Adjustable flue gas uniform distribution device for submerged combustion gasifier

A submerged combustion and adjustable technology, applied in the field of LNG vaporizers, can solve the problem of serious icing in the "dead zone" that cannot be adjusted for the injection speed, and achieve the effects of saving energy consumption, facilitating maintenance, and avoiding the formation of ice layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing.

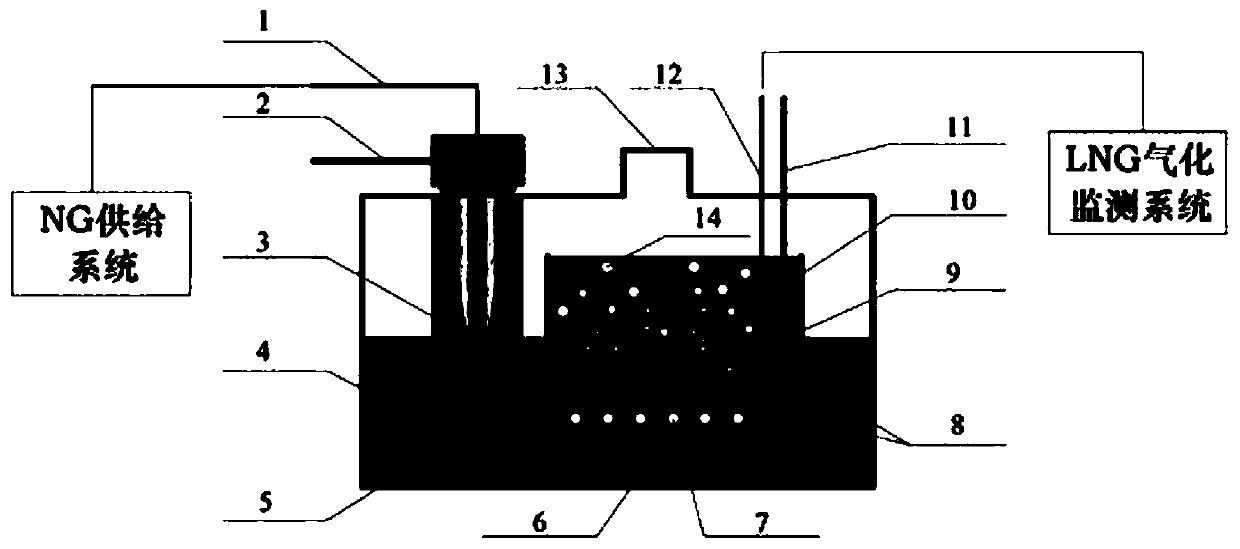

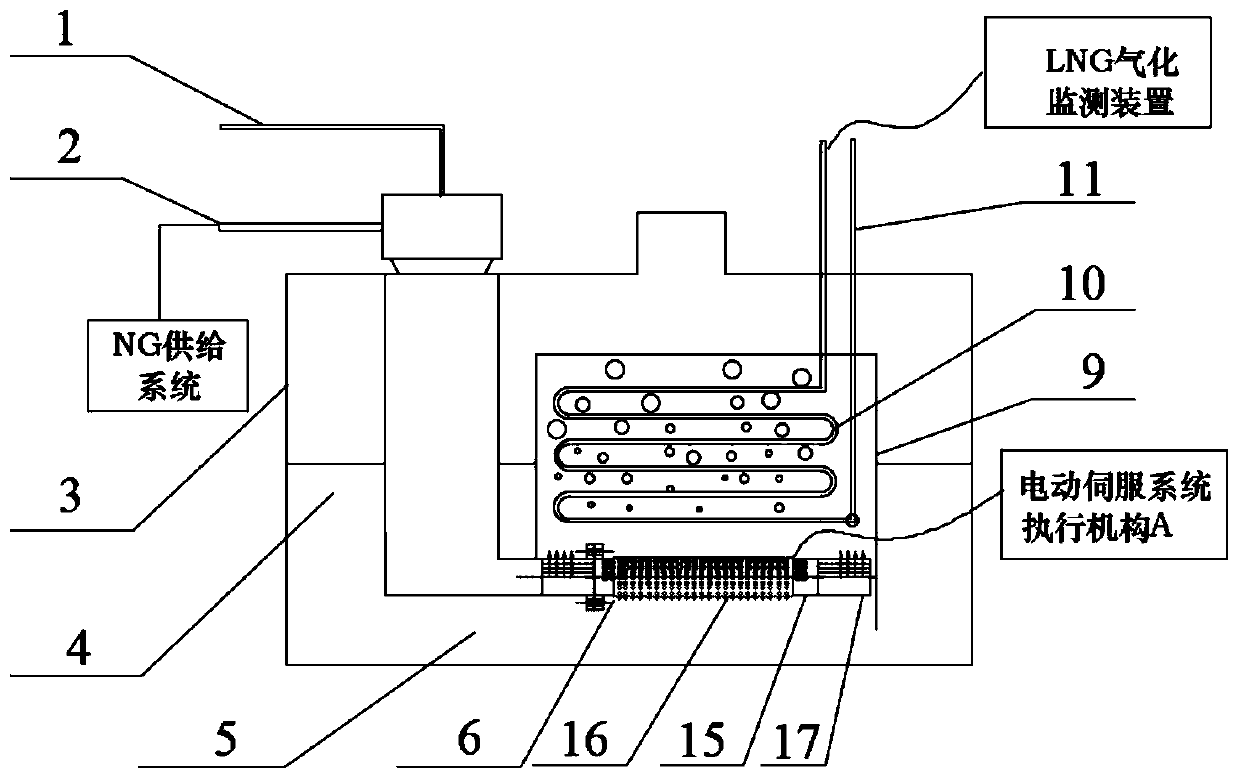

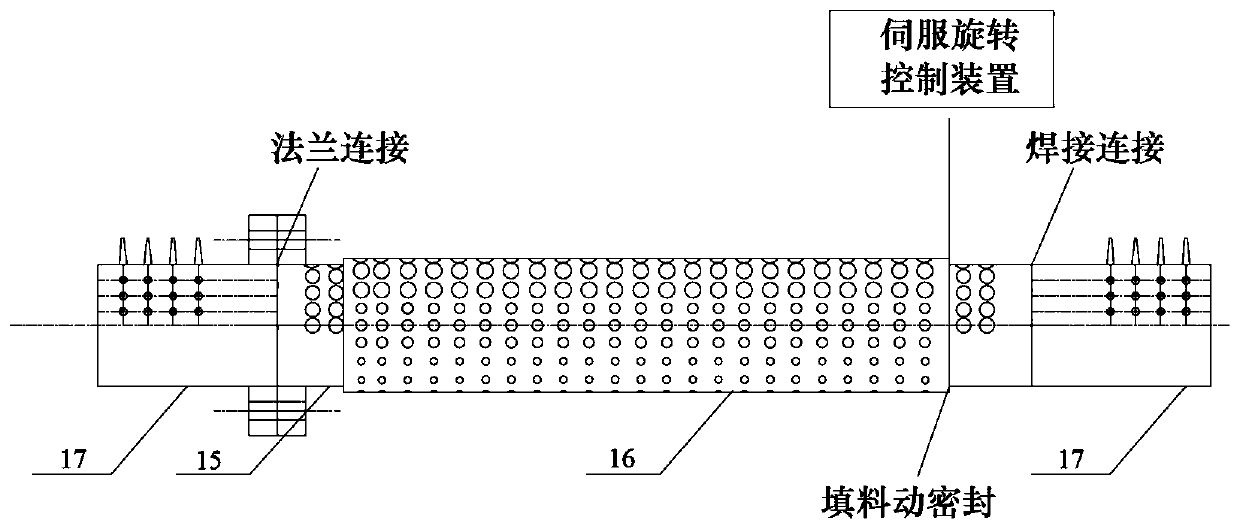

[0025] figure 1 It is an adjustable flue gas uniform distribution device commonly used in submerged combustion gasifiers in the prior art. NG passes through NG inlet 1, air 2 passes through air inlet 2 and is mixed and burned in combustion chamber 3, and the combustion chamber 3 is immersed in the water bath 4, and the generated flue gas of the combustion product is used as a heat source for LNG gasification heating. The flue gas enters the flue gas distributor 6 along with the flue gas pipe 5 , the flue gas homogenizer 6 is located below the cofferdam 9 , and the heat transfer tube bundle 10 is arranged in the cofferdam 9 in a direction perpendicular to the flue gas pipe 5 . The flue gas is sprayed into the water bath 4 in the form of bubbles 14 through the flue gas injection holes 7, causing the water bath 4 to generate "pseudo-static" turbulence and traverse the heat trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com