Electric pump conveying system for solid-liquid rocket engine

A technology of solid-liquid rocket and delivery system, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc. It can solve the problems of turbo pump performance degradation, complex structure, unsuitable for high chamber pressure, and long-term work, and achieve accurate The effect that the flow rate and adjustment are easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

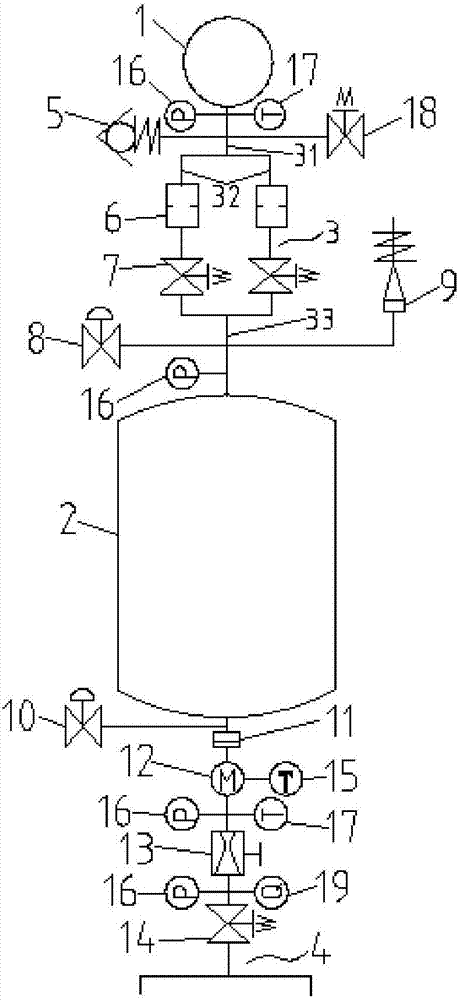

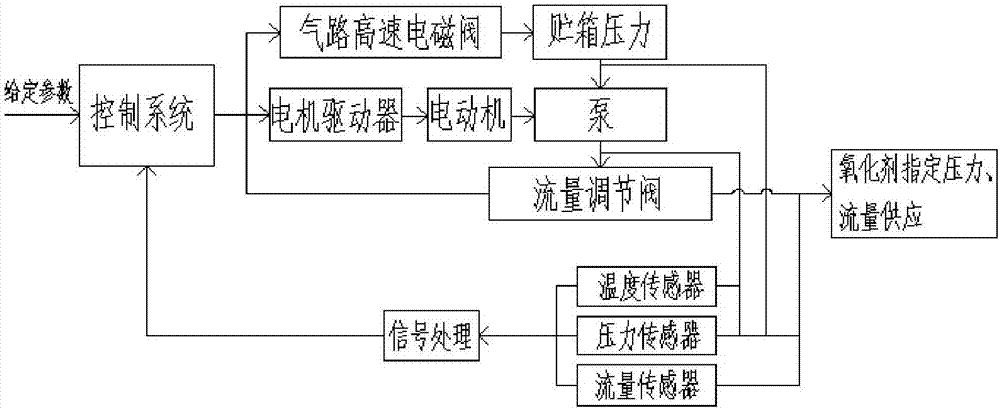

[0032] figure 1 Schematic diagram of the structure of the solid-liquid rocket motor electric pump delivery system provided by Embodiment 1 of the present invention; figure 2 The control principle block diagram of the control system provided for the first embodiment of the present invention; Figure 1-Figure 2 As shown, the solid-liquid rocket motor electric pump delivery system provided by the present invention includes a high-pressure gas cylinder 1 and a storage tank 2, and the high-pressure gas cylinder 1 is connected with the storage tank 2 through a pipeline one 3, and the storage tank 2 passes through Pipeline 2 4 is connected to the thrust chamber;

[0033] The pipeline one 3 is respectively equipped with a booster check valve 5, an orifice plate 6, an air path high-speed solenoid valve 7, a storage tank exhaust hand valve 8 and a safety valve 9;

[0034] The pipeline 2 4 is respectively equipped with a filling and discharging hand valve 10 , a diaphragm valve 11 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com