Heat exchanging type boiler

A boiler and water tank technology, which is applied in the field of heat exchange boilers, can solve the problems of boiler rupture, improvement, and long-term cleaning of water tanks or water pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] best practice

[0029] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

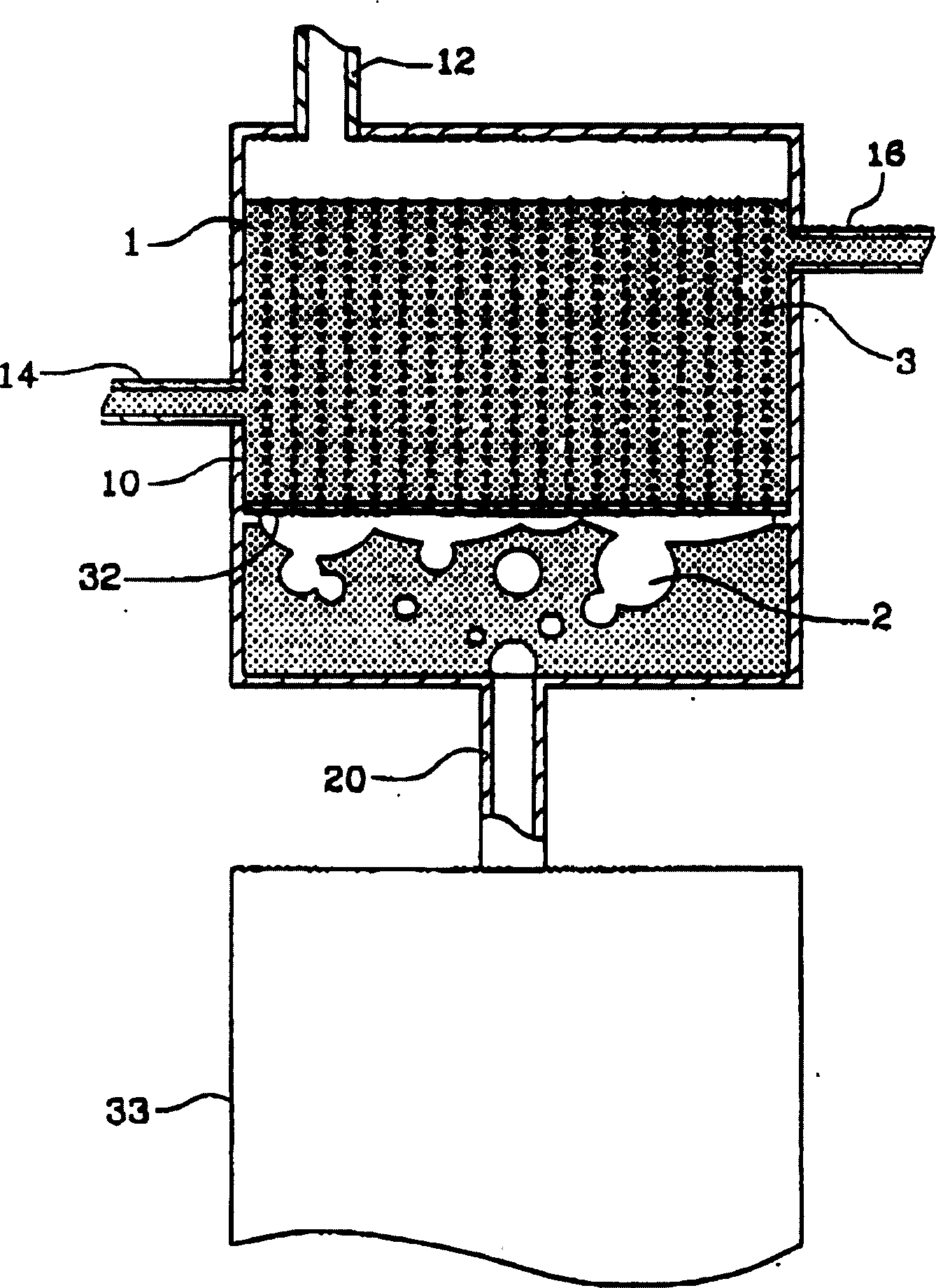

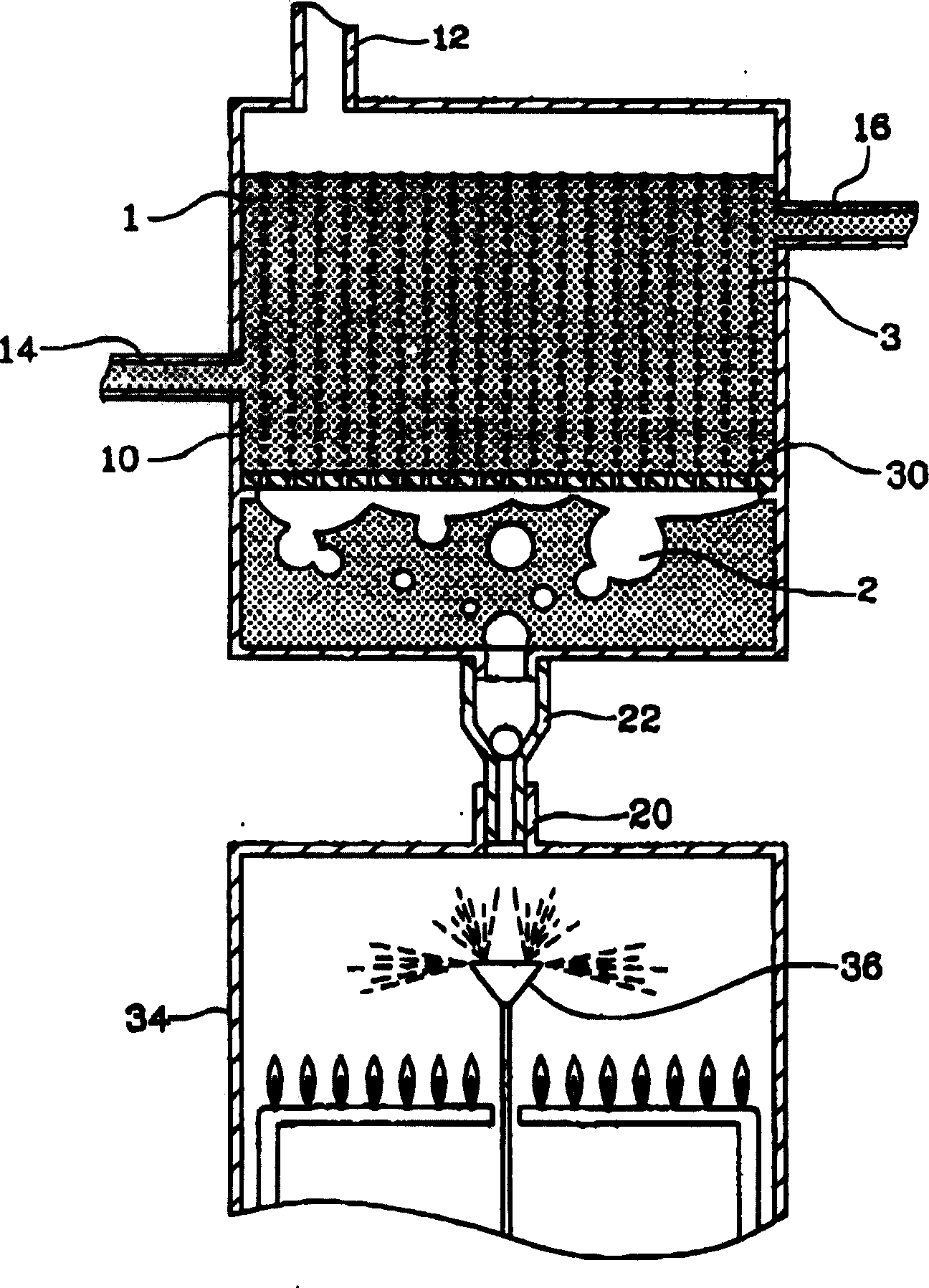

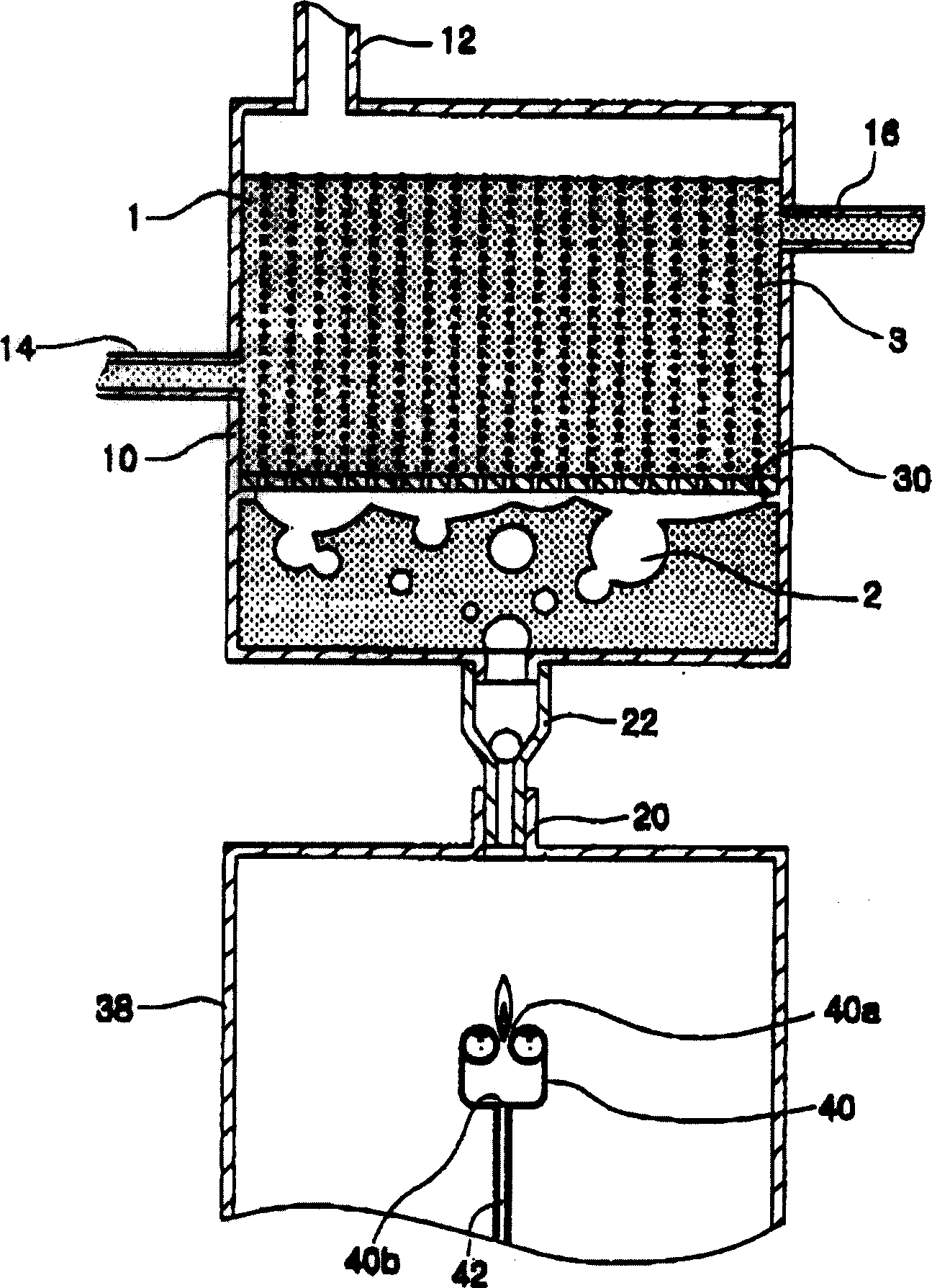

[0030] First refer to figure 1 , the first embodiment of the heat exchange boiler of the present invention includes a water tank 10 with a certain amount of water, and a combustible gas supply pipe 20 for providing bubbles of high-temperature combustible gas 2 in the water tank 10, and a drainage film 32 for dissolving The bubbles of the combustible gas 2 emitted from the combustible gas supply pipe 20 are dispersed in the form of very small bubbles 3 so that the contact area of the bubbles of the combustible gas 2 can be expanded.

[0031] In this case, the water tank 10 is in the shape of a closed box, which has a steam discharge pipe 12 through which combustible gas and steam are discharged at the top plate, and a water supply pipe 14 for supplying water 1 at one side of the water tank 10 into the water tank 10, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com