High-temperature foaming agent for thickened oil steam huff and puff and preparation method thereof

A high-temperature foaming agent and steam technology, used in the field of thermal oil recovery, can solve problems such as steam channeling, and achieve the effects of uniform bubble size, prolonged half-life, good high temperature resistance and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

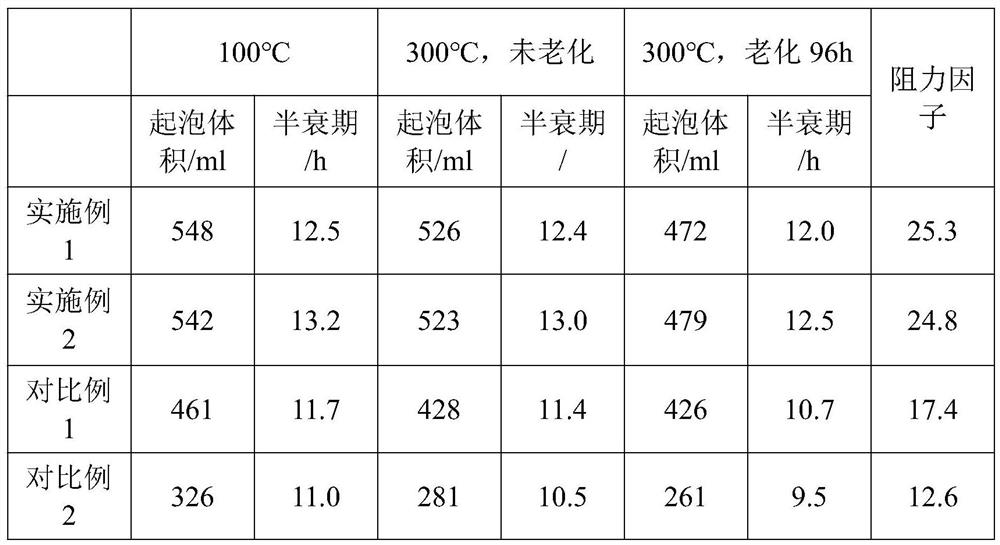

Examples

Embodiment 1

[0018] Step 1: Add Ce(NO 3 ) 3 ·6H 2 O was added to deionized water, stirred for 8 min, and then Ce(NO 3 ) 2 ·6H 2 The O solution was dropped into the sodium alginate solution, and stirred rapidly until the gel was formed; then the gel was dried in a vacuum environment at 33°C for 8 hours, and the sample was transferred to a muffle furnace and heated to a temperature of 630°C after drying Calcined for 3h to obtain honeycomb CeO 2 . where Ce(NO 3 ) 3 ·6H 2 The volume ratio of O solution and sodium alginate solution was 1:5.

[0019] Step 2: Add sodium acrylate and 1-vinyl-2-pyrrolidone into deionized water, and ultrasonicate for 20 minutes to obtain mixed solution A; the CeO prepared in step 1 2 Add deionized water, sonicate for 3 minutes to obtain a mixed solution, then add sodium α-olefin sulfonate to the mixed solution under stirring at room temperature, after the addition is completed, adjust the pH of the system to 7 with NaOH solution and continue stirring for 3...

Embodiment 2

[0022] Step 1: Add Ce(NO 3 ) 3 ·6H 2 O was added to deionized water, stirred for 6 min, and then Ce(NO 3 ) 2 ·6H 2 The O solution was dropped into the sodium alginate solution and stirred rapidly until the gel was formed; then the gel was dried in a vacuum environment at 35°C for 6 hours, and the sample was transferred to a muffle furnace and heated to a temperature of 630°C after drying Calcined for 3h to obtain honeycomb CeO 2 . where Ce(NO 3 ) 3 ·6H 2 The volume ratio of O solution and sodium alginate solution was 1:6.

[0023] Step 2: Add sodium acrylate and 1-vinyl-2-pyrrolidone into deionized water, and sonicate for 24 minutes to obtain mixed solution A; the CeO prepared in step 1 2 Add deionized water, sonicate for 5 minutes to obtain a mixed solution, then add sodium α-olefin sulfonate to the mixed solution under stirring at room temperature, after the addition is completed, adjust the pH of the system to 7 with NaOH solution and continue stirring for 40 minu...

Embodiment 3

[0026] Step 1: Add Ce(NO 3 ) 3 ·6H 2O was added to deionized water, stirred for 7 min, and then Ce(NO 3 ) 2 ·6H 2 The O solution was dropped into the sodium alginate solution, and stirred rapidly until the gel was formed; then the gel was dried in a vacuum environment at 30°C for 6 hours, and the sample was transferred to a muffle furnace and heated to a temperature of 630°C after drying Calcined for 2h to obtain honeycomb CeO 2 . where Ce(NO 3 ) 3 ·6H 2 The volume ratio of O solution and sodium alginate solution was 1:7.

[0027] Step 2: Add sodium acrylate and 1-vinyl-2-pyrrolidone into deionized water, and sonicate for 27 minutes to obtain mixed solution A; the CeO prepared in step 1 2 Add deionized water, sonicate for 4 minutes to obtain a mixed solution, then add sodium α-olefin sulfonate to the mixed solution with stirring at room temperature, after the addition is completed, adjust the pH of the system to 7 with NaOH solution and continue stirring for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com