Gas-oxygen-kerosene rocket-engine pressurizing delivery system and small-rocket-engine propellant supplying system

A technology of pressurized conveying system and rocket engine, which is applied to rocket engine devices, jet propulsion devices, machines/engines, etc., can solve problems such as being unsuitable for small-scale rocket engines, increasing system complexity, and increasing design costs. The effect of reduced degree and mass, reduced piping connections, compact construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

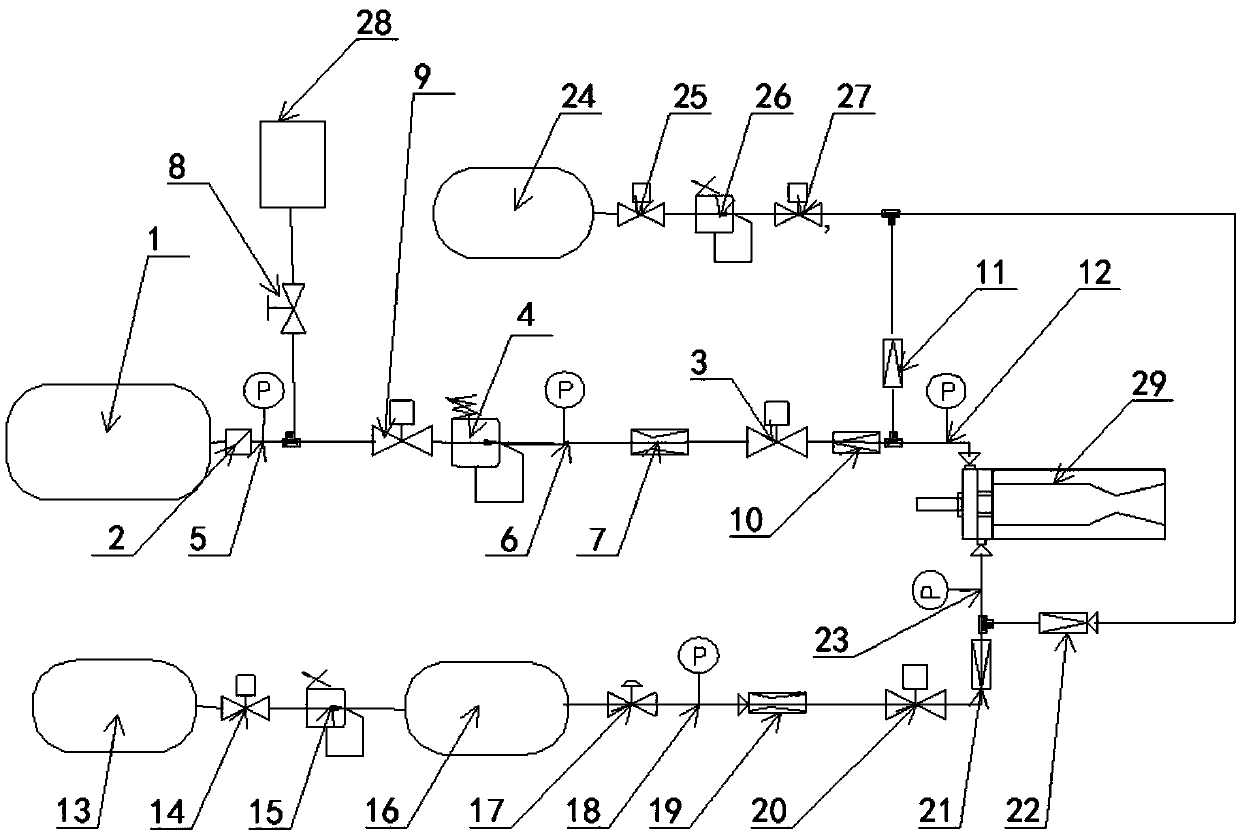

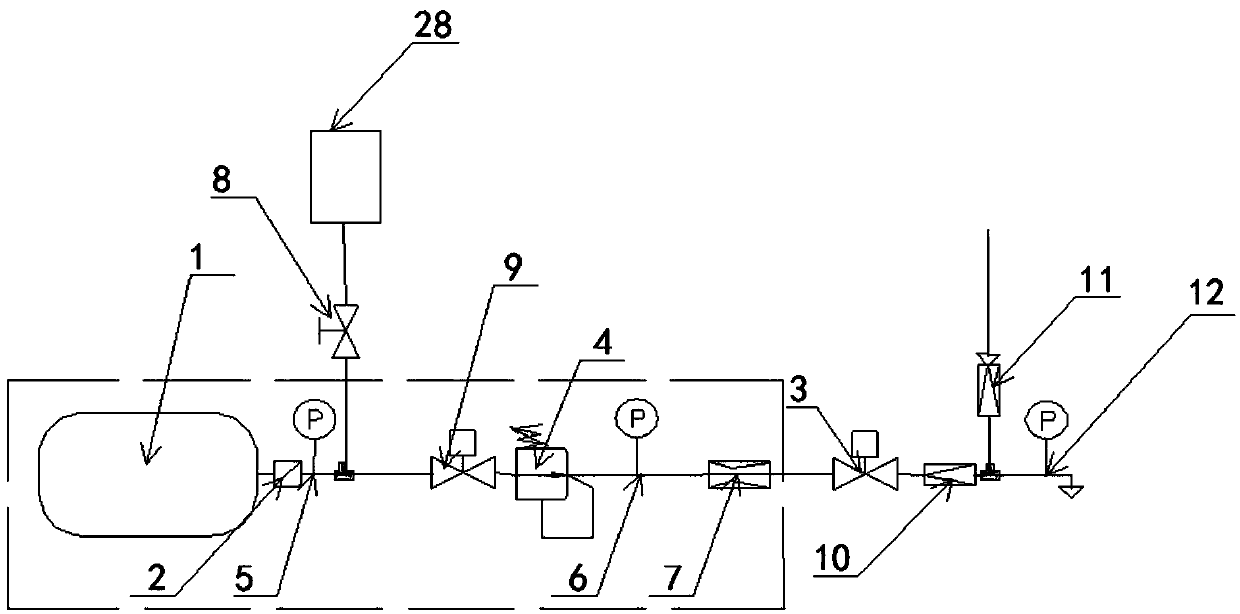

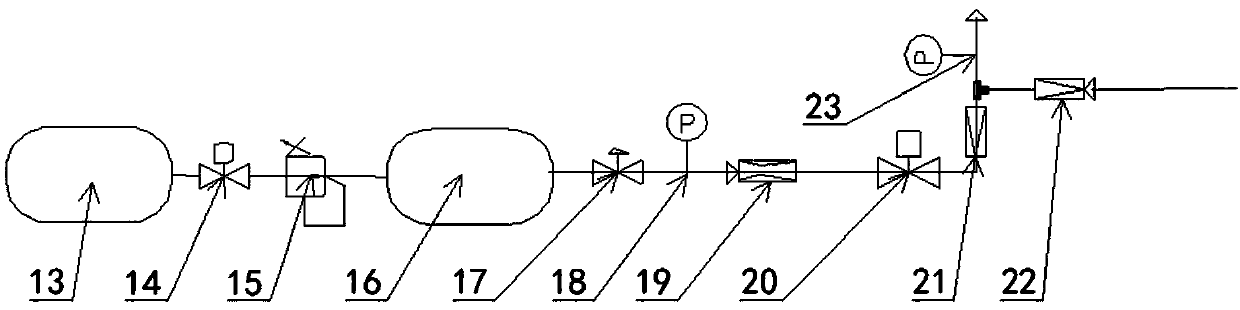

[0044] like Figure 1-5 As shown, the gas-oxygen-kerosene rocket engine pressurized delivery system provided in this embodiment includes an oxygen supply system, a fuel supply system and a blow-off system;

[0045] The oxygen supply system includes an oxygen storage tank valve assembly 30, a first stop valve 3, a first one-way valve 10 and a second one-way valve 11;

[0046] The oxygen storage tank valve assembly 30, the first stop valve 3 and the first one-way valve 10 are connected in sequence through pipelines, the second one-way valve 11 is connected with the blowing system, and the first one-way valve The outlet of the valve 10 and the outlet of the second one-way valve 11 are connected to the thrust chamber 29 through the same pipeline; such a design avoids blowing off nitrogen from entering the oxygen supply system;

[0047] The fuel supply system enters the thrust chamber 29 through a pipeline after being connected with the blowing system.

[0048] In an optional imp...

Embodiment 2

[0057] Embodiment 2 of the present invention provides a small rocket engine propellant supply system, including the gas-oxygen kerosene rocket engine pressurized delivery system described in Embodiment 1 above.

[0058] The small rocket engine propellant supply system provided by Embodiment 2 of the present invention is provided with the gas-oxygen kerosene rocket engine pressurized delivery system provided by Embodiment 1, so it has the advantages of the gas-oxygen kerosene rocket engine pressurized delivery system provided by Embodiment 1. All beneficial effects will not be repeated here.

[0059] In summary, gas-oxygen has the excellent characteristics of non-toxic, non-polluting, non-corrosive, and does not require low-temperature storage. Aiming at the small-scale characteristics of small rockets, a gas-oxygen kerosene pressurized delivery system solution is proposed, but there is almost no such solution in China. The research on the gas-oxygen kerosene propellant deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com