Low-temperature propellant supplying system, method and device

A low-temperature propellant and supply system technology, applied in jet propulsion devices, rocket engine devices, gas turbine engine tests, etc., can solve problems such as high difficulty in implementation and complicated test methods, and achieve the effect of stable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

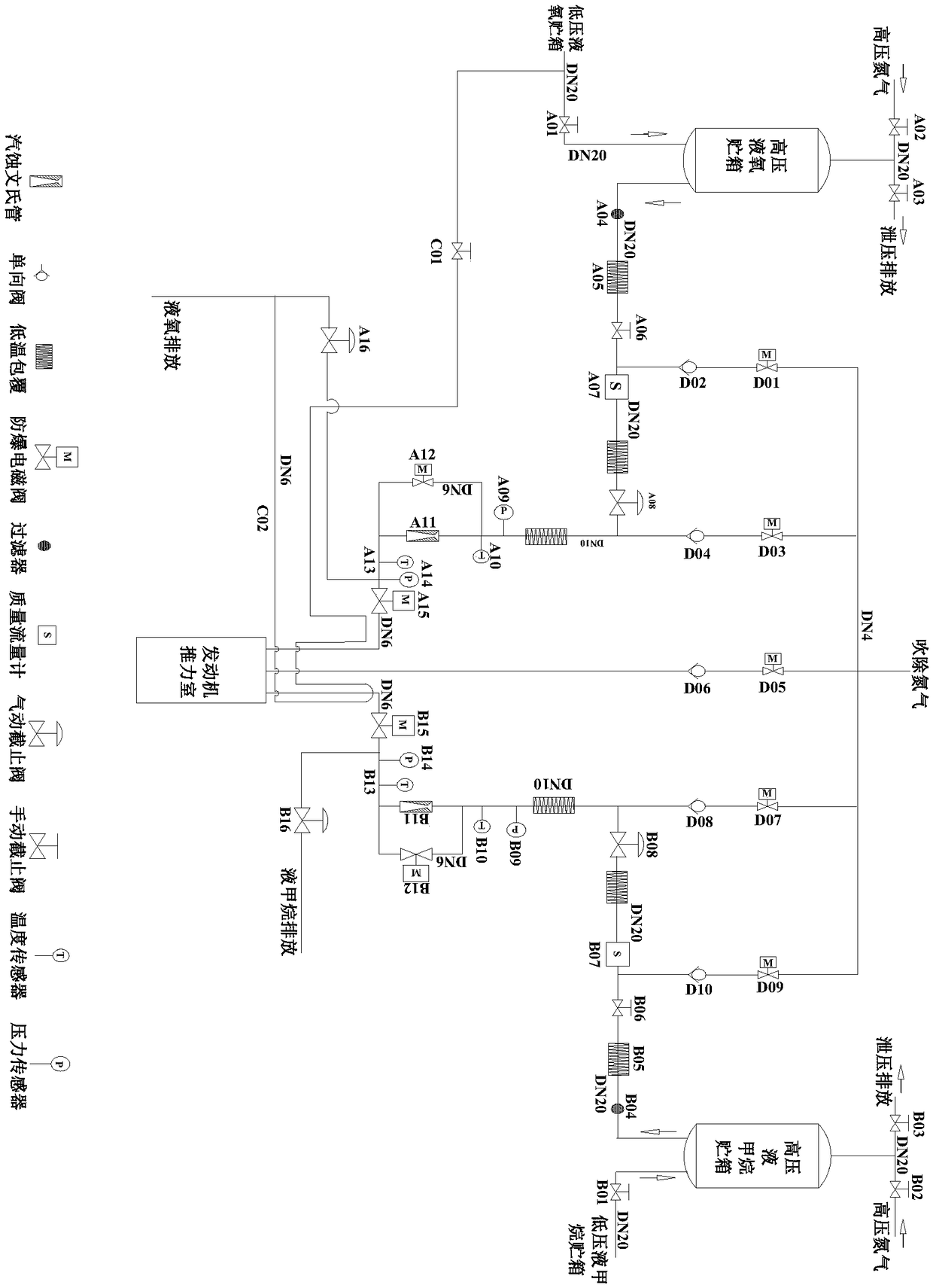

[0061] see figure 1 As shown, Embodiment 1 of the present application provides a cryogenic propellant supply system, including: a nitrogen blowing system 101 , an oxidant supply system 102 , a fuel supply system 103 and a low-pressure liquid oxygen cooling system 104 .

[0062] The nitrogen purge system 101 is used for purging the system piping before and after the experiment and testing the air tightness of the cryogenic propellant supply system.

[0063] When the airtightness of the low-temperature propellant supply system is qualified, the oxidizer supply system 102 is used to deliver liquid oxygen to the thrust chamber of the engine; and the fuel supply system 103 is used to supply the thrust chamber of the engine The chamber transports liquid methane.

[0064] The low-pressure liquid oxygen cooling system 104 is used to cool the pipeline between the solenoid valve (A15, B15) and the thrust chamber of the engine, wherein one solenoid valve (A15) is arranged between the ox...

Embodiment 2

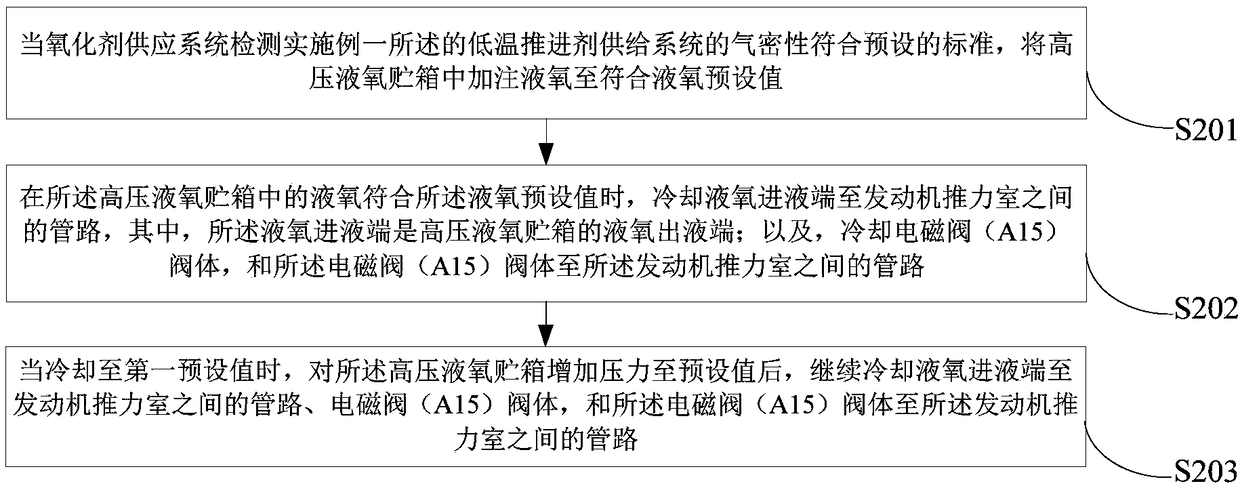

[0082] see figure 2 As shown, Embodiment 2 of the present application also provides a low-temperature propellant cooling method, including:

[0083] S201: When the oxidant supply system detects that the airtightness of the low-temperature propellant supply system described in Embodiment 1 meets the preset standard, fill the high-pressure liquid oxygen storage tank with liquid oxygen to meet the preset value of liquid oxygen;

[0084] S202: When the liquid oxygen in the high-pressure liquid oxygen storage tank meets the liquid oxygen preset value, cool the pipeline between the liquid oxygen inlet port and the engine thrust chamber, wherein the liquid oxygen inlet port is The liquid oxygen outlet end of the high-pressure liquid oxygen storage tank;

[0085] as well as,

[0086] Cooling the solenoid valve (A15) valve body, and the pipeline between the solenoid valve (A15) valve body and the engine thrust chamber;

[0087] S203: When cooling to the first preset value, after in...

Embodiment 3

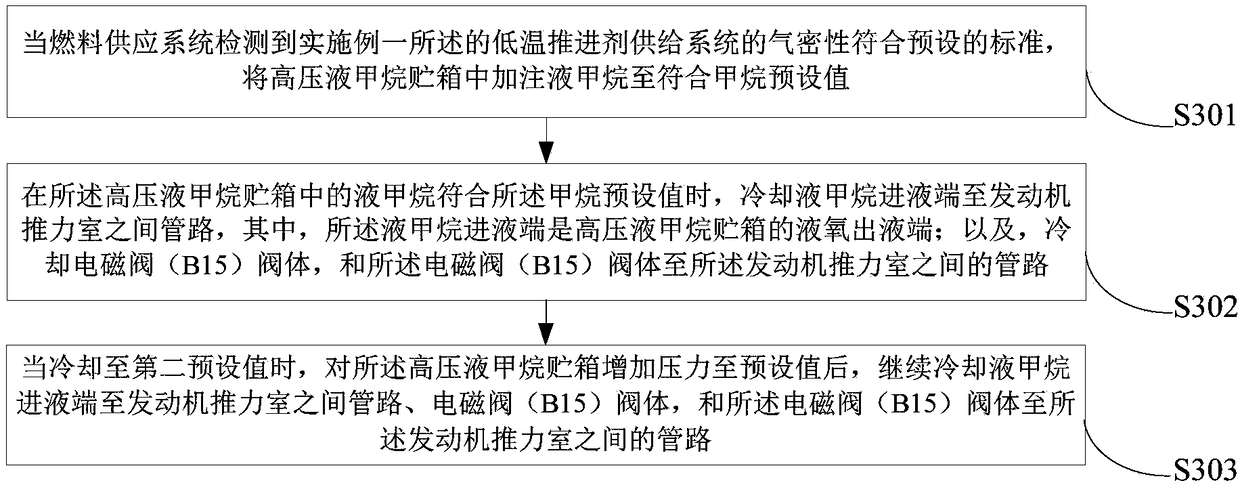

[0089] see image 3 As shown, Embodiment 3 of the present application also provides another low-temperature propellant cooling method, including:

[0090] S301: When the fuel supply system detects that the airtightness of the low-temperature propellant supply system described in Embodiment 1 meets the preset standard, fill the high-pressure liquid methane storage tank with liquid methane to meet the preset value of methane;

[0091] S302: When the liquid methane in the high-pressure liquid methane storage tank meets the methane preset value, the pipeline between the coolant methane liquid inlet end and the engine thrust chamber, wherein the liquid methane liquid methane liquid inlet end is a high-pressure liquid The liquid oxygen outlet end of the methane storage tank;

[0092] as well as,

[0093] Cooling the solenoid valve (B15) valve body, and the pipeline between the solenoid valve (B15) valve body and the engine thrust chamber;

[0094] S303: When cooling to the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com