Hydrogen-peroxide-based RBCC (Rocket Based Combined Cycle) engine pressure pumping and squeezing integrated fuel system

A hydrogen peroxide and fuel system technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of inability to achieve overall structure cooling, inability to perform integrated cooling, engine engineering application limitations, etc., to achieve system use The effect of mature maintenance technology, meeting long-time working requirements, and eliminating contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

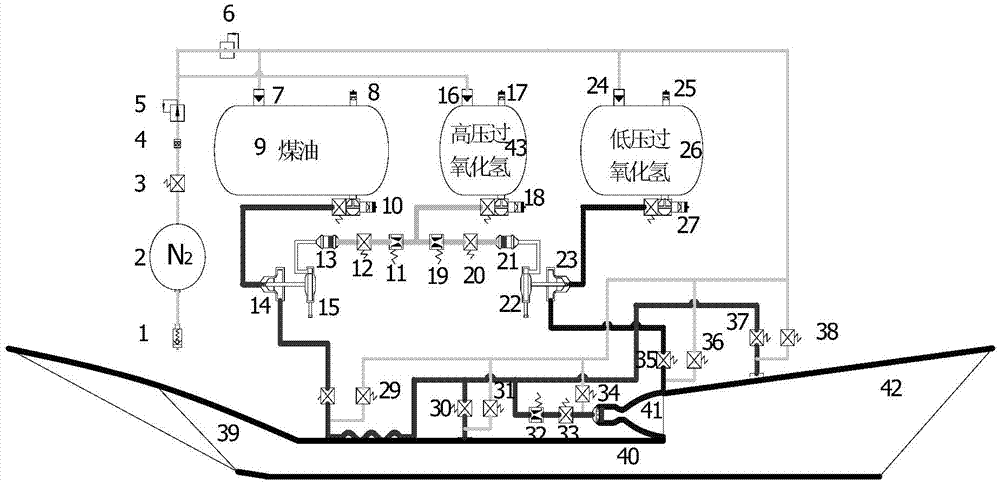

[0033] The invention provides a hydrogen peroxide-based RBCC engine pumping / extruding integrated fuel system, including a booster unit, a supply unit, an engine body and a connecting pipeline unit; the booster unit is used to boost the supply unit; The supply unit is connected to the engine body through the connecting pipeline unit and supplies propellant to the engine body;

[0034] The supply unit includes a kerosene supply assembly, a high-pressure hydrogen peroxide supply assembly, and a low-pressure hydrogen peroxide supply assembly;

[0035] The kerosene supply assembly includes a kerosene storage tank 9 and a kerosene check valve 7, a kerosene gas release valve 8 and a kerosene electric explosion valve 10 respectively arranged on the kerosene storage tank 9;

[0036] The high-pressure hydrogen peroxide supply assembly includes a high-pressure hydrogen peroxide storage tank 43 and a high-pressure hydrogen peroxide check valve 16, a high-pressure hydrogen peroxide deflati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com