Modularized heat-capacity type thrust chamber

A thrust chamber, heat capacity technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of high cost, separation, and no modular design structure of the overall thrust chamber, and achieve good sealing Effect, low cost ratio, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with examples in conjunction with the accompanying drawings. The examples adopt a multi-nozzle thrust chamber structure for illustration, and the method is also suitable for single-nozzle combustion chamber working conditions.

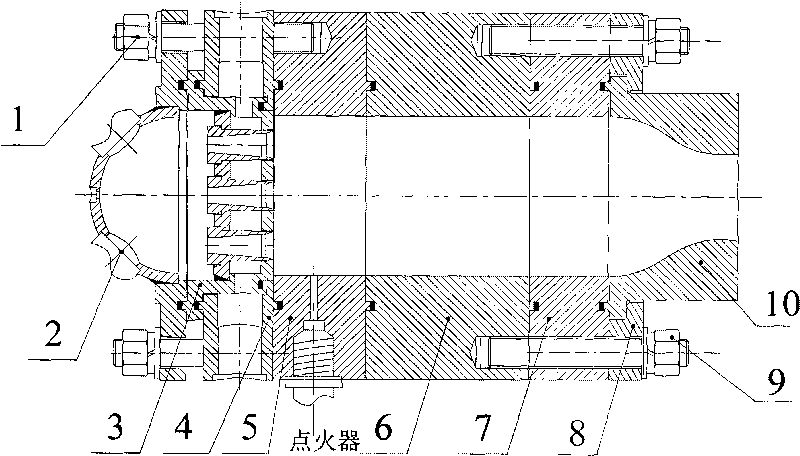

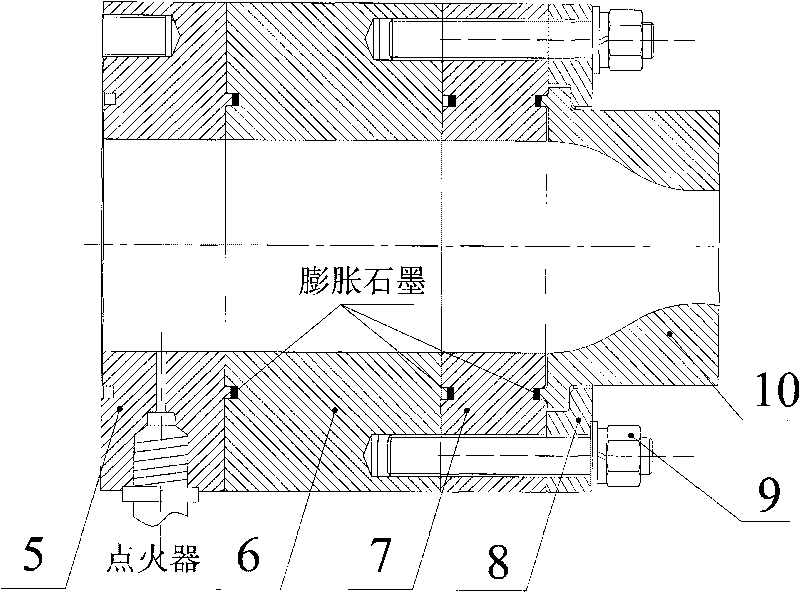

[0012] Such as figure 1 , the modular thrust chamber mainly includes: head bolt 1, head top cover 2, head injector assembly 3, head bottom cover 4, body cylinder first section 5, body cylinder second Section 6, the third section 7 of the body cylinder section, the tail flange 8, the tail bolt 9, and the tail nozzle part 10.

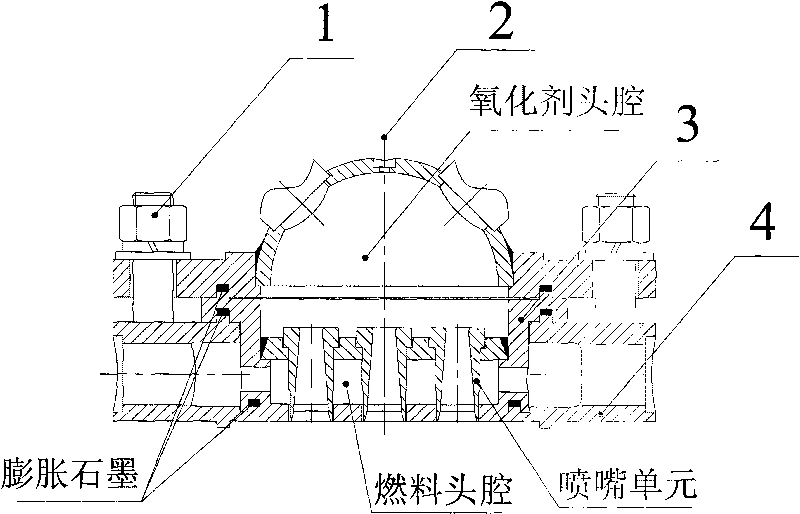

[0013] Such as figure 2 An assembly drawing of the thrust chamber head. The head top cover 2, the head injector assembly 3, and the head bottom cover 4 form the head part of the thrust chamber. The head top cover 2 is the oxidant inlet part, and forms the oxidant head cavity with the head injector assembly 3; the head bottom cover 4 is the fuel inlet part, and the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com