Aspirators for producing vacuum using the Venturi effect

An aspirator, venturi technology, applied in the field of aspirator, can solve the problems of limited vacuum mass flow rate, consumption of engine air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following detailed description explains the general principles of the invention, furthermore examples of the invention are illustrated in the accompanying drawings. In the drawings, like reference numbers indicate identical or functionally similar elements.

[0025] "Fluid," as used herein, refers to any liquid, suspension, colloid, gas, plasma, or combination thereof.

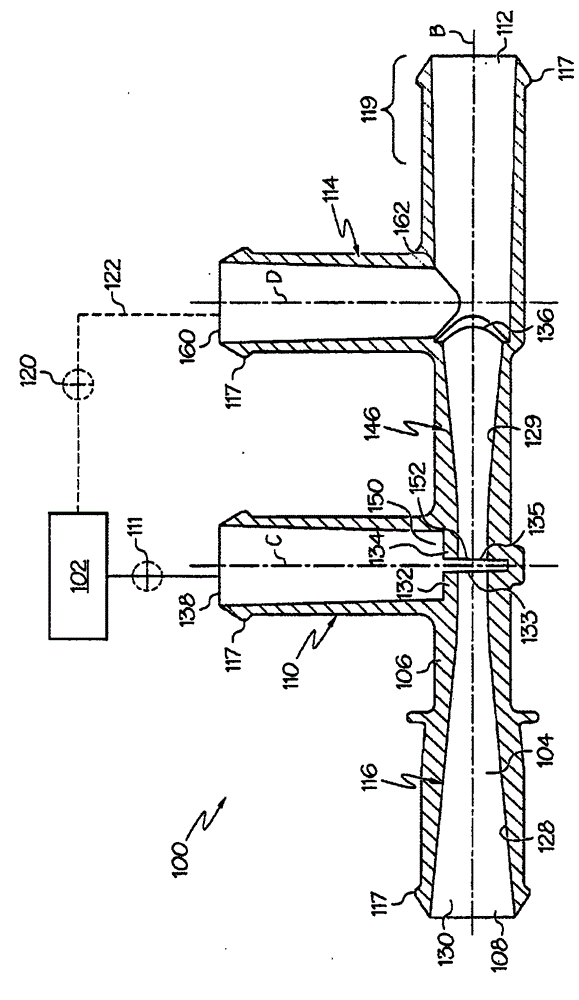

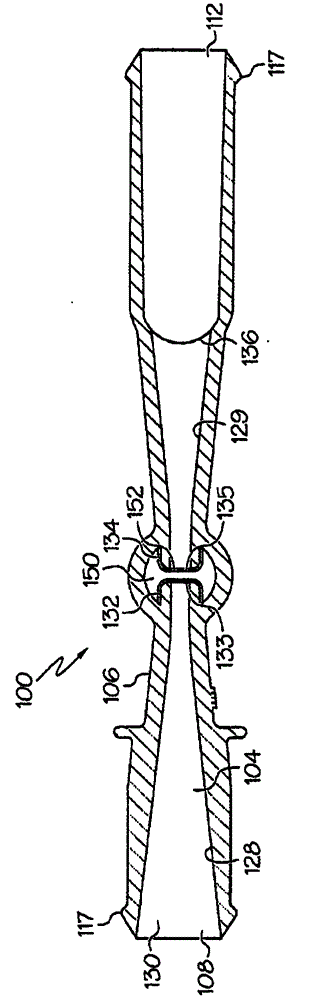

[0026] figure 1 and 2 Different views of the aspirator 100 are shown. The aspirator 100 may be used in an engine, such as that of a vehicle, to provide vacuum to a device. exist figure 1 The middle aspirator 100 is connected to a device 102 requiring a vacuum, while the aspirator 100 generates a vacuum for said device 102 by means of air flow through a channel 104, which extends approximately along the length of the aspirator and is designed to generate Venturi effect. The aspirator 100 includes a body 106 defining a passage 104, while the body 106 has three or more ports that may be connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com