Tea spreading and cooling device

A technology of tea leaves and racks, which is applied in the field of tea processing equipment, and can solve the problems of unable to cool tea leaves automatically, and achieve the effect of avoiding clogging and facilitating loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

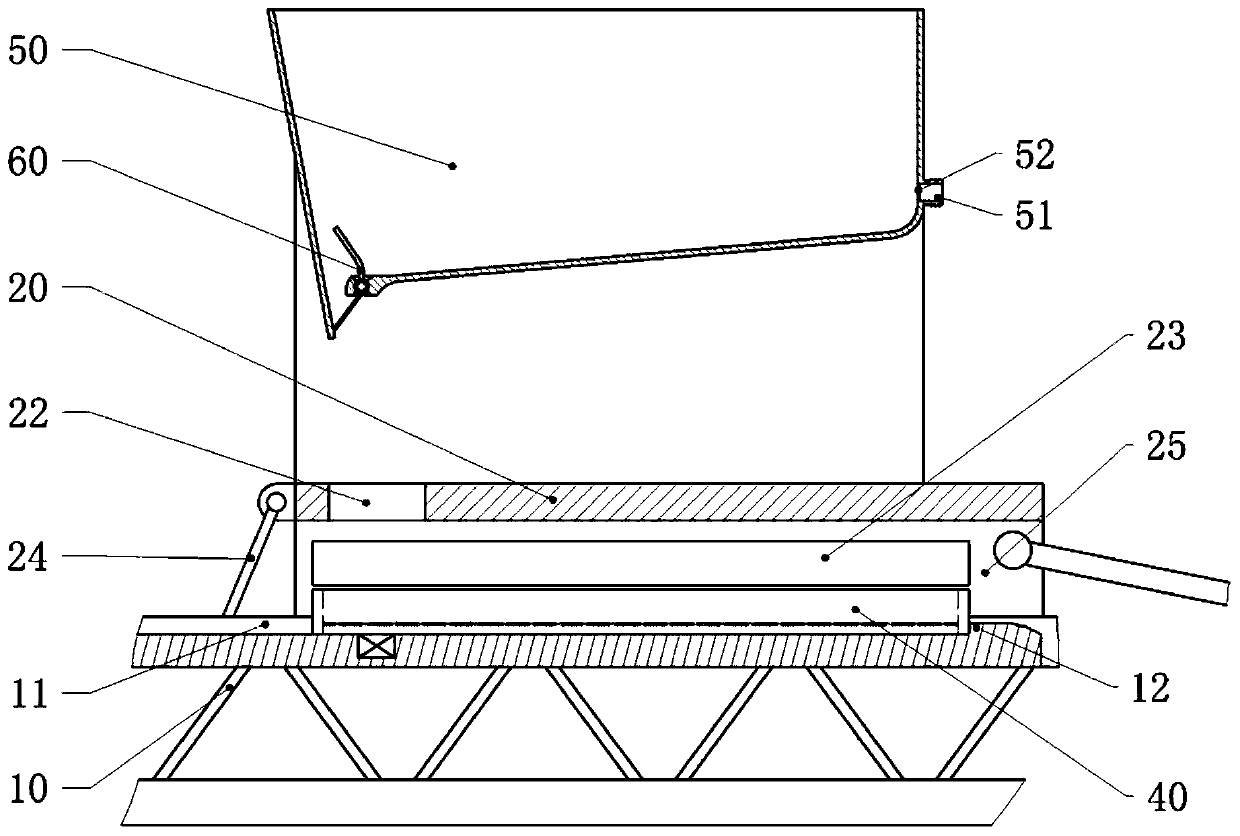

[0031] Such as figure 1 As shown, the tea cooling device includes a frame body 10 and a cooling mechanism from bottom to top, the frame body 10 is a quilted frame structure and is fixed on the ground, and the upper surface of the frame body 10 is provided with a panel; figure 1 Among them, the horizontal direction along the paper surface is the horizontal direction, and the direction perpendicular to the paper surface is the vertical direction. Rails 11 are provided on both sides of the panel of the frame body 10, and the rails 11 are arranged along the transverse direction.

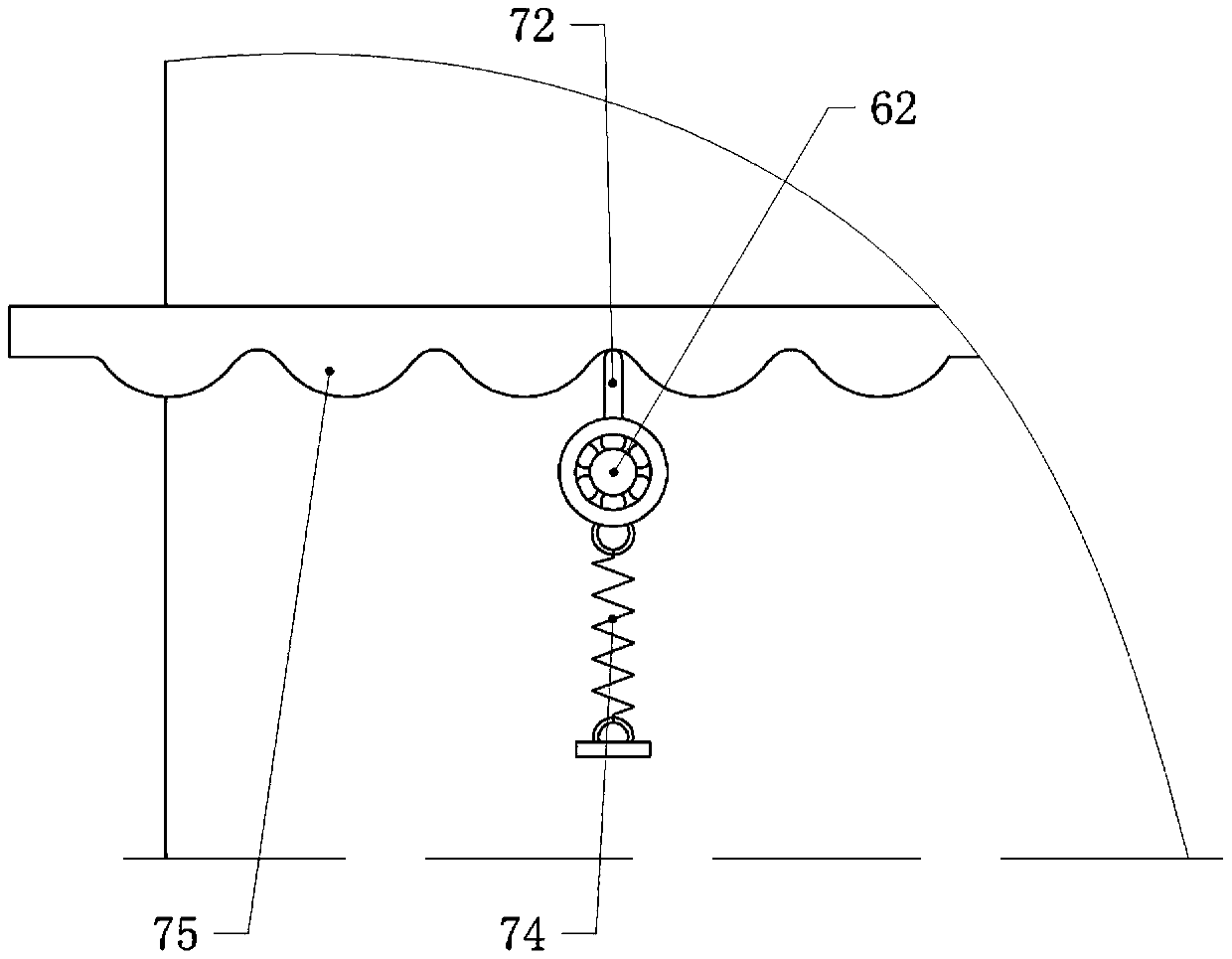

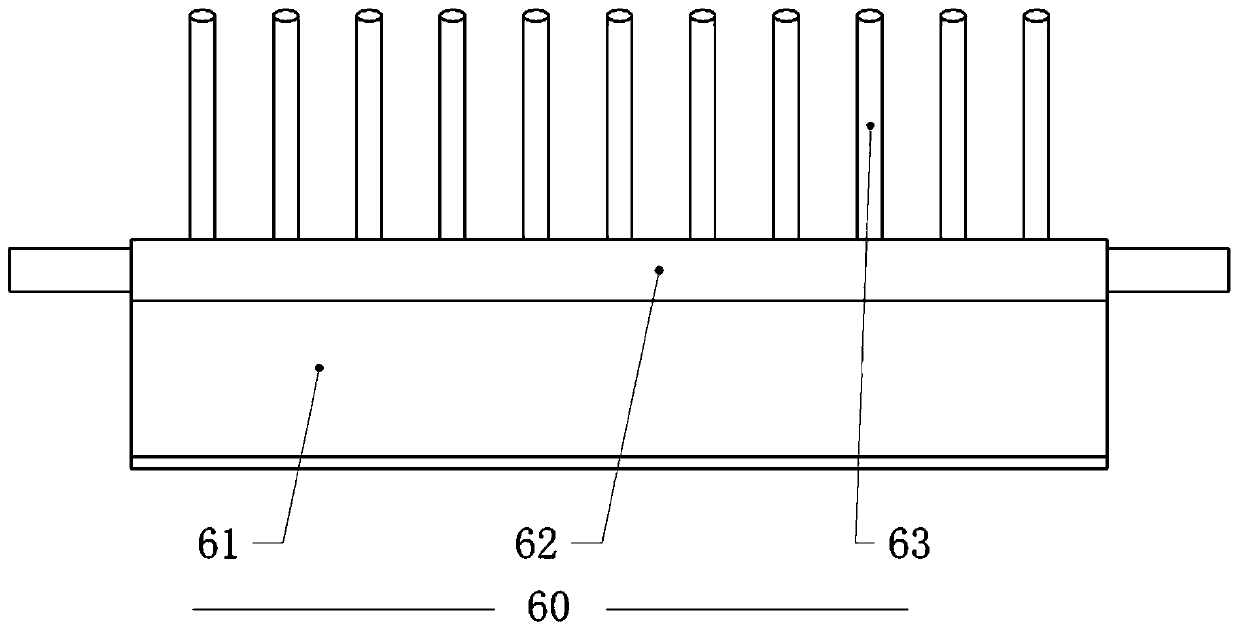

[0032] The cooling mechanism includes a reciprocating slide 20 and a hopper 50 , and the hopper 50 is fixed on the reciprocating slide 20 and is located above the reciprocating slide 20 . The bottom of the reciprocating slide 20 is provided with a through groove 25 arranged horizontally and running through the left and right sides of the reciprocating slide 20, and the cooling net 40 is placed on the pa...

Embodiment 2

[0041] The difference between Embodiment 2 and Embodiment 1 is that, as Figure 4 As shown, the internal structure of the cylinder body 31 in the second embodiment is different. The cylinder body 31 communicates with the outside through the intake check valve 34, and is connected with the air blast port 51 through the pressing valve 35; the bottom of the cylinder body 31 is provided with a compression chamber 33 , the pressing valve 35 is arranged in the compression chamber 33, and the pressing valve 35 is turned on when the piston 32 presses the pressing valve 35. The ratio of the volume of the compression chamber 33 to the maximum volume of the cylinder body 31 is 1 / 4. When the piston 32 compresses the air, it must be compressed to a certain pressure in the compression chamber 33, and then the pressing valve 35 is opened and the air flow is blown into the hopper 50 through the tuyeres 51; , to have a better stirring effect on the tea.

[0042] In addition, the air inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com