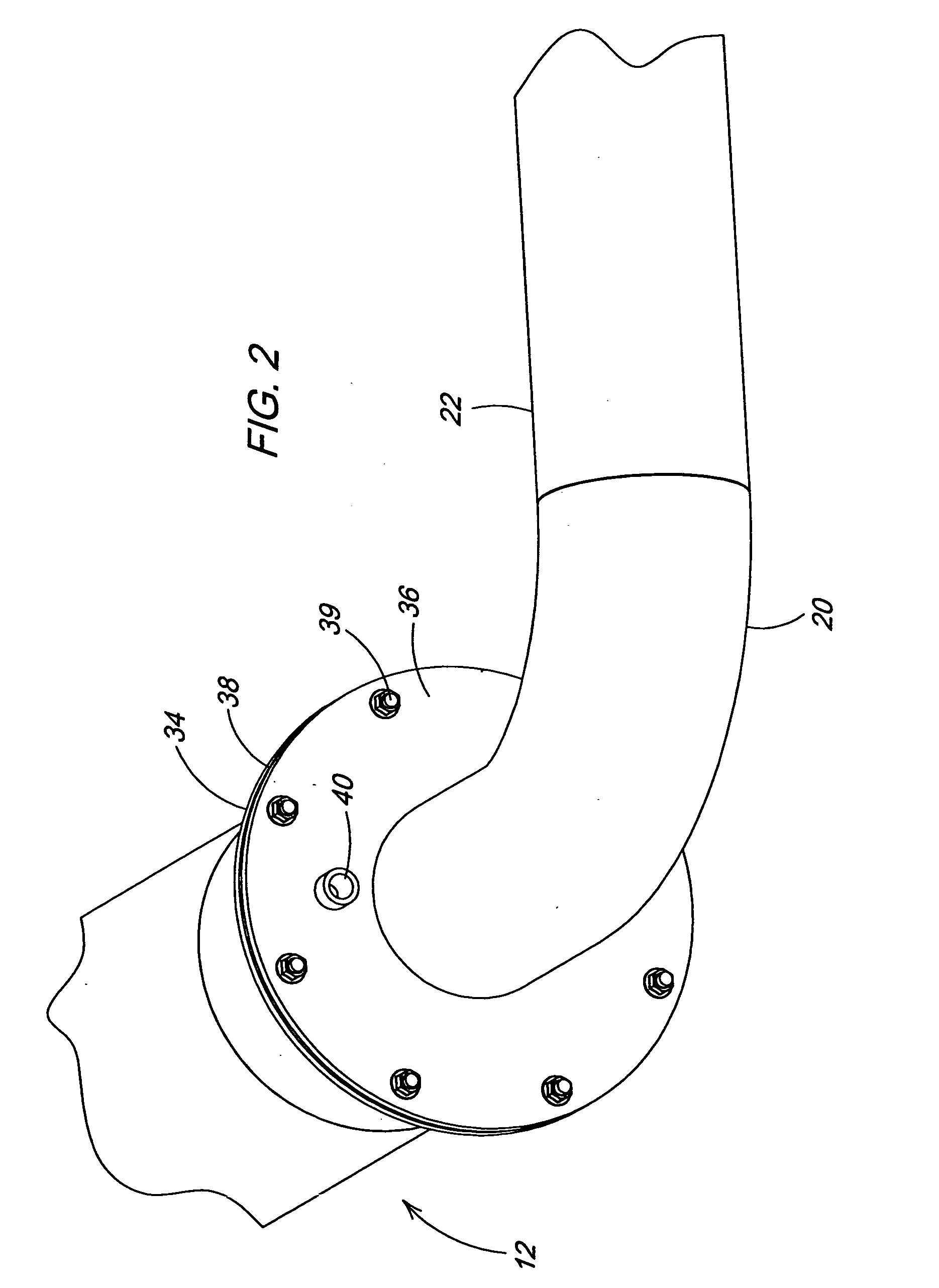

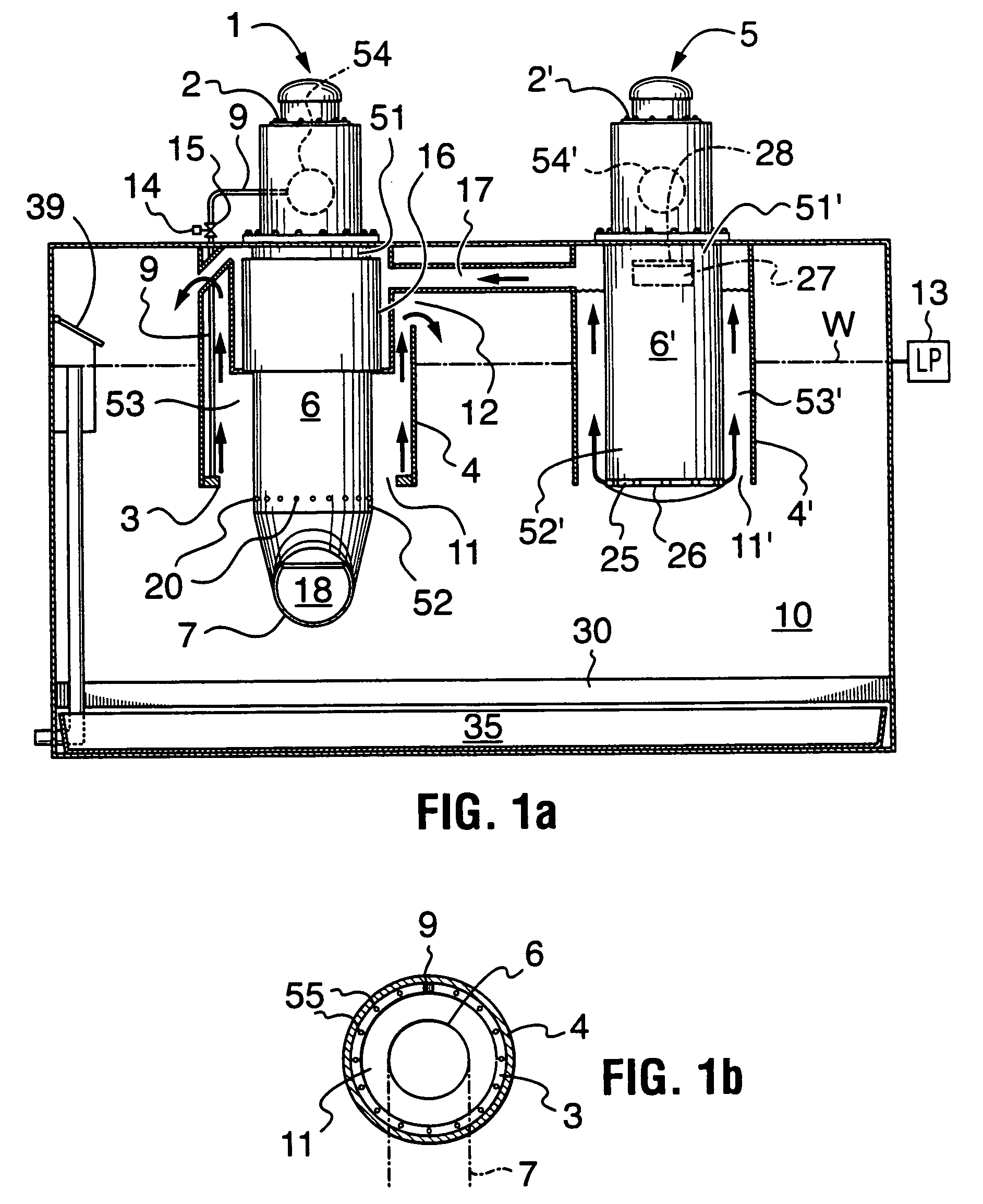

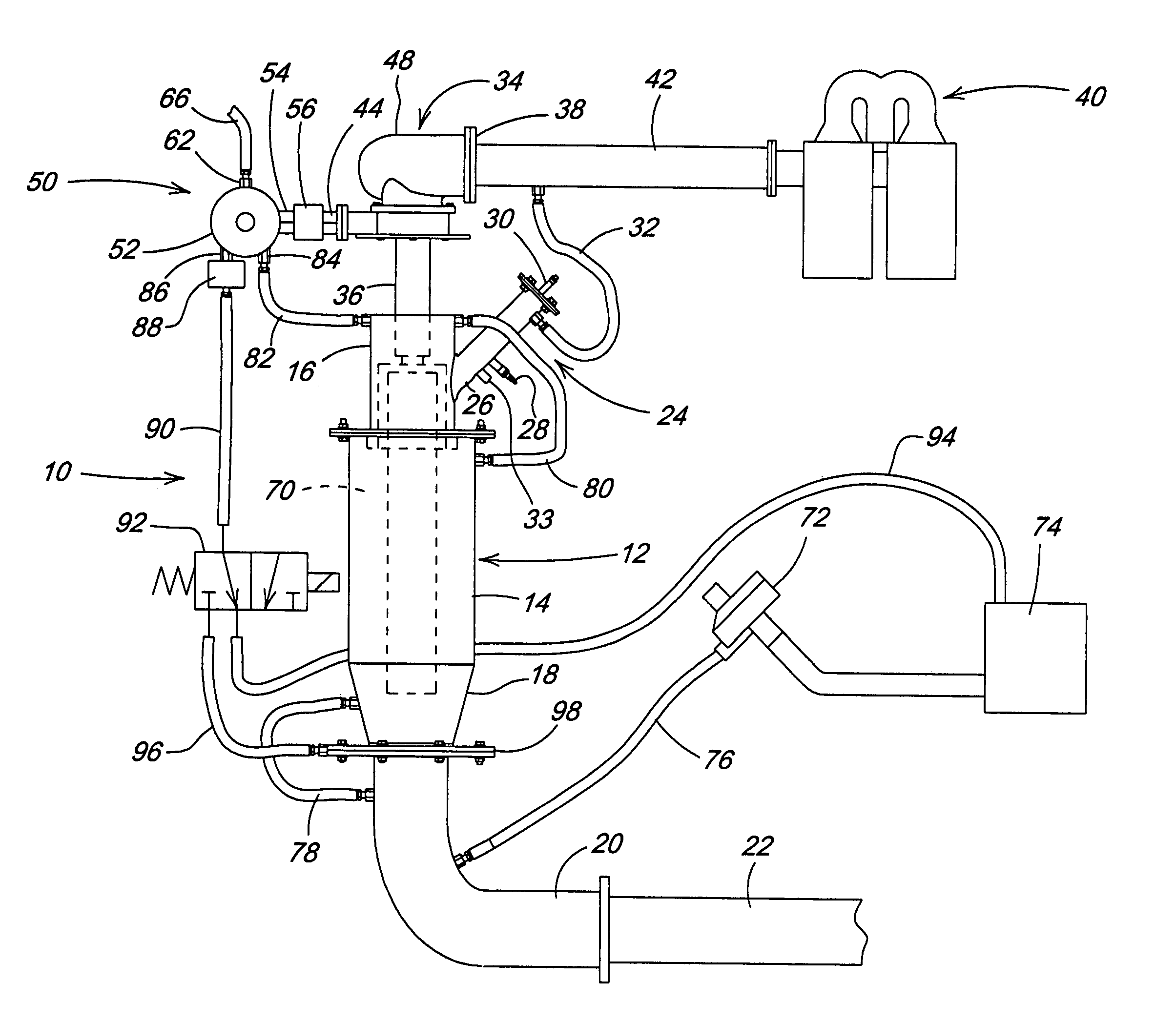

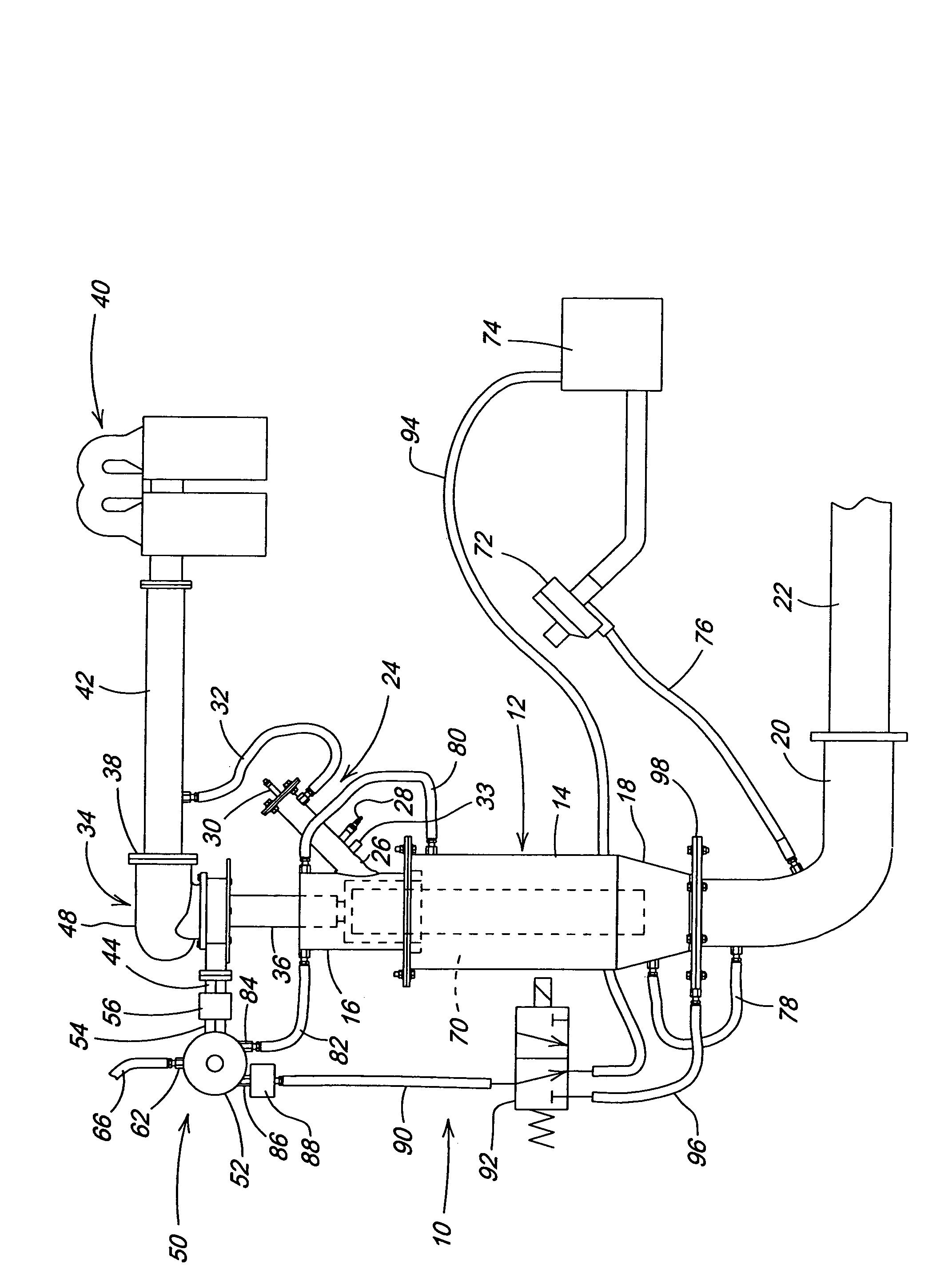

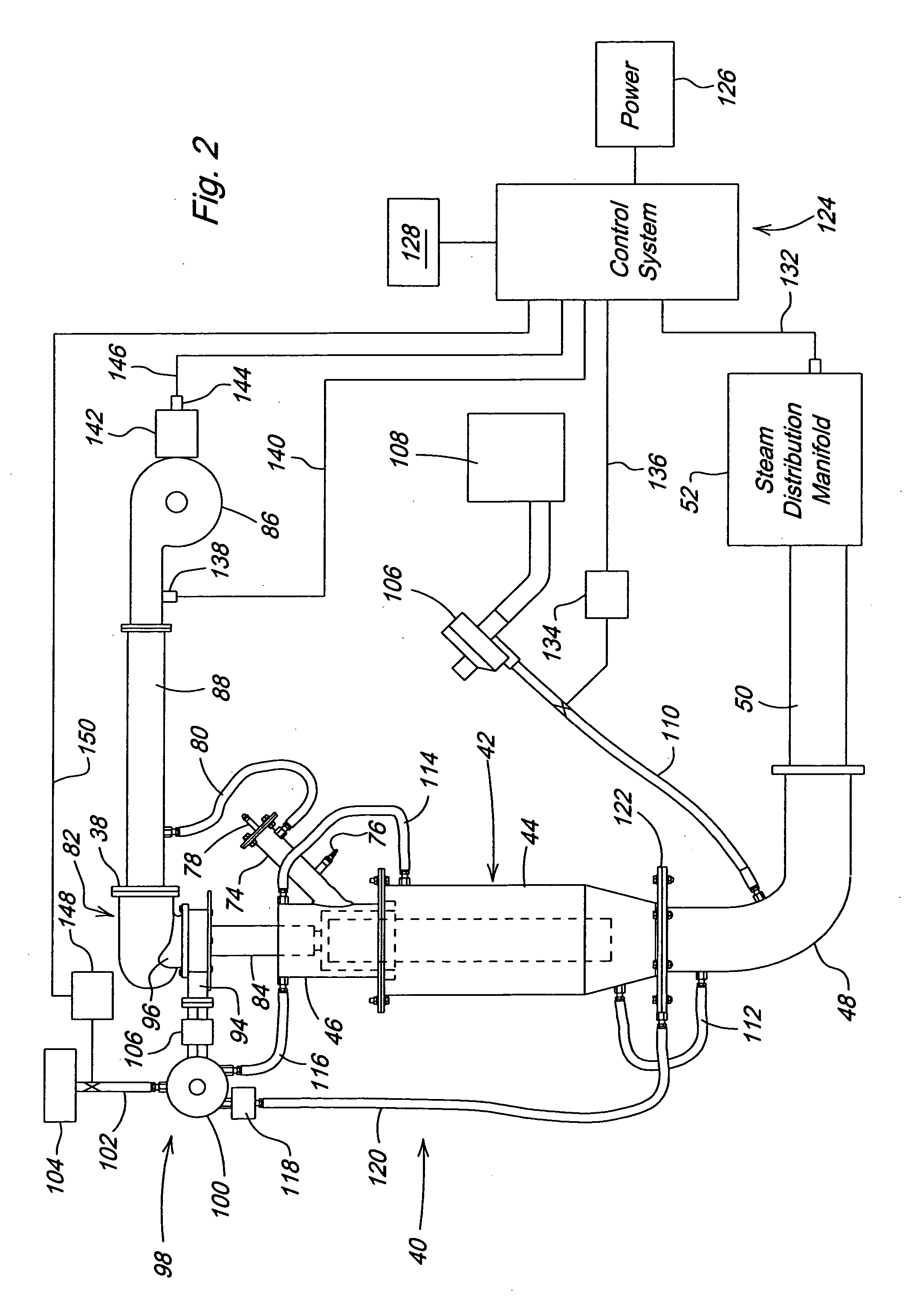

Submerged combustion disposal of produced water

InactiveUS7845314B2Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

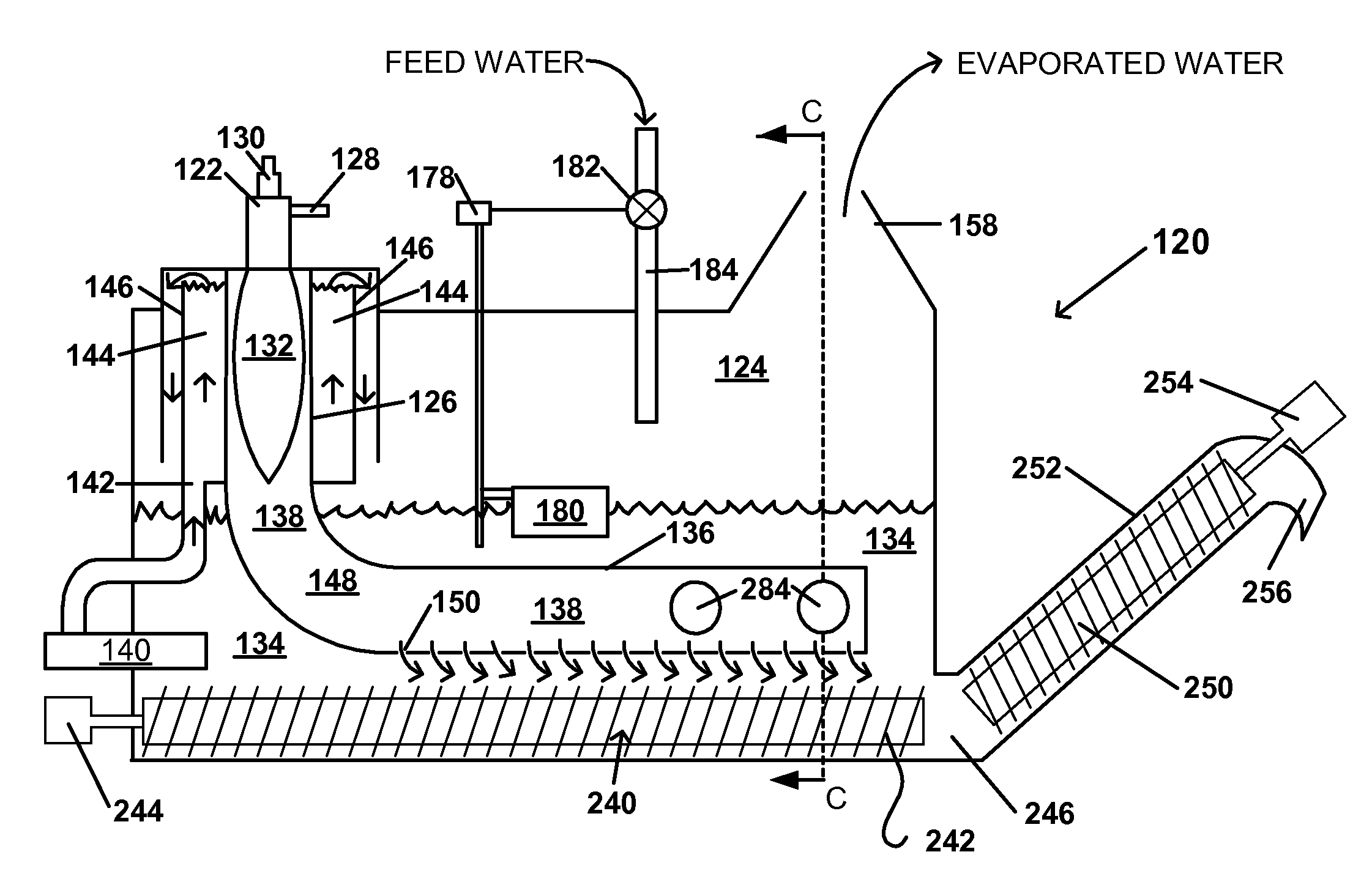

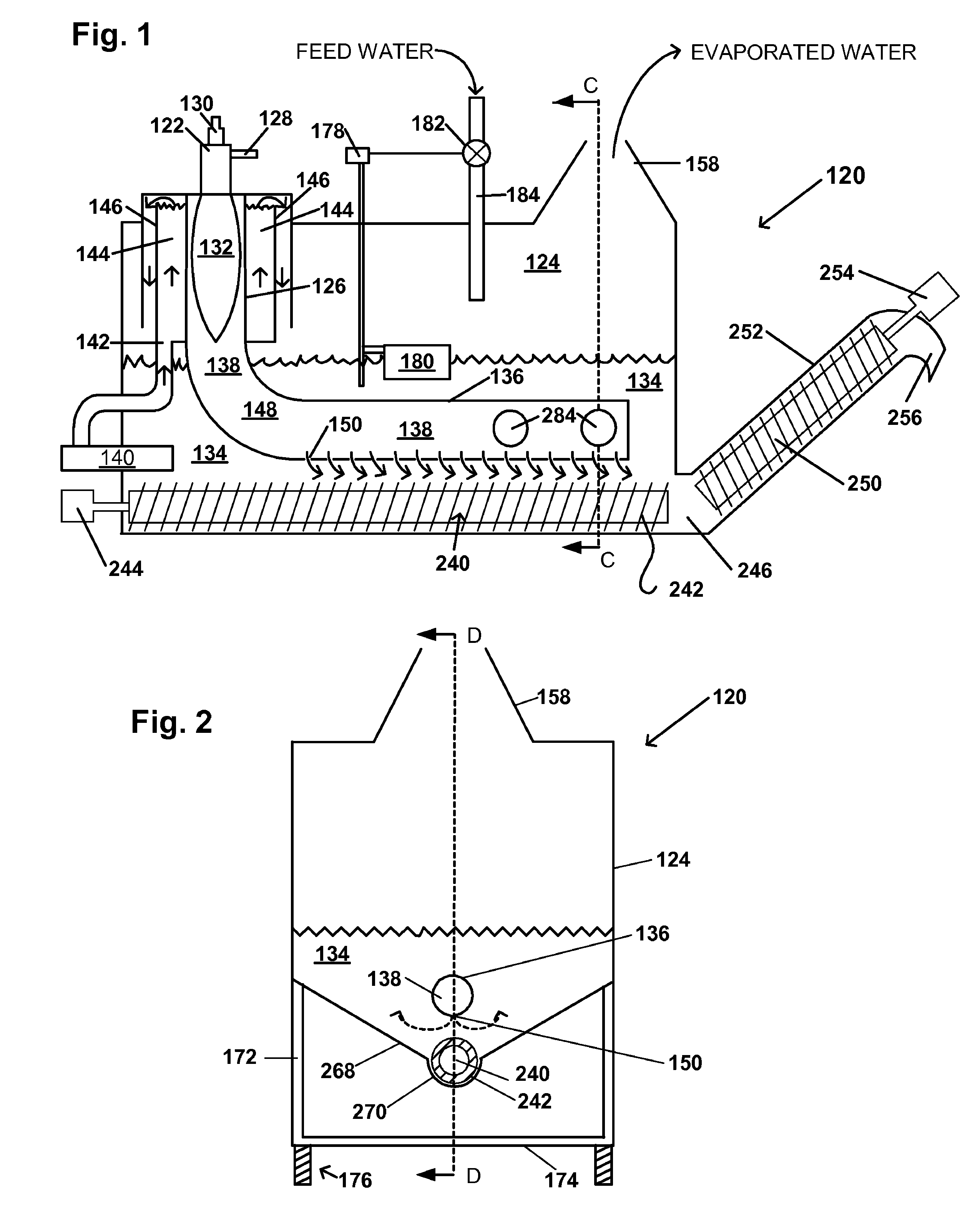

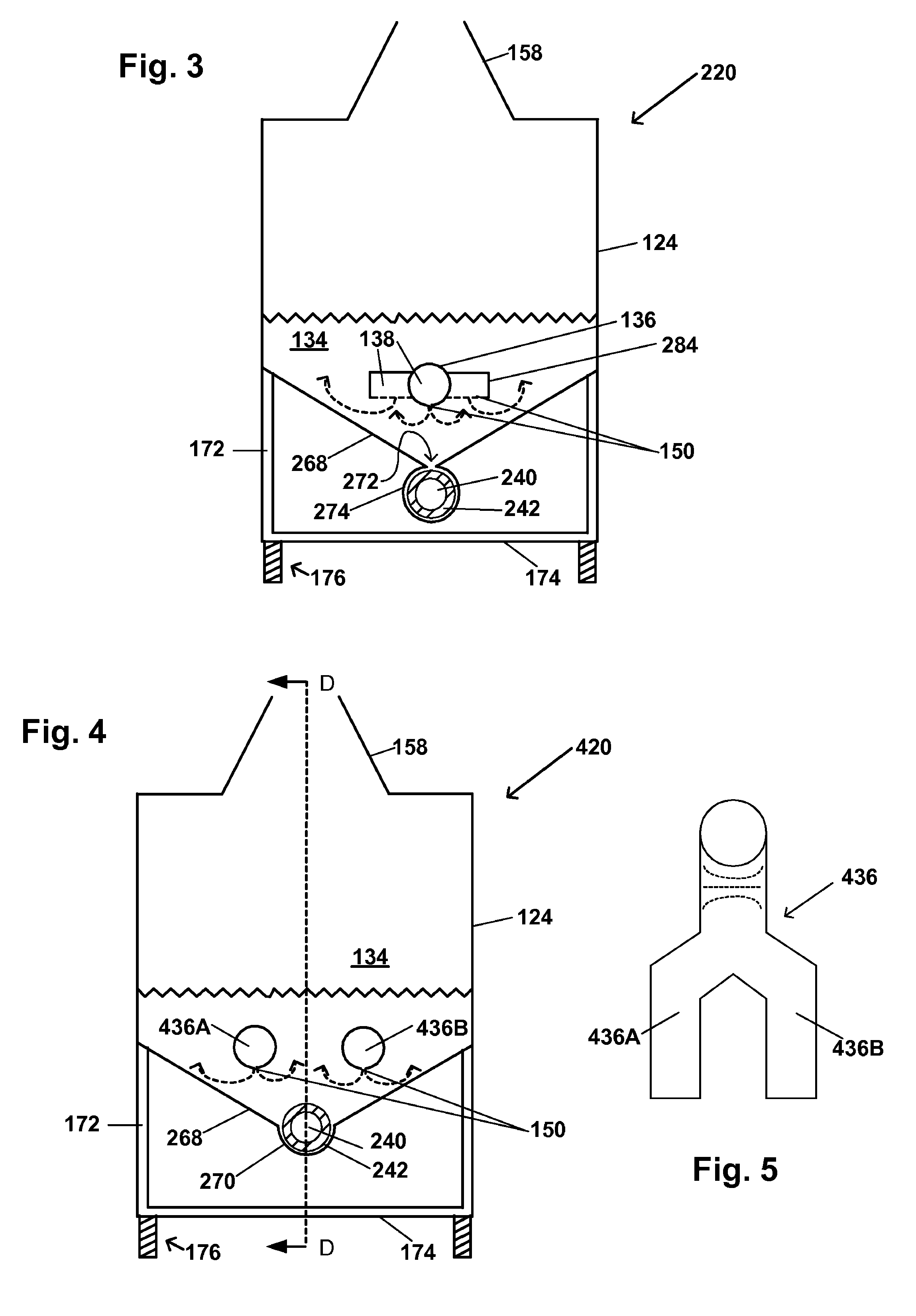

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

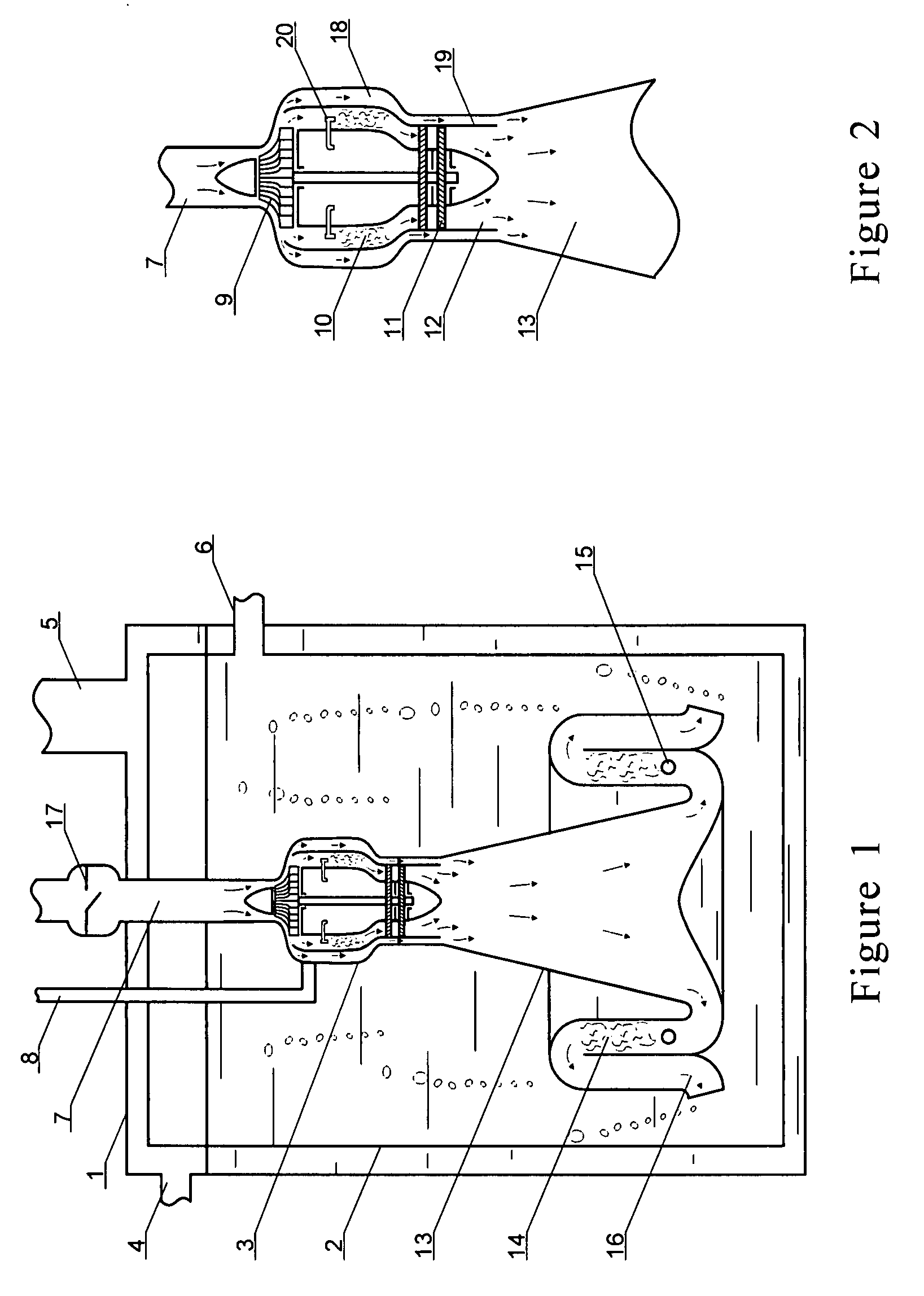

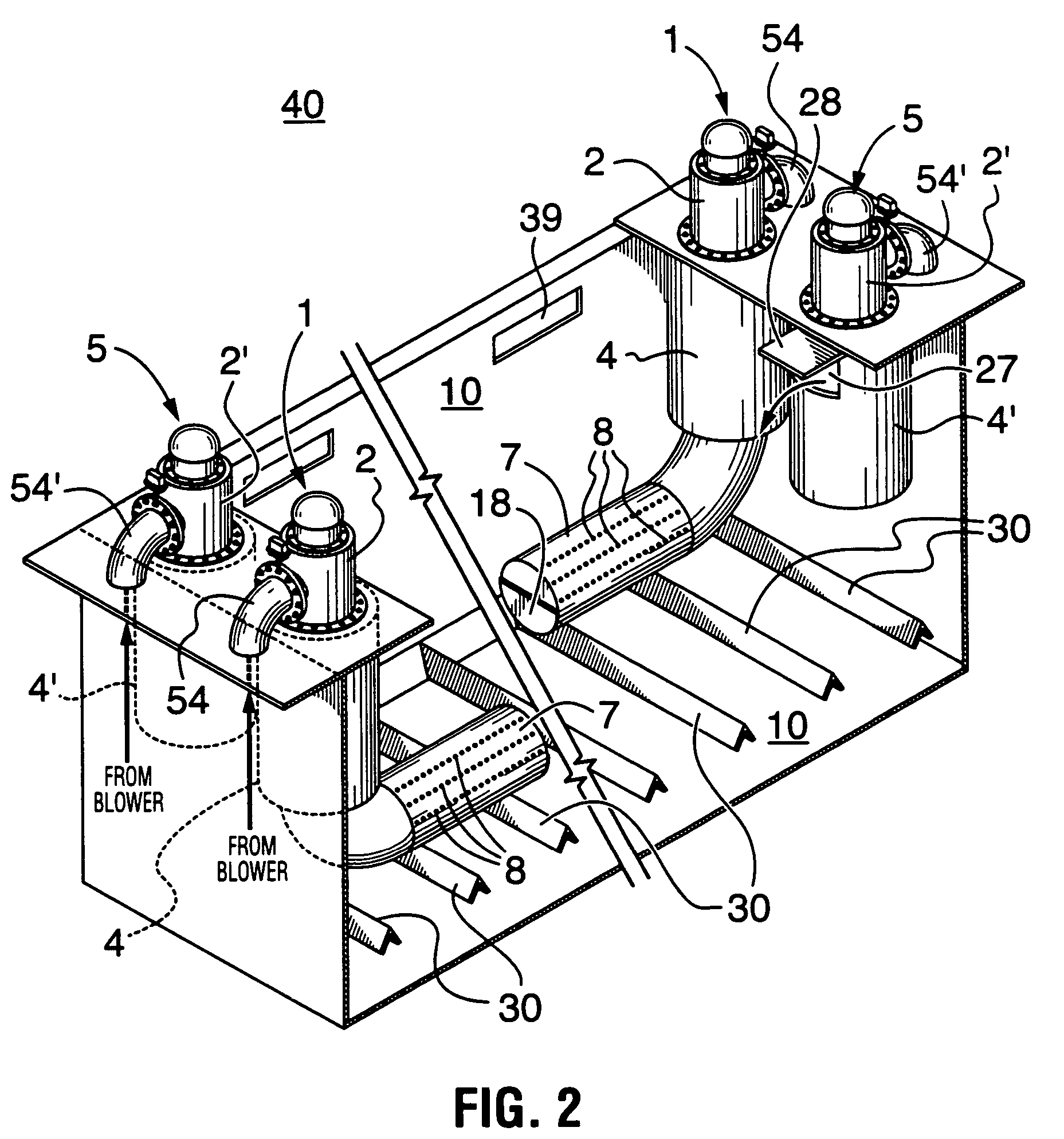

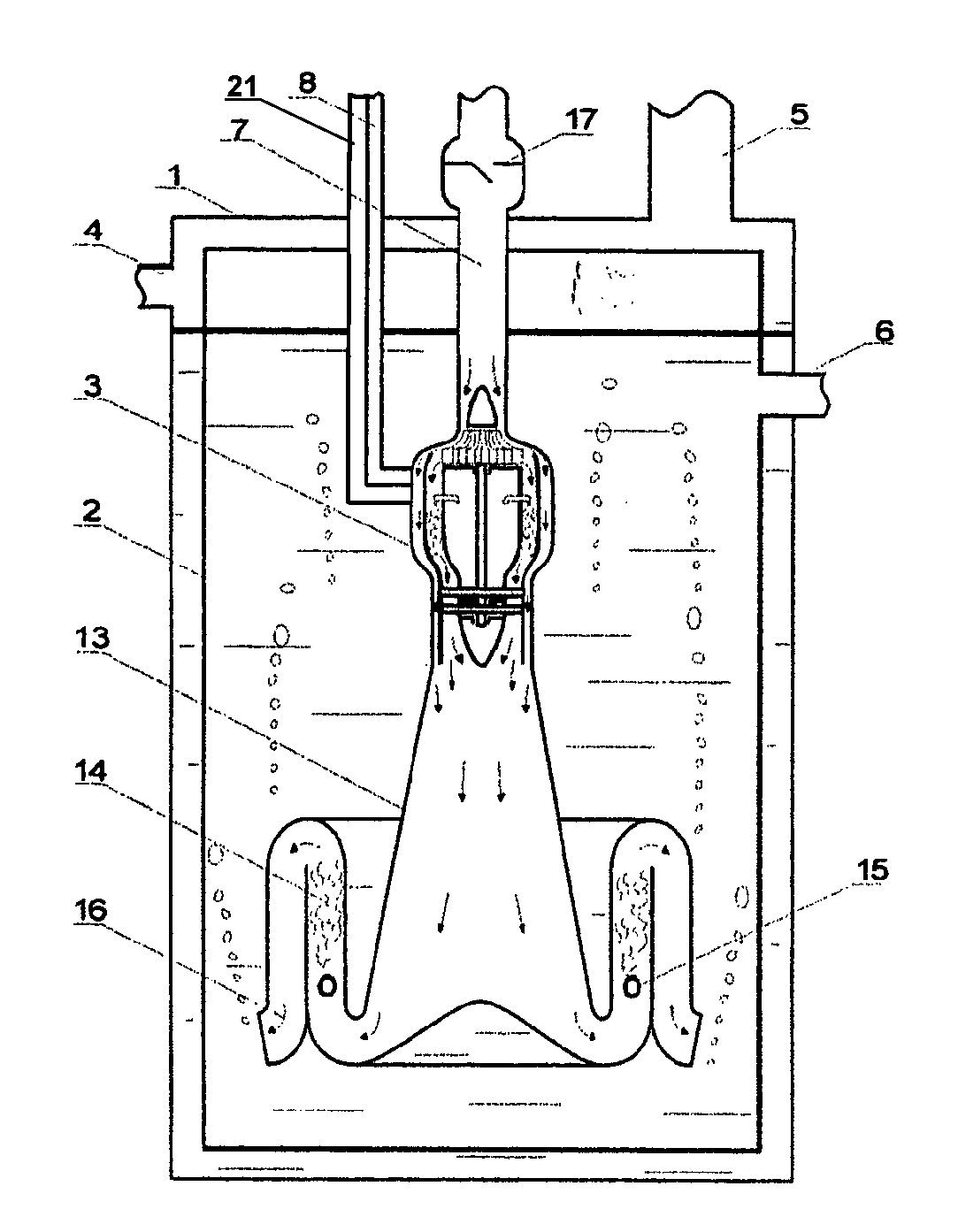

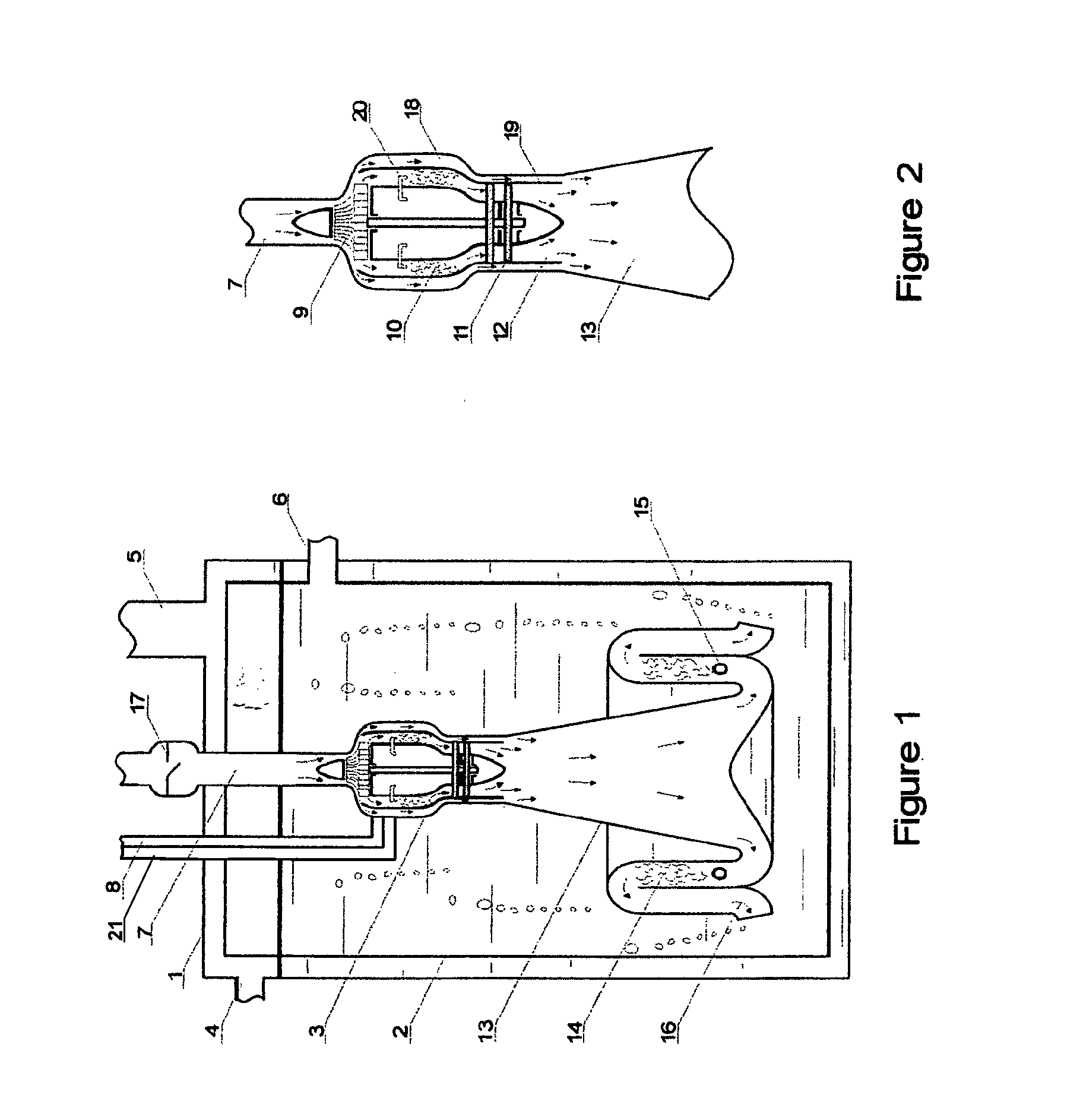

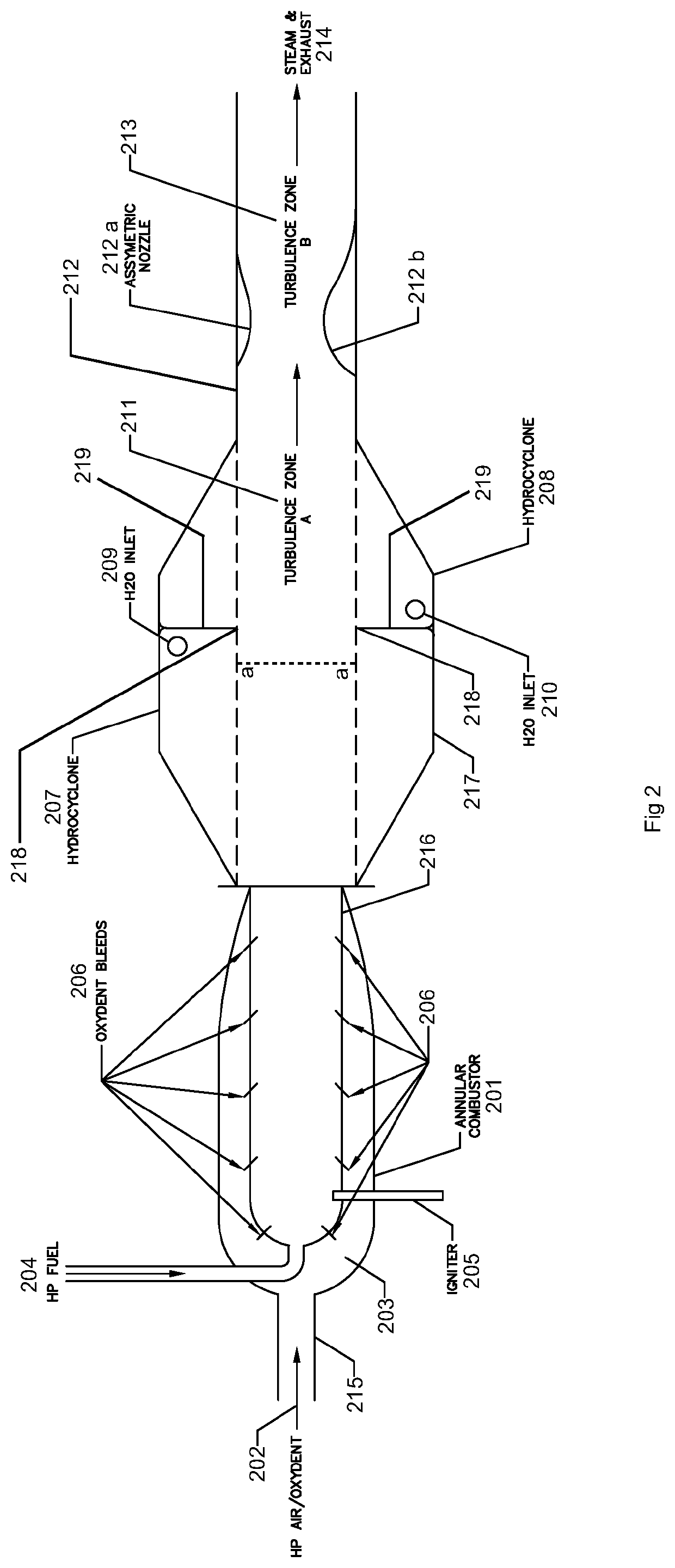

Method and device of turbine submerged combustion boiler

InactiveUS20080035078A1Improve energy efficiencySteam generation using pressureGas turbine plantsComing outHigh energy

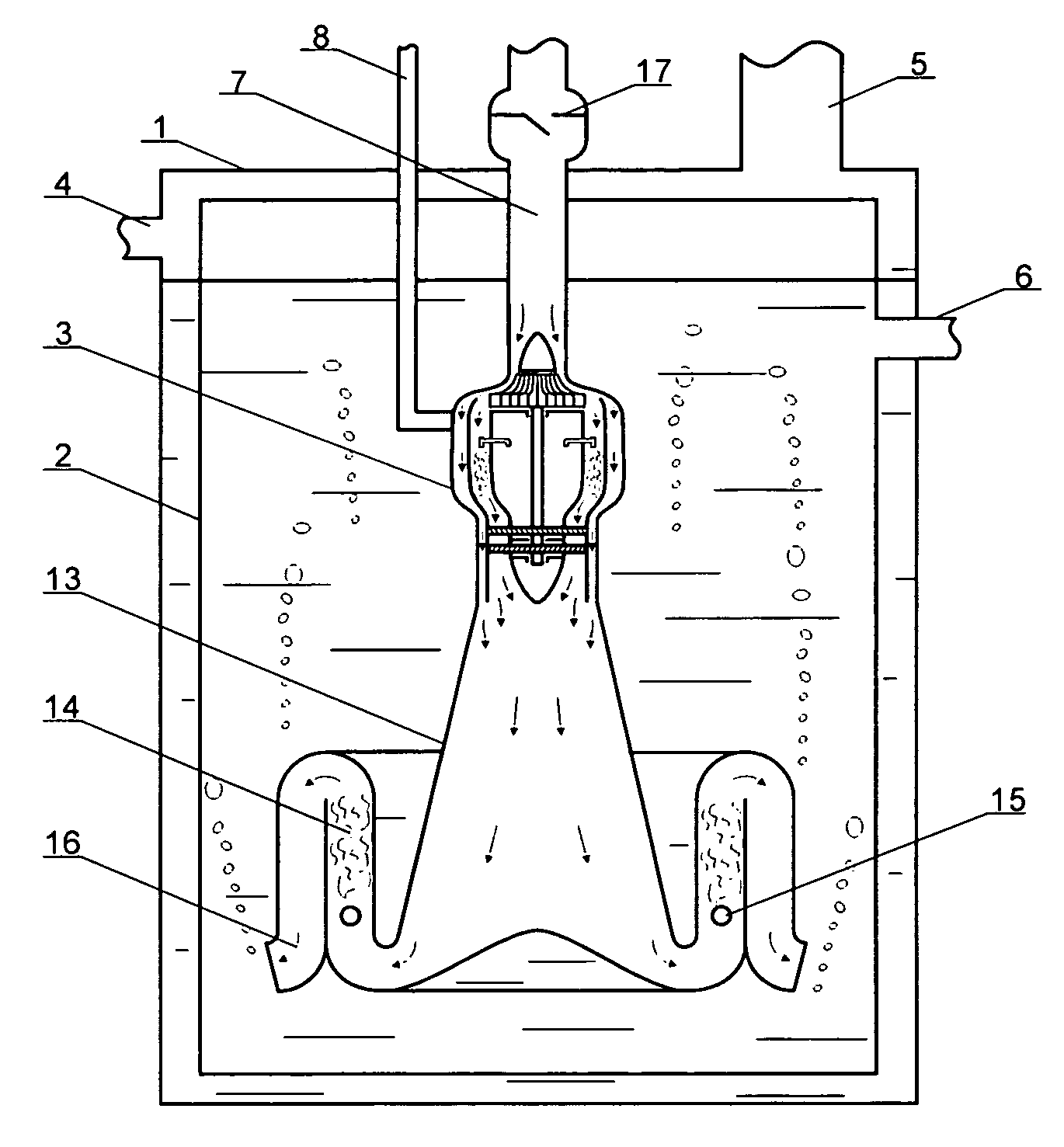

The invention is about a submerged combustion method and the device; in details, it is a submerged combustion method and the device utilizing turbine heat engine principle. In the invention, turbine power combustion means is used and substituted conventional submerged combustion system that must equip air blowing means. The high temperature gases generated from the combustion within the turbine power combustion means will do works on turbine, which will drive the air compressor means of the turbine power combustion means to induce air for combustion, and will drive the second-time complete combustion of high temperature gases and the complement fuel, and then the gases will come out from water bottom against tank water pressure and carry out heat interchange with tank water. The turbine submerged combustion boiler device of the invention need not equip air blowing means additionally which would consume energy. So it has high energy efficiency and a simple system structure. And it has features of high heat interchange rate, stable long term heat efficiency, environmental protection, etc.

Owner:LI WEICHENG

Submerged combustion disposal of produced water

InactiveUS20080110417A1Easy to handleEasy disposalBoiler cleaning apparatusSedimentation separationCombustion systemCombustion chamber

The present invention relates to a method of disposing of produced water and to a produced water disposal apparatus including a container for receiving and holding produced water; and a burner having a combustion chamber, wherein at least a portion of the combustion chamber is submerged in the water and the submerged portion of the combustion chamber comprises a sparger tube through which combustion gases emerge into, mix with and agitate the water. The present invention further relates to a mechanism for removing debris from the produced water disposal apparatus. In one embodiment, heat is supplied from an externally operated combustion system, rather than the submerged combustion. In one embodiment, the apparatus provides a concentrator, in which a solute can be removed and recovered from an aqueous medium containing the solute.

Owner:TDU LLC

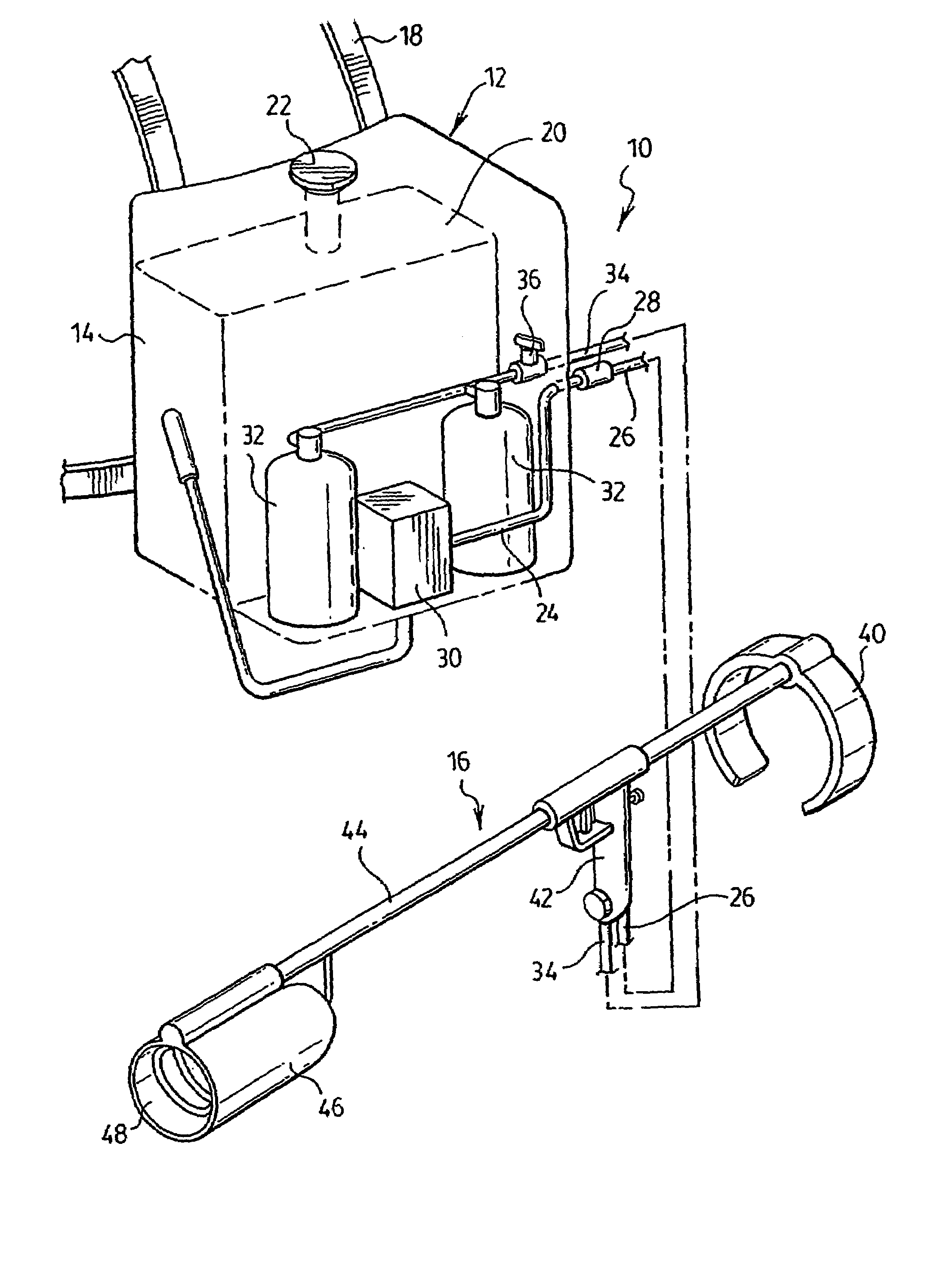

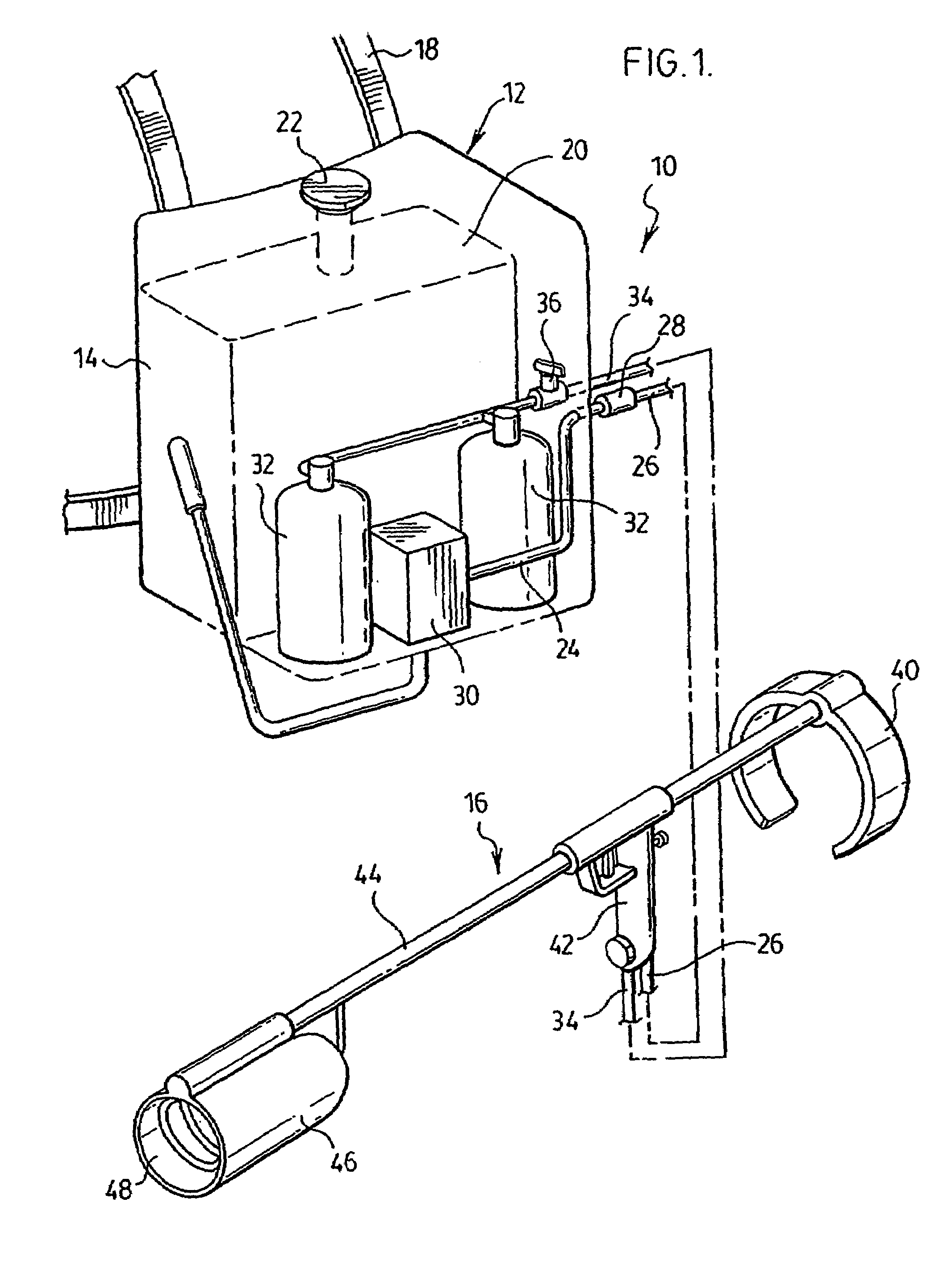

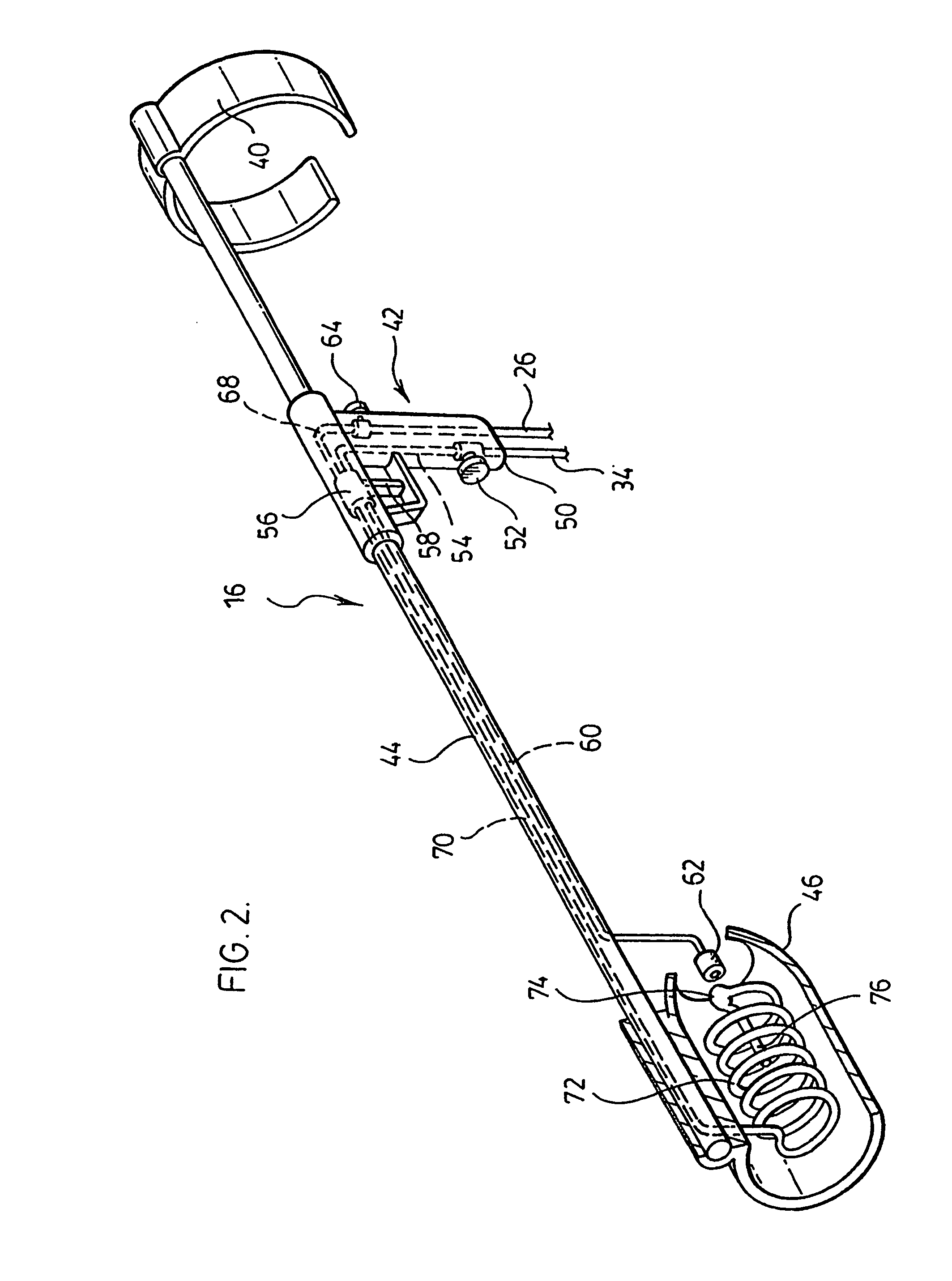

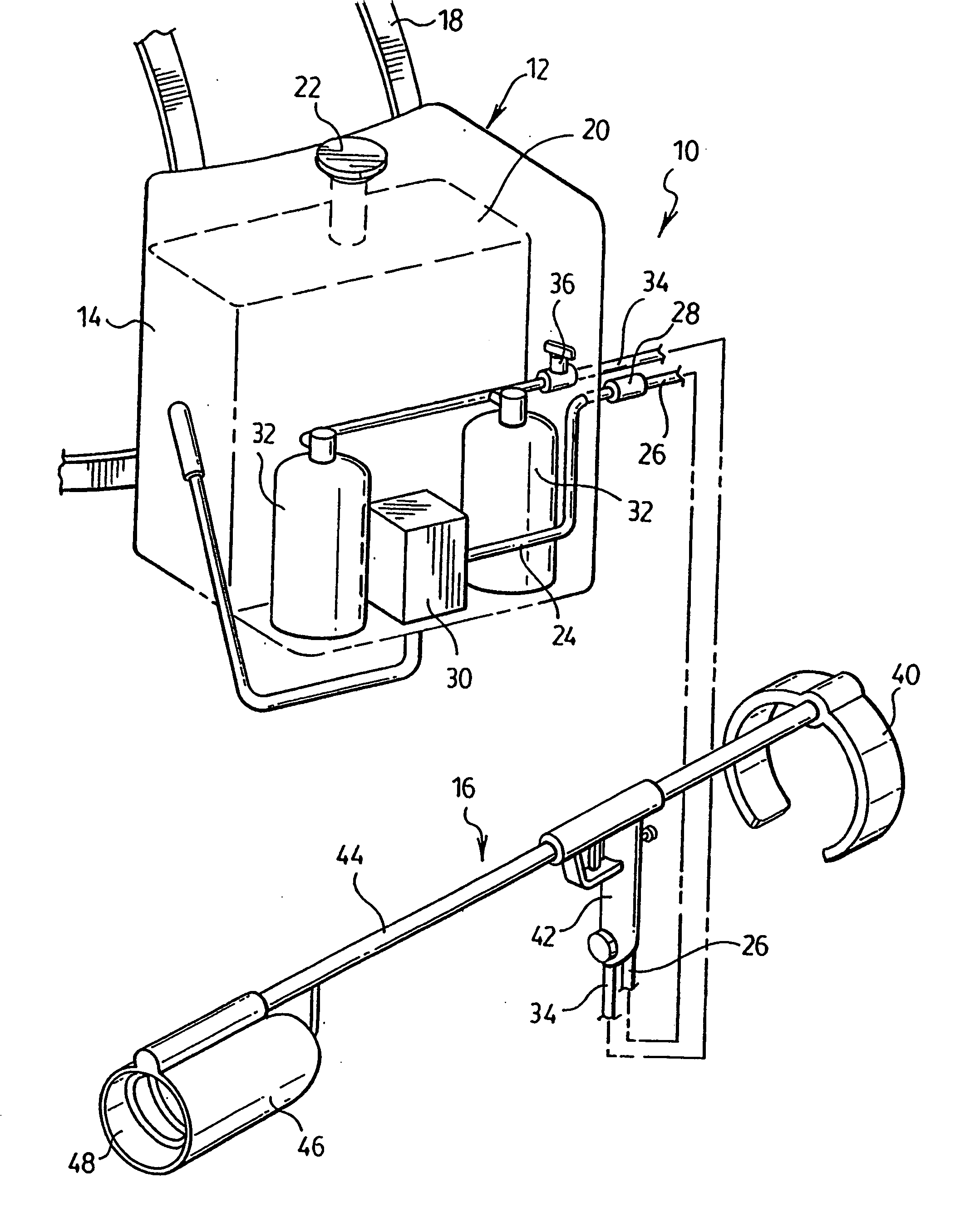

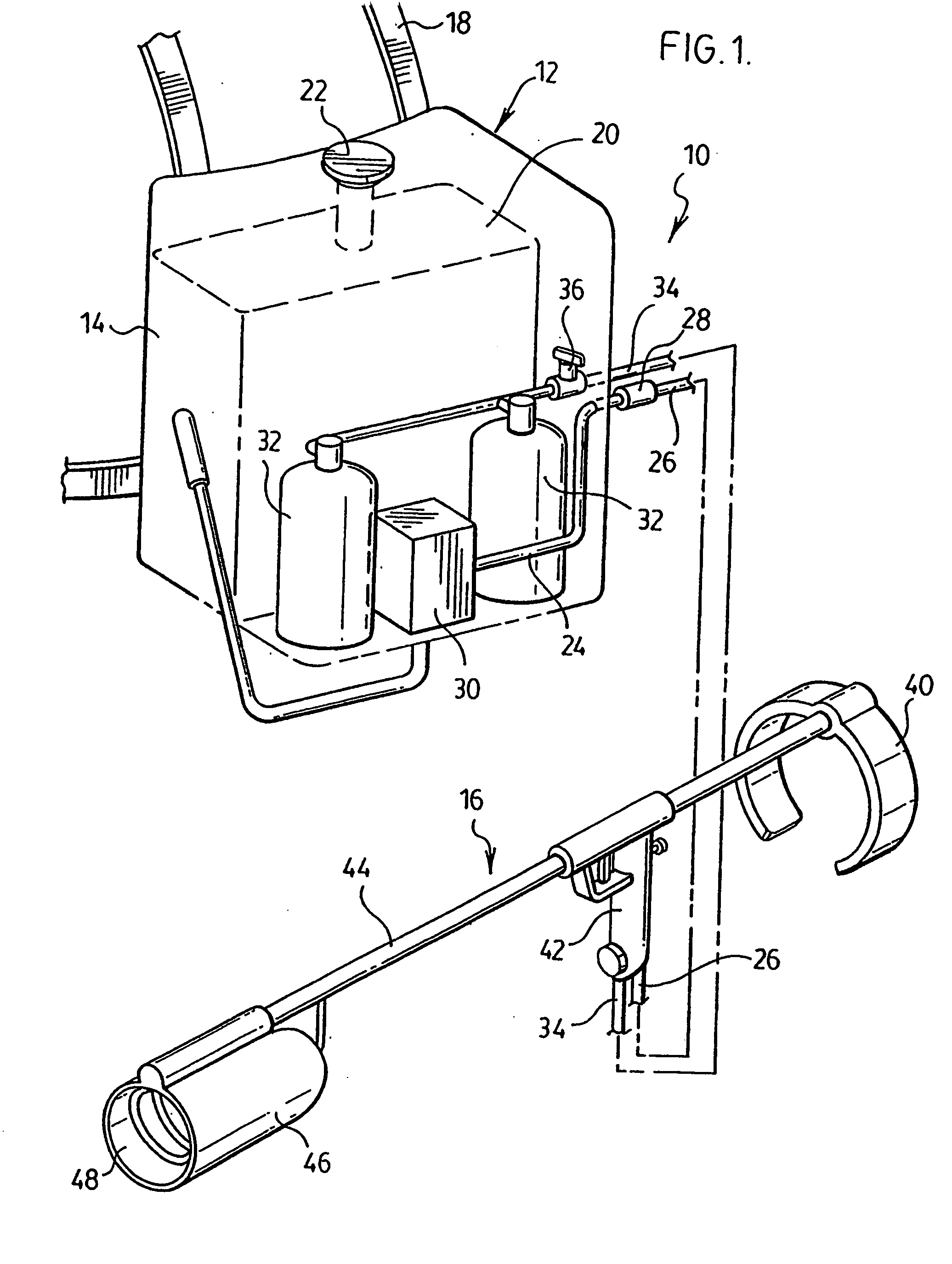

Portable steam and heat generator

The present invention is directed to an apparatus for directing steam, hot water or hot water vapor and hot air onto a target area, the apparatus comprising a water container and a fuel container connected and supplying water and fuel to an applicator wand with an applicator head which generates steam and heat for application adjacent to the target area of application to the unwanted vegetation. Steam is generated immediately adjacent to the target area within the applicator head and combined with surplus heat from the steam generation process to produce heated steam and water vapor for application to the target area. In a preferred embodiment of the invention, the applicator wand is hand held, the applicator head having an inlet, an outlet and a body therebetween, the water and fuel being supplied to a steam generator and burner within the body of the applicator head which generates steam and hot air adjacent to the target area for application through the outlet to the target area.

Owner:GREENSTEAM

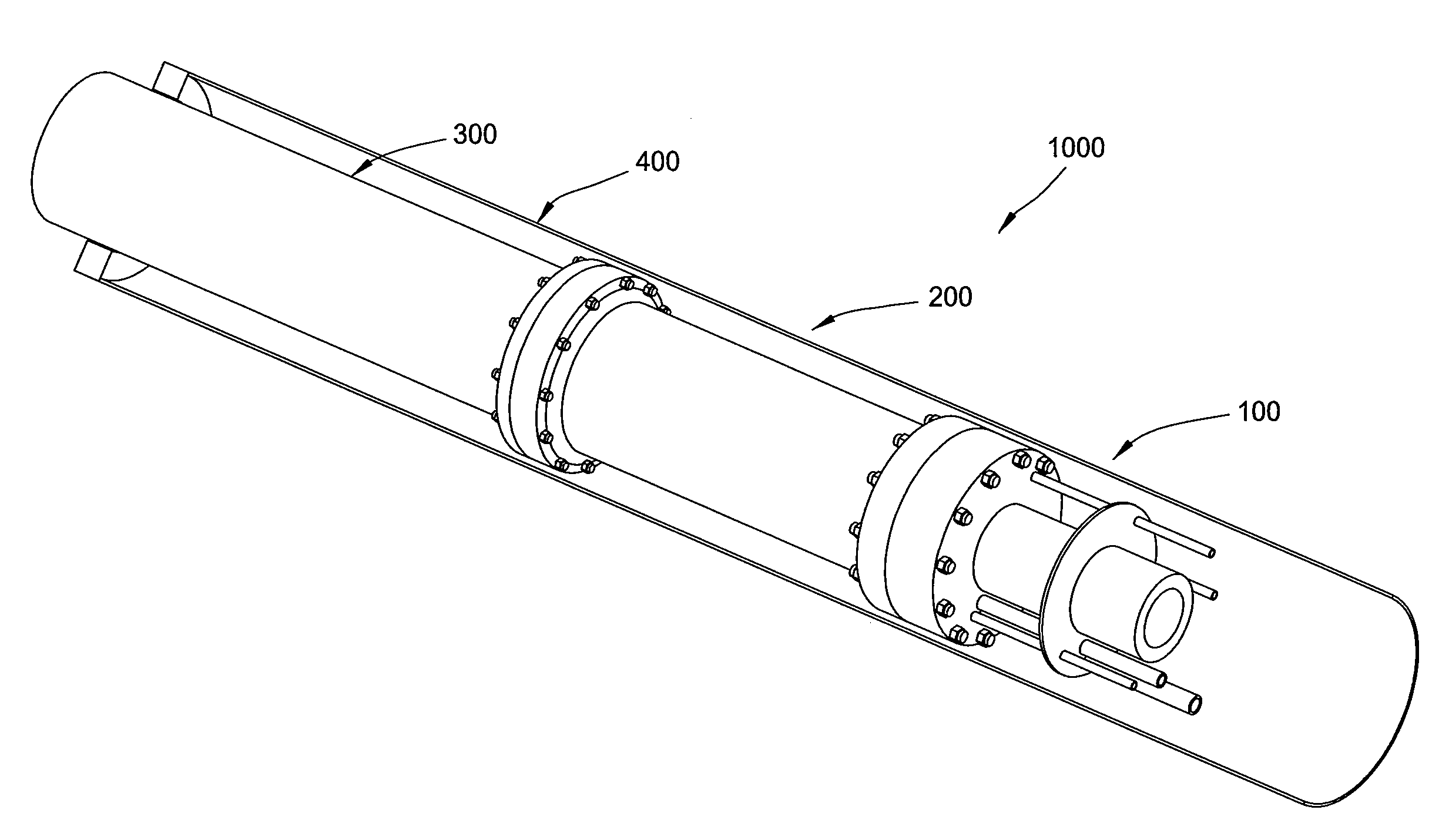

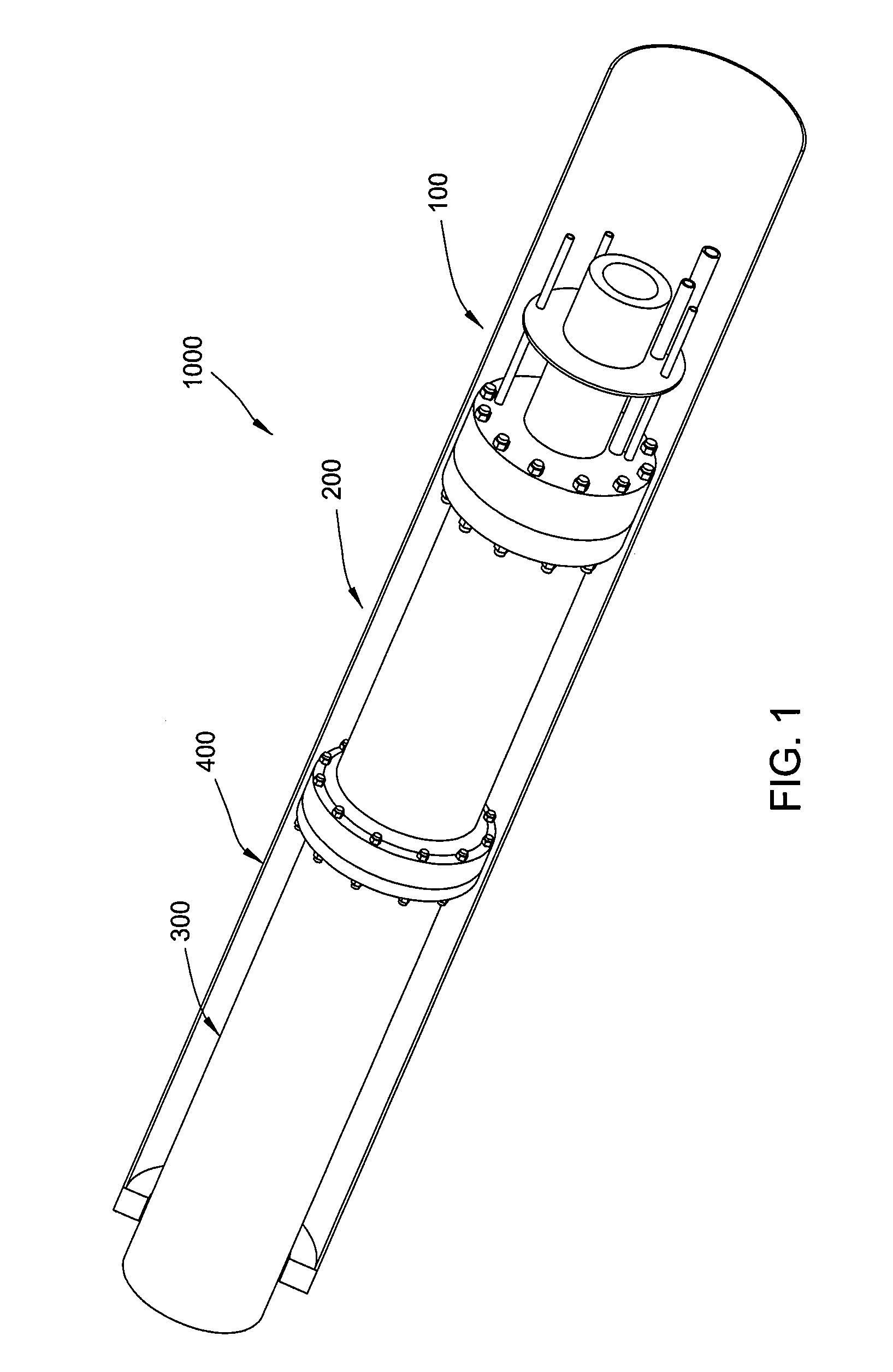

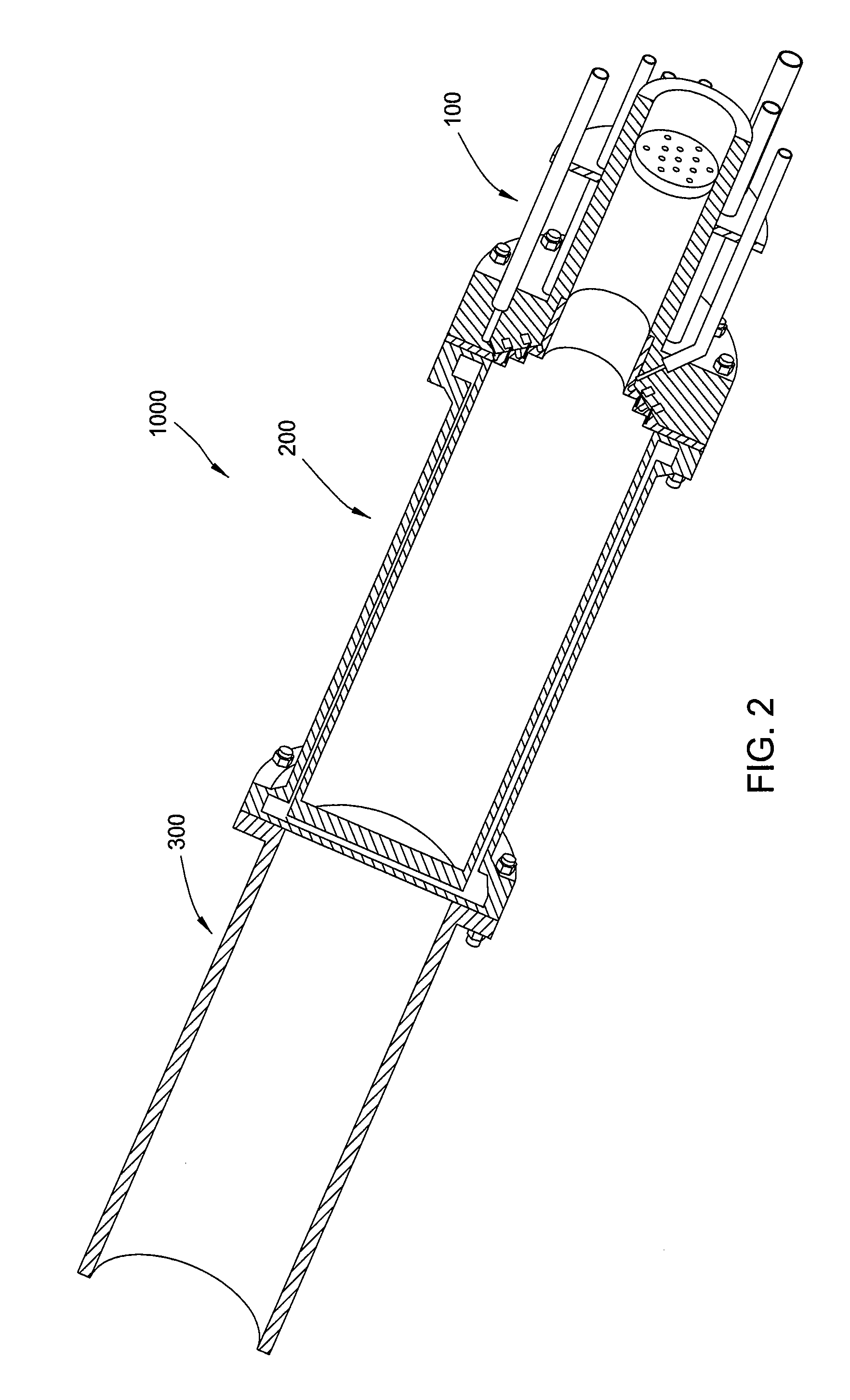

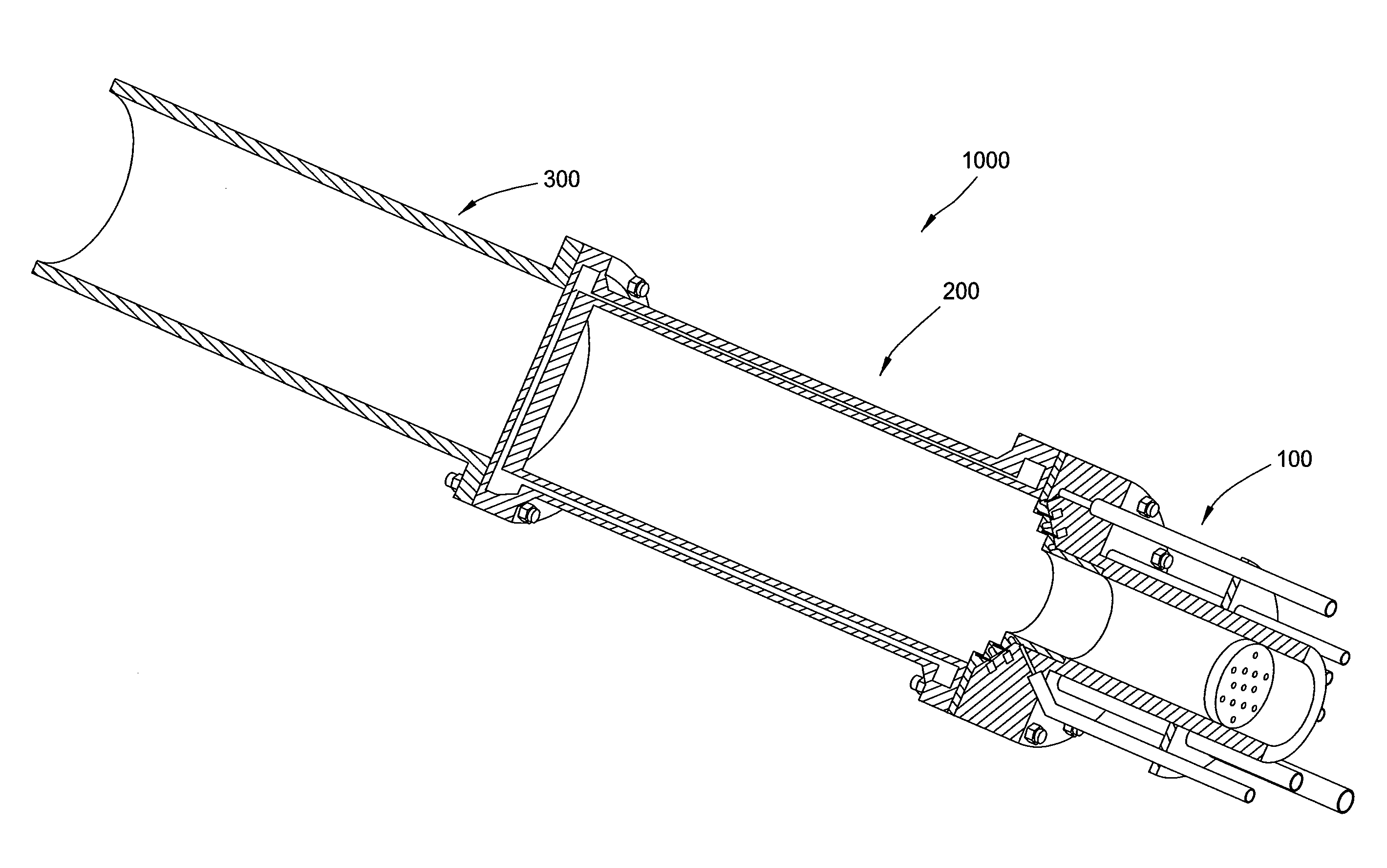

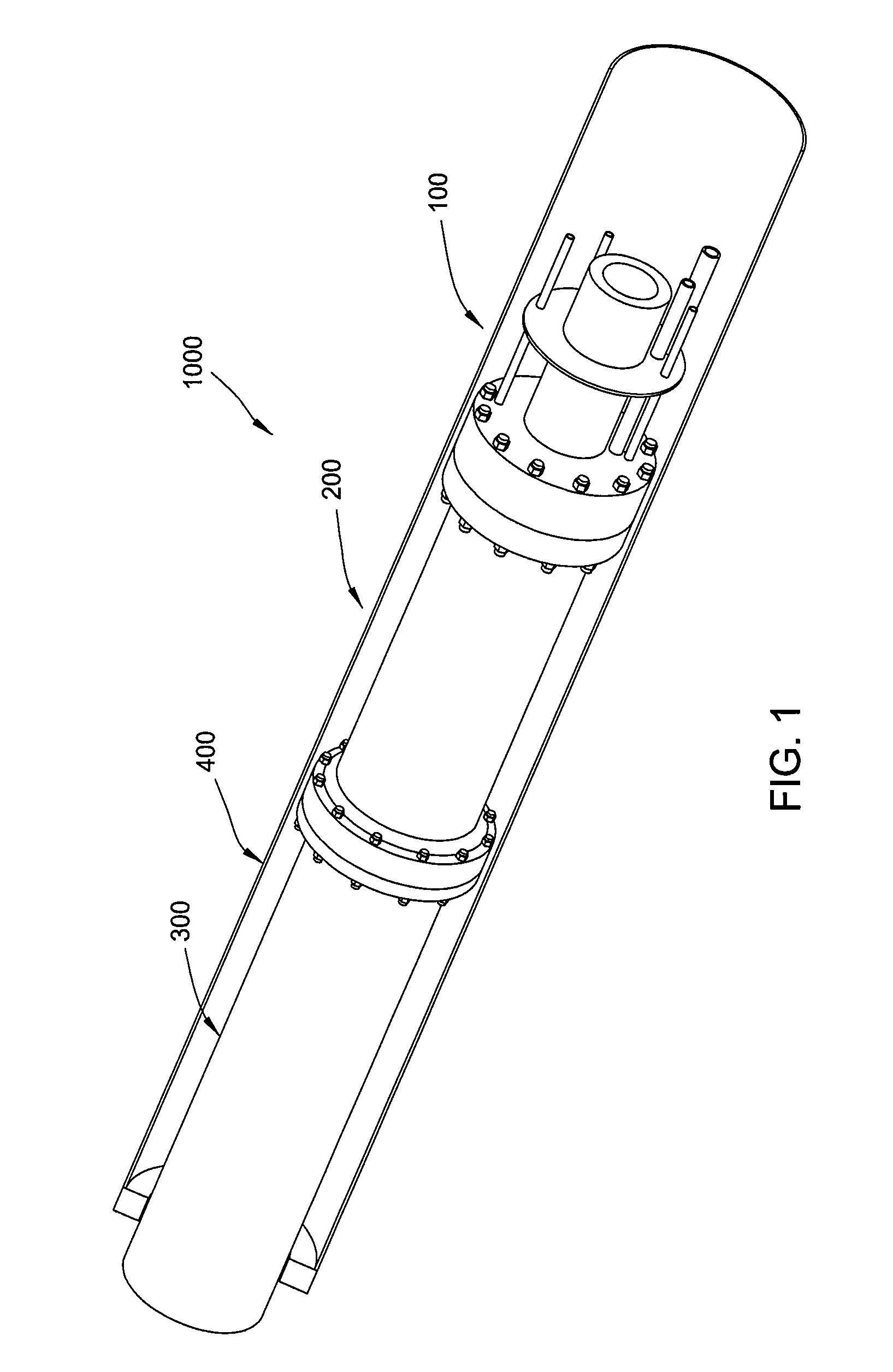

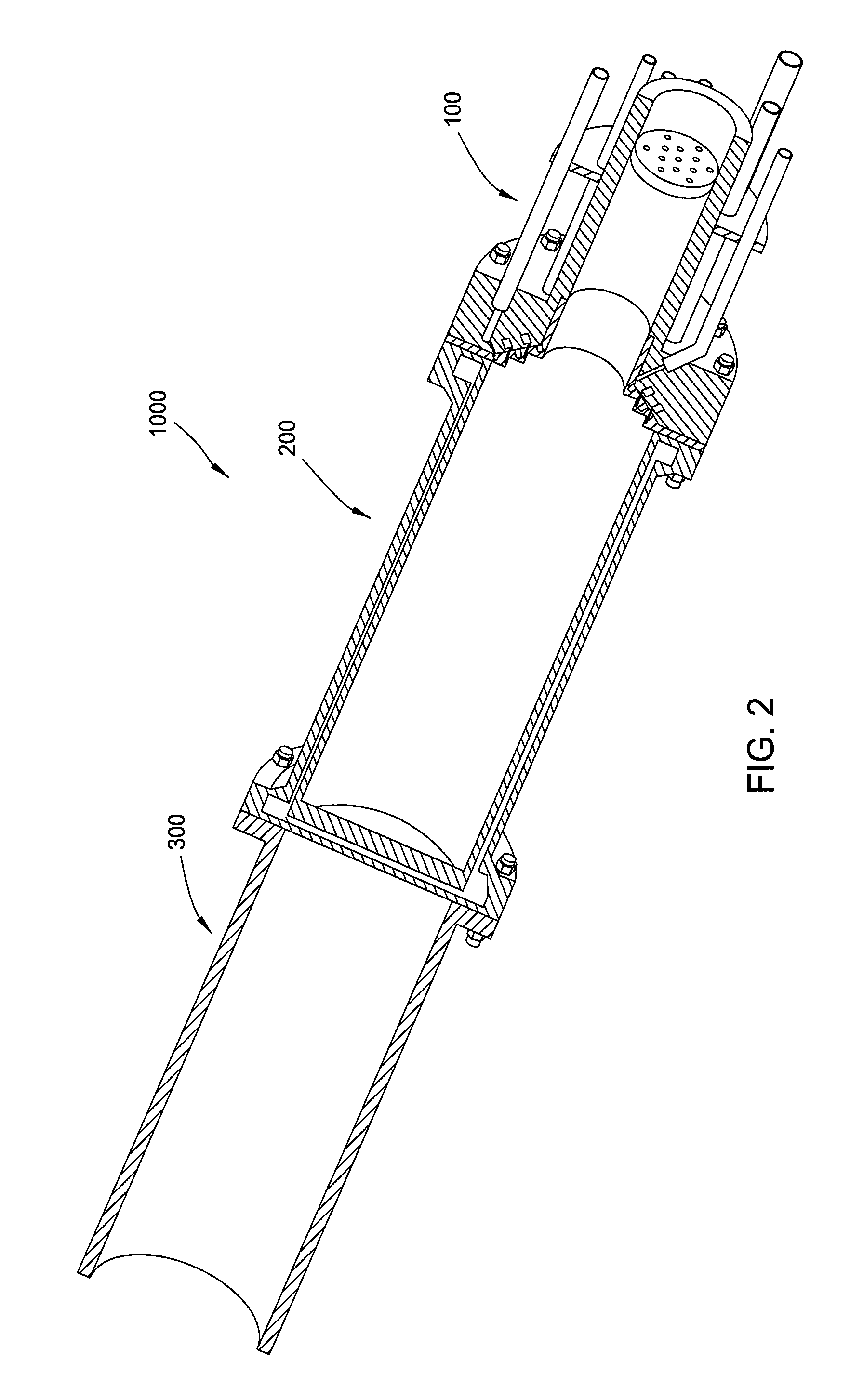

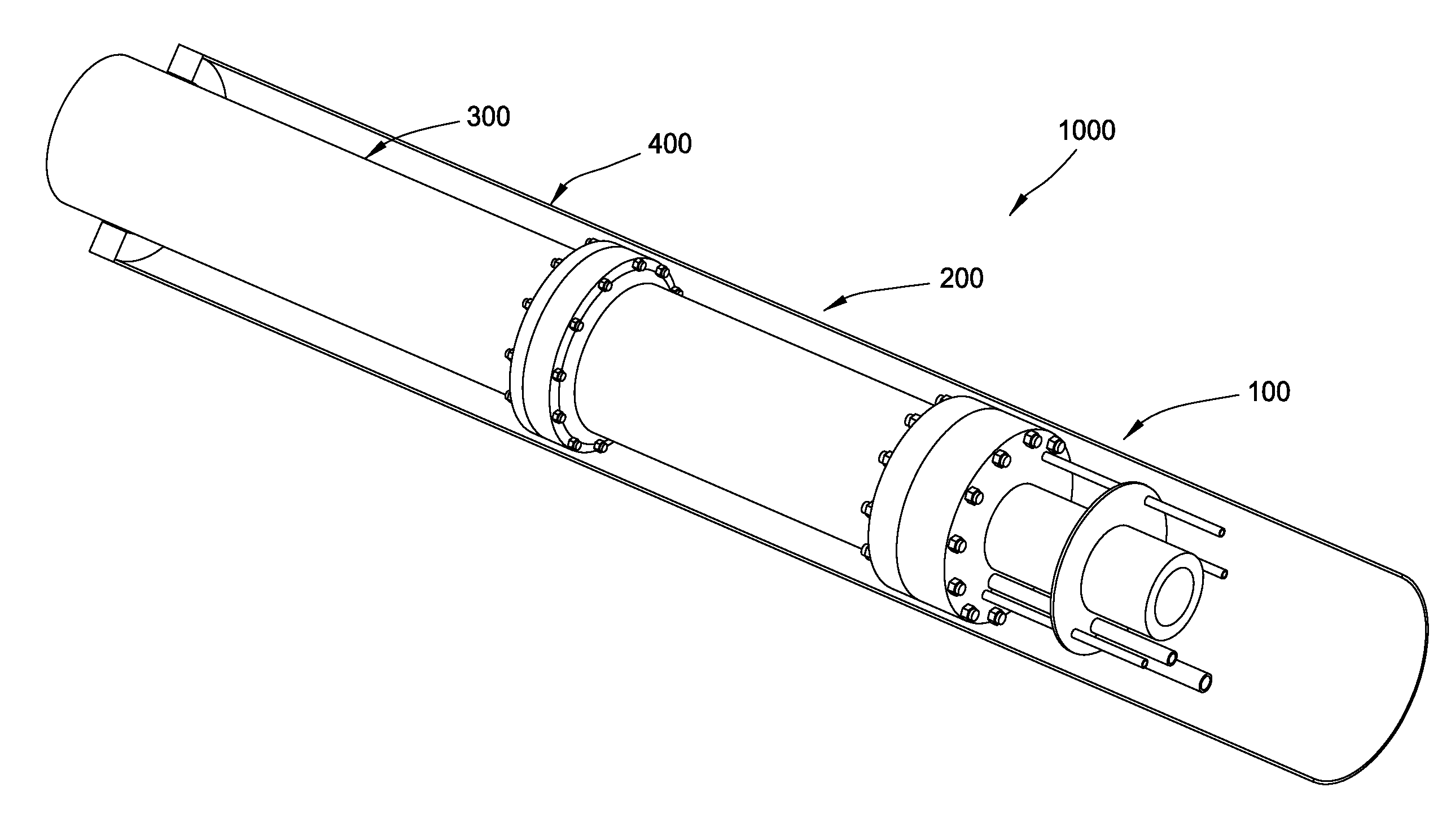

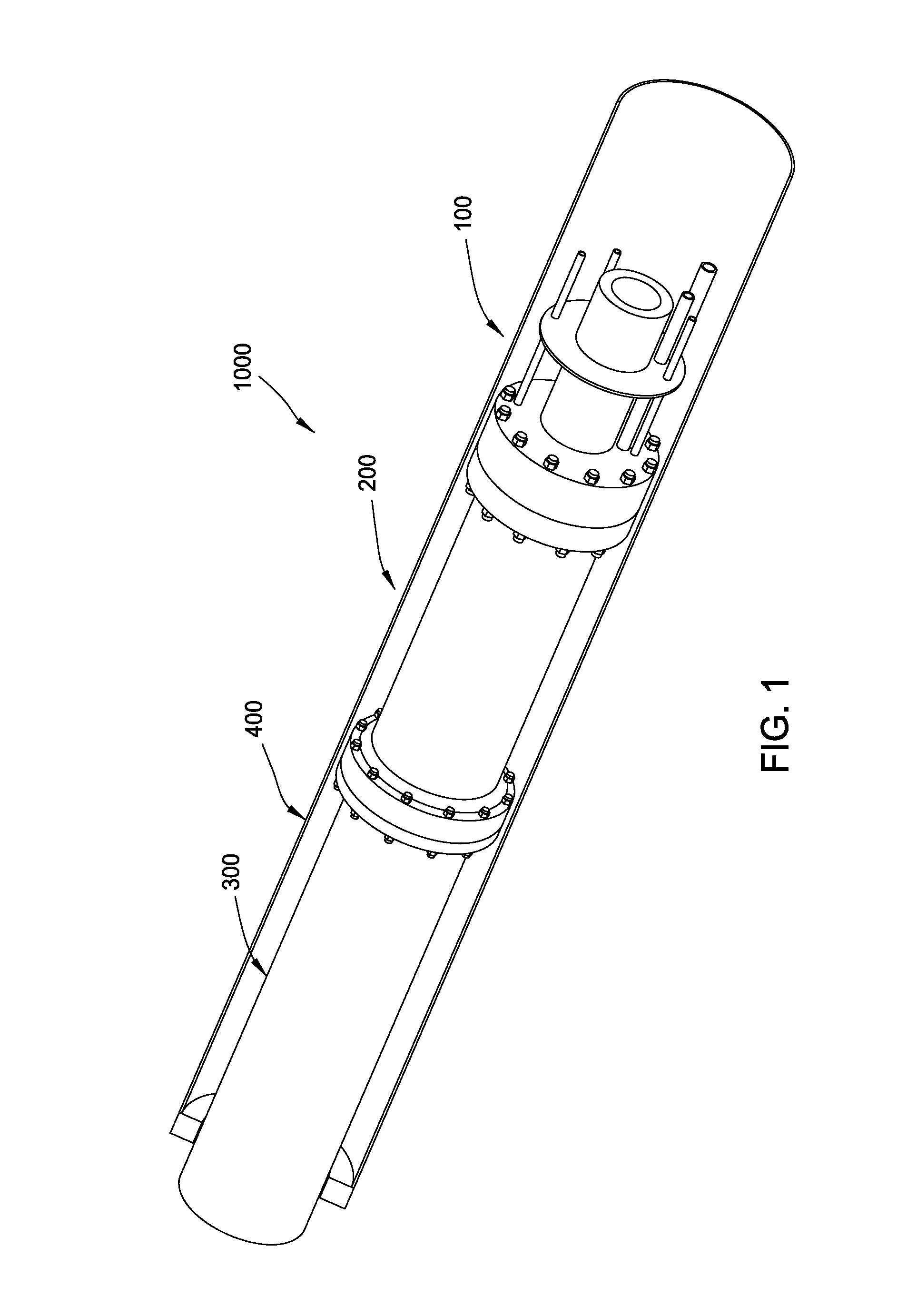

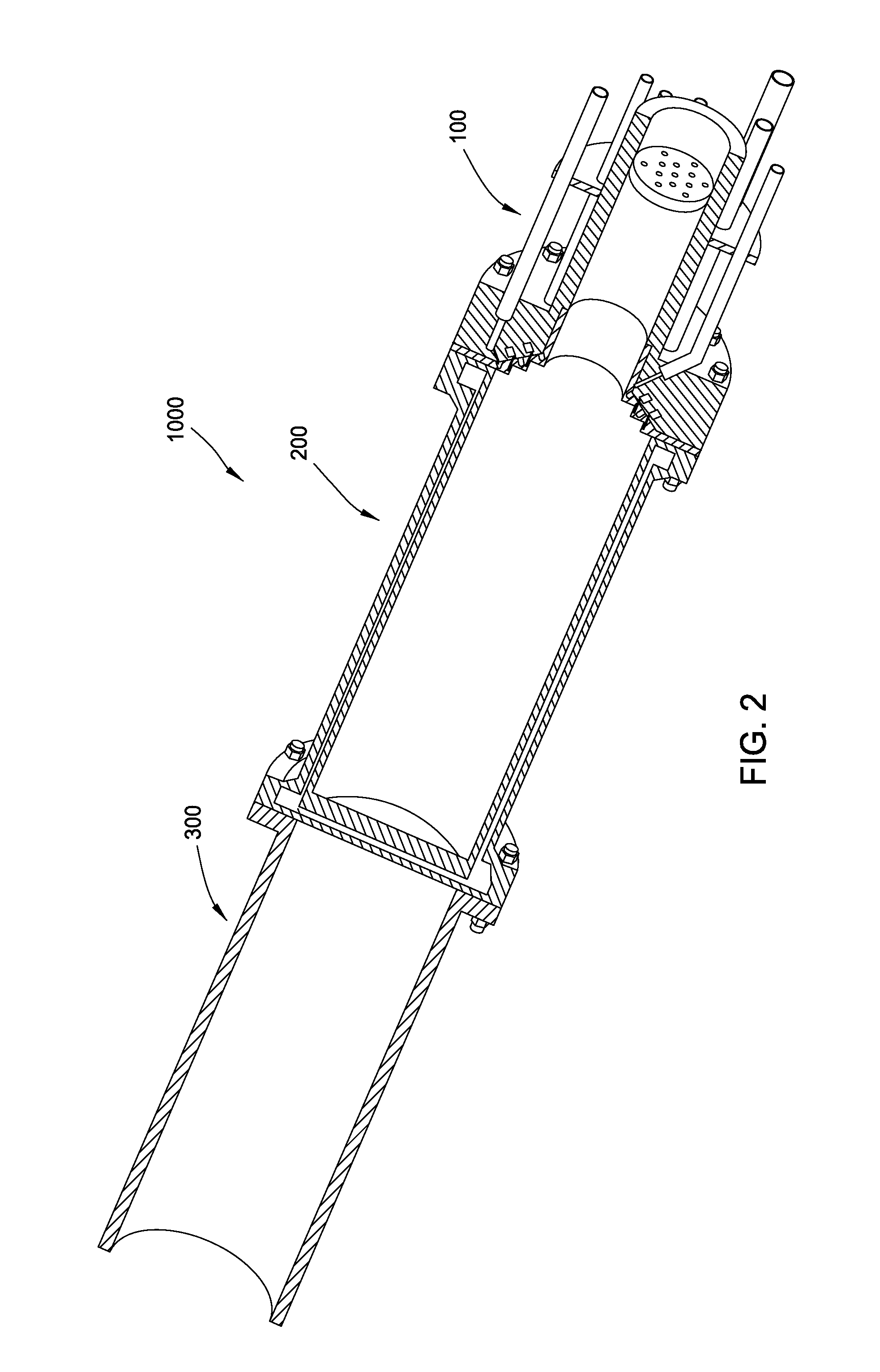

Downhole steam generator and method of use

A downhole steam generation system may include a burner head assembly, a liner assembly, a vaporization sleeve, and a support sleeve. The burner head assembly may include a sudden expansion region with one or more injectors. The liner assembly may include a water-cooled body having one or more water injection arrangements. The system may be optimized to assist in the recovery of hydrocarbons from different types of reservoirs. A method of recovering hydrocarbons may include supplying one or more fluids to the system, combusting a fuel and an oxidant to generate a combustion product, injecting a fluid into the combustion product to generate an exhaust gas, injecting the exhaust gas into a reservoir, and recovering hydrocarbons from the reservoir.

Owner:WORLD ENERGY SYST

Portable steam and heat generator

The present invention is directed to an apparatus for directing steam, hot water or hot water vapor and hot air onto a target area, the apparatus comprising a water container and a fuel container connected and supplying water and fuel to an applicator wand with an applicator head which generates steam and heat for application adjacent to the target area of application to the unwanted vegetation. Steam is generated immediately adjacent to the target area within the applicator head and combined with surplus heat from the steam generation process to produce heated steam and water vapor for application to the target area. In a preferred embodiment of the invention, the applicator wand is hand held, the applicator head having an inlet, an outlet and a body therebetween, the water and fuel being supplied to a steam generator and burner within the body of the applicator head which generates steam and hot air adjacent to the target area for application through the outlet to the target area.

Owner:GREENSTEAM

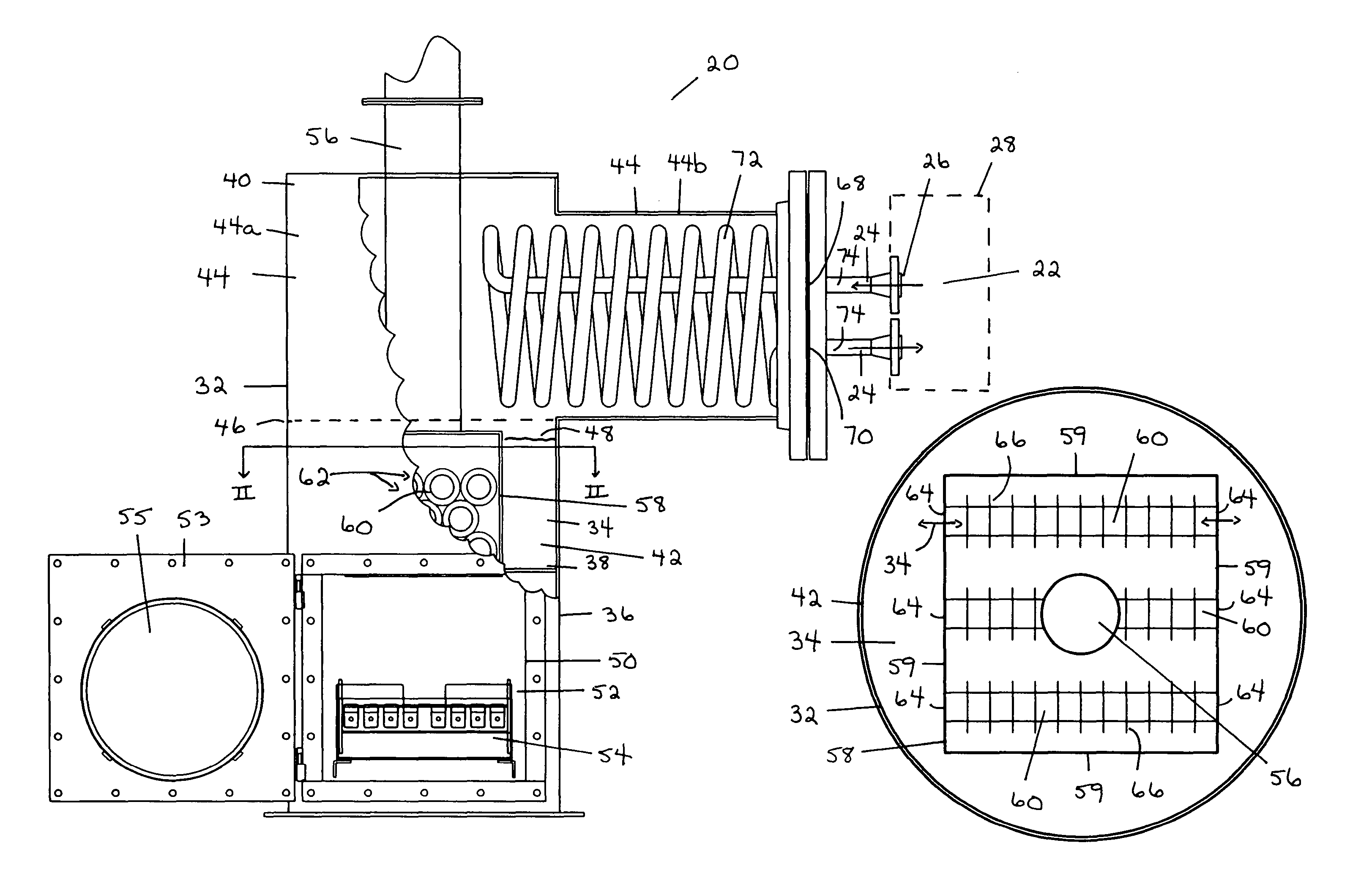

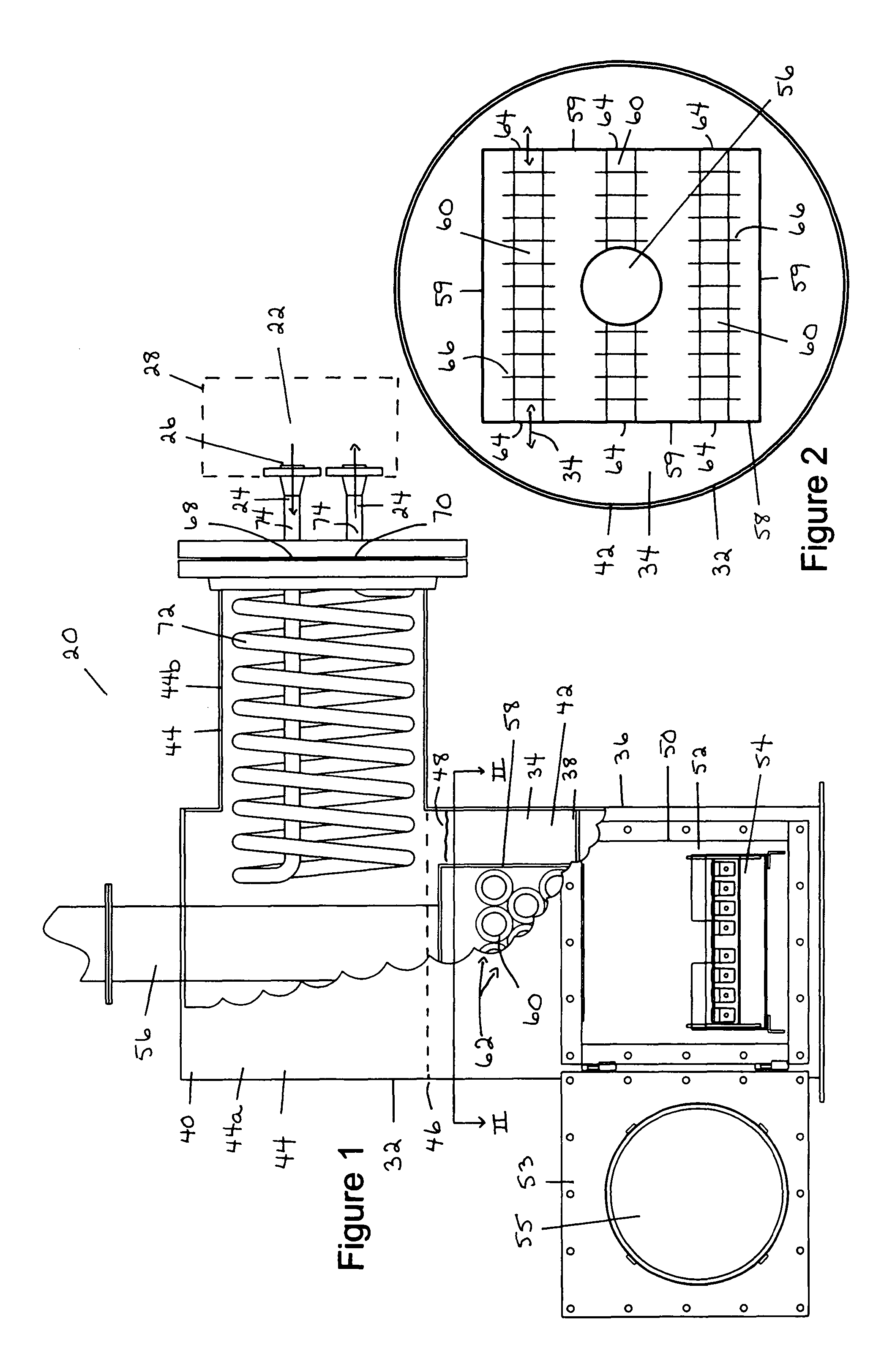

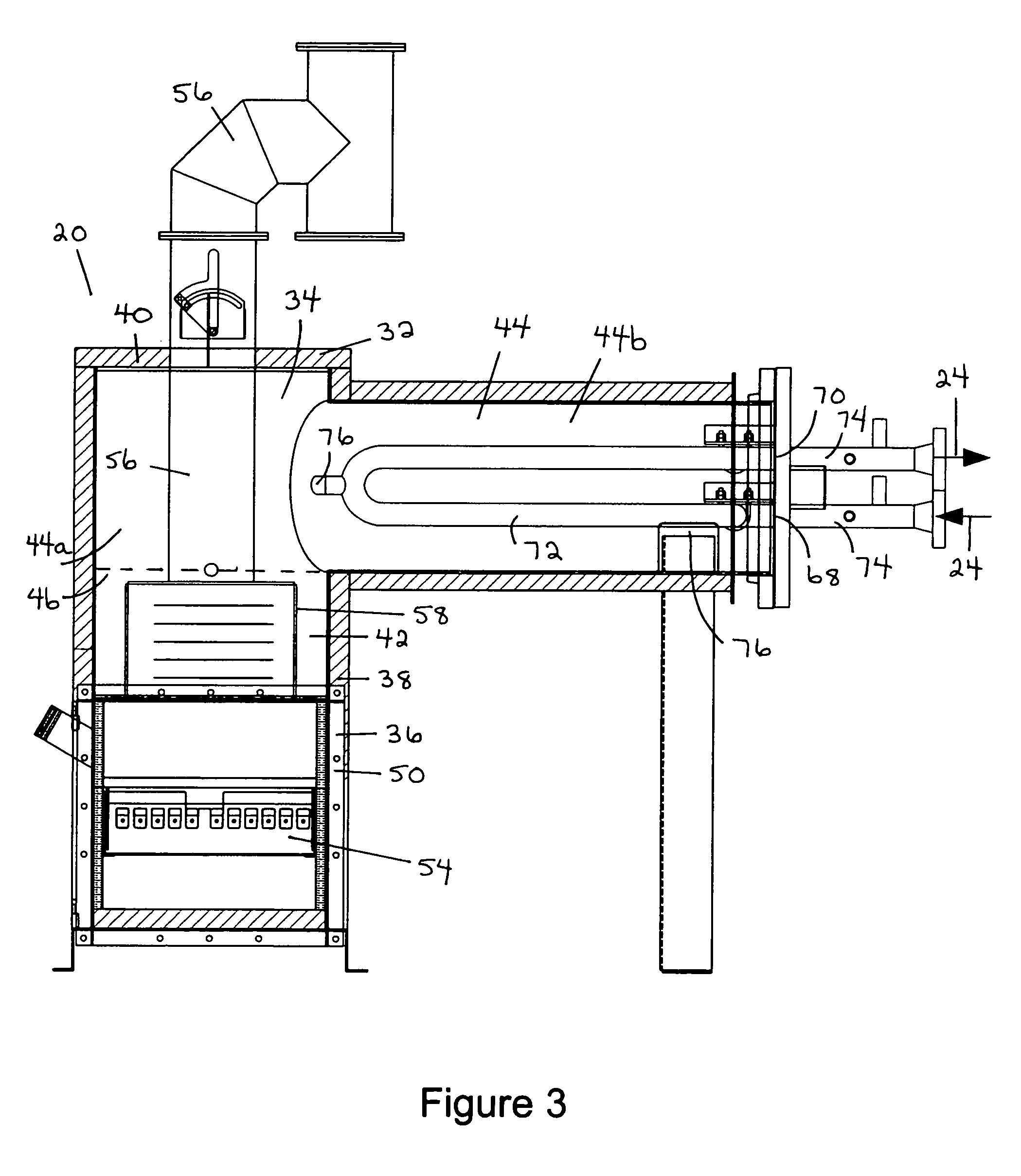

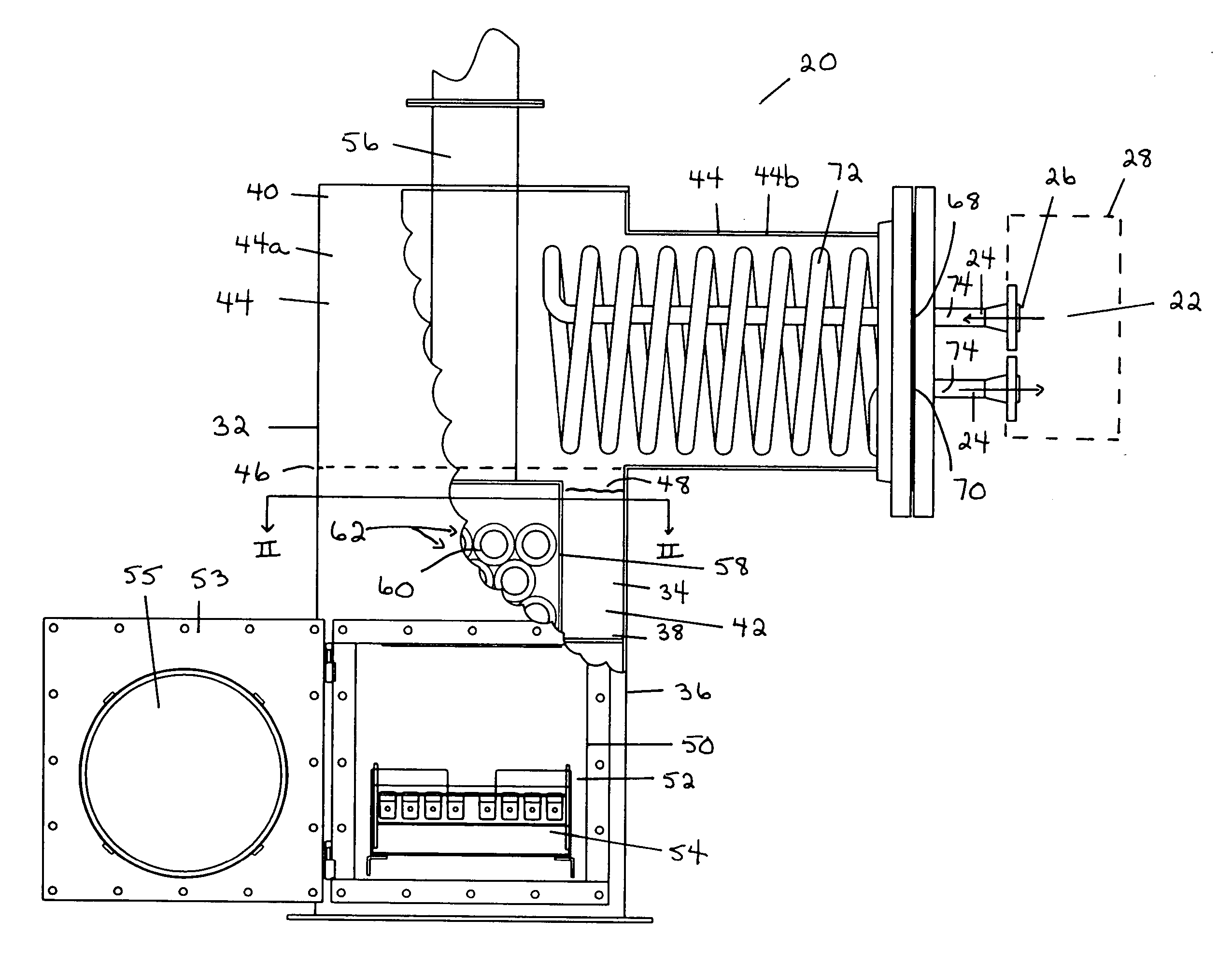

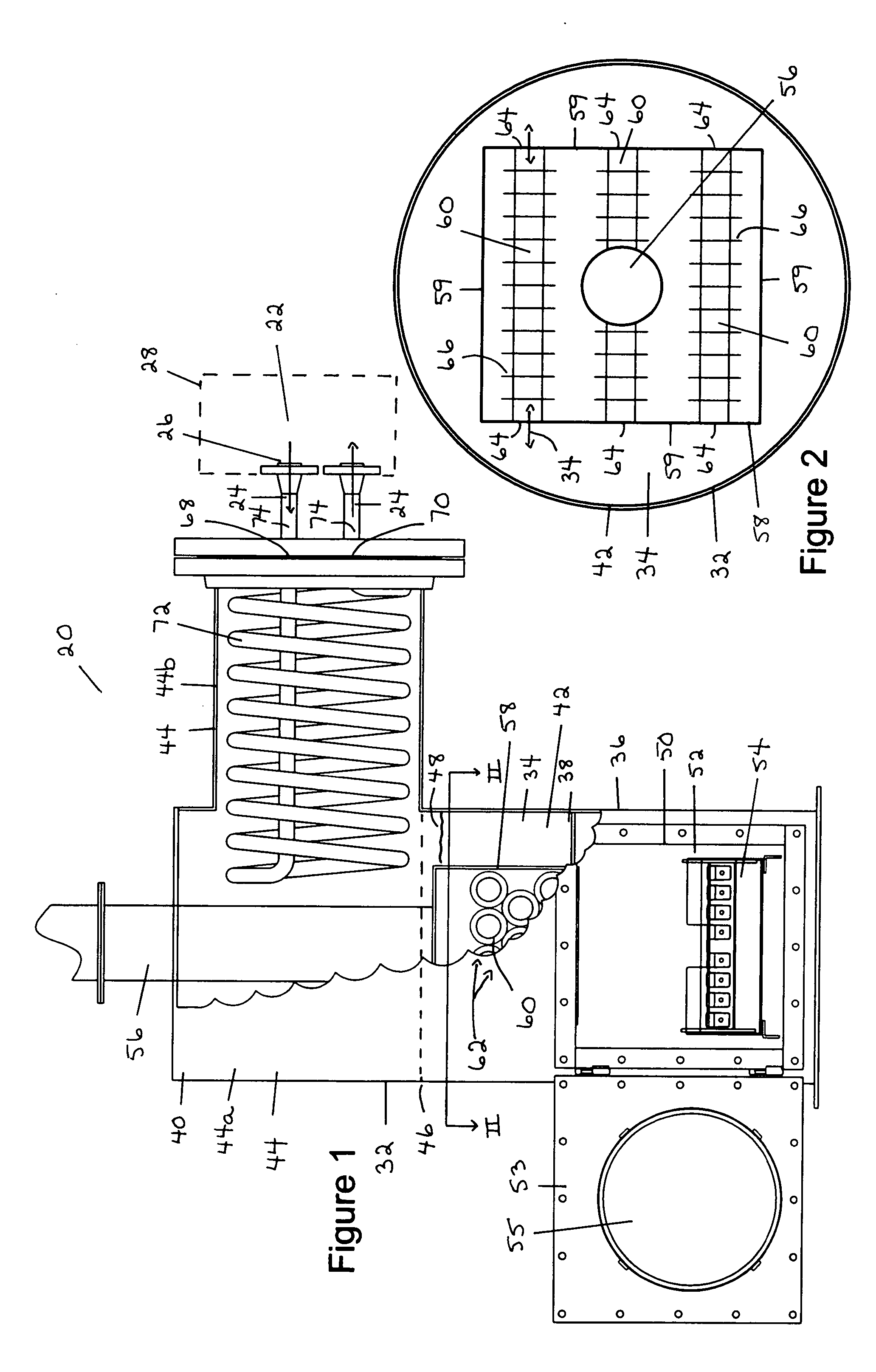

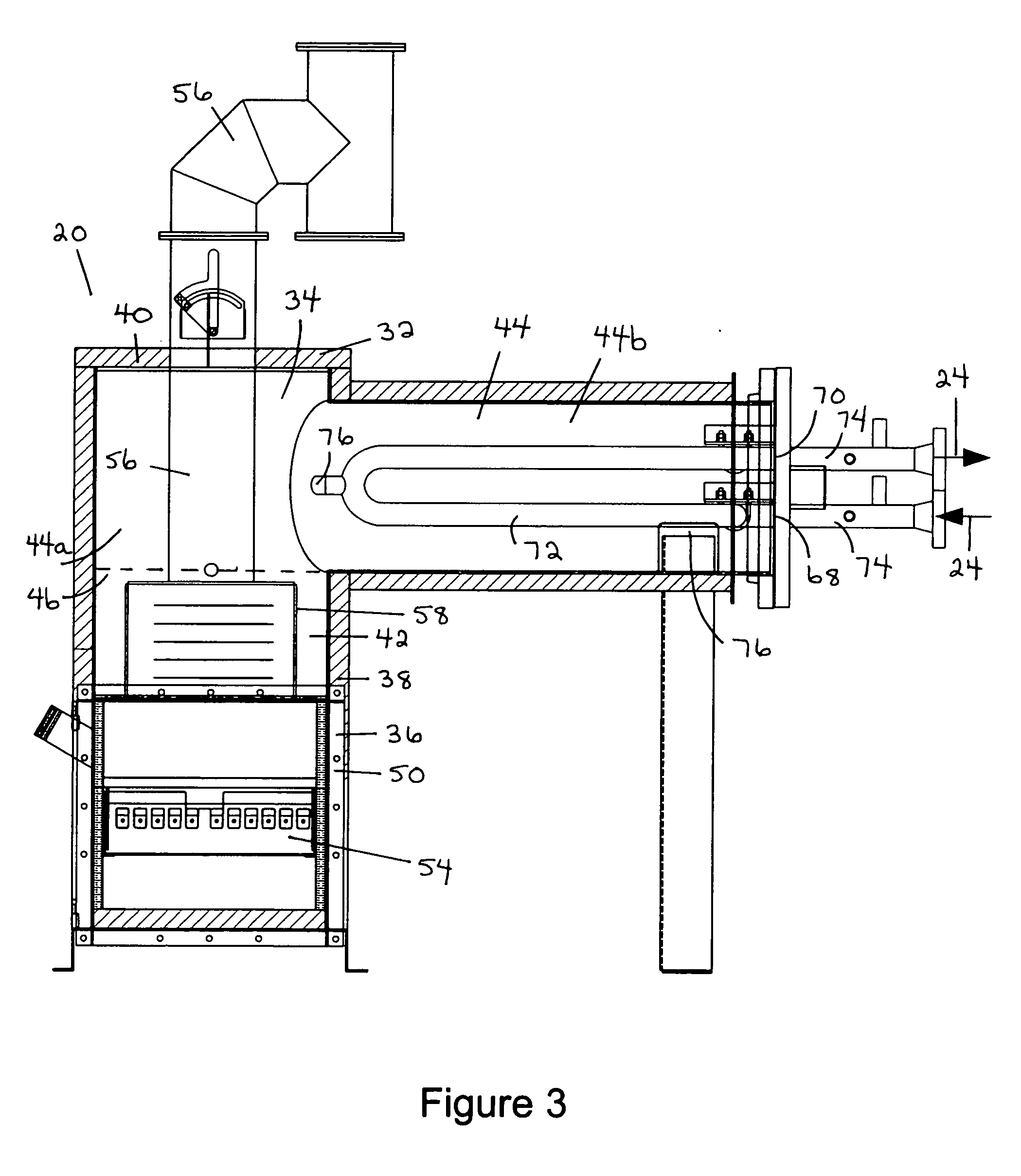

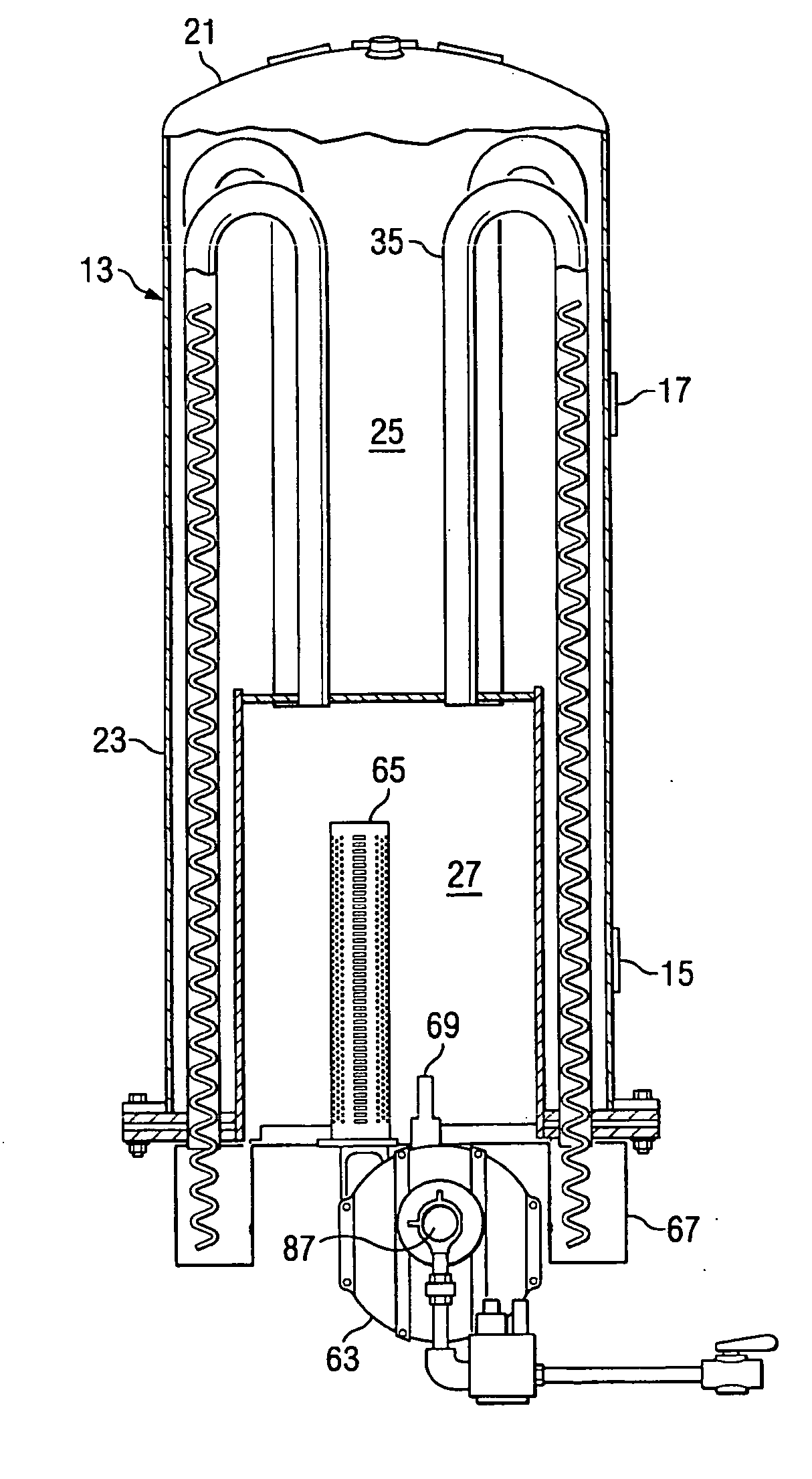

Heat exchange apparatus

ActiveUS7841305B2Improve heat transfer effectSteam generation using pressureSubmerged flame steam boilersEngineeringPressure reduction

A heat exchange apparatus for use in transferring heat to a heat sink. Preferably, the heat sink is comprised of a natural gas supply line at a pressure reduction station. Alternately, the heat sink is comprised of a storage tank. The apparatus is comprised of a heat exchange vessel, adapted to contain an amount of a heat exchange fluid, and a heat source. The heat exchange vessel includes a sump section at a lower end thereof, and a heat transfer section for transferring heat to the heat sink. The heat exchange vessel further includes a single communication junction between the sump section and the heat transfer section which provides fluid communication therebetween. The heat source is associated with the sump section and adapted to add heat to the heat exchange fluid in order to cause the heat exchange fluid to evaporate in the heat exchange vessel.

Owner:TECVALCO LTD

Heat exchange apparatus

ActiveUS20070000453A1Improve heat transfer effectSteam generation using pressureSubmerged flame steam boilersEngineeringPressure reduction

A heat exchange apparatus for use in transferring heat to a heat sink. Preferably, the heat sink is comprised of a natural gas supply line at a pressure reduction station. Alternately, the heat sink is comprised of a storage tank. The apparatus is comprised of a heat exchange vessel, adapted to contain an amount of a heat exchange fluid, and a heat source. The heat exchange vessel includes a sump section at a lower end thereof, and a heat transfer section for transferring heat to the heat sink. The heat exchange vessel further includes a single communication junction between the sump section and the heat transfer section which provides fluid communication therebetween. The heat source is associated with the sump section and adapted to add heat to the heat exchange fluid in order to cause the heat exchange fluid to evaporate in the heat exchange vessel.

Owner:TECVALCO LTD

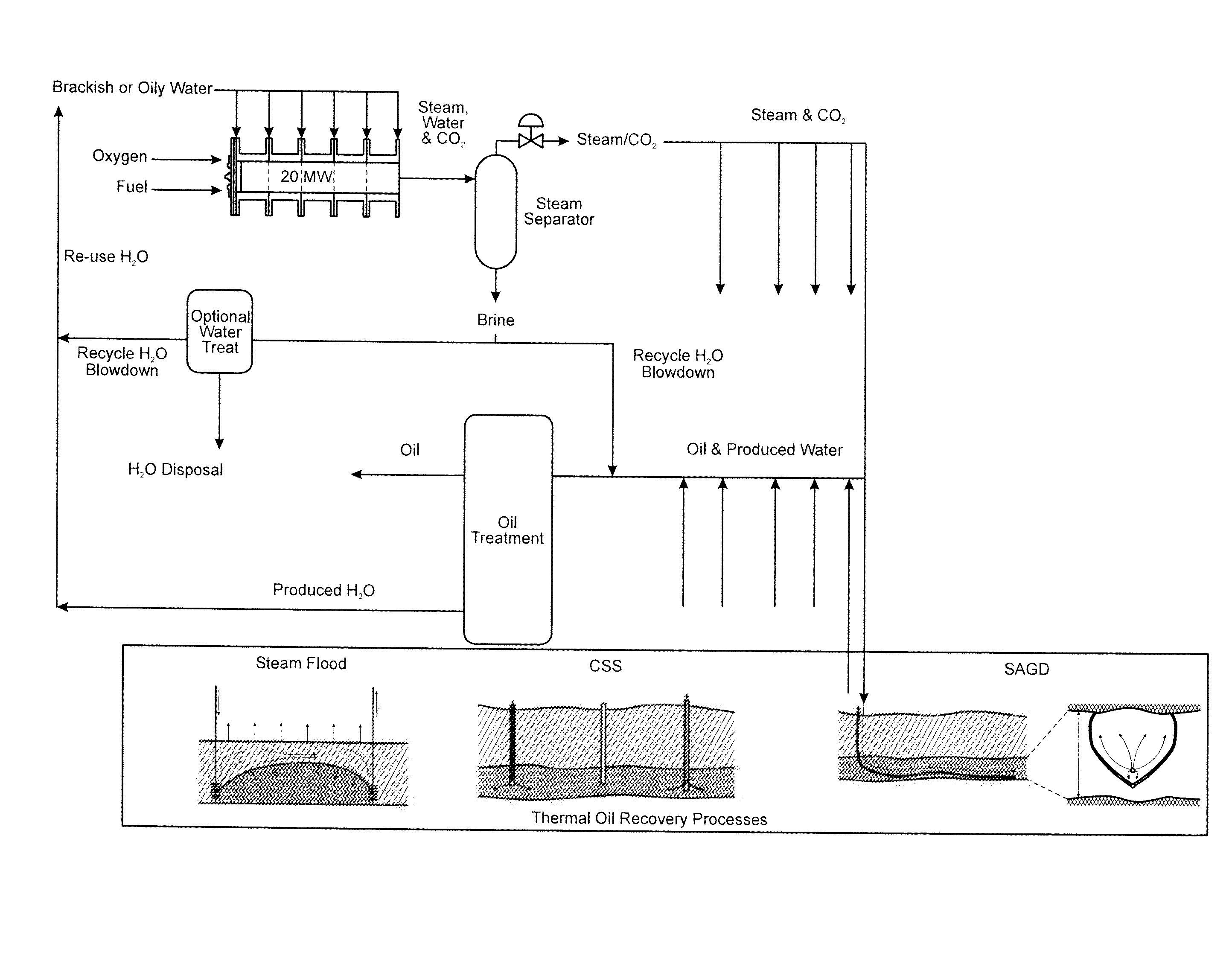

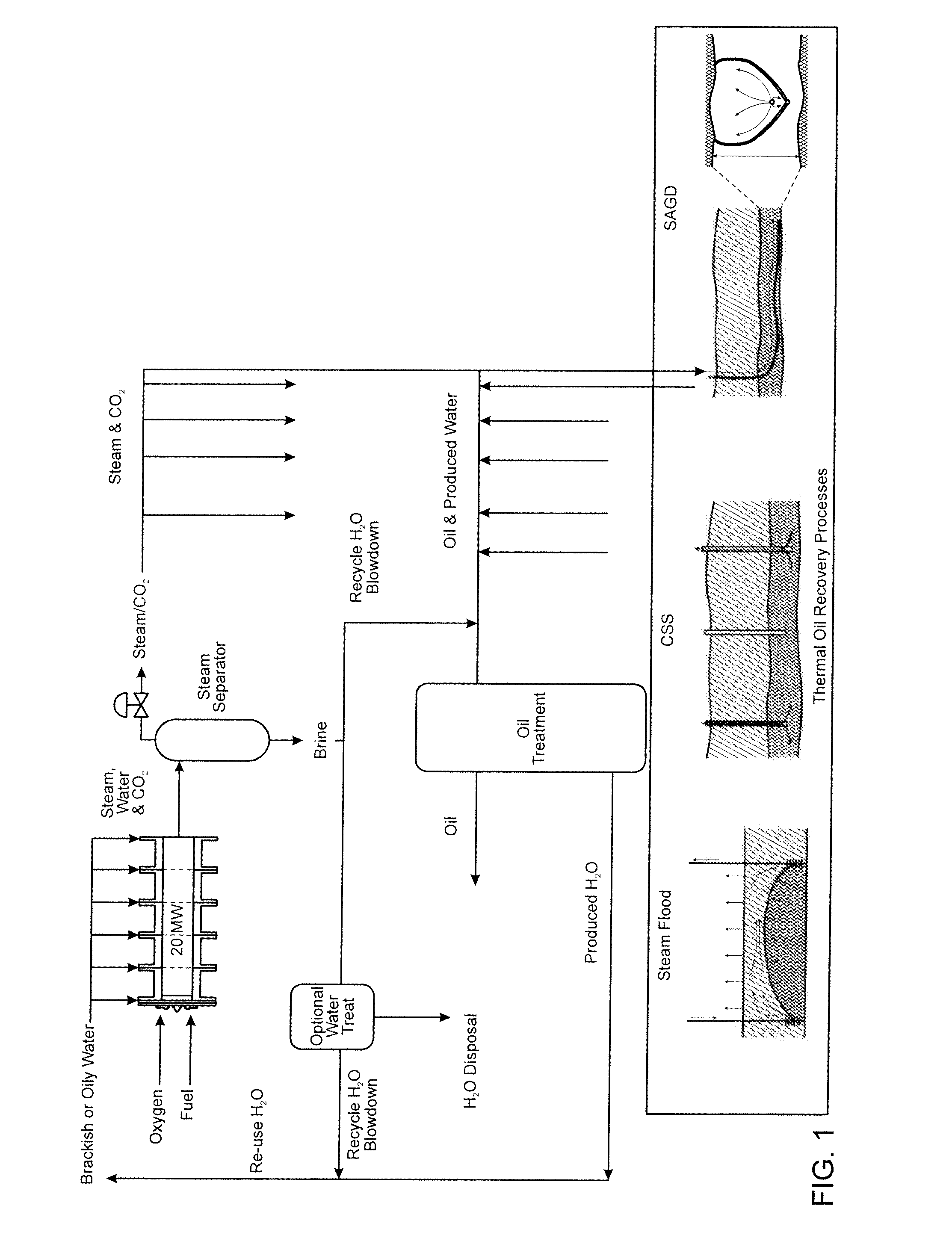

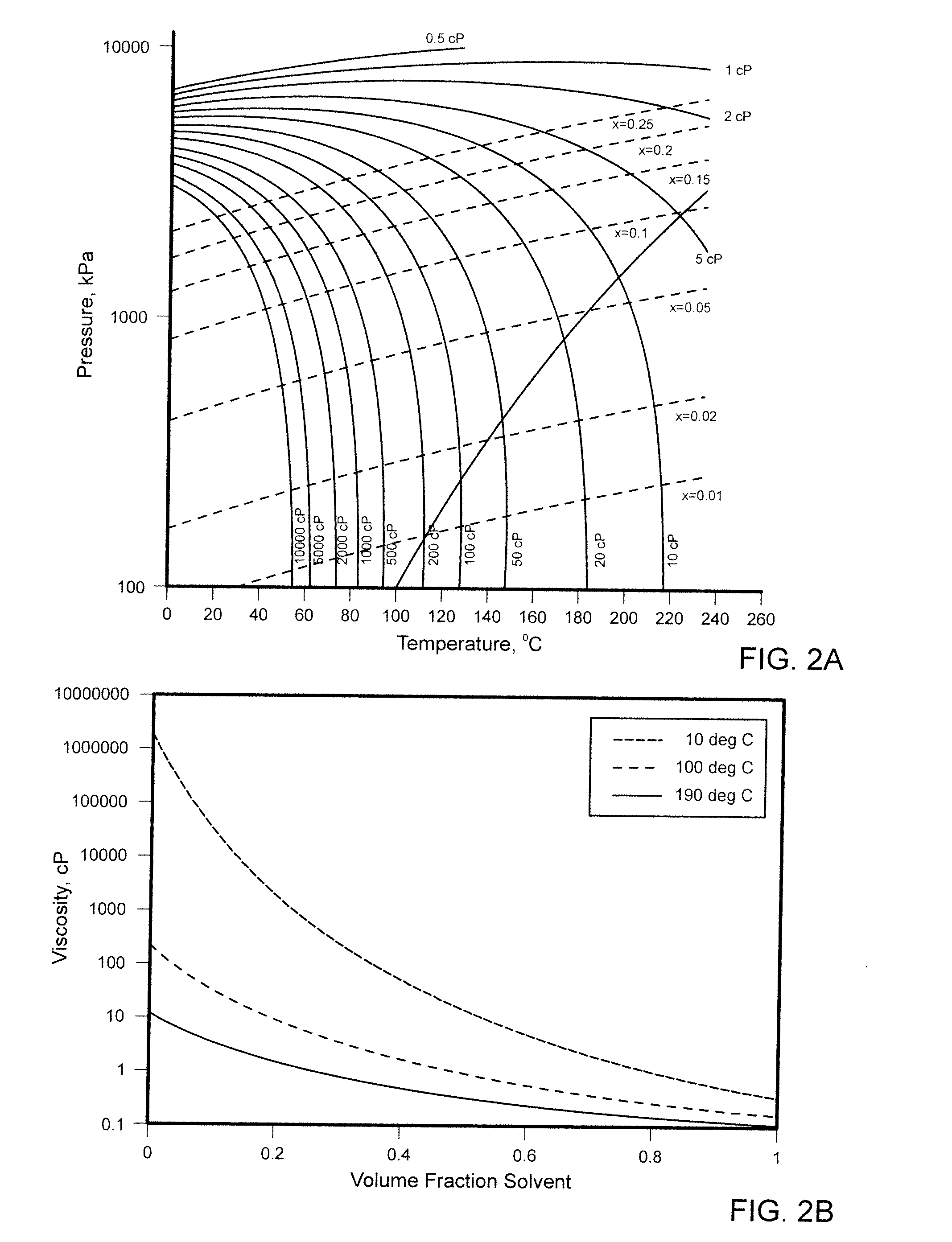

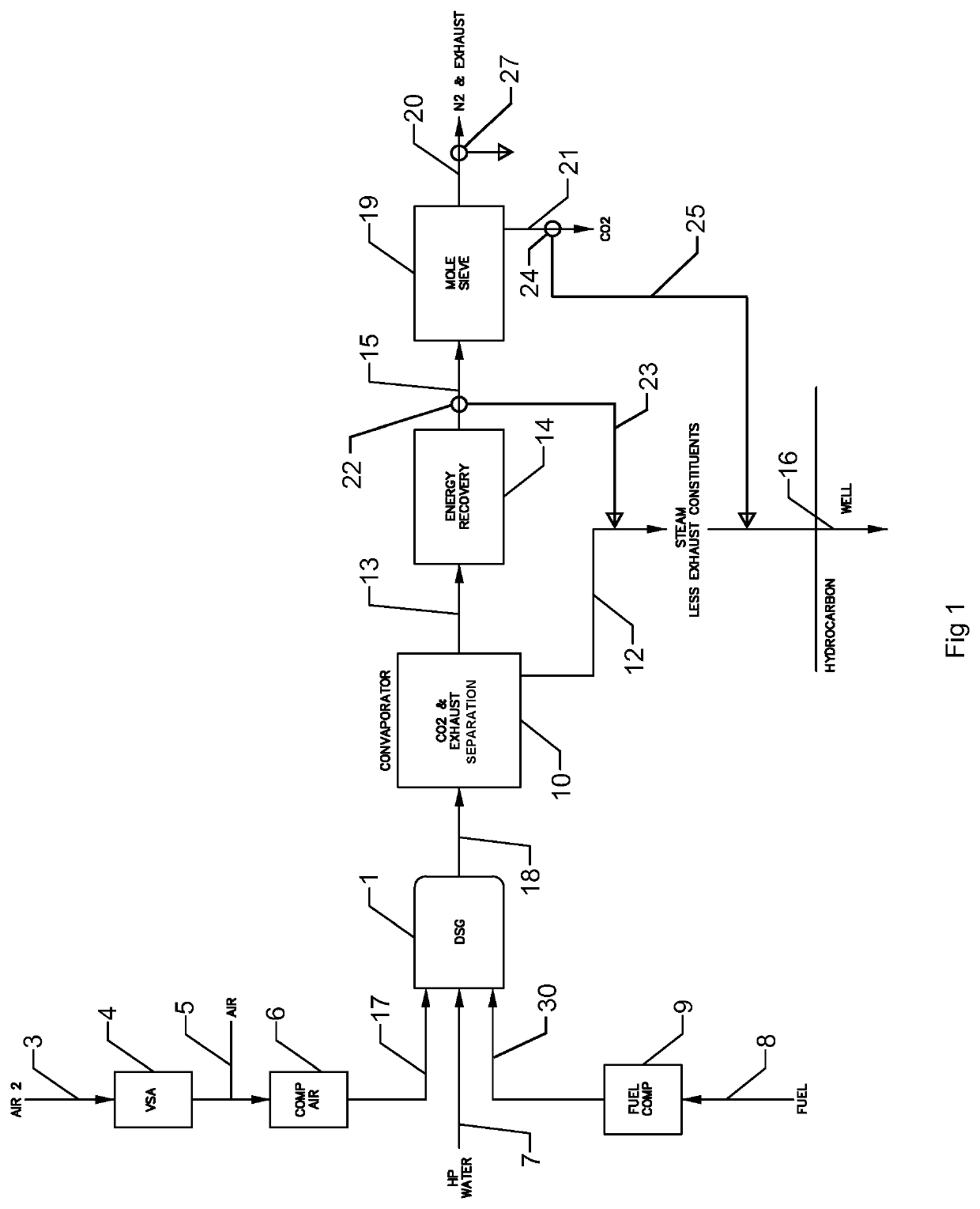

Zero emission steam generation process

InactiveUS20120160187A1Eliminate requirementsImprove thermal efficiencySteam generation using pressureSubmerged flame steam boilersWater requirementProduced water

This invention provides a new process to generate steam directly from untreated water produced simultaneously with thermally recovered crude oil, and to inject the steam and combustion products into a hydrocarbon reservoir to recover hydrocarbons and to sequester a portion of the carbon dioxide produced during the creation of steam. The invention removes the ongoing additional water requirements for thermal oil recovery and the need for surface treating of produced water for re-use, yielding improved process efficiencies, reduced environmental impact, and improved economic value.

Owner:PAXTON CORP +2

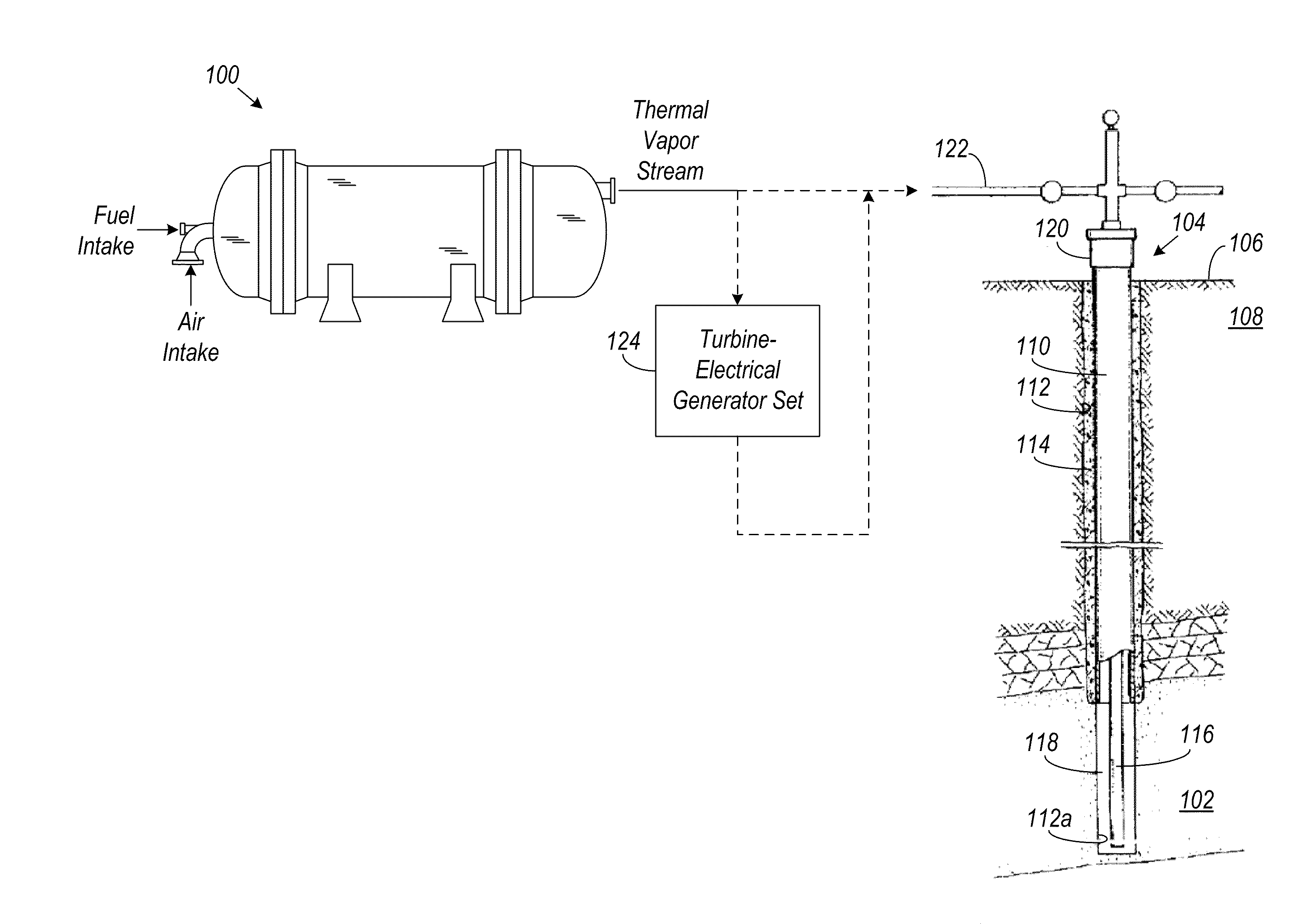

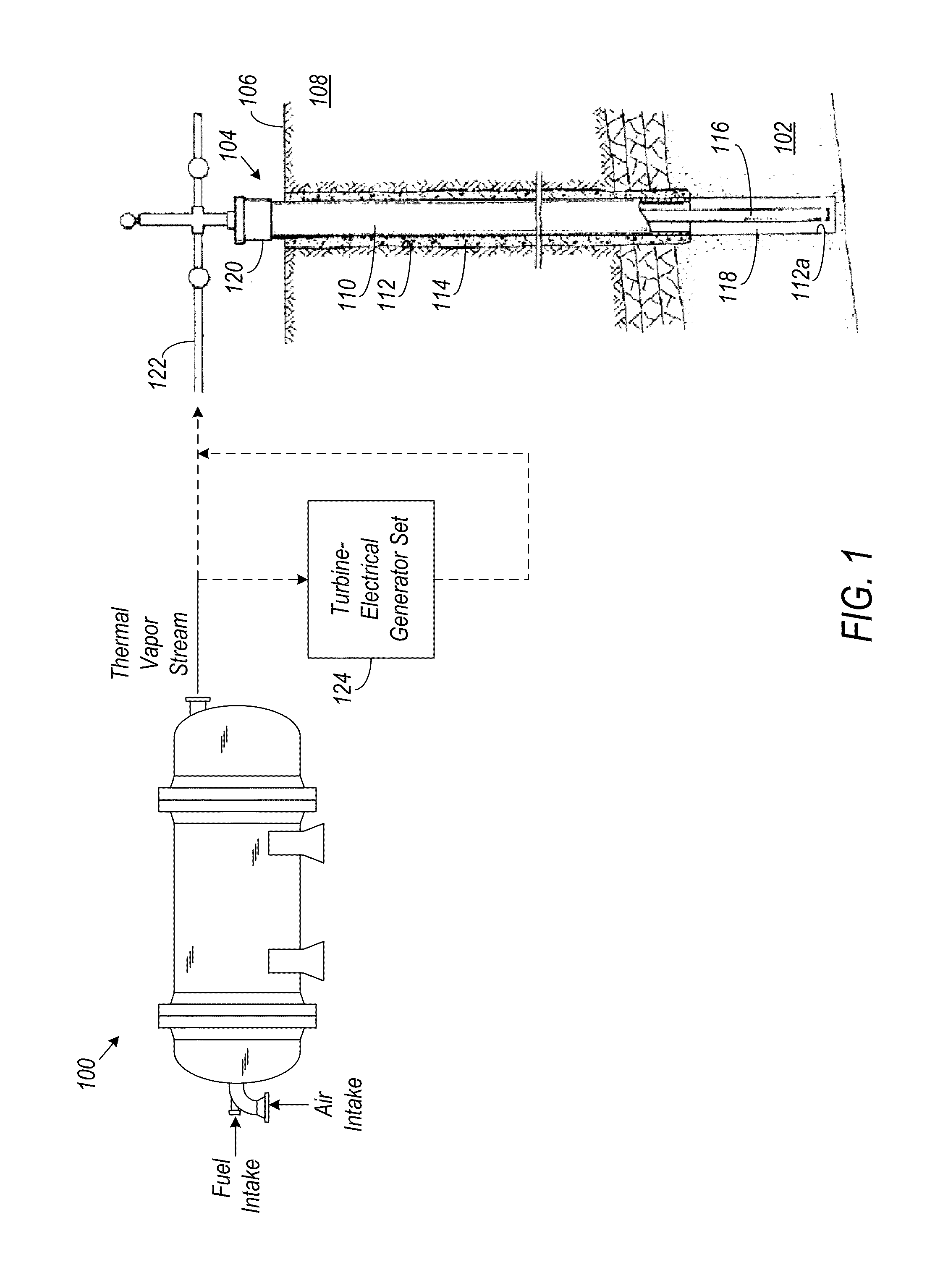

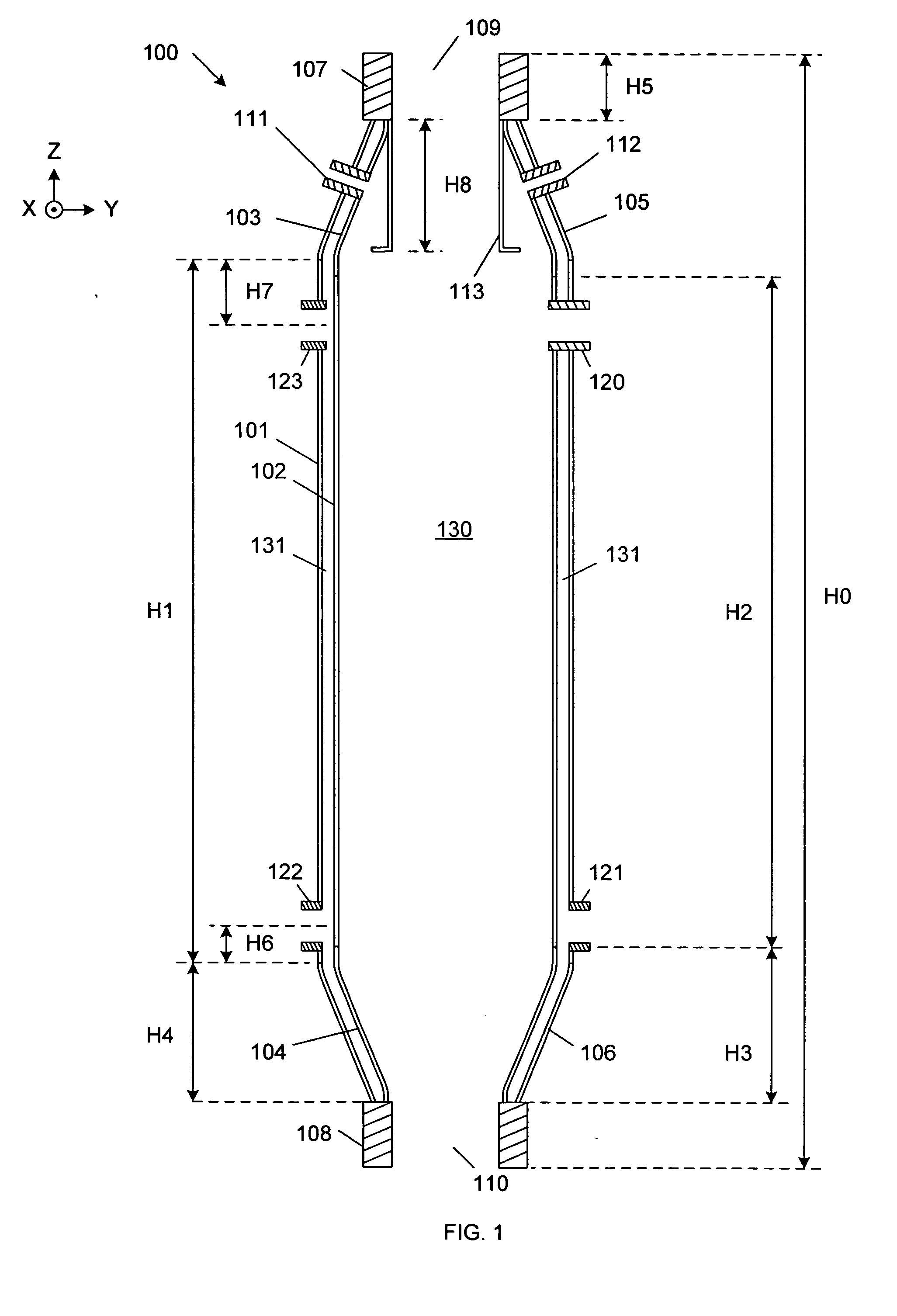

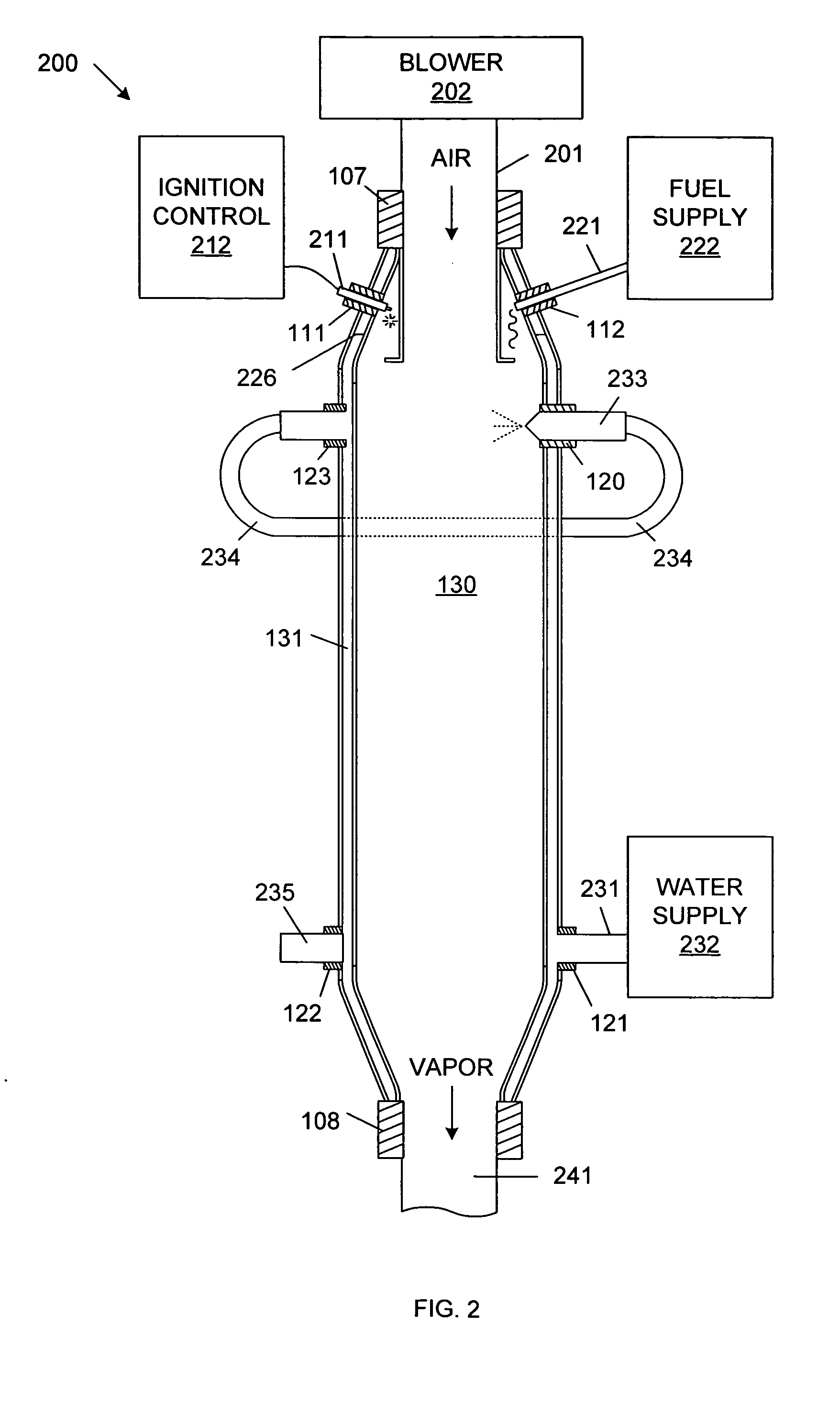

Thermal vapor stream apparatus and method

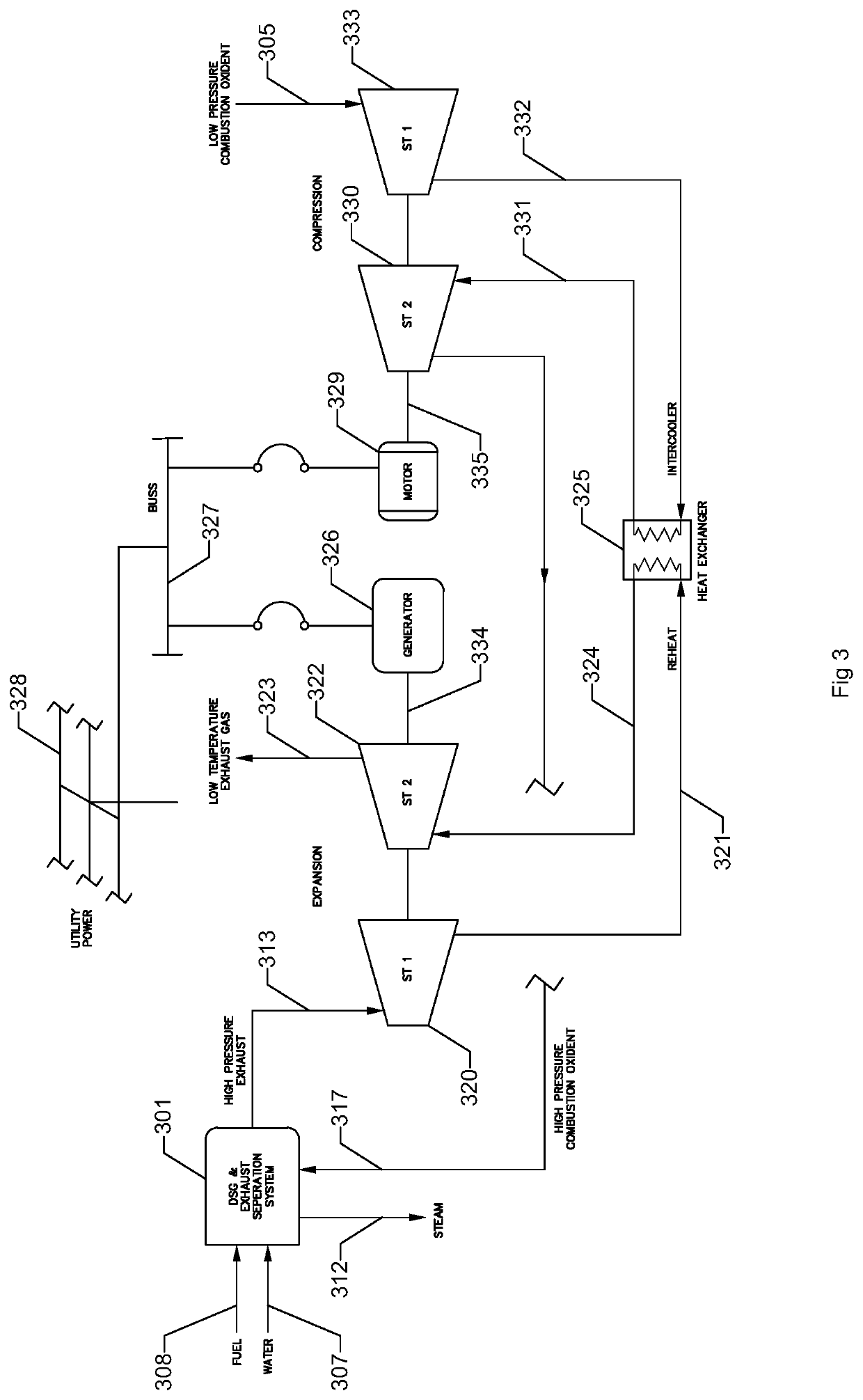

InactiveUS20110036095A1Easy injectionPromote recoverySteam generation using pressureGas turbine plantsEngineeringHigh pressure

A low emission and environmentally friendly apparatus and method is used to generate a high pressure stream of thermal vapor. The thermal vapor stream may be injected into a subterranean formation for recovery of highly viscous petroleum or used to turn a steam turbine for driving an electrical generator. In one implementation, the high pressure stream of thermal vapor is generated by burning a high temperature fuel, including any short or long chain hydrocarbon products from methane to coal, in an enclosed vessel to produce combustion gases. Various techniques may be used to improve heat distribution and lower the temperature of the combustion gases. Water may be used to quench the combustion gases and produce the superheated steam or vapor. The water may be introduced onto the combustion gases by spraying, weeping, dripping, and the like.

Owner:EOR TECH HLDG INC

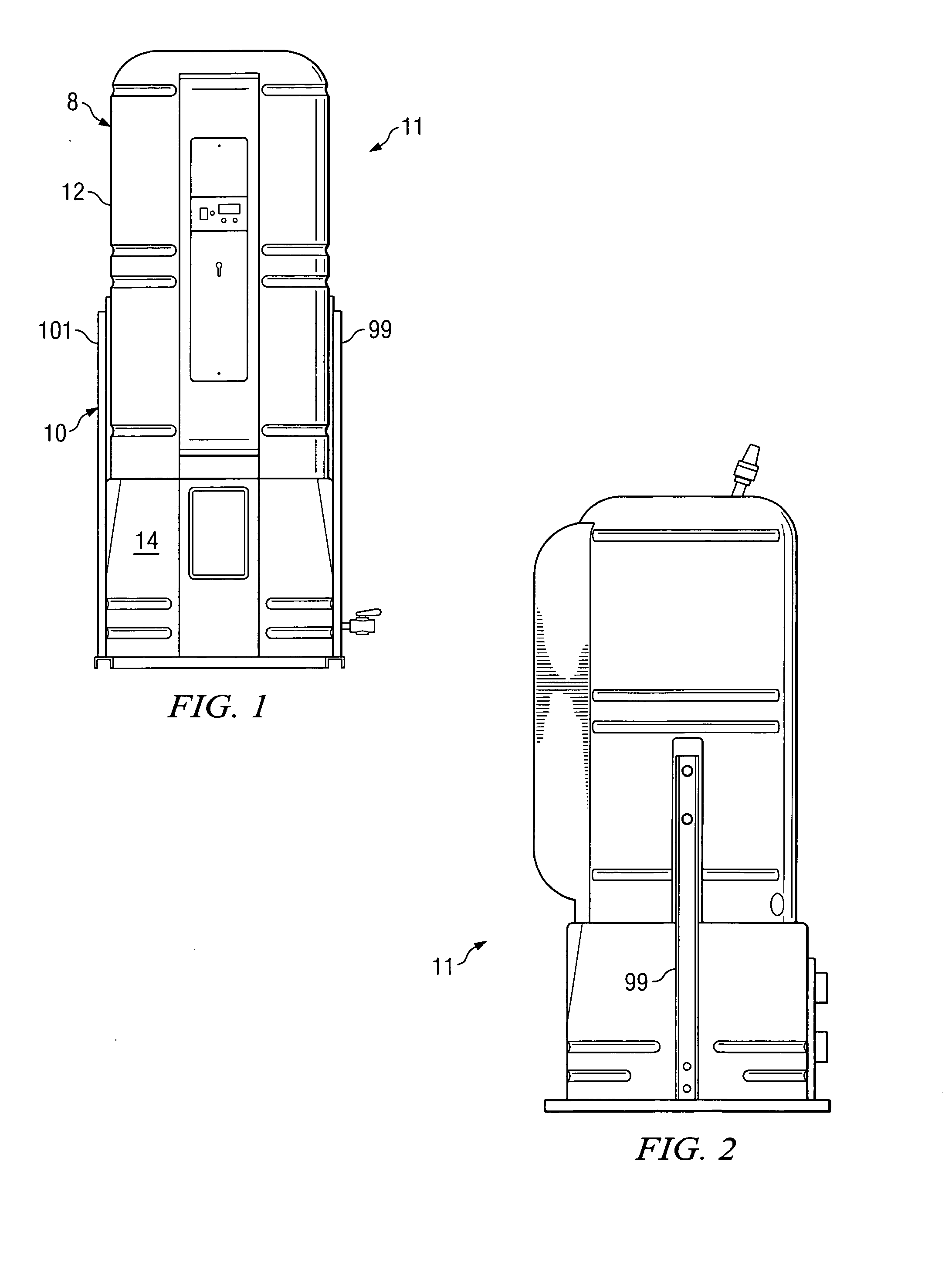

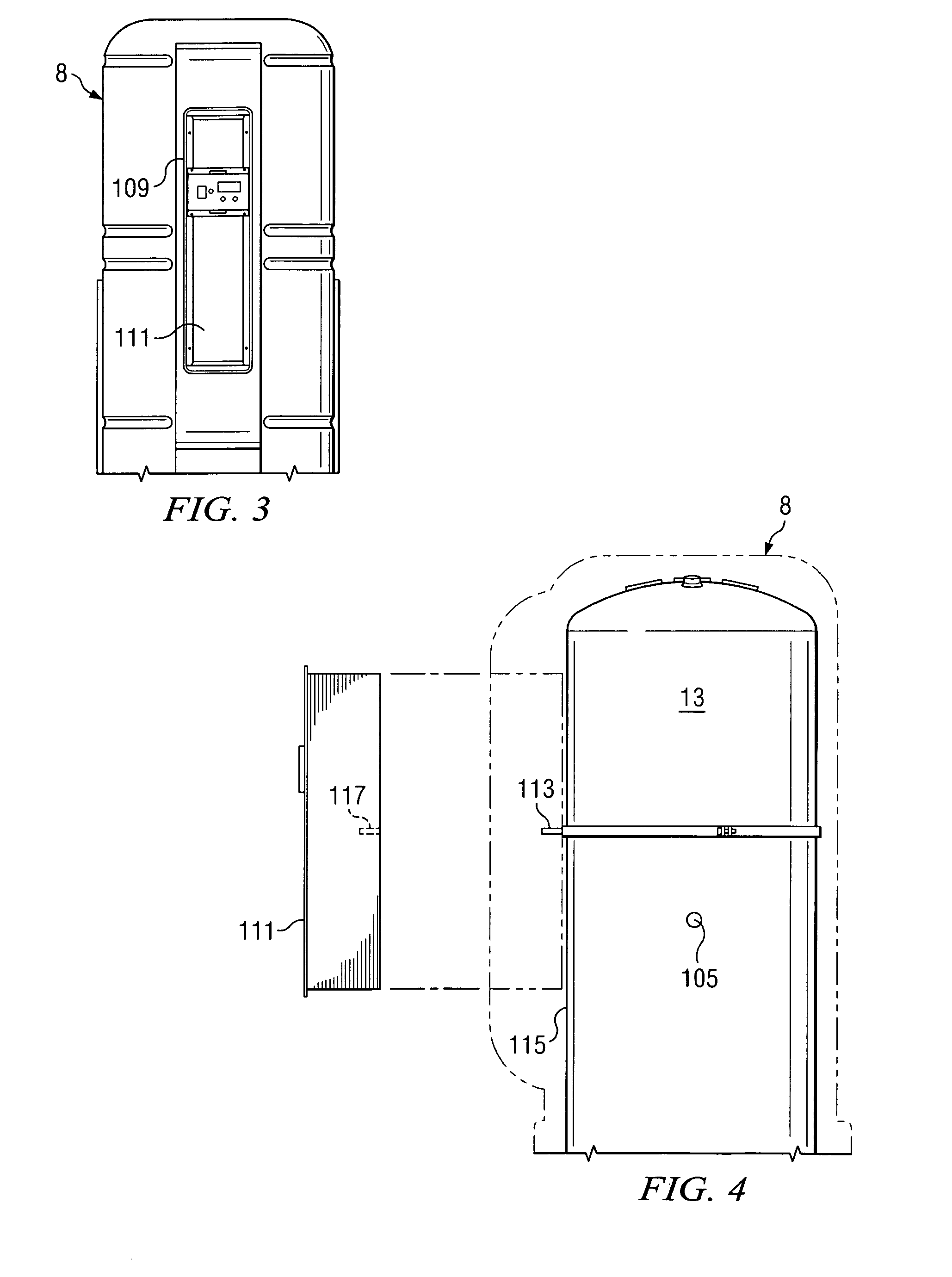

Condensing gas fired water heater

InactiveUS20070125318A1Easy to optimizeImprove heat transfer performanceSteam generation using pressureSubmerged flame steam boilersCombustion chamberCombustor

A water heater is shown having a closed metal tank with an upwardly mounted combustion chamber and burner / blower assembly. Curved fire tubes convey the products of combustion from the chamber to an exterior mounted flue assembly. The closed tank is enclosed by a rotomolded jacket. A support stand with vertically arranged support legs supports the tank in a normally vertical position but also allows the tank to be pivoted to a horizontal position on the support stand for maintenance or repair operations.

Owner:PVI IND +1

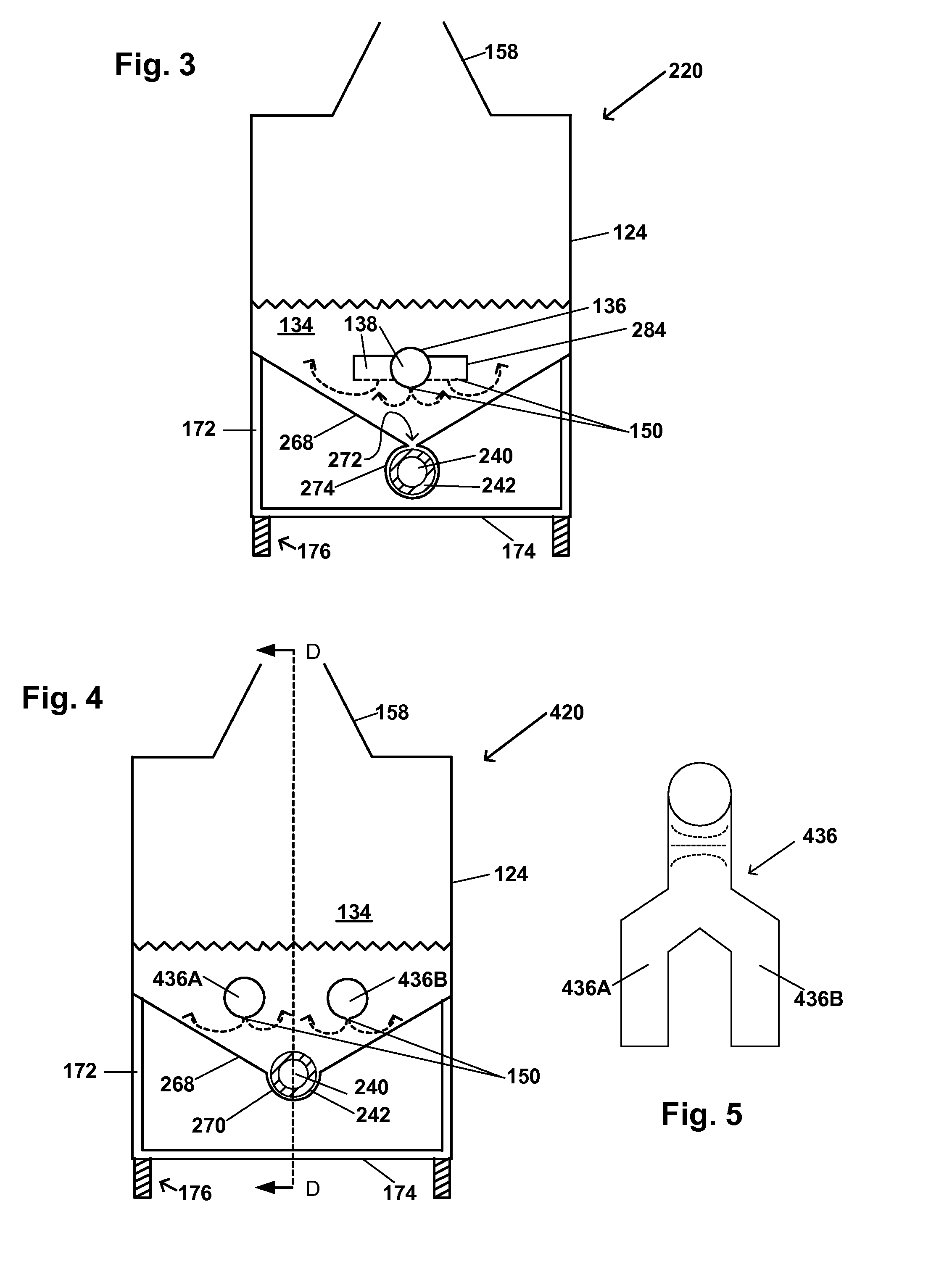

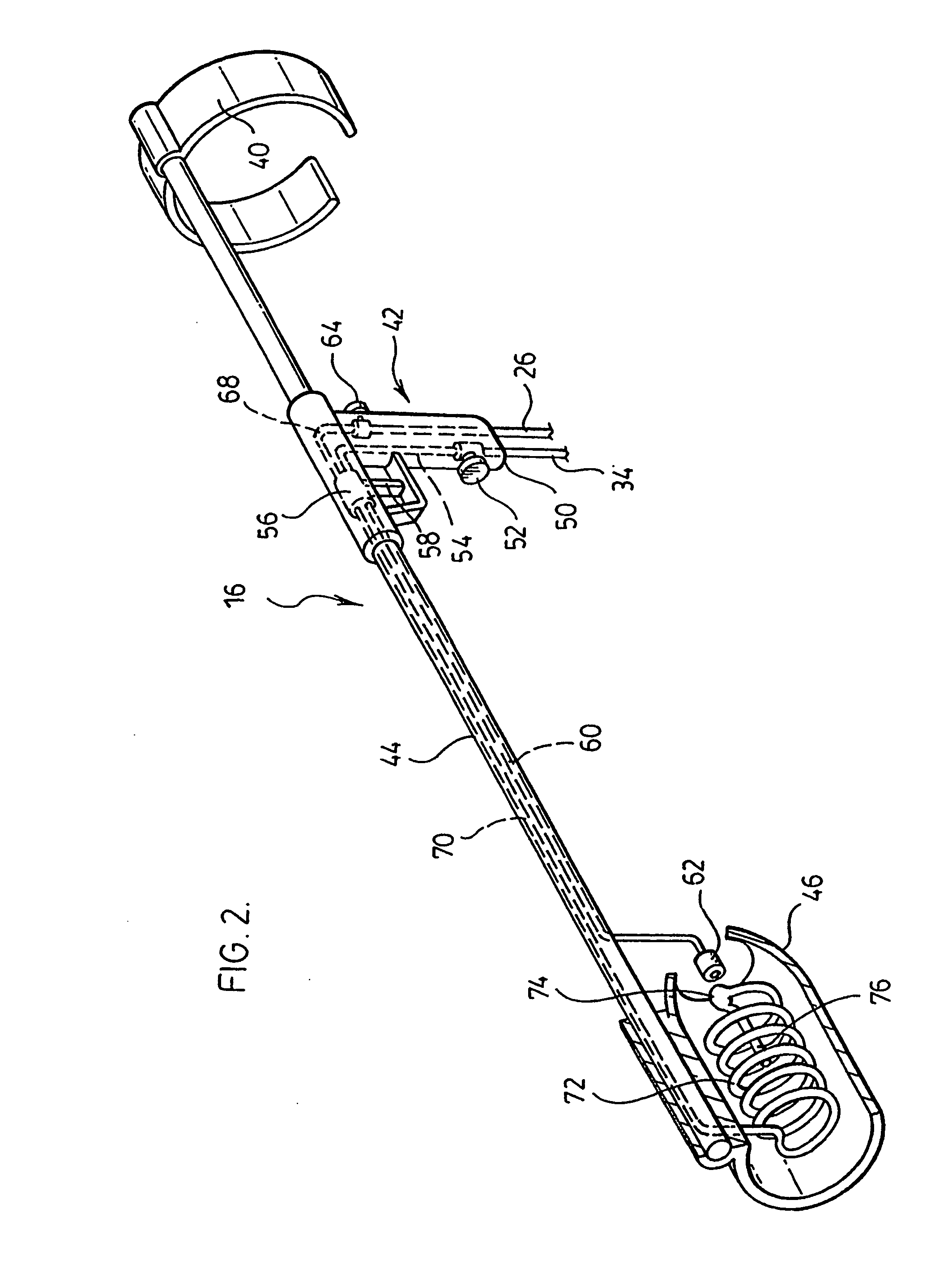

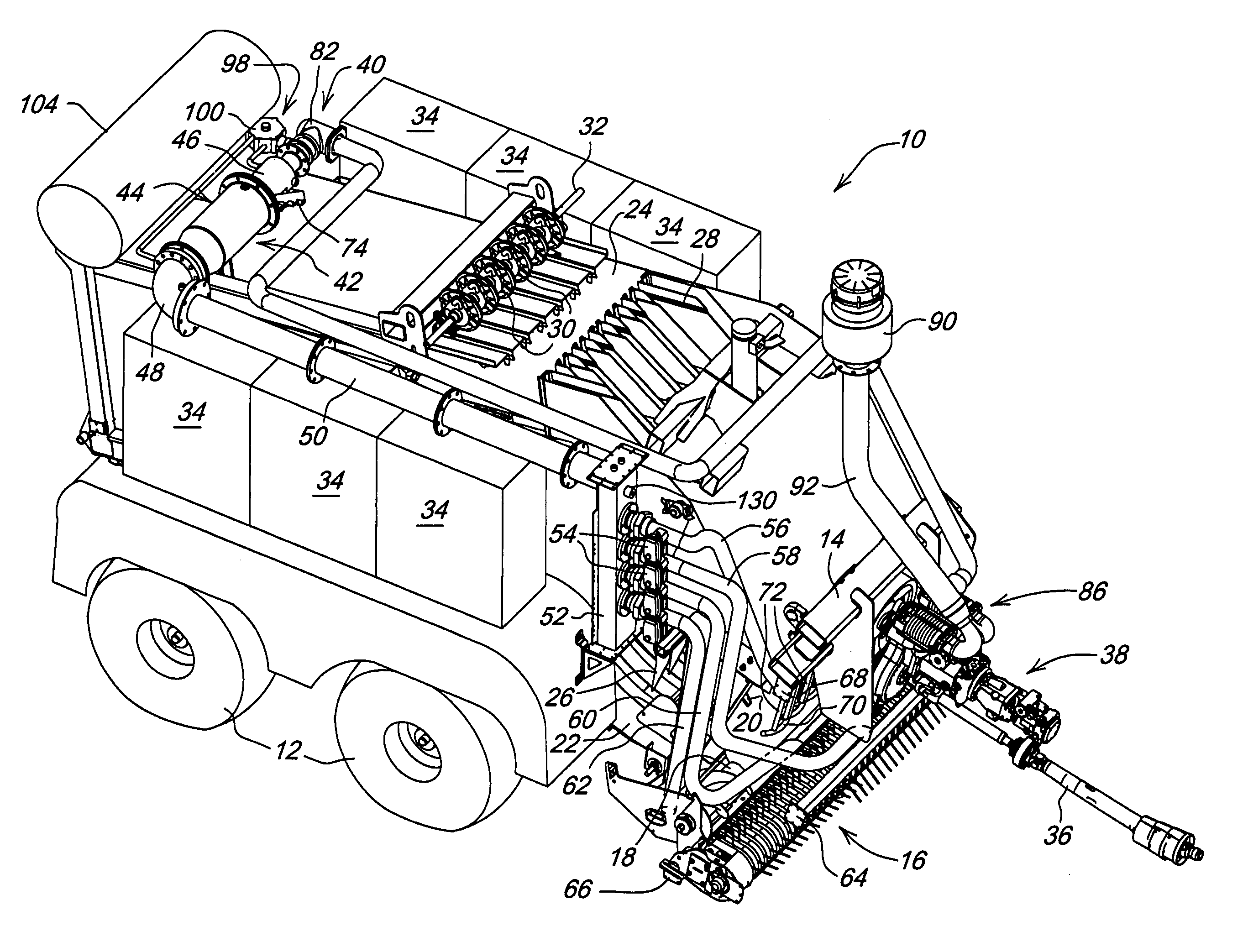

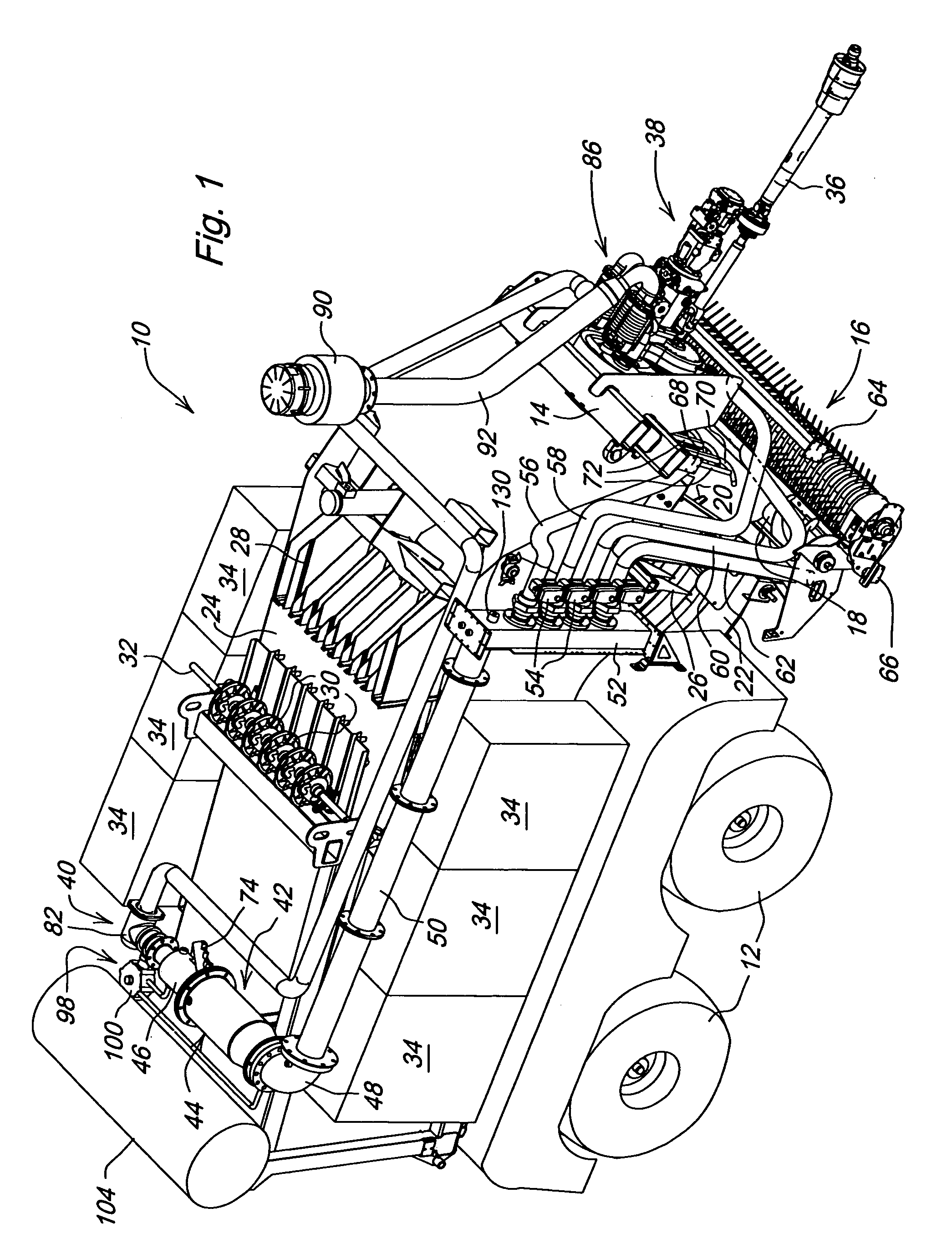

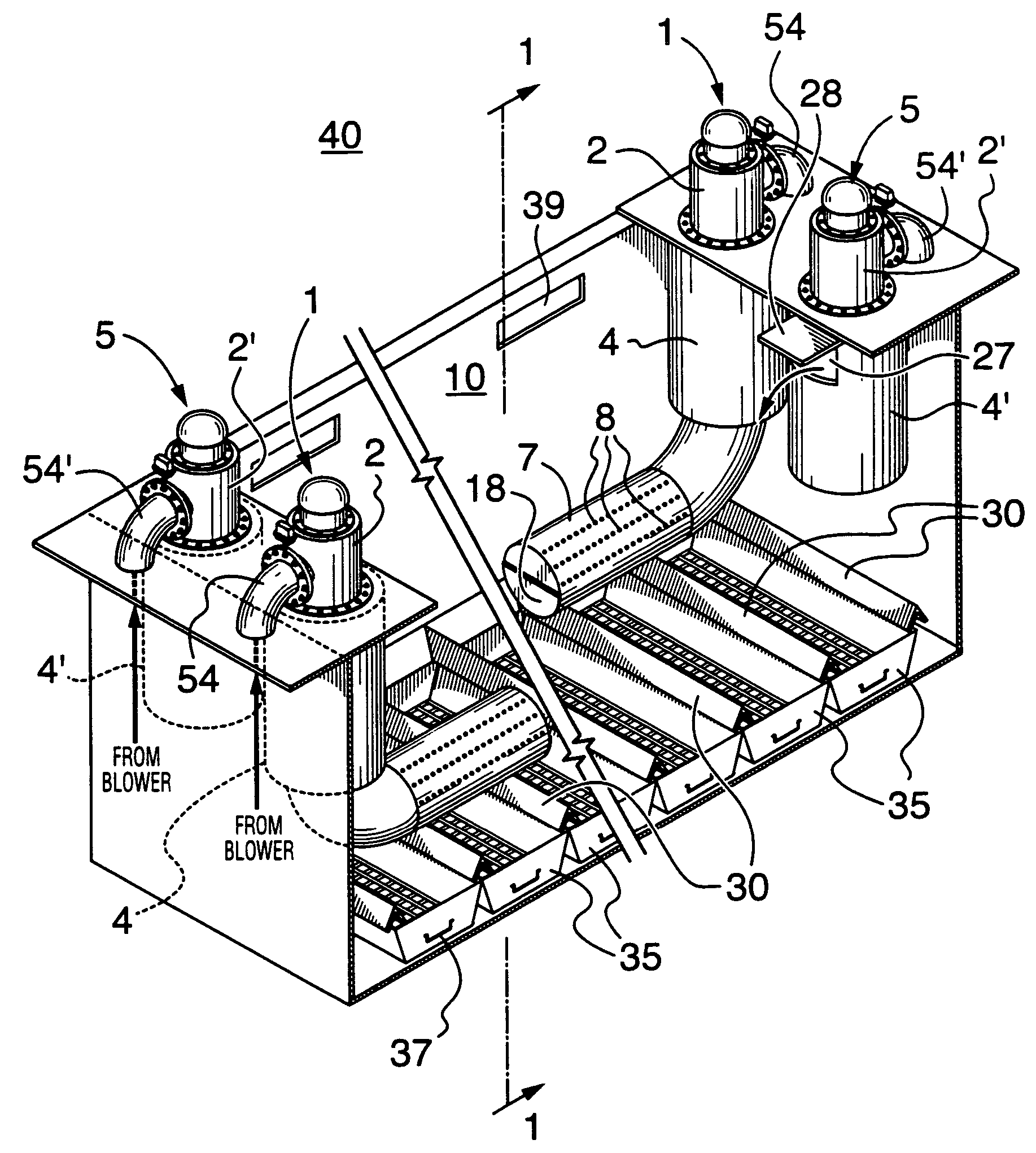

Startup burner assembly for snow melting apparatus and method of snow melting

ActiveUS20060137677A1Improve efficiencyEffective distributionPilot flame ignitersWater heatersCombustion chamberCombustor

A startup burner assembly for use in snow melting applications, and which permits initiation of snow melting without first supplying water as a coolant. The startup burner assembly comprises a fuel burner having adjustable combustion output and a nozzle to facilitate the emergence of products of combustion, and a combustion chamber having a first portion in substantially air-tight communication with the fuel burner and enclosing the nozzle and a second portion shaped and dimensioned for disposition into a snow melting receptacle or pit. The combustion chamber has a plurality of discharge holes formed at least on the second portion thereof to permit the egress of products of combustion from the fuel burner into the tank or pit, and thereby permit agitation and melting of snow loaded therein, The startup burner assembly also includes an air cooling assembly for supplying air to cool at least the first portion of the combustion chamber.

Owner:TRECAN COMBUSTION

Downhole steam generator and method of use

A downhole steam generation system may include a burner head assembly, a liner assembly, a vaporization sleeve, and a support sleeve. The burner head assembly may include a sudden expansion region with one or more injectors. The liner assembly may include a water-cooled body having one or more water injection arrangements. The system may be optimized to assist in the recovery of hydrocarbons from different types of reservoirs. A method of recovering hydrocarbons may include supplying one or more fluids to the system, combusting a fuel and an oxidant to generate a combustion product, injecting a fluid into the combustion product to generate an exhaust gas, injecting the exhaust gas into a reservoir, and recovering hydrocarbons from the reservoir.

Owner:WORLD ENERGY SYST

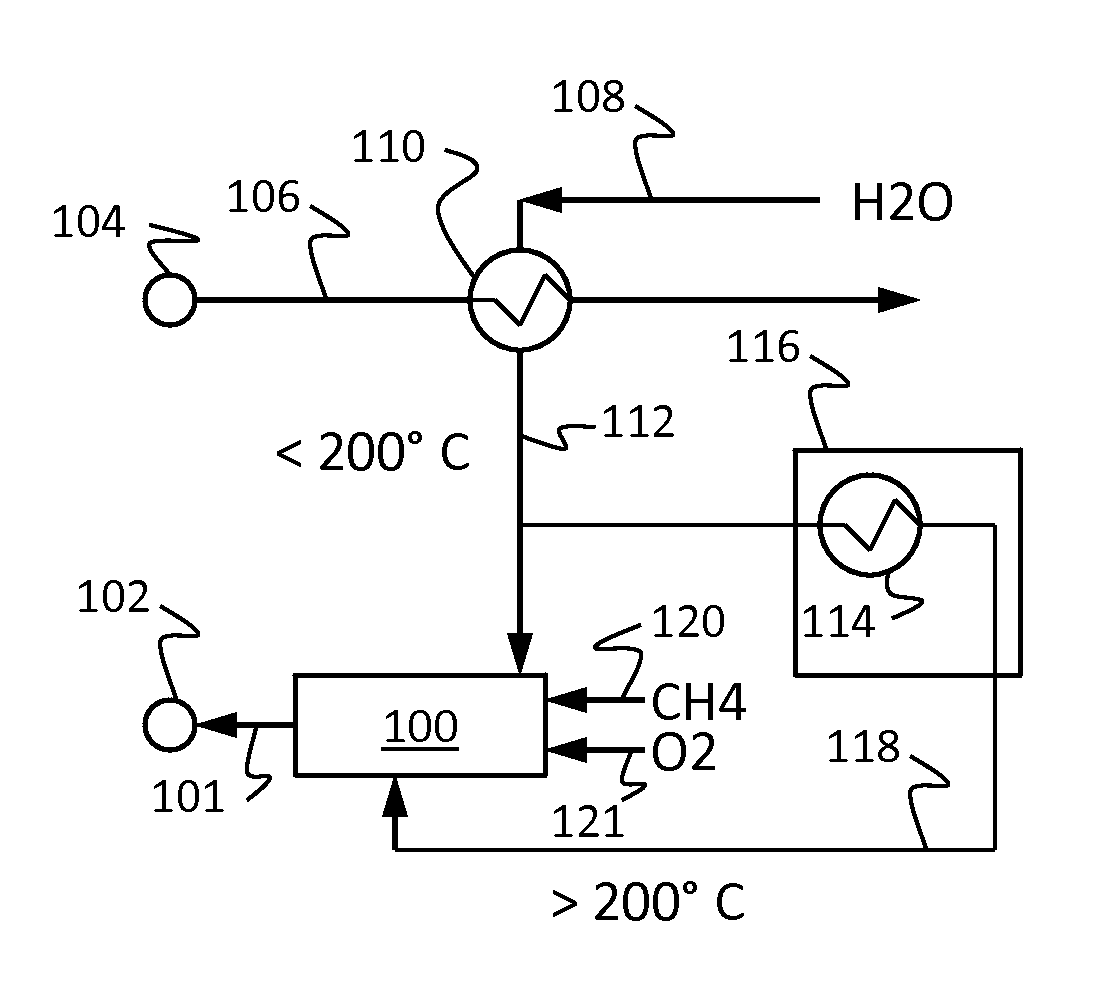

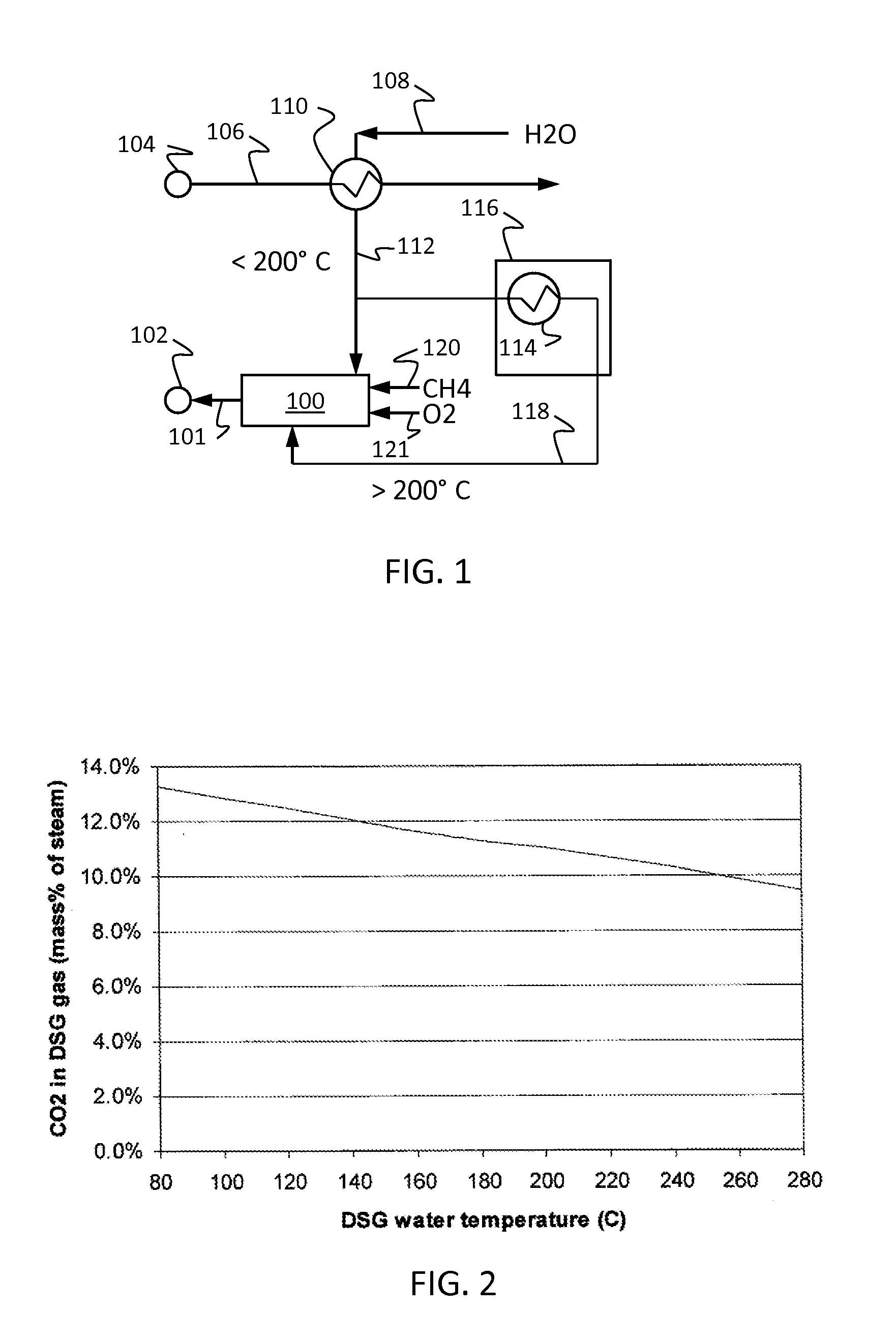

Direct steam generation co2 output control

InactiveUS20140060825A1Steam generation using pressureCombustion processEngineeringIncrease temperature

Methods and systems generate steam and carbon dioxide mixtures suitable for injection to assist in recovering hydrocarbons from oil sands based on concentration of the carbon dioxide in the mixtures as influenced by temperature of water introduced into a direct steam generator. Increasing temperature of the water to above 200° C. before introduction into the direct steam generator may utilize heat from an electrical power generation unit. Enthalpy of this preheated water impacts amount of fuel needed to burn in the direct steam generator and hence the concentration of the carbon dioxide, which may be below 11% by mass percent of the steam.

Owner:CONOCOPHILLIPS CO

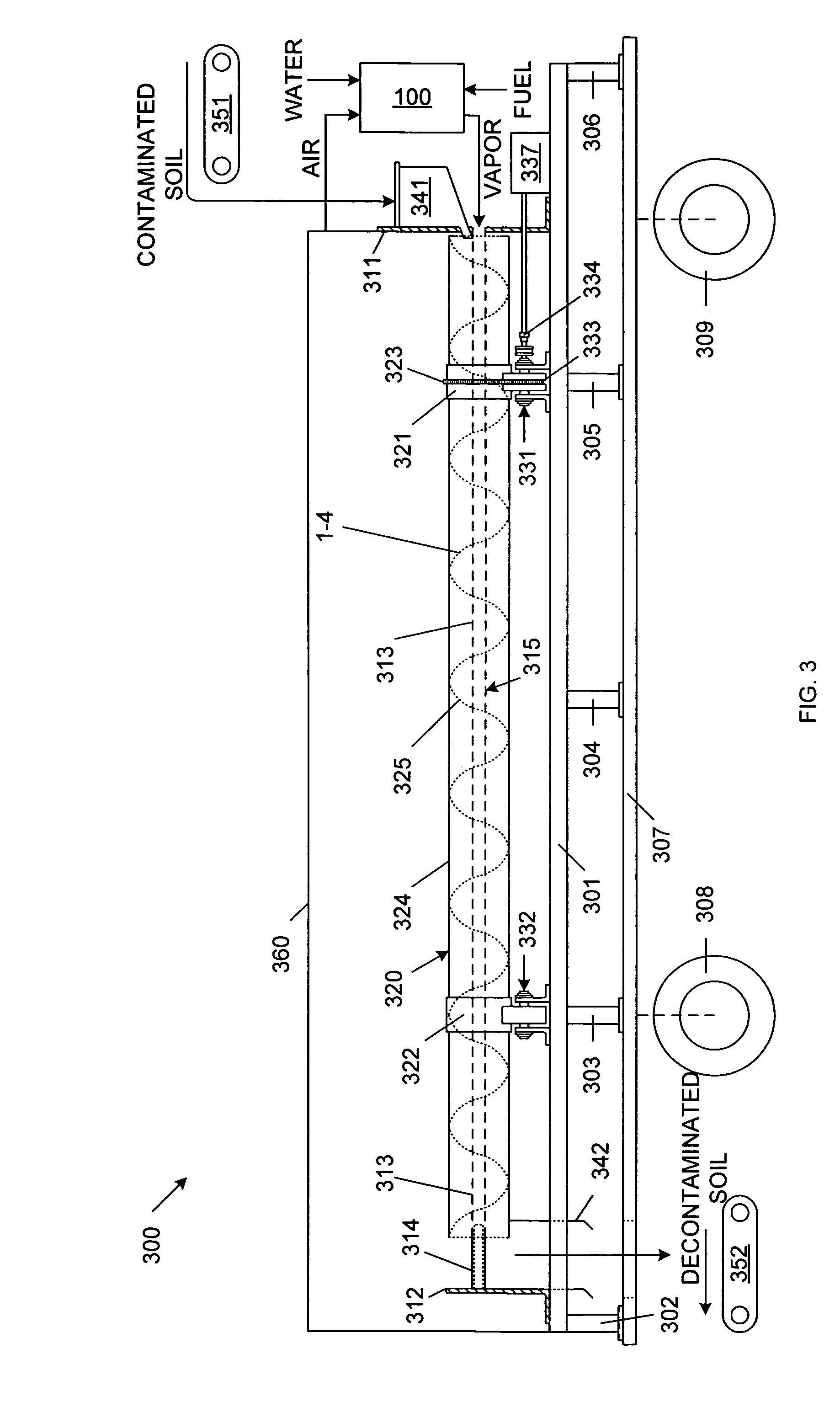

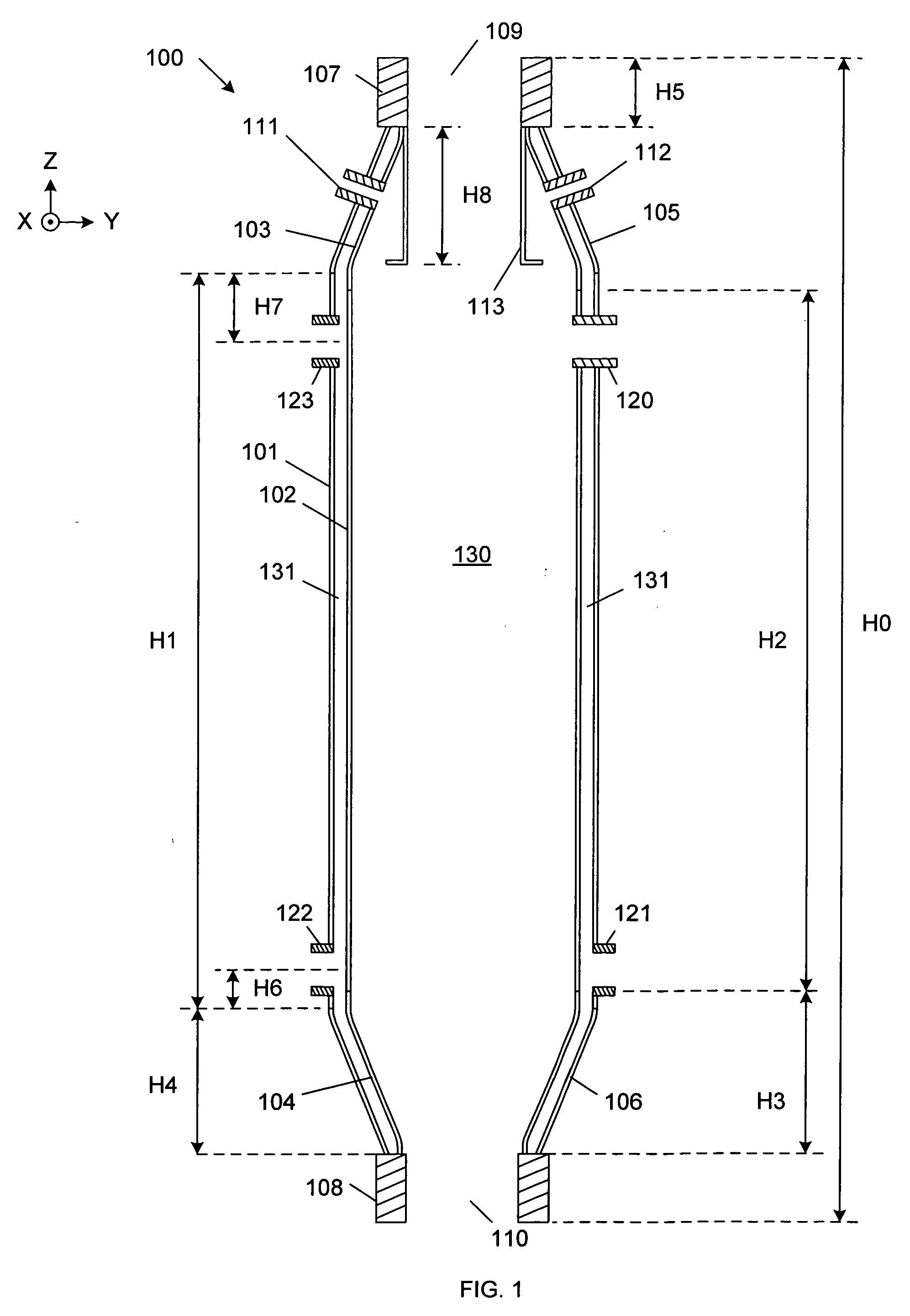

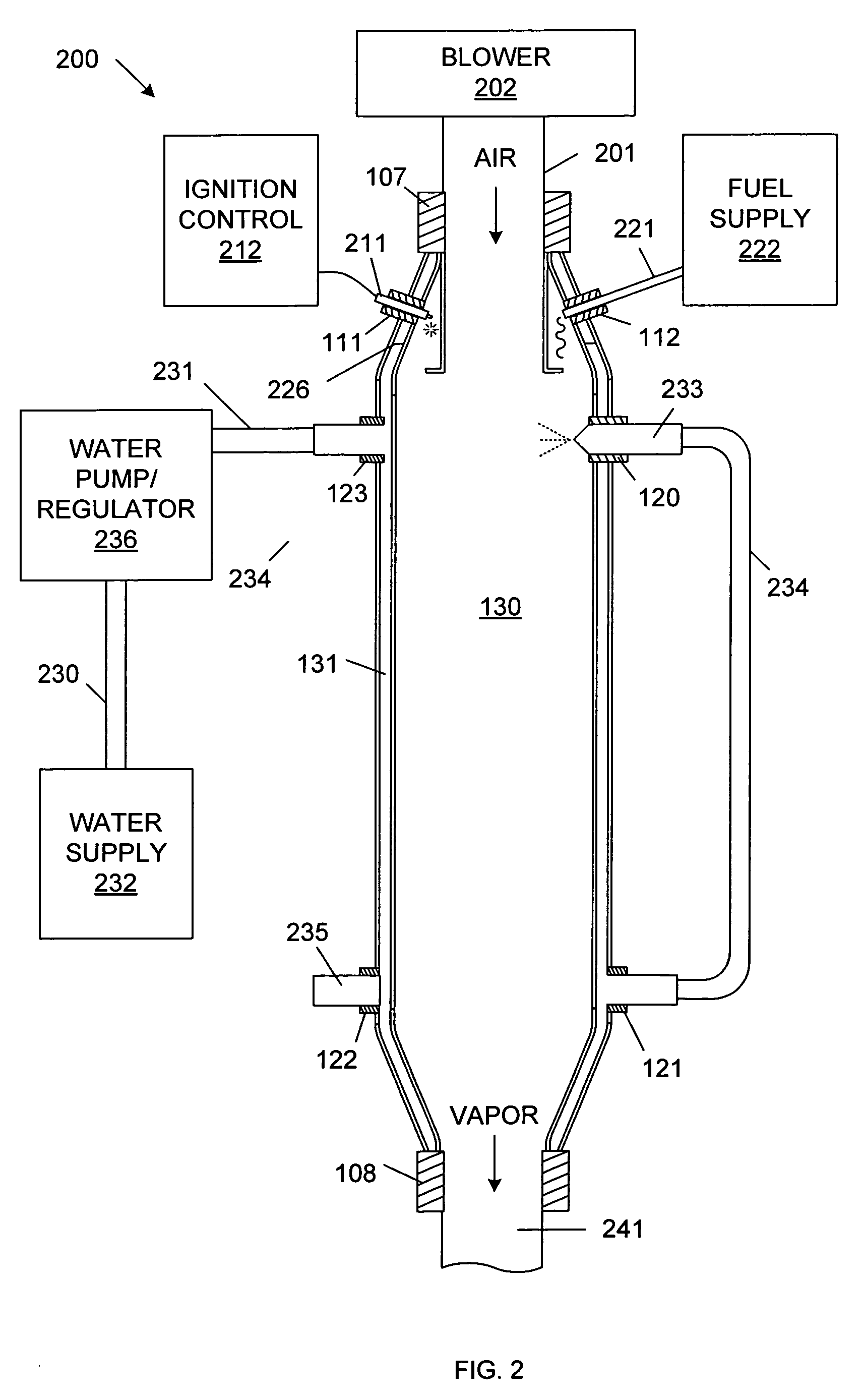

Environmental clean-up system

InactiveUS20050080312A1Improve efficiencyEfficient systemBoiler water tubesContaminated soil reclamationCombustion chamberWater vapor

An efficient high-temperature water vapor generator is used to de-contaminate soil. The vapor generator includes a combustion chamber and a surrounding structure, wherein a cavity is located therebetween. Water is routed through the cavity and into the combustion chamber, where water vapor and heat are generated in the presence of fuel, ignition and air. The generated heat pre-heats the water in the cavity, thereby creating an efficient system. The water vapor is forced into a vapor tube (which has openings for emitting the vapor), thereby heating the vapor tube to temperatures of 800° F. or greater. A soil tube having lifting paddles located therein surrounds the vapor tube. Contaminated soil enters one end of the soil tube. The soil tube is rotated, thereby moving the contaminated soil into contact with the vapor tube (decontaminating the soil). The lifting paddles move the soil toward the second end of the rotating soil tube.

Owner:JAVAHERIAN MEHRDAD

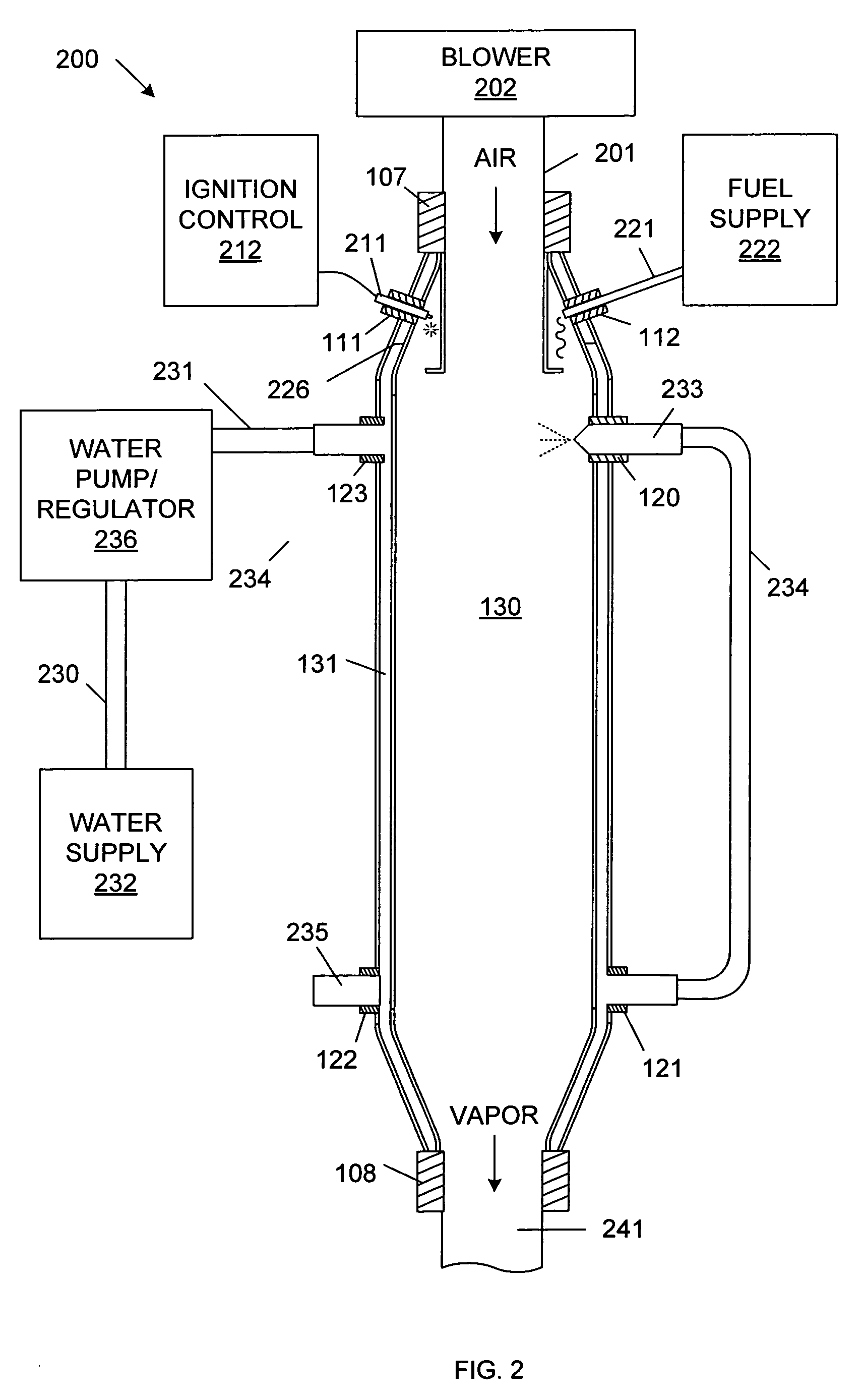

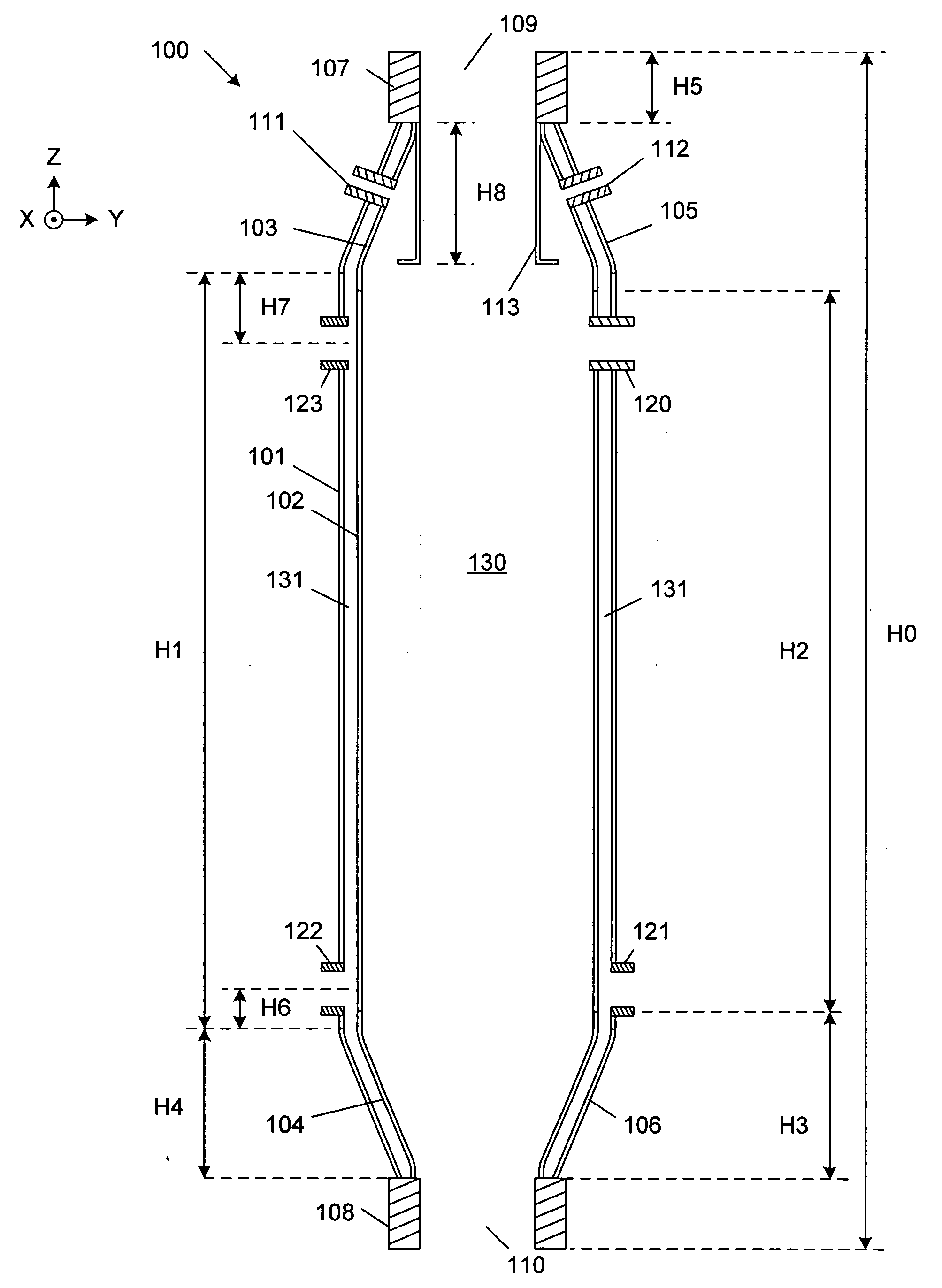

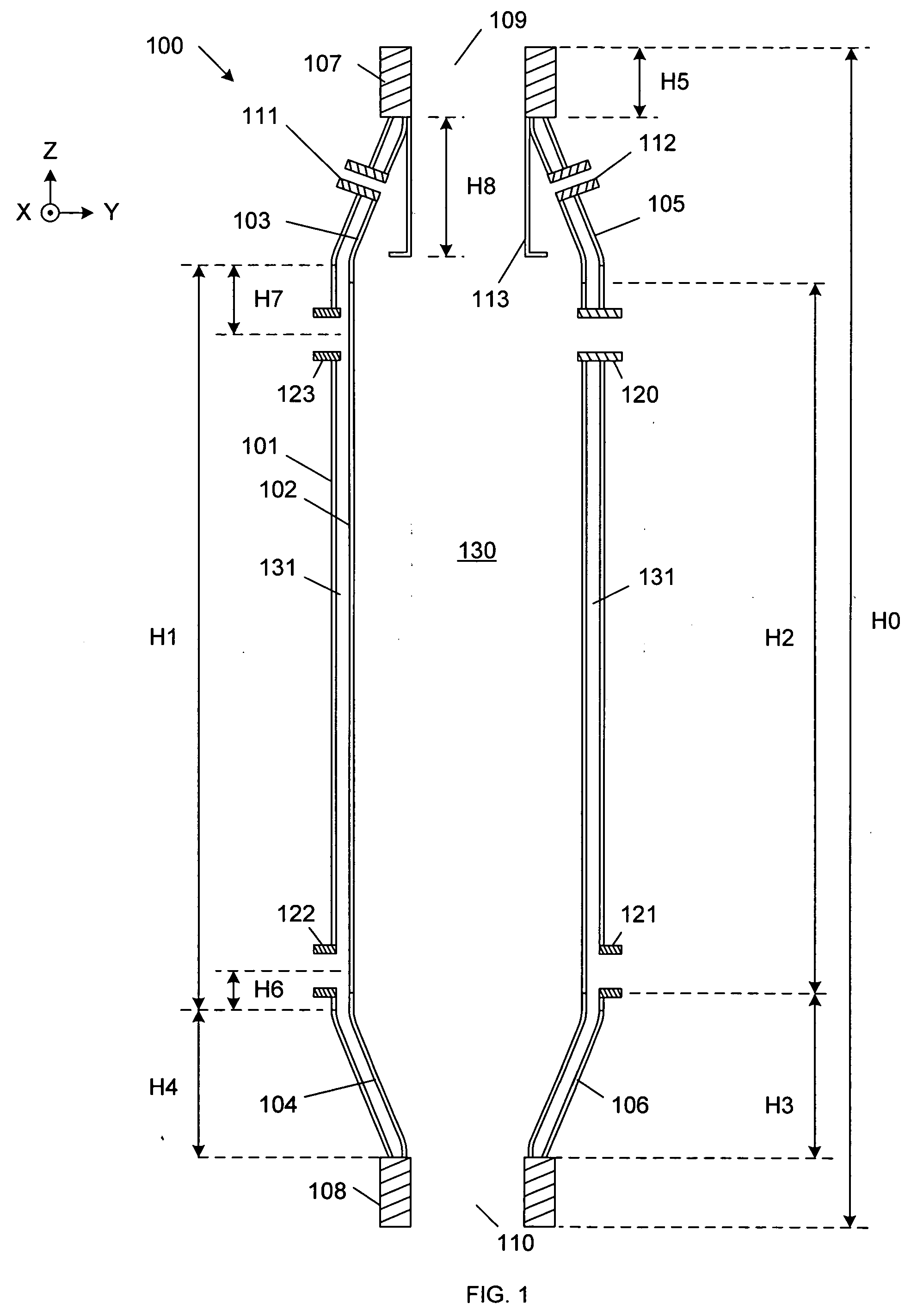

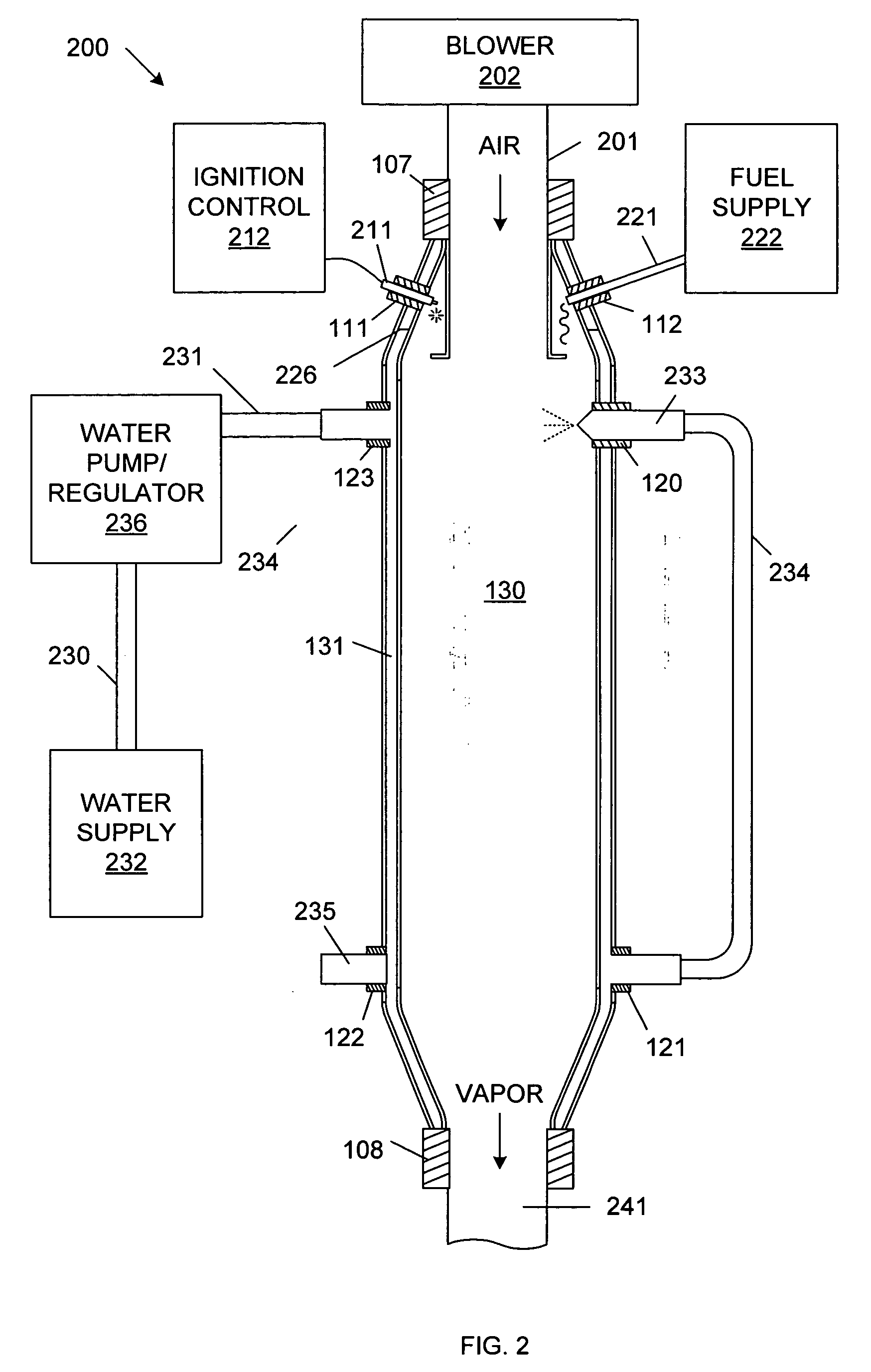

Combustion chamber design with water injection for direct-fired steam generator and for being cooled by the water

InactiveUS20060000427A1Eliminate needSuperheating controlSteam generation using pressureCombustion chamberInjection port

A direct-fired steam generator body defines a combustion chamber and having an exhaust outlet. A mixing chamber is provided for receiving the exhaust gases from the combustion chamber. A flange joint between an elbow forming part of the mixing chamber and the end of the steam generator body defining the exhaust outlet is designed so as to be cooled by process water coupled to the joint by an injection port provided in one of the flanges.

Owner:DEERE & CO

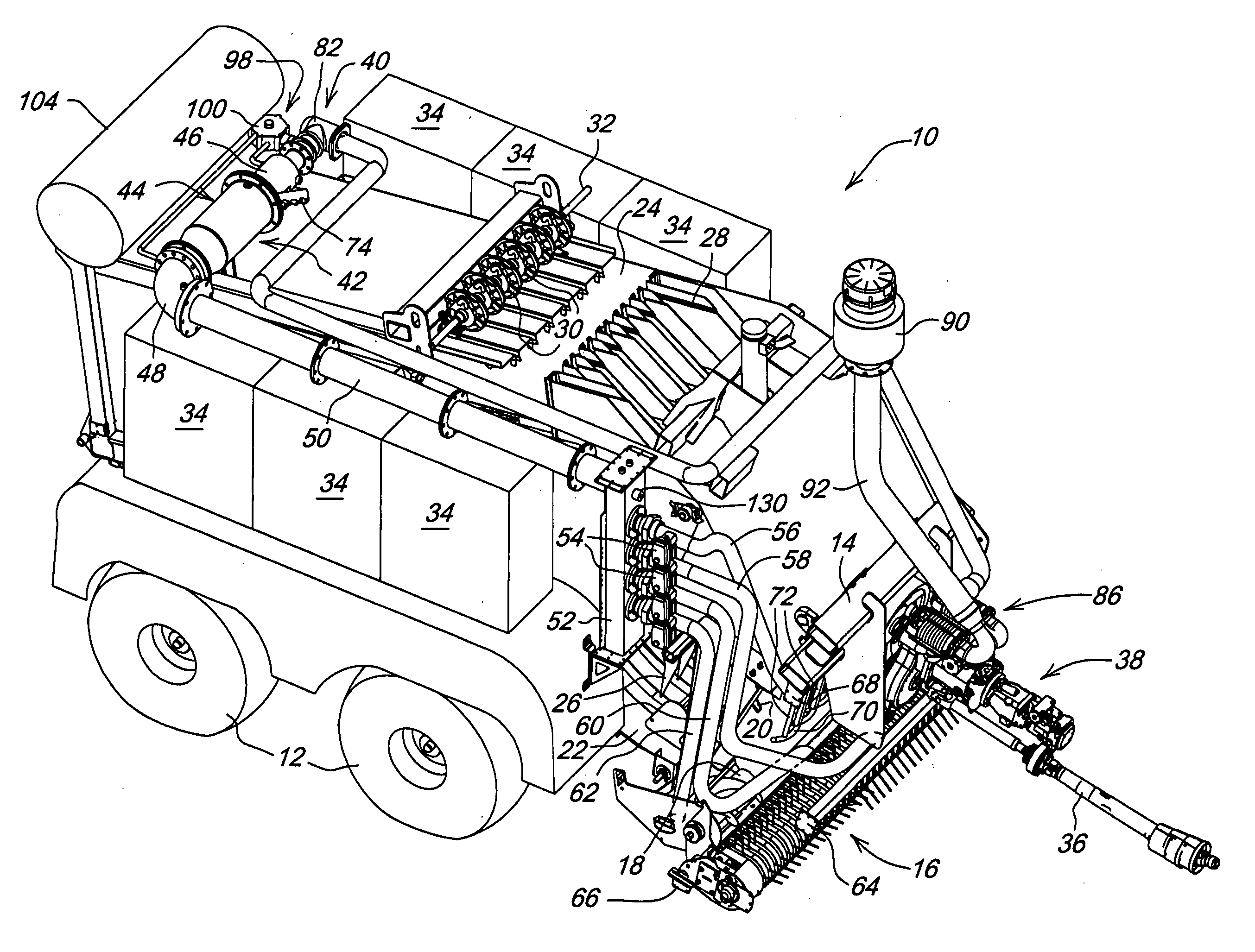

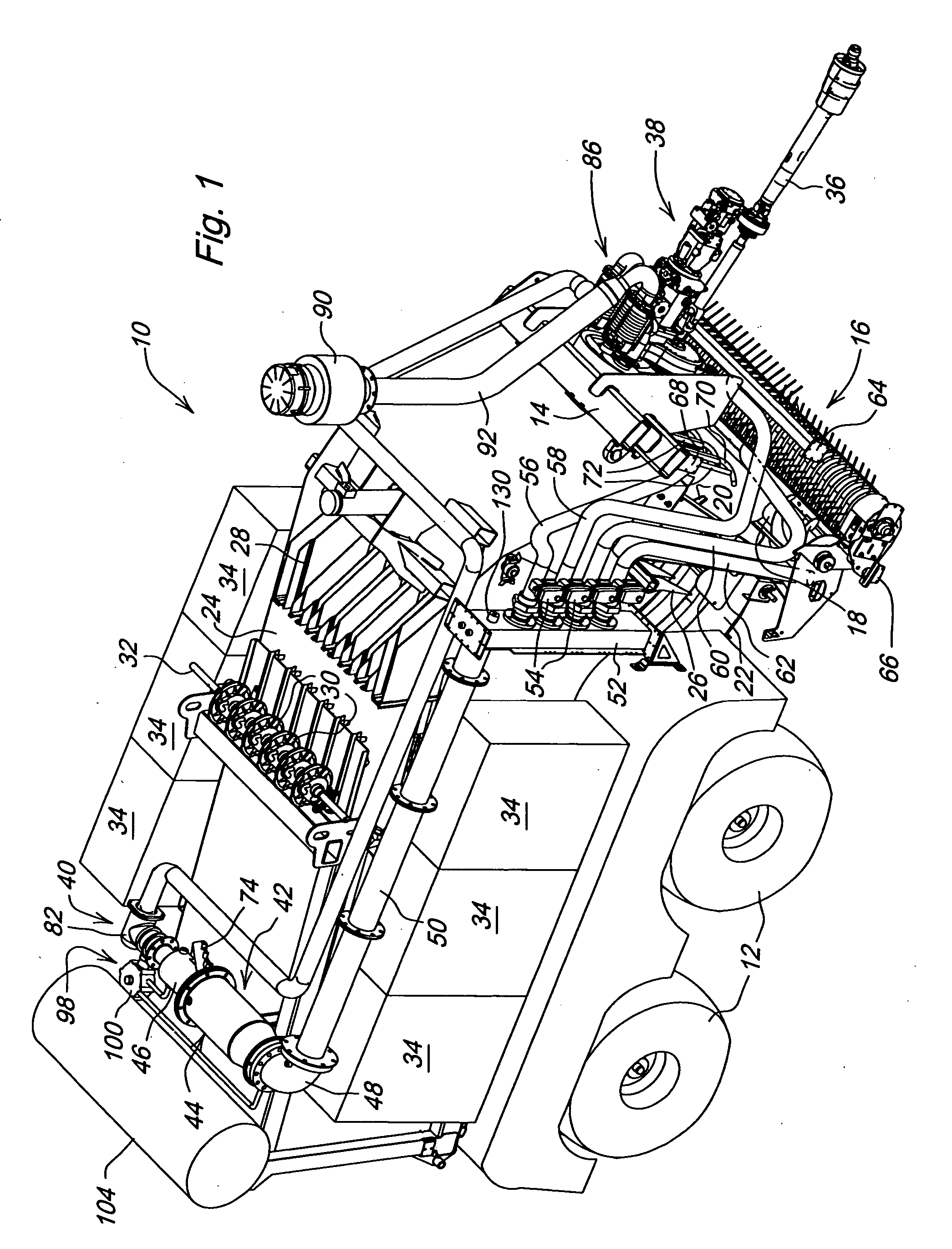

Using an estimated heat output value of a direct-fired steam generator in controlling water flow to maintain a desired constant steam temperature

InactiveUS7261032B2Constant outputSimple waySteam generation using pressureMowersDirect combustionWater flow

A direct-fired steam generator used for supplying steam for re-hydrating dry crop during baling is controlled so as to produce a desired constant steam temperature output by collecting data from which the heat output of the steam generator can be calculated and using this calculation together with the difference between the actual steam temperature and the desired steam temperature to control the amount of process water sent to the steam generator in order to correct any error in steam temperature. Steam temperature is measured in either one of the steam injection manifolds or in an injection tube coupled to an injection manifold so as to be close to the point of application of the steam to the crop.

Owner:DEERE & CO

Steam boiler

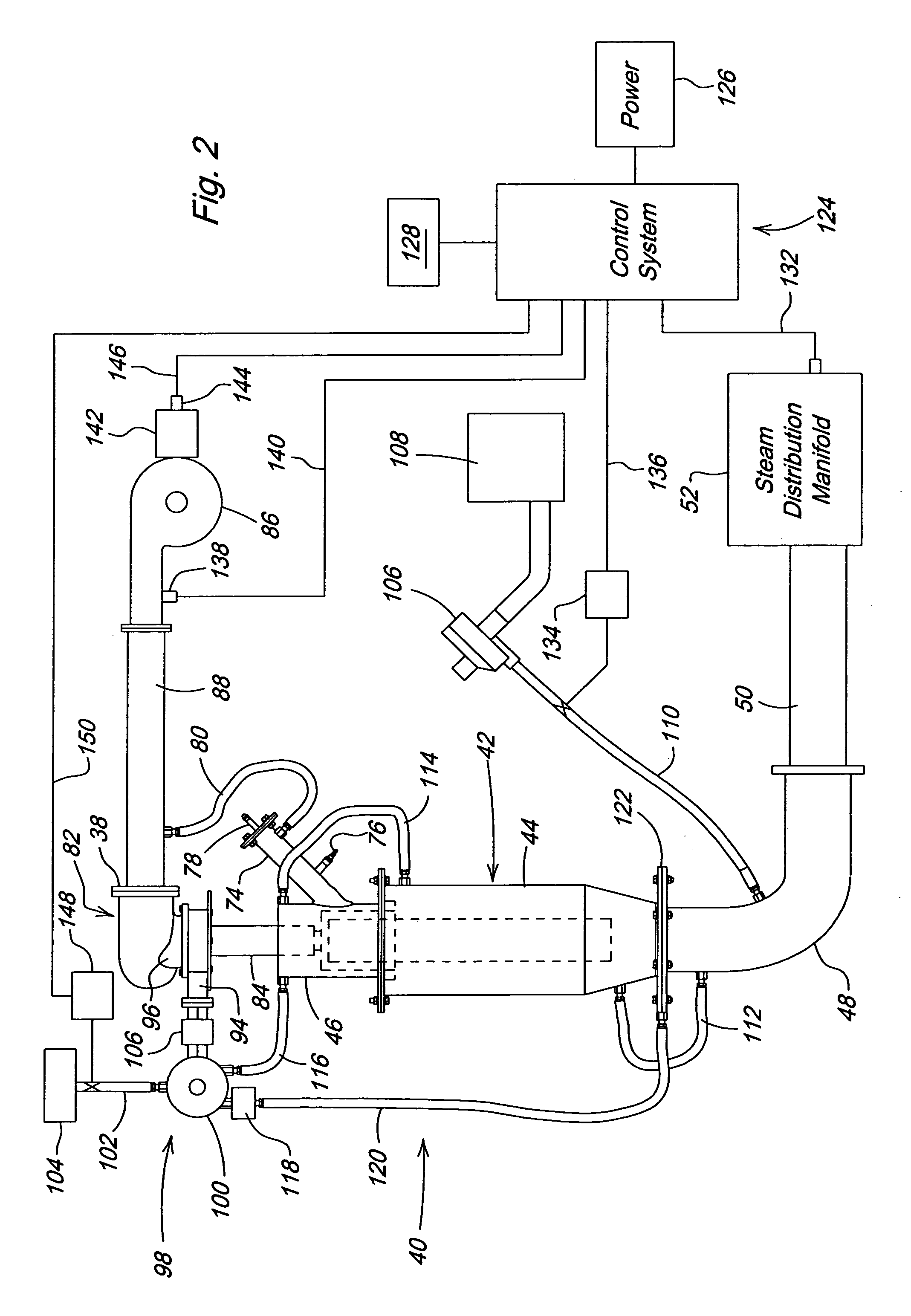

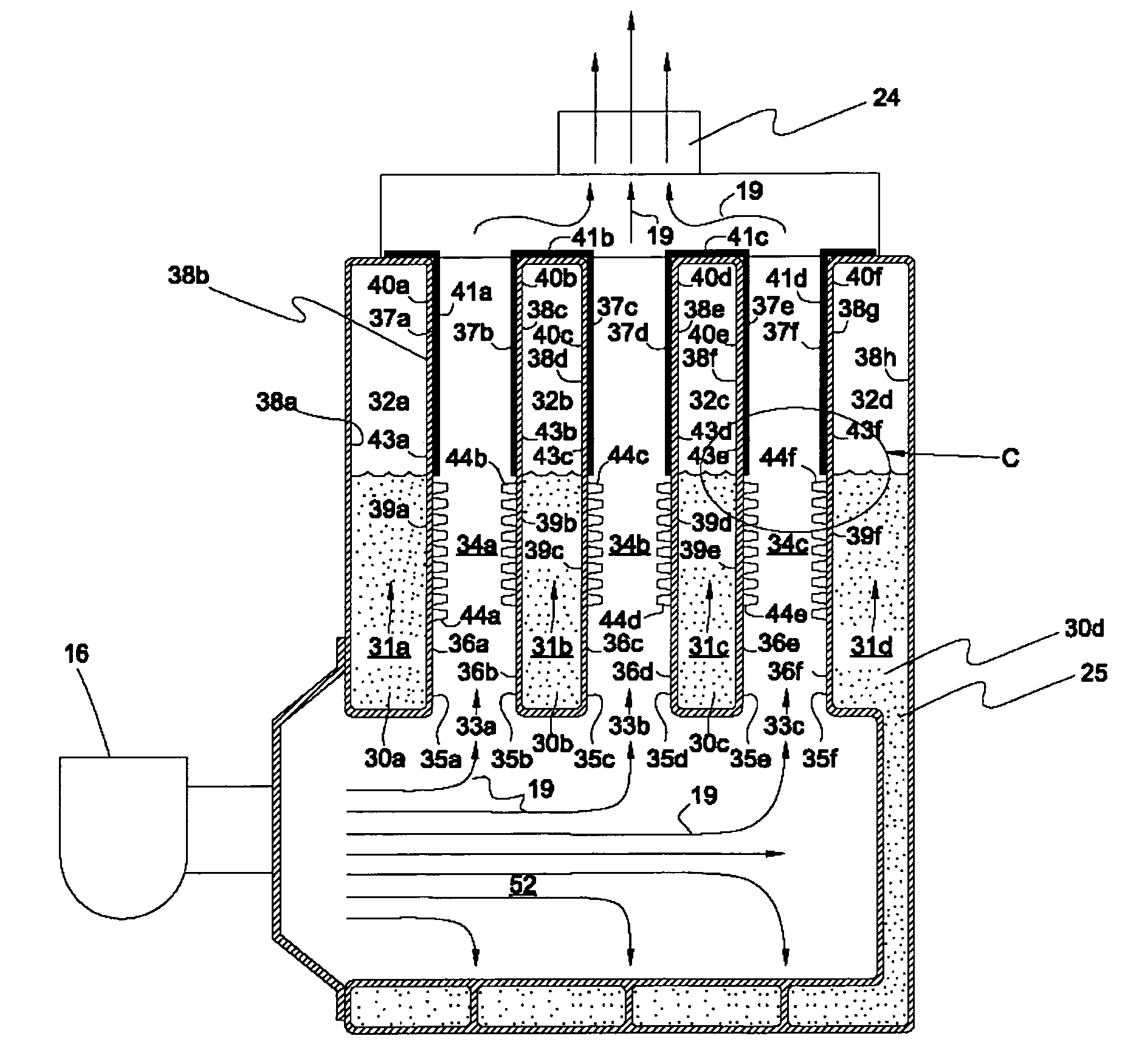

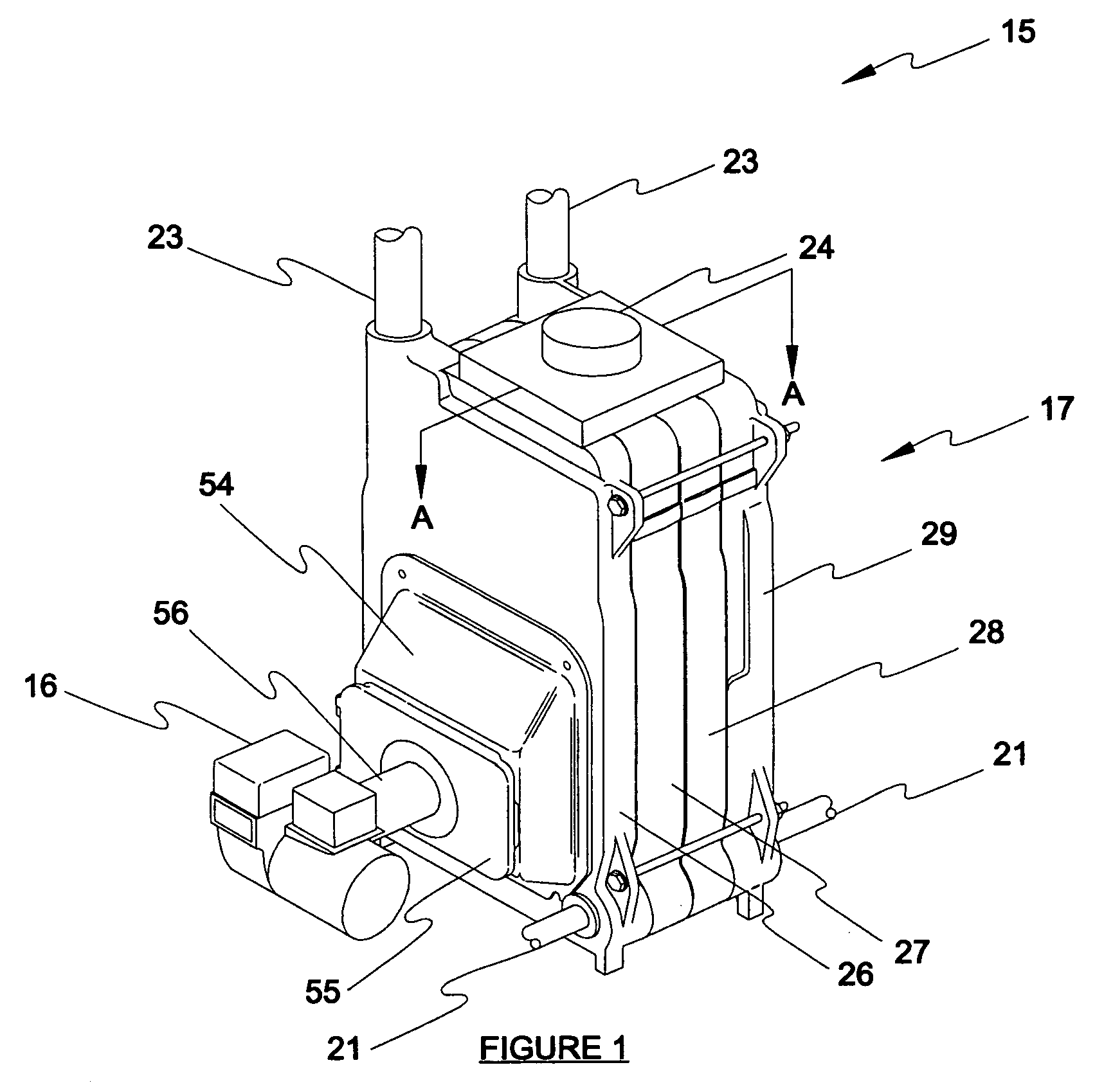

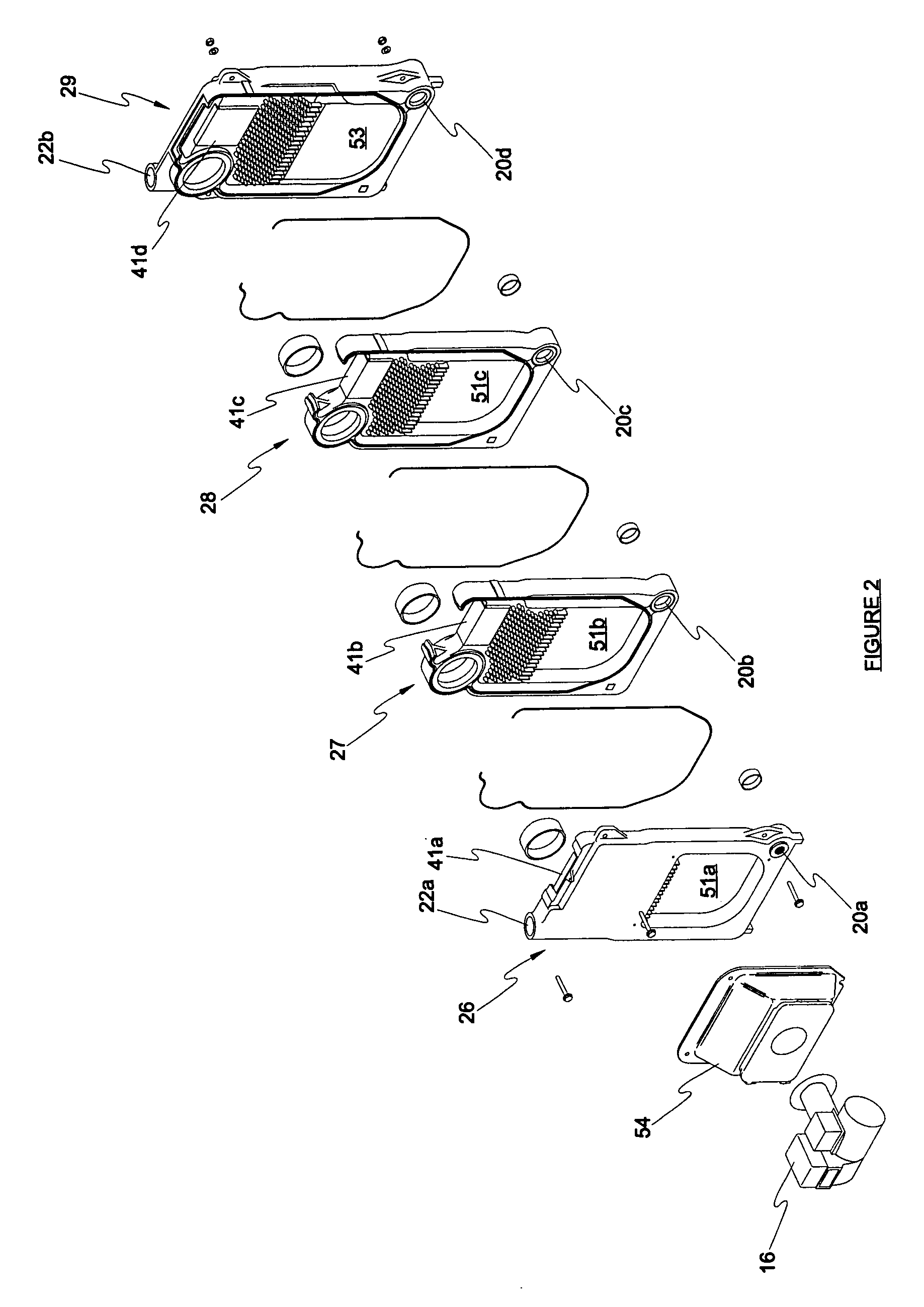

A steam boiler (15) comprising a fuel burning device (16) disposed in a combustion chamber and adapted to burn a fuel to form combustion gases (19), a passage (30) extending between a water inlet (20) and a steam outlet (23), the passage having a water space (31) and a steam space (32), a flue passage (33) extending between the combustion chamber and a flue outlet (24) and having a gas heat transfer space (34), a heat exchange element (43) between the gas heat transfer space and the water and steam spaces, the heat exchange element having a gas-side surface (35) that absorbs heat from the combustion gases and an opposed water-side surface (38) that radiates heat, the water-side surface having a first portion (39) adjacent to the water space and a second portion (40) adjacent to the steam space, the gas-side surface having a first portion (36) opposite the water-side first portion and a second portion (37) opposite the water-side second portion, the water-side first portion having a surface area and the water side second portion having a surface area, the gas-side first portion having a surface area and the gas-side second portion having a surface area, and a heat shield (41, 42, 45, 48) covering at least some of the surface area of the gas-side second portion. The surface area of the gas-side first portion may be greater than the surface area of the water-side first portion and the surface area of the gas-side second portion may be less than or approximately equal to the surface area of the water-side second portion.

Owner:ECR INT

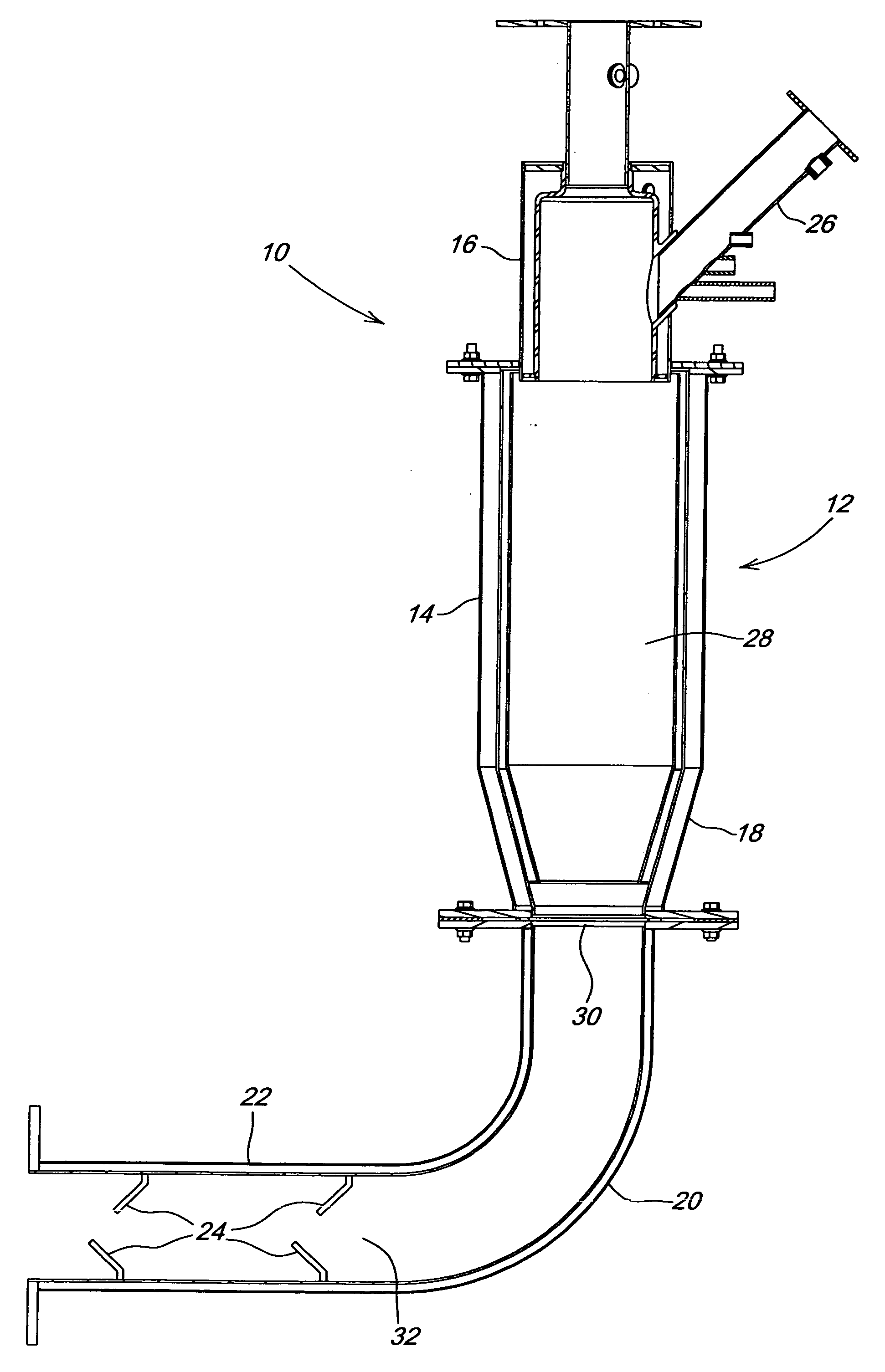

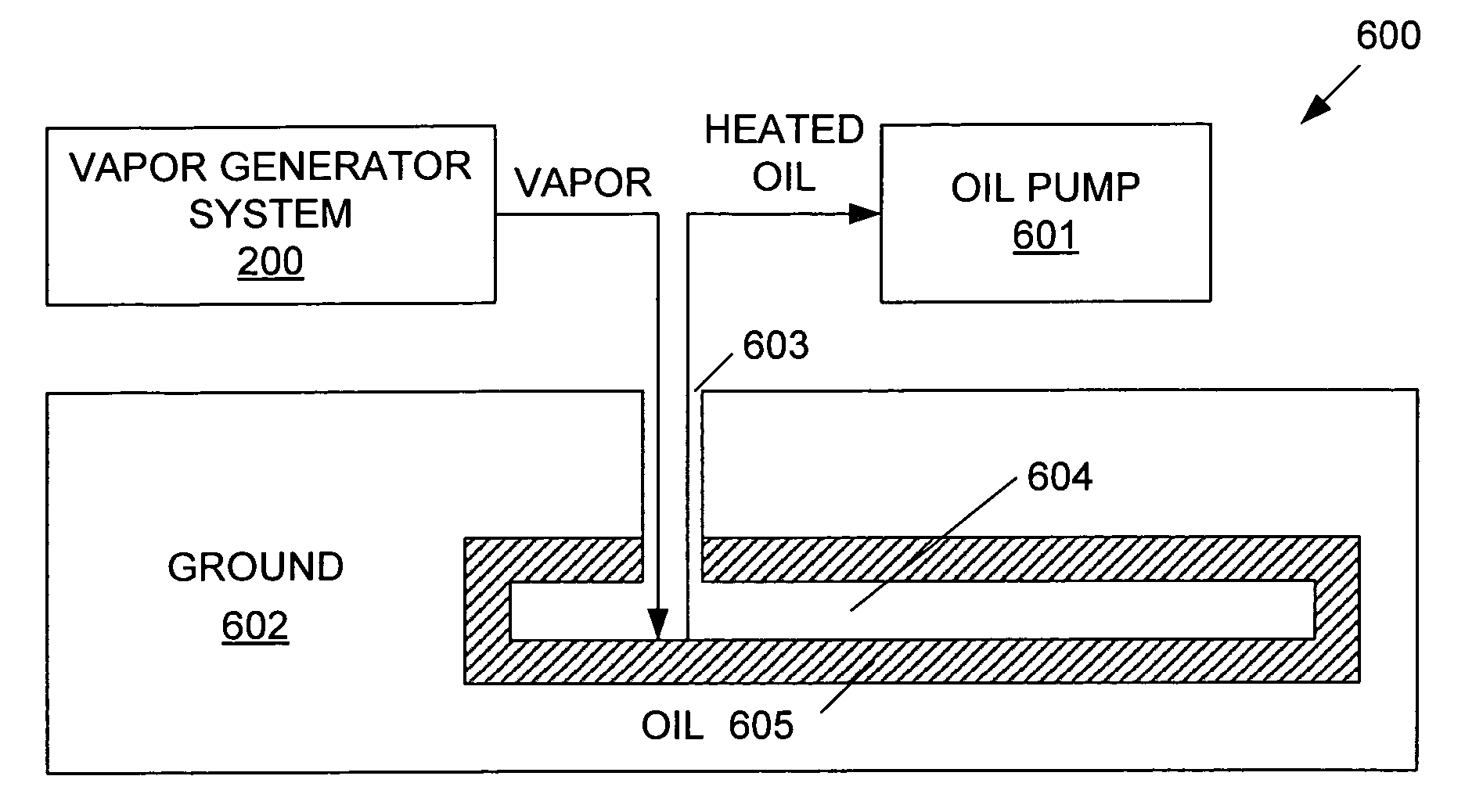

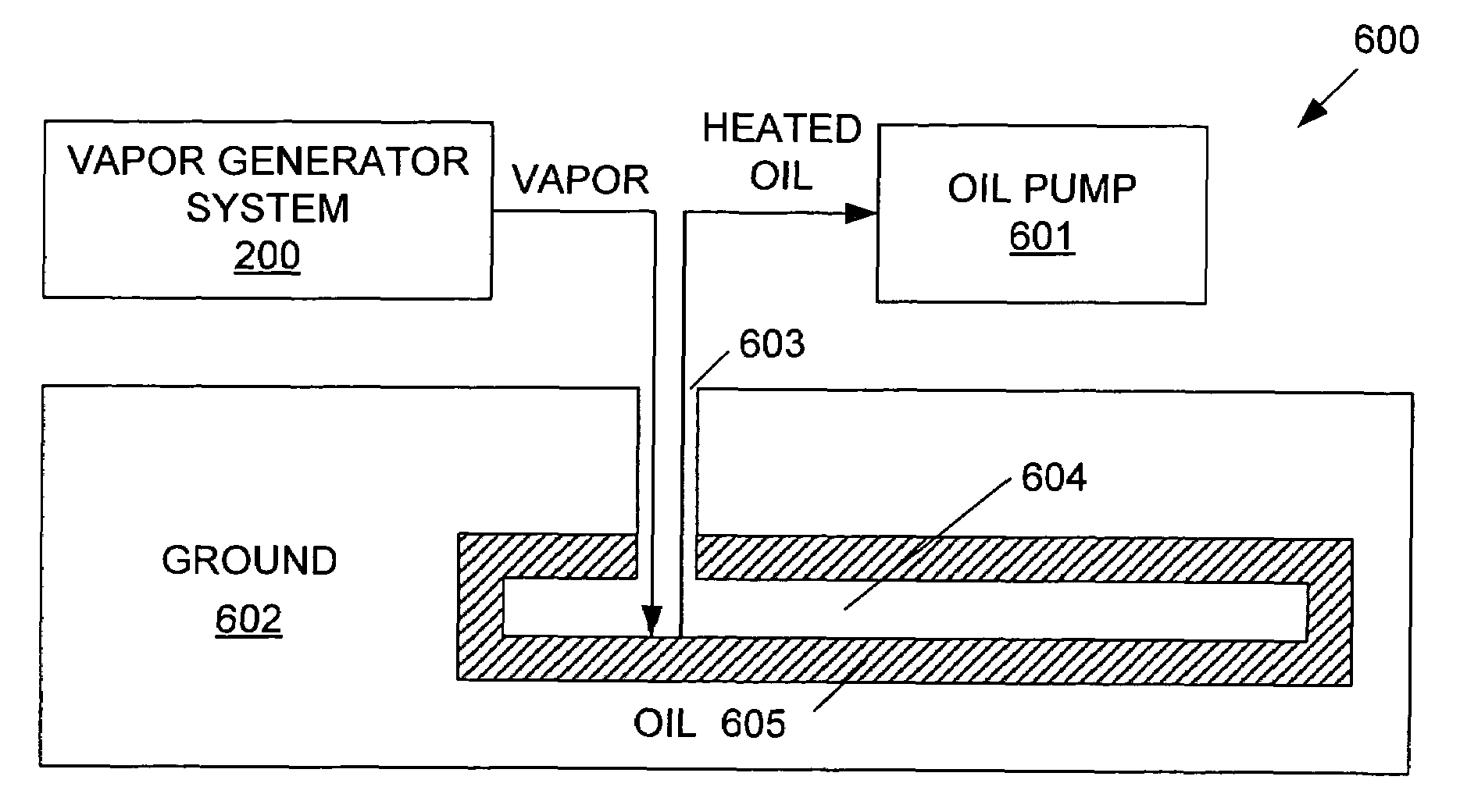

Heavy oil extraction system

ActiveUS20060024135A1Improve efficiencyEfficient systemContaminated soil reclamationOutput powerCombustion chamberWater vapor

An efficient high-temperature water vapor generator is used to heat heavy oil located in an underground cavity, thereby reducing the viscosity of the oil and enabling the oil to be pumped to the surface. The vapor generator includes a combustion chamber and a surrounding structure, wherein a cavity is located therebetween. Water is routed through the cavity and into the combustion chamber, where water vapor and heat are generated in the presence of fuel, ignition and air. The generated heat pre-heats the water in the cavity, thereby creating an efficient system. The water vapor is forced into the underground cavity, thereby heating the oil located in the cavity.

Owner:JAVAHERIAN MEHRDAD

Startup burner assembly for snow melting apparatus and method of snow melting

ActiveUS7455060B2Effective distributionImprove efficiencyPilot flame ignitersWater heatersCombustion chamberCombustor

A startup burner assembly for use in snow melting applications, and which permits initiation of snow melting without first supplying water as a coolant. The startup burner assembly comprises a fuel burner having adjustable combustion output and a nozzle to facilitate the emergence of products of combustion, and a combustion chamber having a first portion in substantially air-tight communication with the fuel burner and enclosing the nozzle and a second portion shaped and dimensioned for disposition into a snow melting receptacle or pit. The combustion chamber has a plurality of discharge holes formed at least on the second portion thereof to permit the egress of products of combustion from the fuel burner into the tank or pit, and thereby permit agitation and melting of snow loaded therein, The startup burner assembly also includes an air cooling assembly for supplying air to cool at least the first portion of the combustion chamber.

Owner:TRECAN COMBUSTION

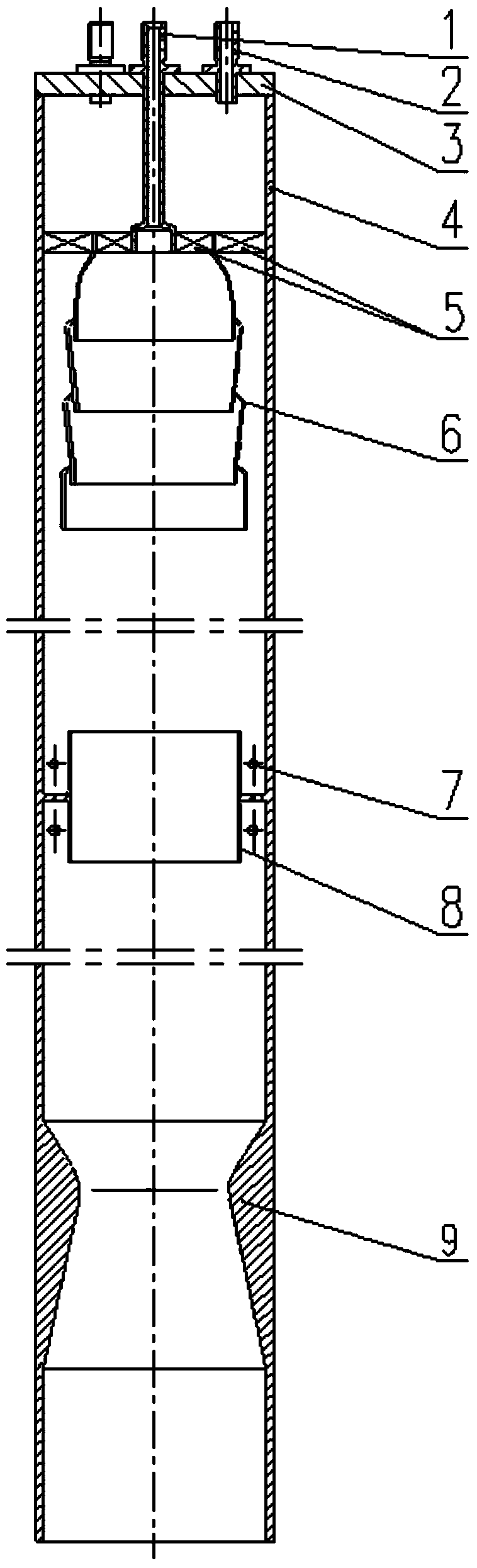

Steam generator used for thickened oil exploitation

InactiveCN103527162AEliminate heat lossShort injection timeSteam generation using pressureFluid removalSpray nozzleEvaporation

The invention discloses a steam generator used for thickened oil exploitation. The steam generator used for thickened oil exploitation comprises a cylindrical barrel body, a dual-ring hydrocyclone, a flame tube, a water film generator and an evaporation converter, wherein the dual-ring hydrocyclone, the flame tube, the water film generator and the evaporation converter are located in the barrel body and are arranged in a coaxial mode in the gas flowing direction in sequence, an end cover provided with a fuel gas inlet connecting pipe and a forced air inlet connecting pipe is fixed at the gas inlet end of the barrel body, forced air is divided into an inner eddy current and an outer eddy current by the dual-ring hydrocyclone fixedly arranged at the position of an inlet of the flame tube, the inner eddy current and the outer eddy current enter the internal space and external space of the flame tube respectively, the forced air entering the flame tube is mixed with fuel gas and then burns to form flame currents, part of the forced air entering a ring runner between the flame tube and the barrel body enters the flame currents through a through-flow hole in the wall surface of the flame tube, most of the forced air entering the ring runner between the flame tube and the barrel body flows out through an outlet, the water film generator is composed of at least one circle of pressure water nozzles arranged on the inner wall of the barrel body, and the evaporation converter is a section of runner with the inner cavity contracting gradually at first and expanding gradually afterwards. The steam generator used for thickened oil exploitation has the advantages of being reasonable in structure, high in reliability, long in service life, saving in energy, and high in efficiency.

Owner:CHENGDU ENGINE GROUP

Downhole steam generator and method of use

ActiveUS20140209310A1Steam generation using pressureInsulationHydrocotyle bowlesioidesCombustion products

A downhole steam generation system may include a burner head assembly, a liner assembly, a vaporization sleeve, and a support sleeve. The burner head assembly may include a sudden expansion region with one or more injectors. The liner assembly may include a water-cooled body having one or more water injection arrangements. The system may be optimized to assist in the recovery of hydrocarbons from different types of reservoirs. A method of recovering hydrocarbons may include supplying one or more fluids to the system, combusting a fuel and an oxidant to generate a combustion product, injecting a fluid into the combustion product to generate an exhaust gas, injecting the exhaust gas into a reservoir, and recovering hydrocarbons from the reservoir.

Owner:WORLD ENERGY SYST

Heavy oil extraction system

ActiveUS7293532B2Improve efficiencyEfficient systemContaminated soil reclamationOutput powerCombustion chamberWater vapor

An efficient high-temperature water vapor generator is used to heat heavy oil located in an underground cavity, thereby reducing the viscosity of the oil and enabling the oil to be pumped to the surface. The vapor generator includes a combustion chamber and a surrounding structure, wherein a cavity is located therebetween. Water is routed through the cavity and into the combustion chamber, where water vapor and heat are generated in the presence of fuel, ignition and air. The generated heat pre-heats the water in the cavity, thereby creating an efficient system. The water vapor is forced into the underground cavity, thereby heating the oil located in the cavity.

Owner:JAVAHERIAN MEHRDAD

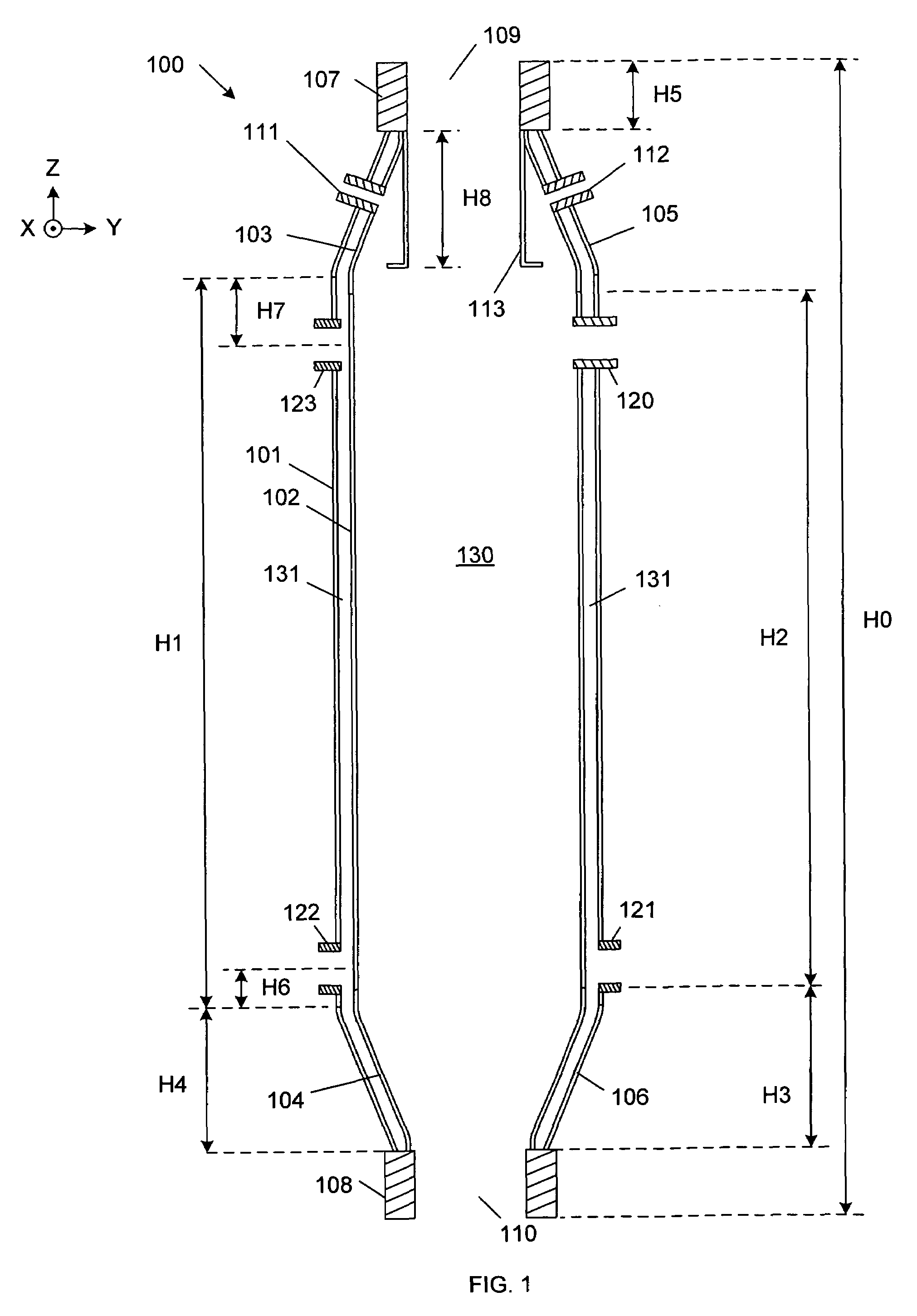

Vapor generator with preheater and method of operating same

InactiveUS20070283905A1Improve efficiencyEfficient systemBoiler water tubesSteam generation using pressureCombustion chamberWater vapor

An efficient high-temperature water vapor generator includes a combustion chamber and a surrounding structure, wherein a cavity is located therebetween. Water is pumped into the cavity at a location near a first end of the combustion chamber. Water is removed from the cavity at a location near a second end of the combustion chamber, opposite the first end. The water removed from the cavity is injected into the combustion chamber at a location near the first end. Fuel and air are also introduced into the combustion chamber at the first end. The fuel and air are ignited near the first end of the combustion chamber, thereby creating high-temperature water vapor, and pre-heating the water in the cavity surrounding the combustion chamber.

Owner:JAVAHERIAN MEHRDAD

Crop re-hydration system utilizing a direct-fired steam generator having continuous water circulation

InactiveUS6978740B1Avoid problemsProblematic formWater circulationSteam generation using pressureCombustion chamberDouble wall

A direct-fired steam generator system is used in conjunction with a baler for providing steam for re-hydrating the crop being baled. Cooling water is pumped through water jackets defined by double walls surrounding the combustion chamber and adjacent components, with this water being routed exteriorly of the water jackets and back to a three-way water control valve provided for normally routing the water back to the cooling water reservoir. The control valve is selectively actuated to couple the returning water to an injector flange for metering the water into an outlet end of the combustion chamber only when a flame is present or soon to be present in the combustion chamber, whereby the water will come into contact with hot combustion gases and be changed to steam which is routed on to be applied to the crop being baled.

Owner:DEERE & CO

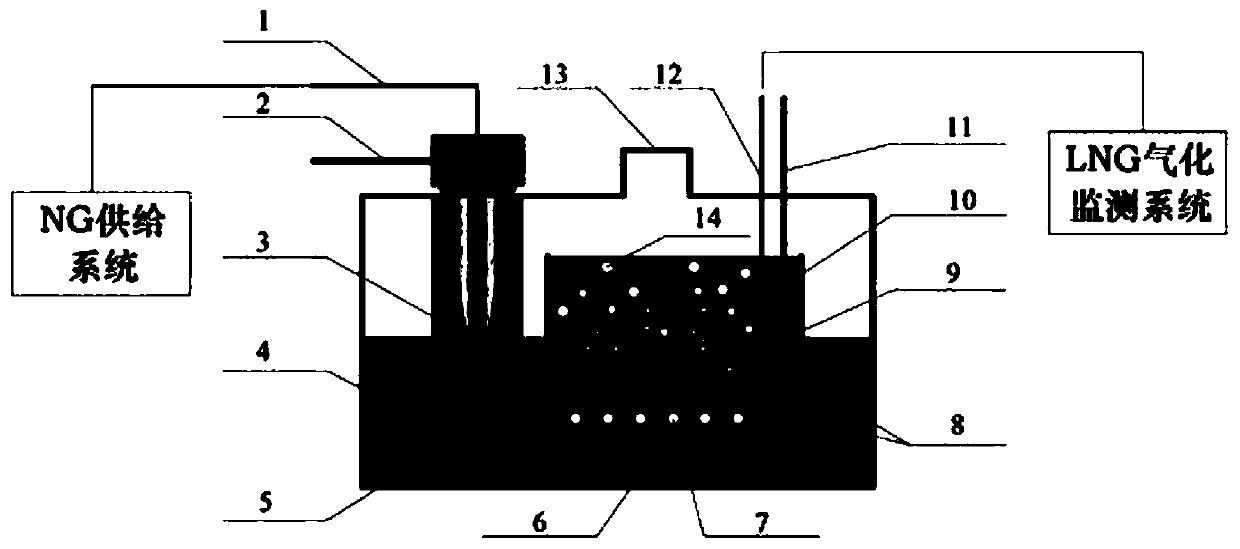

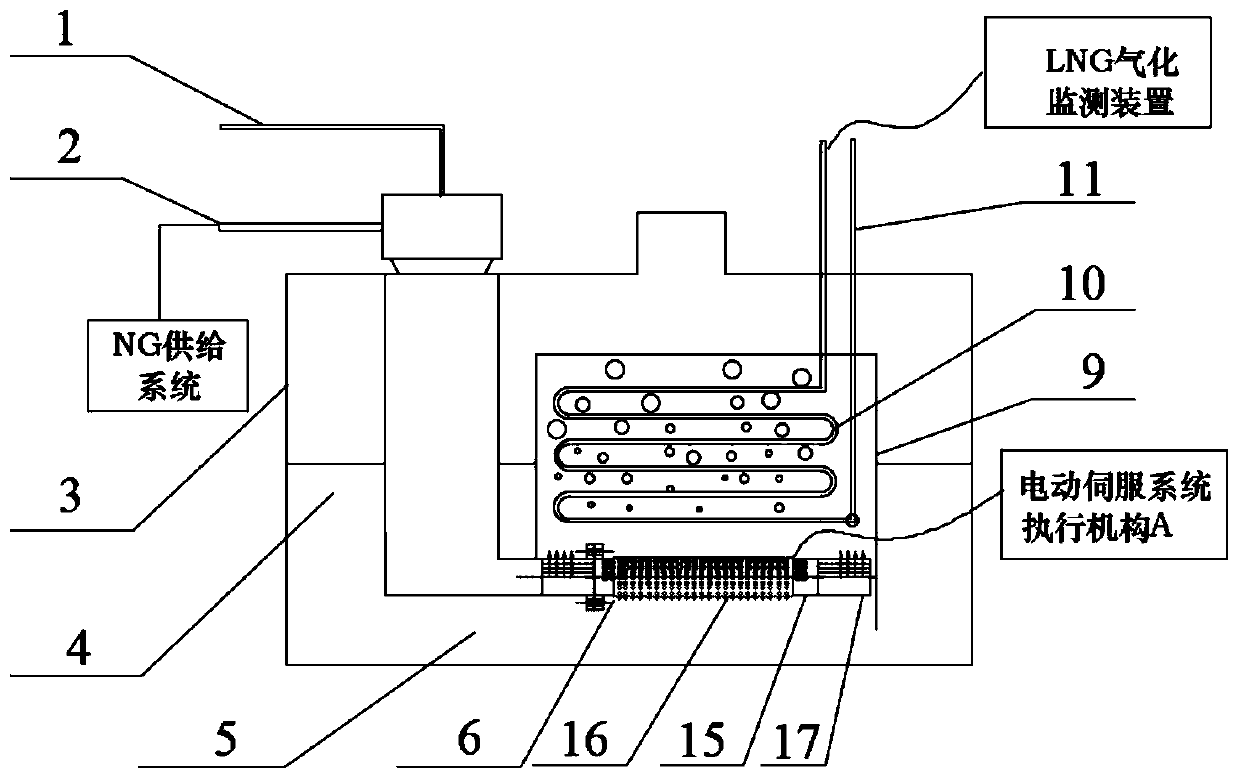

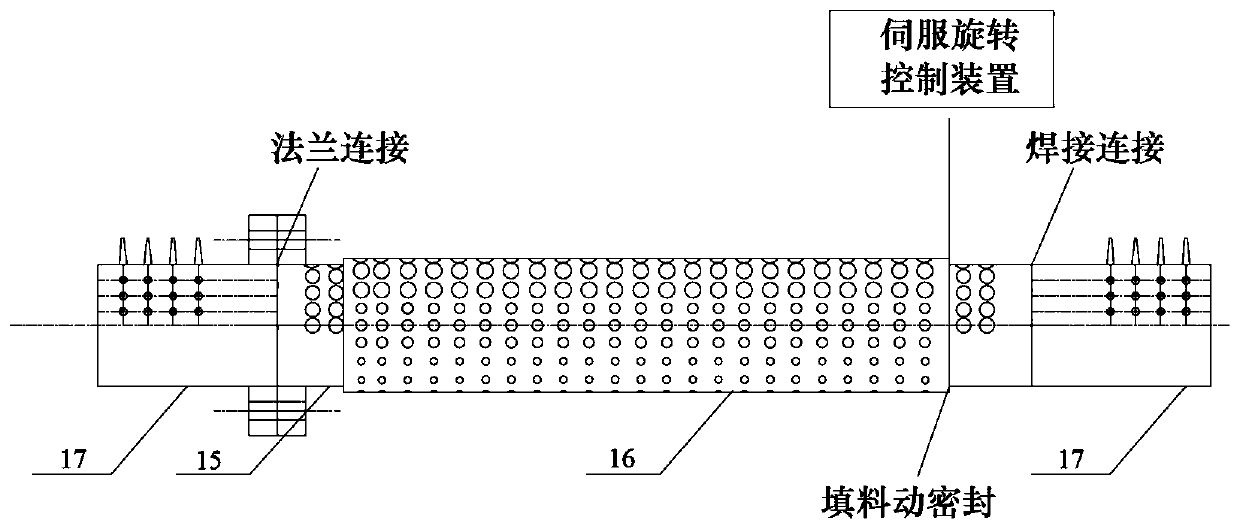

Adjustable flue gas uniform distribution device for submerged combustion gasifier

ActiveCN110925727AIncrease disturbanceReduce consumptionSteam generation using pressureSubmerged flame steam boilersThermodynamicsFlue gas

The invention discloses an adjustable flue gas uniform distribution device for an submerged combustion gasifier. The adjustable flue gas uniform distribution device comprises a flue gas uniform distributor, wherein the flue gas uniform distributor is composed of an inner flue gas uniform distributor pipe section, an outer flue gas uniform distributor pipe section and a dead zone turbulent flow section; two ends of the inner flue gas uniform distributor pipe section are connected with the dead zone turbulent flow section, one end of the inner flue gas uniform distributor pipe section is in a flange connection mode, and the other end of the inner flue gas uniform distributor pipe section is in a welding mode; and the inner flue gas uniform distributor pipe section is coaxially embedded intothe outer flue gas uniform distributor pipe section, and the outer flue gas uniform distributor pipe section is connected with the power output of an electric servo system actuating mechanism. According to the requirement of the gasification rate and the gasification amount, the electric servo system actuating mechanism A drives the outer flue gas uniform distributor pipe section to rotate to a corresponding angle to change the diameter of a flue gas spraying hole so as to adjust the effective flue gas spraying area, and therefore, the spraying speed of the flue gas is controlled in a certainrange, so that the flue gas fully exchanges heat with a water bath, the disturbance of a strong transverse pipe bundle is achieved, the freezing of a serpentine coil pipe is avoided, and the purpose of improving the gasification rate is achieved.

Owner:XI'AN PETROLEUM UNIVERSITY

Method and device of turbine submerged combustion boiler

InactiveUS8671689B2Improve energy efficiencyStable and reliableSteam generation using pressureGas turbine plantsComing outCombustion system

Owner:LI WEICHENG

Large scale cost effective direct steam generator system, method, and apparatus

ActiveUS11242772B2Pressure-fired steam boilersSteam generation using pressureCombustionExhaust fumes

Owner:XDI HLDG LLC

Using an estimated heat output value of a direct-fired steam generator in controlling water flow to maintain a desired constant steam temperature

InactiveUS20060283164A1Constant outputSimple waySteam generation using pressureMowersDirect combustionWater flow

A direct-fired steam generator used for supplying steam for re-hydrating dry crop during baling is controlled so as to produce a desired constant steam temperature output by collecting data from which the heat output of the steam generator can be calculated and using this calculation together with the difference between the actual steam temperature and the desired steam temperature to control the amount of process water sent to the steam generator in order to correct any error in steam temperature. Steam temperature is measured in either one of the steam injection manifolds or in an injection tube coupled to an injection manifold so as to be close to the point of application of the steam to the crop.

Owner:DEERE & CO

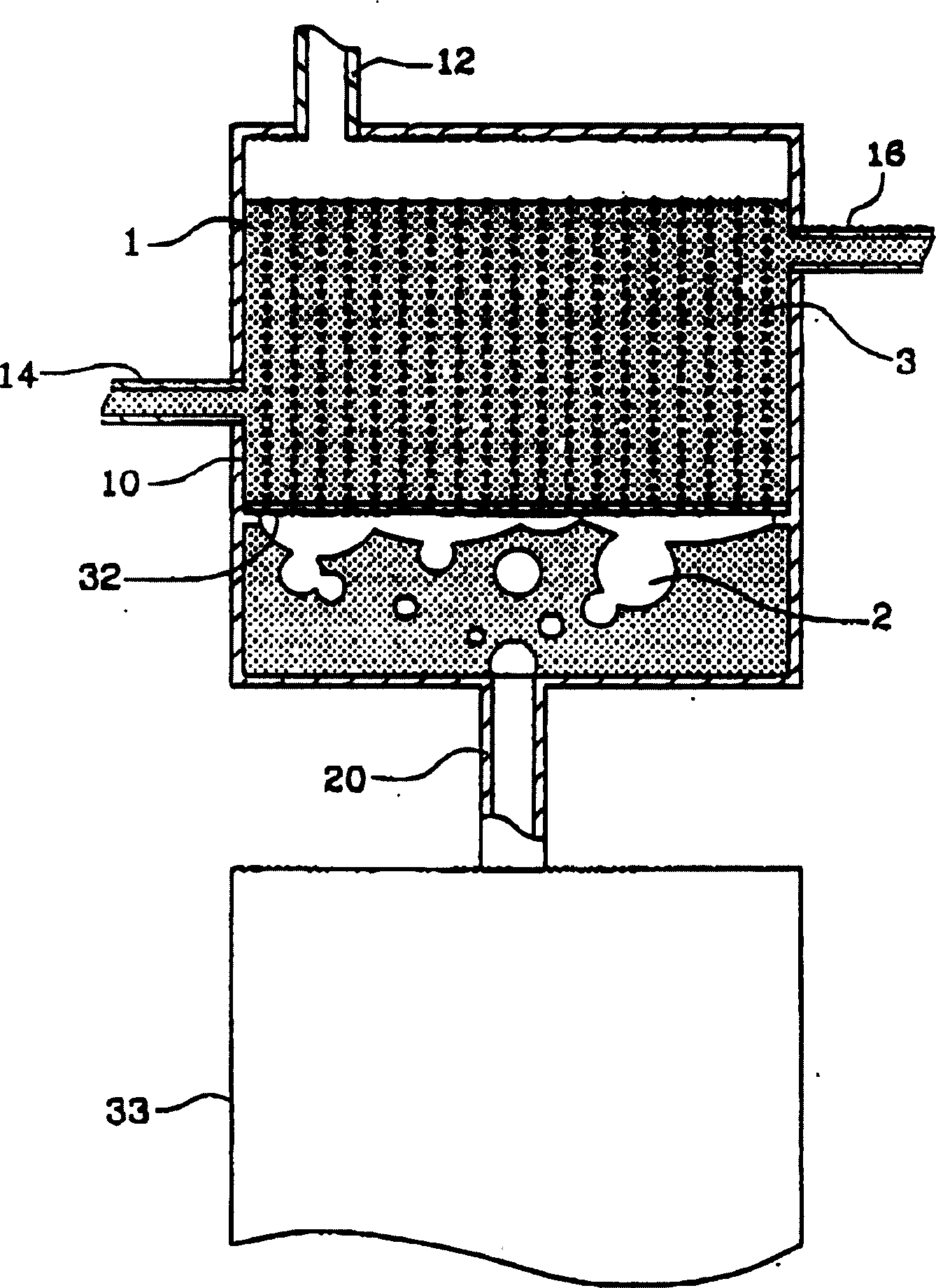

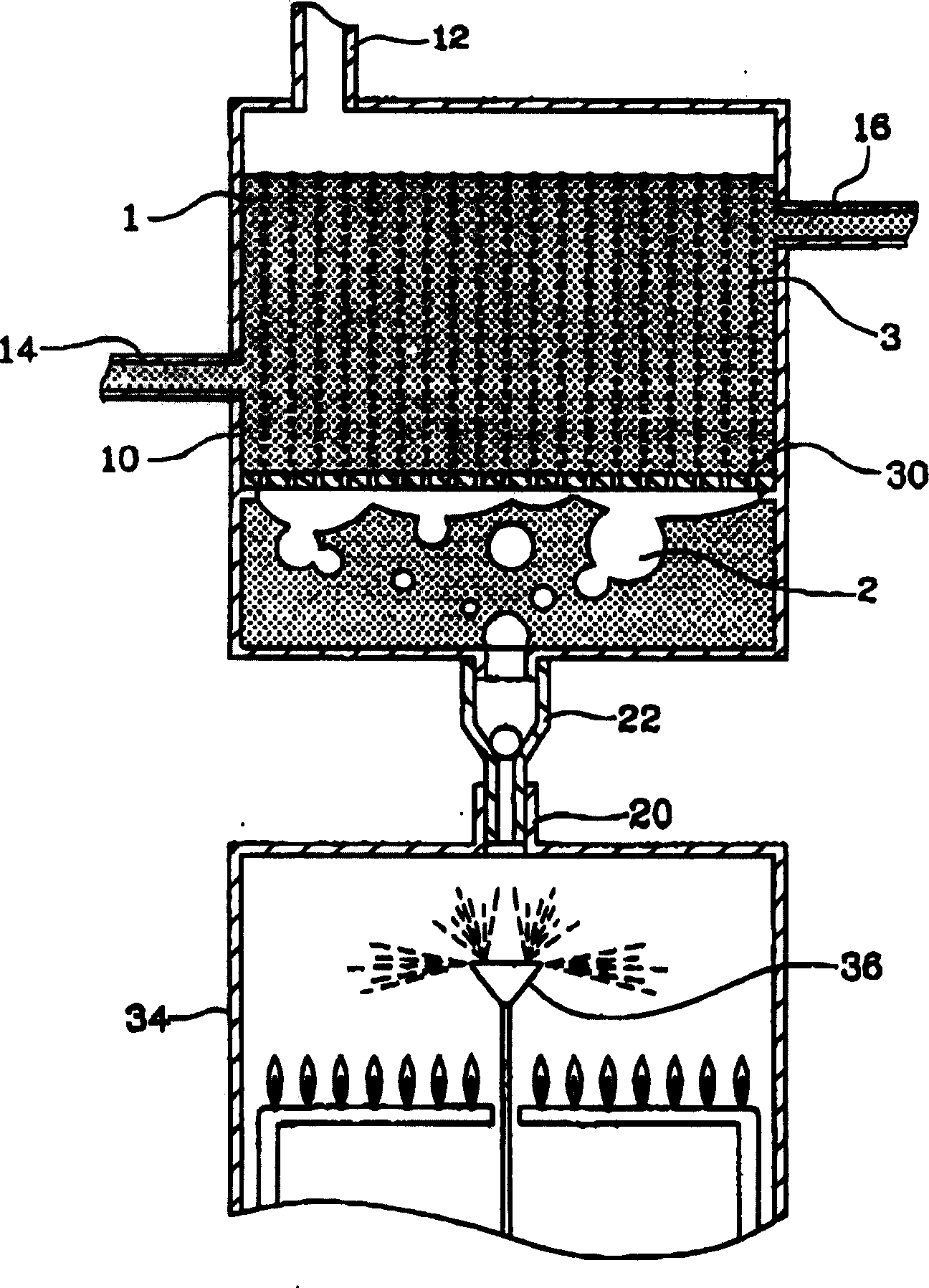

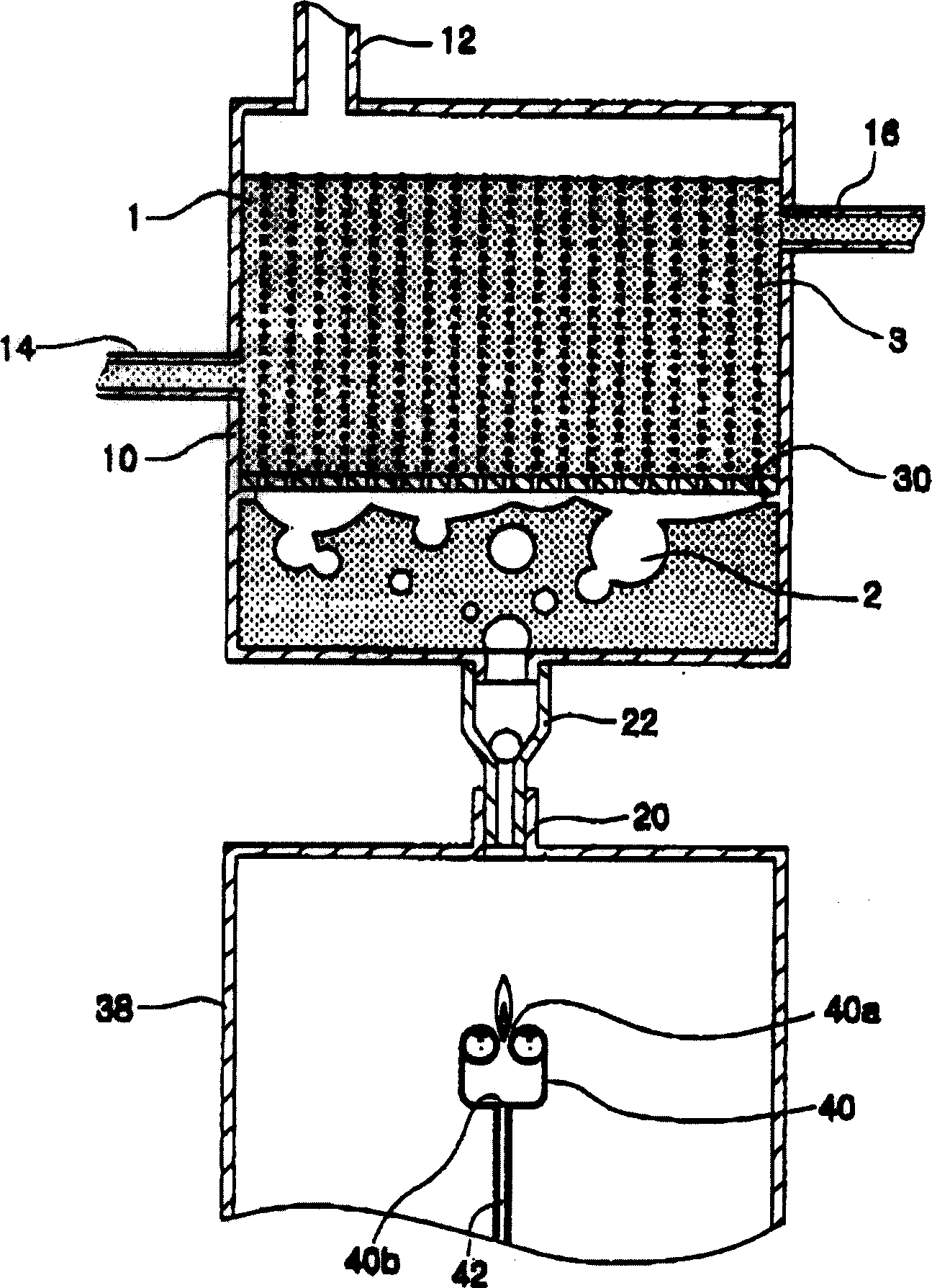

Heat exchanging type boiler

InactiveCN1491334AAvoid meltingPrevent oxidationSteam generation using pressureSubmerged flame steam boilersCombustion chamberWater discharge

The present invention relates to a heat exchanging type boiler that includes: a water retaining reservoir (10) in which a predetermined amount of water is charged; and a combustion chamber (33) for emitting heating gas at a high temperature to the water in the water retaining reservoir (10) through a heating gas supply pipe (20) such that the water in the water retaining reservoir (10) is raised to produce steam at a high pressure, the boiler characterized in that water discharging film (32) disposed between the heating gas supply pipe (20) and the water and having a plurality of fine through holes such taht the water in the water retaining reservoir (10) is not leaked to the combustion chamber (33) and at the same time the heating gas emitted to the water by means of the heating gas supply pipe (20) is distributed in substantially small bubble form. Thus, water heating speed can be considerably increased, heat efficiency of the boiler can be more improved, a volume of the boiler can be decreased, the life of the boiler can be semi-permanently extended since the water retaining reservoir is not directly heated, and the cleaning of the interior of the boiler can be carried out in an easy manner.

Owner:辛昶根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com