Power system for carrier rocket upper stage and orbit transfer vehicle

An orbital transfer and launch vehicle technology, applied in the field of power systems, can solve the problems of health and safety threats to R&D and manufacturing personnel, heavy rocket carrying burden, high propellant toxicity, etc., to improve combustion stability, improve serviceability, and reduce supporting facilities. The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

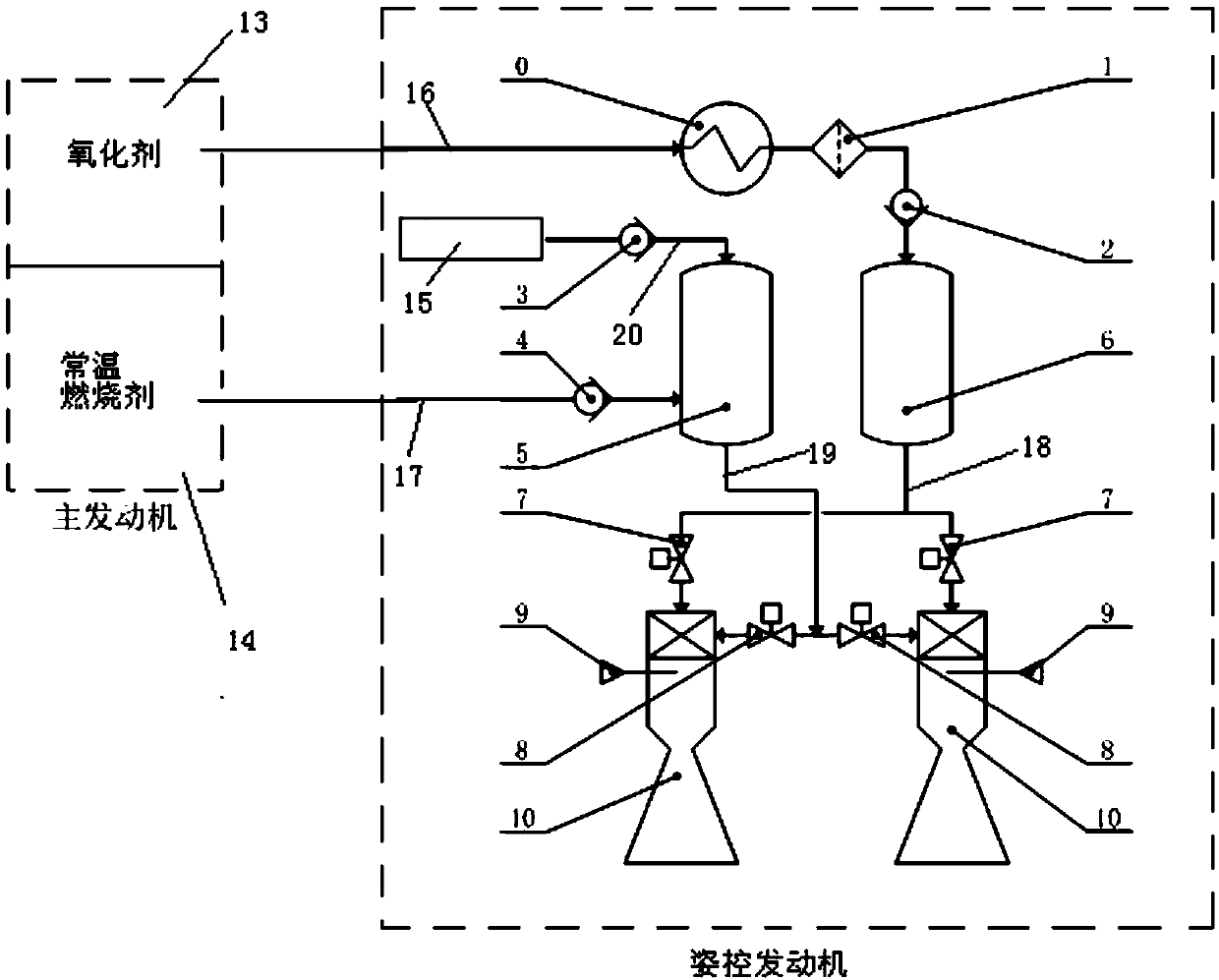

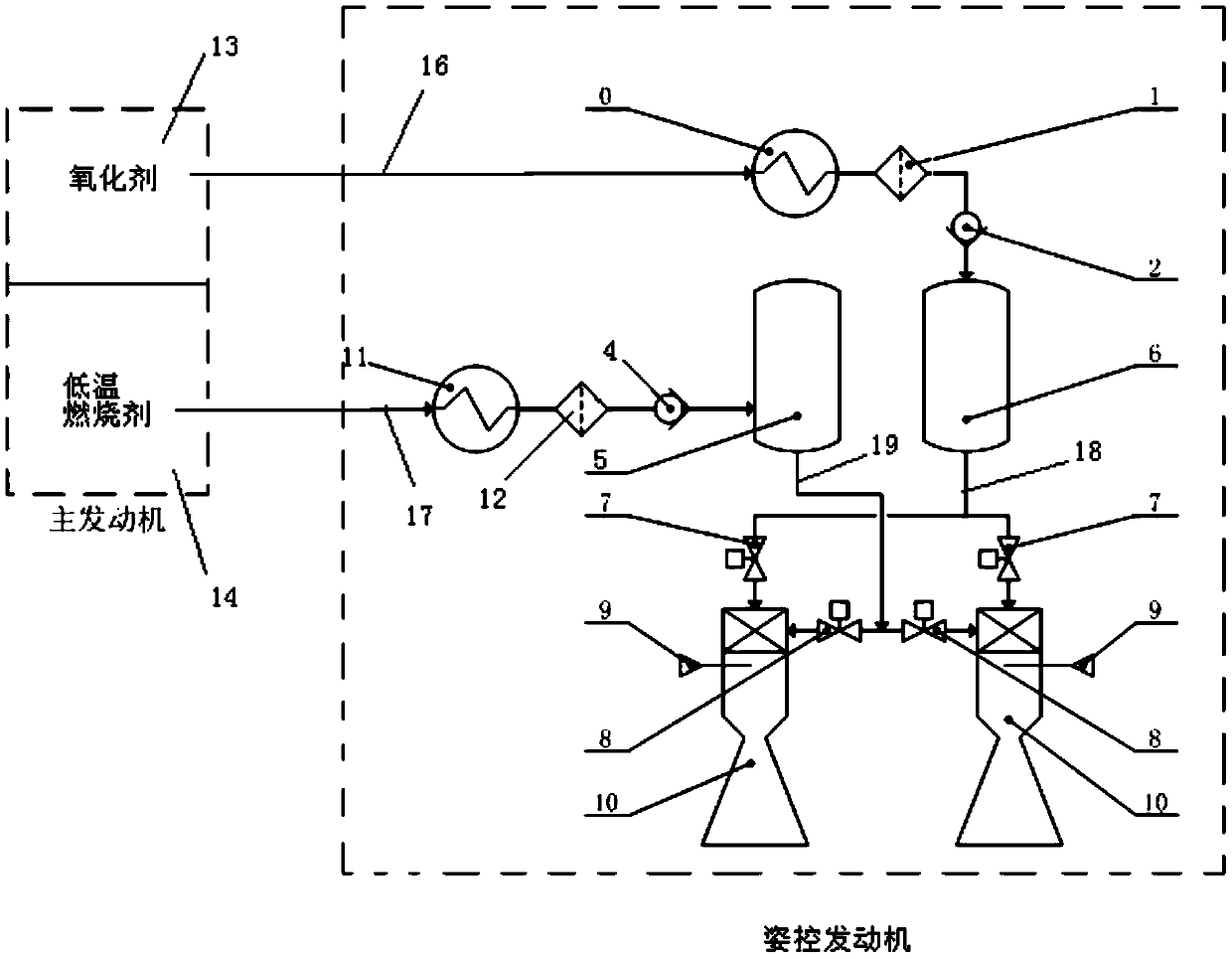

[0026] Such as figure 1 As shown, a power system for the upper stage of a launch vehicle and an orbit transfer vehicle includes a main engine and an attitude control engine.

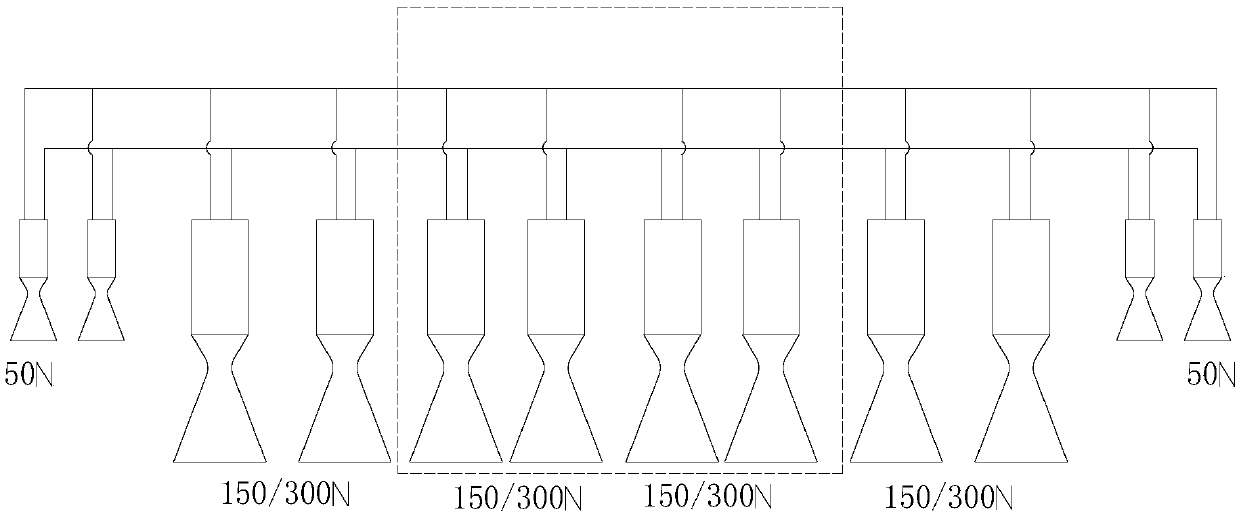

[0027] The main engine is a single low main engine, including the main engine control system, propellant supply system (not shown in the figure) and propellant storage tank; the propellant supply system includes oxidant pump and combustion agent pump; Oxidant storage tank 13 and low pressure normal temperature combustion agent storage tank 5. The attitude-controlled engine includes an attitude-controlled engine control system, a booster device 15 , an oxidant storage tank 6 , a combustion agent storage tank 5 and a thrust chamber 10 . Under the action of the propellant supply system, the propellant storage tank can simultaneously deliver propellant to the thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com