Motor seal

a technology of motor seals and seals, which is applied in the direction of sealing/packing, machines/engines, and wellbore/well accessories, etc., can solve the problems of reducing the life of the pumping assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

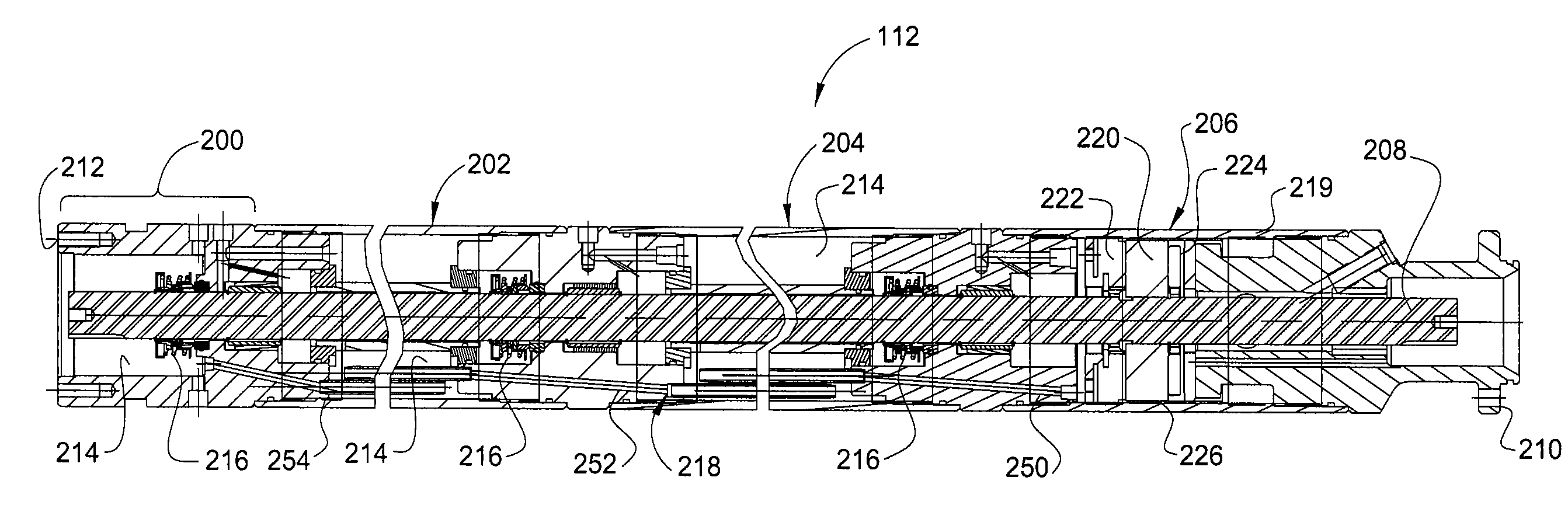

[0022]FIG. 1 is a schematic view of a wellbore 100 according to one embodiment described herein. The wellbore 100 includes a tubular 102 which is secured in the wellbore 100 using cement, not shown. The wellbore 100 and the tubular 102 intersects at least one production zone 104. The tubular 102 is typically a string of casing and / or liner; however, it could be any tubular used in downhole operations. Further, the wellbore 100 may be an open hole wellbore. As shown, a conveyance 106 is within the tubular 102 and coupled to an artificial lift assembly 108. As shown, the conveyance is production tubing; however, it should be appreciated that the conveyance could be any conveyance for delivering the artificial lift assembly 108 into the wellbore 100 for example: a wire line, a slick line, a coiled tubing, a co-rod, a drill string, a casing, etc. The artificial lift assembly 108 pushes the production fluids from the wellbore to the surface of the wellbore 100.

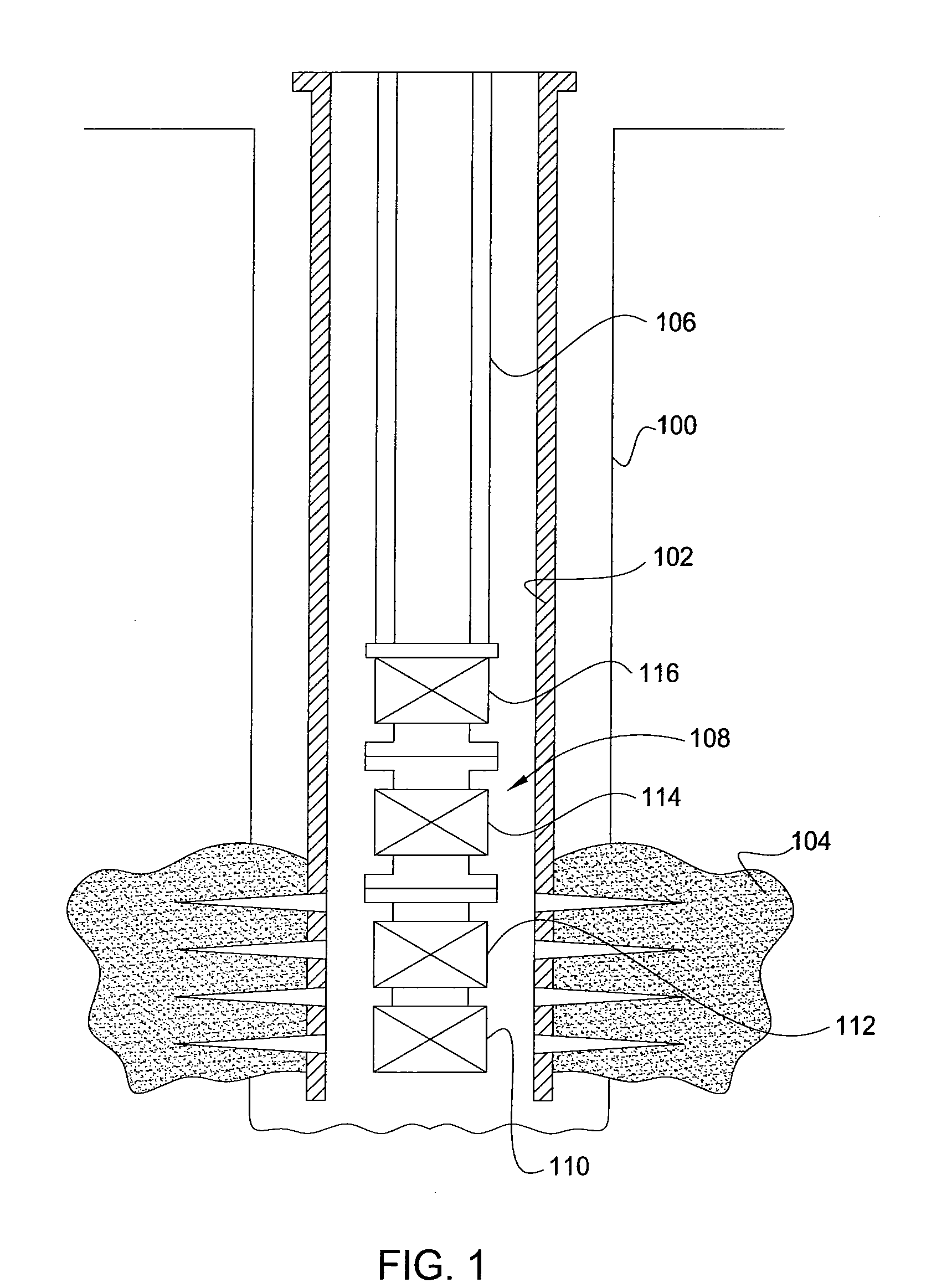

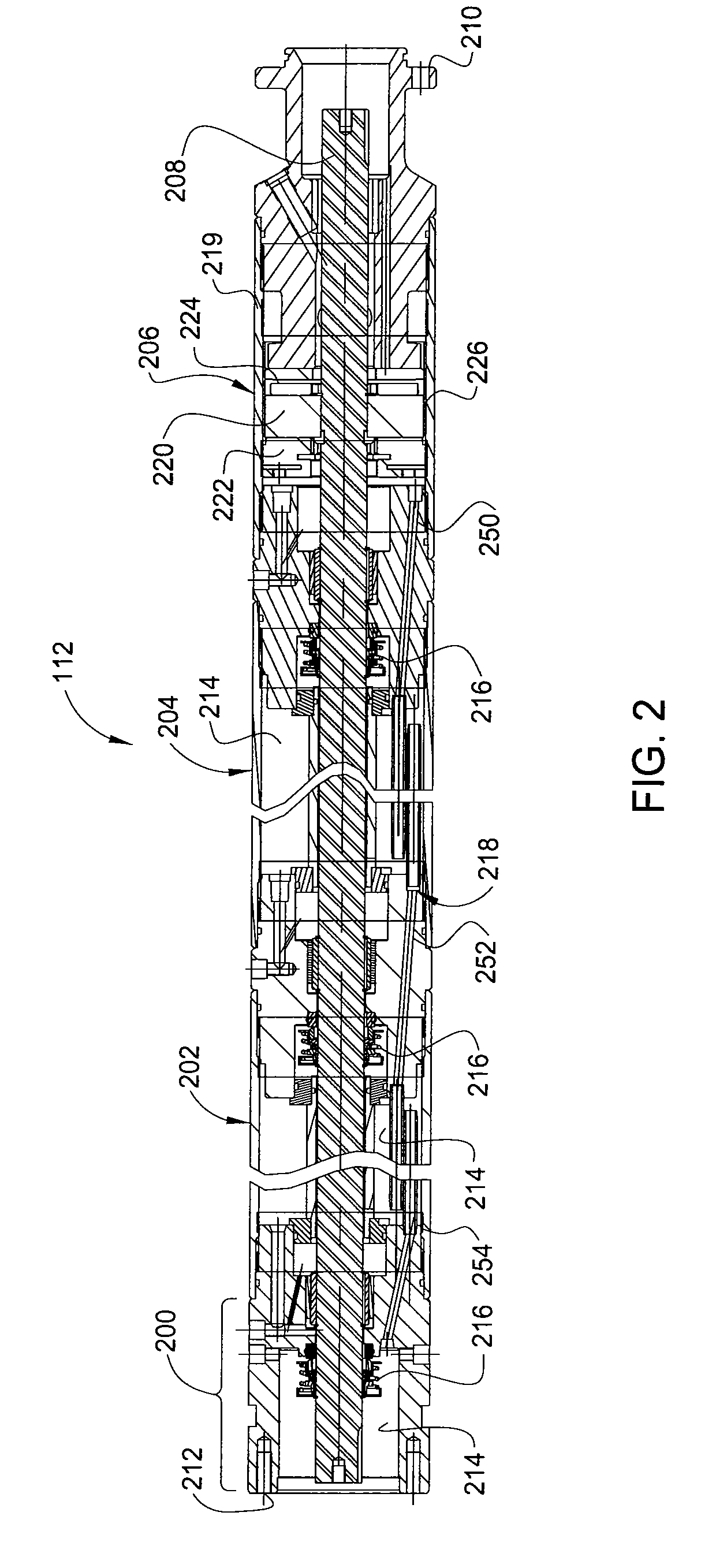

[0023]The artificial lift a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com