Startup burner assembly for snow melting apparatus and method of snow melting

a technology of snow melting apparatus and starter assembly, which is applied in the direction of combustion process, combustion ignition, discharged material handling, etc., can solve the problems of restricting the use of such equipment and water supply in sufficient quantities, and achieve the effect of improving the efficiency of the debris removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

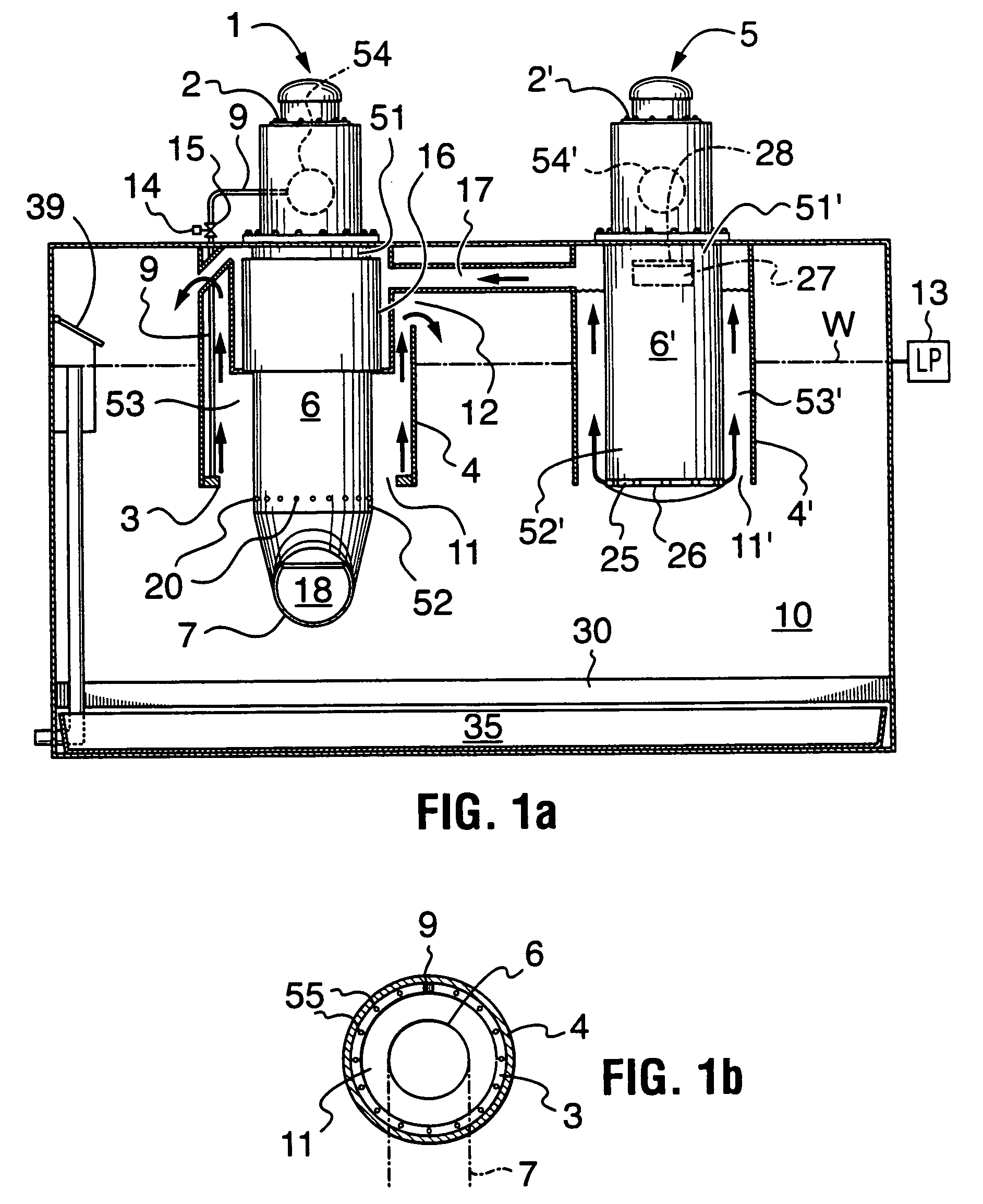

[0050]Snow melters used in snow removal typically incorporate at least one fuel burner to generate the heat required for melting collected snow. In such devices, overheating of the burner is prevented through the use of water as a coolant. This cooling may be provided by pumping water through a jacket surrounding the burner assembly and / or by immersion of at least a portion of the burner assembly into a reservoir of water. The present invention overcomes this requirement for initial water cooling by providing a startup burner assembly which enables burner ignition without initially supplying water as a coolant.

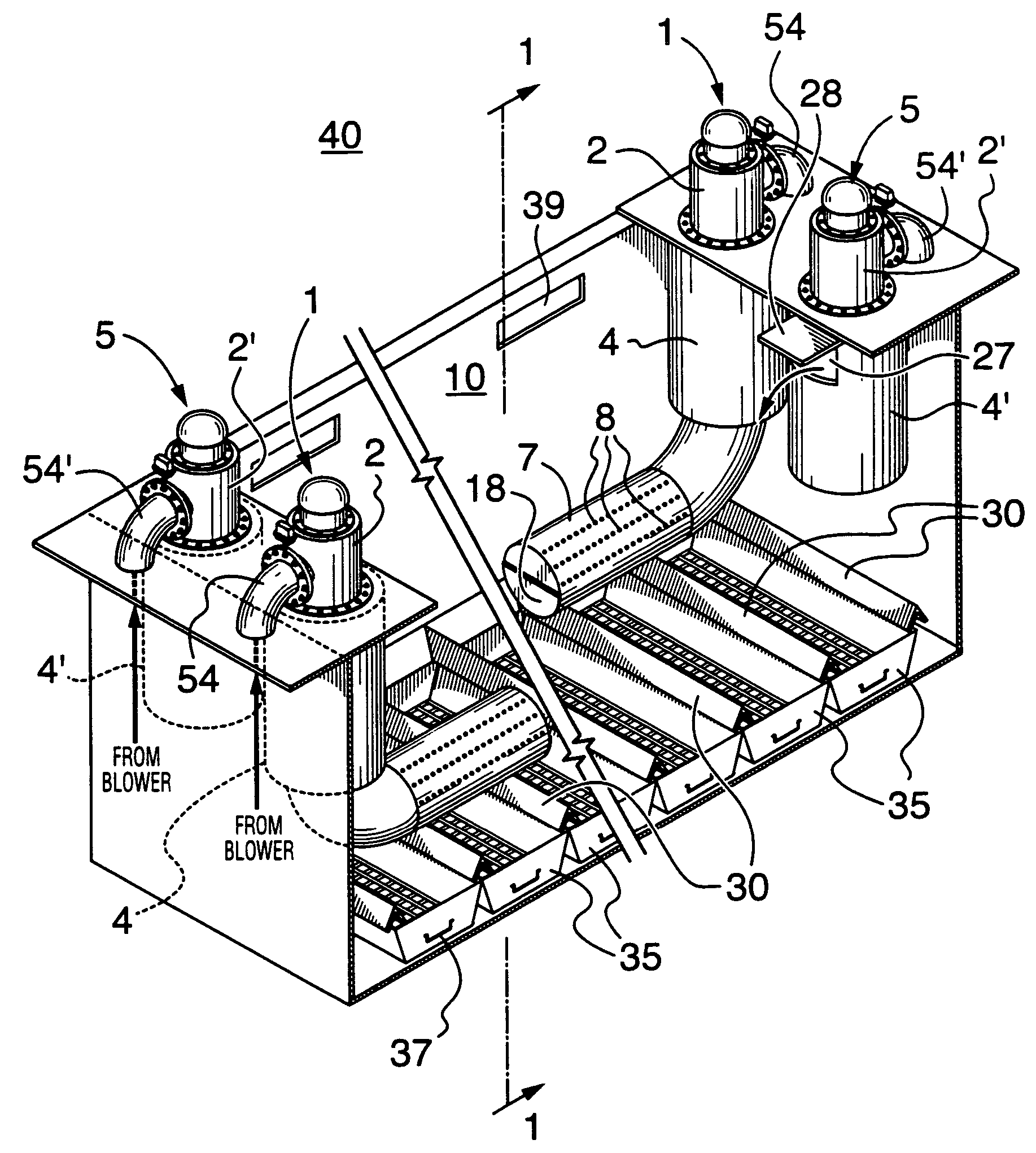

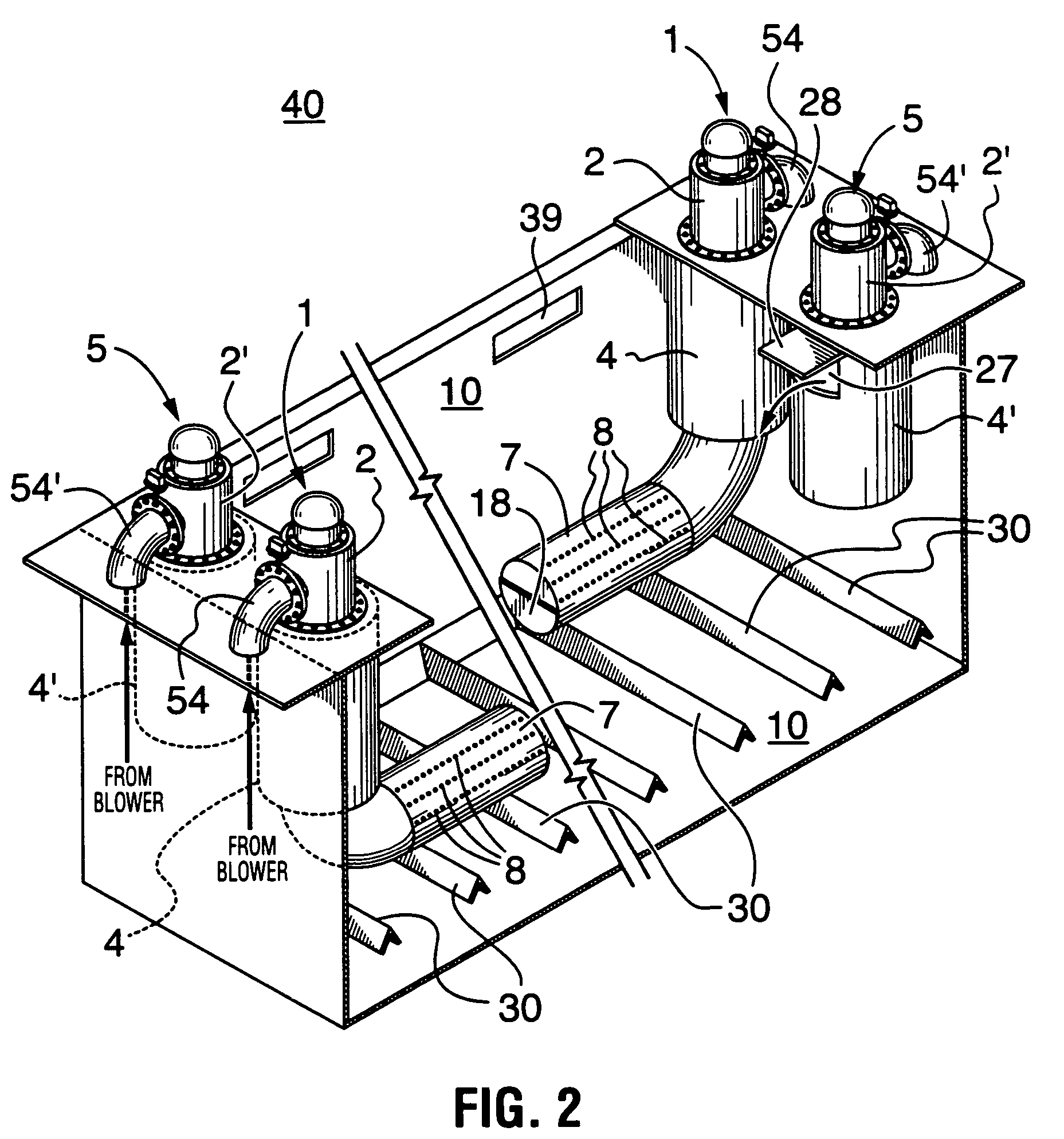

[0051]Most snow melters commonly known and used in the art may be fitted with the burner assembly of the present invention. These include single or multi-burner devices. For illustration FIG. 1a shows a double-burner snow melting device which incorporates an example of the startup burner assembly (1) of the present invention, mounted operably to a receptacle, or tank (10).

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com