Diffusion brazing manufacture method for hydrogen peroxide thrust chamber body

A technology of hydrogen peroxide and a manufacturing method, applied in manufacturing tools, welding equipment, welding equipment and other directions, can solve the problems of long production cycle, rocket launch failure, easy blockage of channels, etc., and achieve product quality improvement, production efficiency improvement, welding simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

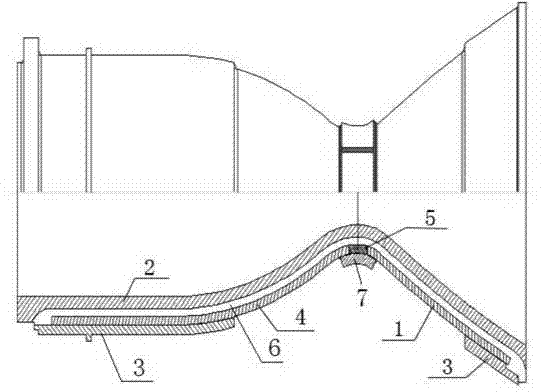

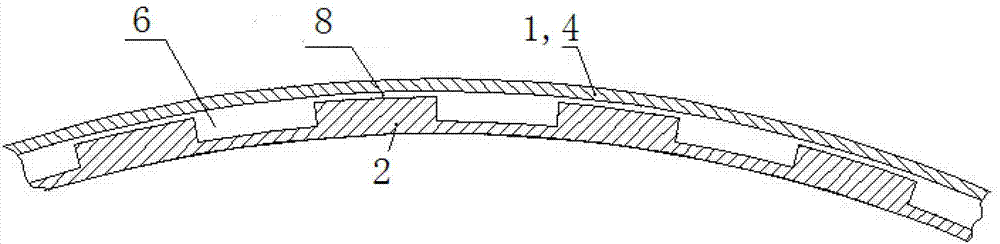

[0020] Such as figure 1 As shown, a hydrogen peroxide thrust chamber body diffusion brazing manufacturing method according to the present invention, the thrust chamber has curved inner and outer walls, wherein the outer surface of the thrust inner wall 2 has 250 passages 6, and the thrust chamber The outer wall includes the outer wall 1 of the nozzle and the outer wall 4 of the middle section, the outer wall 1 of the nozzle and the outer wall 4 of the middle section are connected by a connecting half ring 5, and the outer wall 1 of the nozzle and the outer wall 4 of the middle section are connected with a thrust chamber collector 3; the inner wall of the thrust 2 and the outer wall of the thrust chamber are connected by diffusion brazing, and the specific steps are as follows:

[0021] (a) Before welding, control the assembly gap 8 between the outer surface of the thrust inner wall 2 and the inner surface of the nozzle outer wall 1 and the middle outer wall 4 to be 0.2mm;

[...

Embodiment 2

[0030] Such as figure 1 As shown, a hydrogen peroxide thrust chamber body body diffusion brazing manufacturing method according to the present invention, the thrust chamber has curved inner and outer walls, wherein the outer surface of the thrust inner wall 2 has 200 passages 6, and the thrust chamber The outer wall includes the outer wall 1 of the nozzle and the outer wall 4 of the middle section, the outer wall 1 of the nozzle and the outer wall 4 of the middle section are connected by a connecting half ring 5, and the outer wall 1 of the nozzle and the outer wall 4 of the middle section are connected with a thrust chamber collector 3; the inner wall of the thrust 2 and the outer wall of the thrust chamber are connected by diffusion brazing, and the specific steps are as follows:

[0031] (a) Before welding, control the assembly gap 8 between the outer surface of the thrust inner wall 2 and the inner surface of the nozzle outer wall 1 and the middle outer wall 4 to be 0.04mm...

Embodiment 3

[0039] Such as figure 1 As shown, a hydrogen peroxide thrust chamber body diffusion brazing manufacturing method according to the present invention, the thrust chamber has curved inner and outer walls, wherein the outer surface of the thrust inner wall 2 has 300 passages 6, and the thrust chamber The outer wall includes the outer wall 1 of the nozzle and the outer wall 4 of the middle section, the outer wall 1 of the nozzle and the outer wall 4 of the middle section are connected by a connecting half ring 5, and the outer wall 1 of the nozzle and the outer wall 4 of the middle section are connected with a thrust chamber collector 3; the inner wall of the thrust 2 and the outer wall of the thrust chamber are connected by diffusion brazing, and the specific steps are as follows:

[0040] (a) Before welding, control the assembly gap 8 between the outer surface of the thrust inner wall 2 and the inner surface of the nozzle outer wall 1 and the middle outer wall 4 to 0.9 mm;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com