Gaseous hydrogen/gaseous oxygen eddy current cooling thrust chamber injector

An injector and thrust chamber technology, which is applied in the field of gas-hydrogen/gas-oxygen vortex cooling thrust chamber injectors, can solve the problems of unsatisfactory cooling effect and high temperature of the combustion chamber wall surface, and achieves improved cooling effect, improved stability, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings:

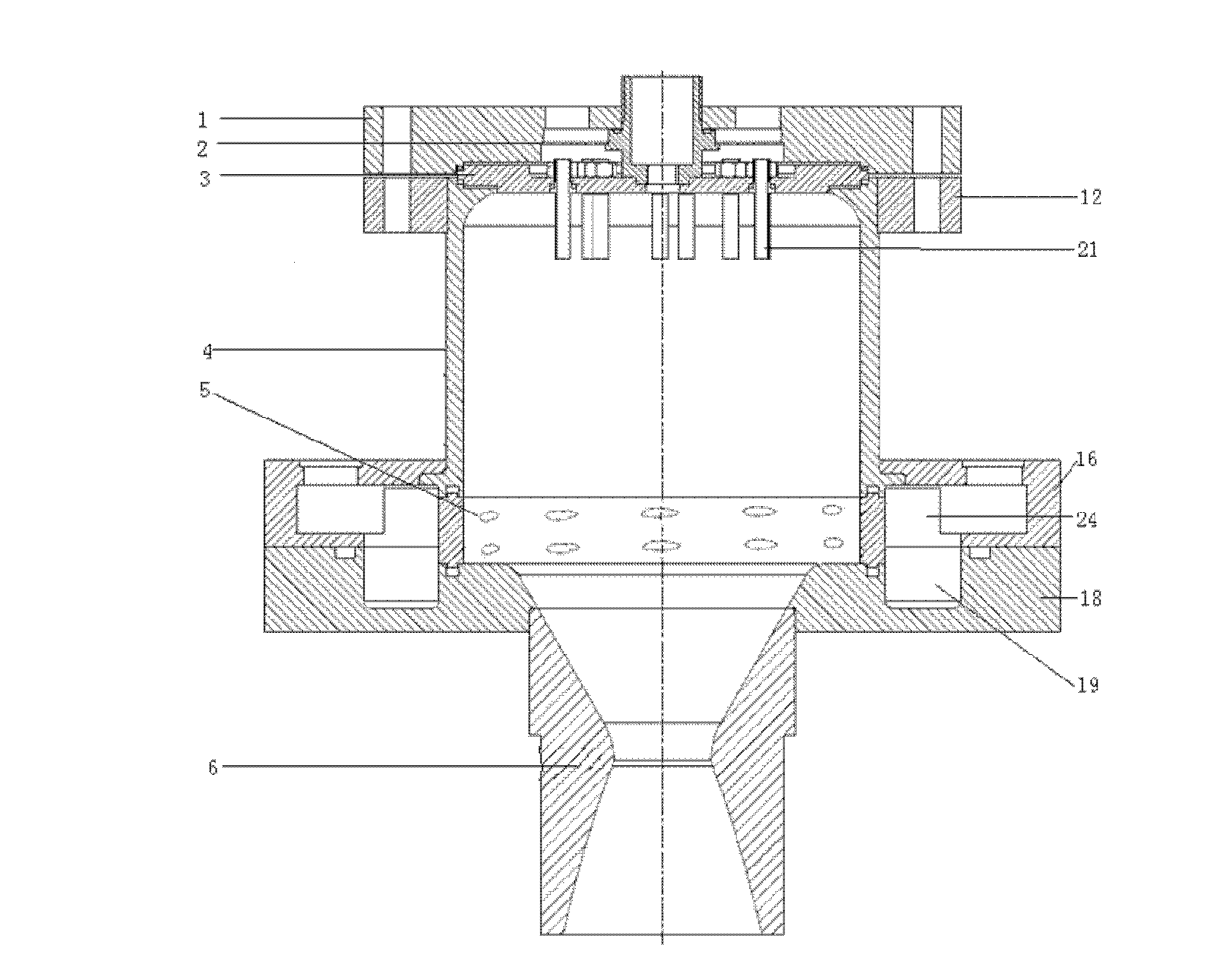

[0036] A gas-hydrogen / gas-oxygen vortex cooling thrust chamber injector proposed by the present invention, such as figure 1 As shown, it includes an injector head 1 , a spoiler 2 , an injection panel 3 , a combustion chamber 4 , a gas-oxygen injection ring 5 and a nozzle 6 .

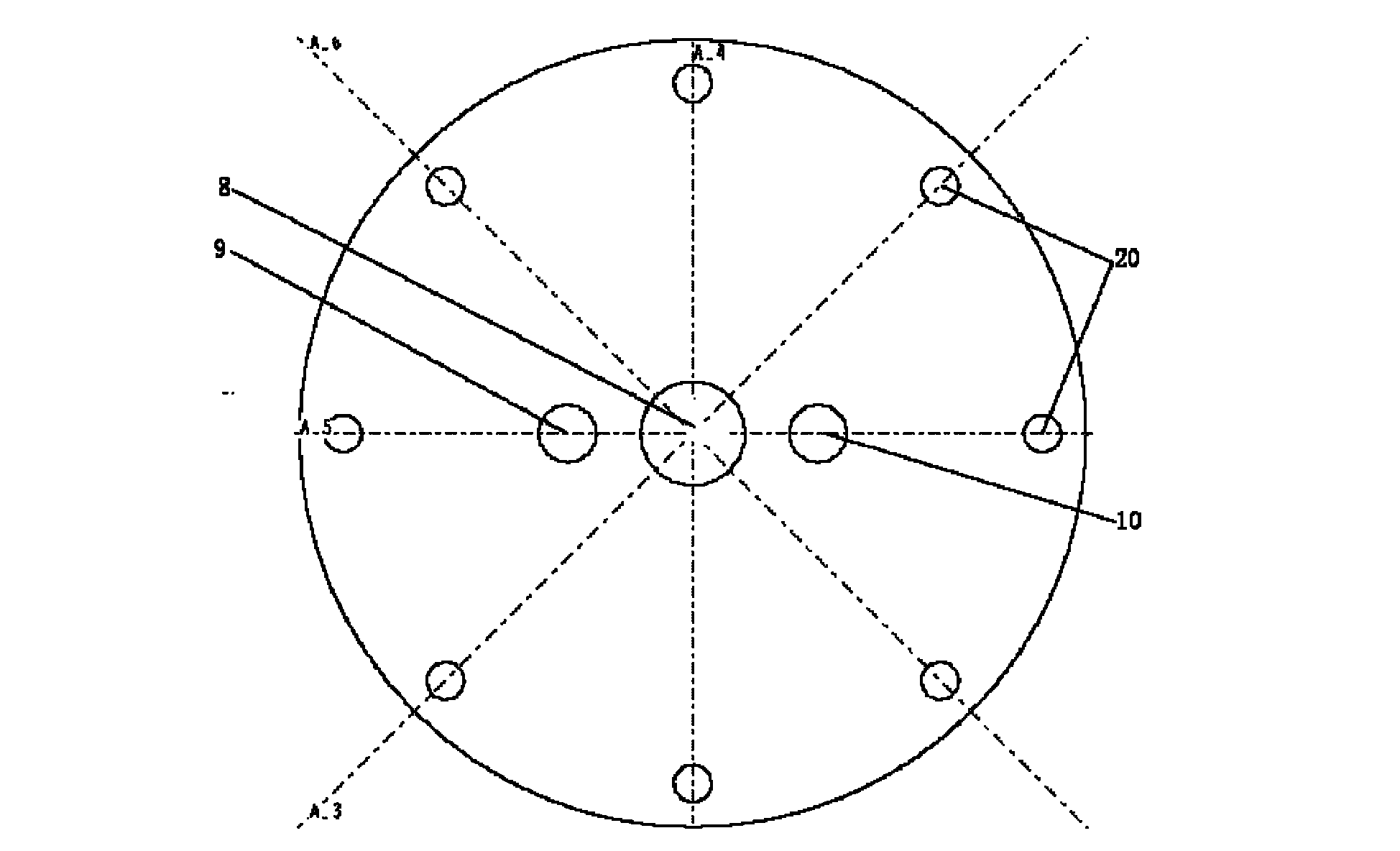

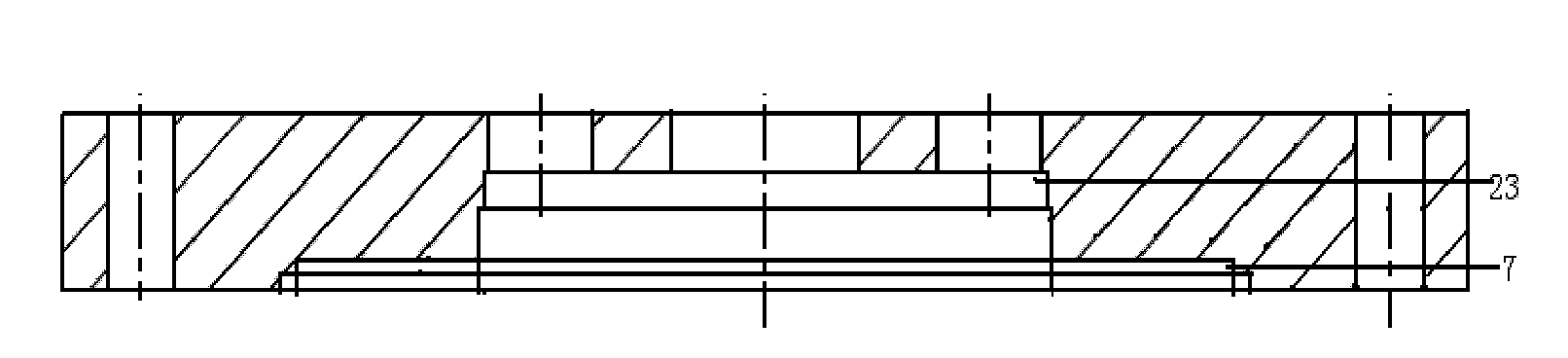

[0037] like figure 2 , image 3 As shown, the injector head 1 is a flat plate structure with a groove A7 at the bottom. The injector head 1 has a plurality of through holes H20 evenly distributed on the outer edge of the groove A7, and the number of the through holes H20 Preferably more than 8; the central position of the injector head 1 has a through hole A8, a spark plug is installed in the through hole A8, and holes B9 and C10 are symmetrically distributed on both sides of the through hole A8, located in the holes B9 and C10 A ring-shaped gas-hydrogen liquid collecting chamber 23 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com